After a protracted and rather overhaul purchased the manor house, it was found that to check have not only a “bare walls”, but with almost empty pockets. I think that in such a situation may be some readers of the respected journal, so I want to share with them my experience (From my life experience I know in Russia do not earn so much, how many you can save) So I had to switch to the manufacture of furniture And started with a headset for the hallway, or rather, with the individual items that formed subsequently to complete the set.

After a protracted and rather overhaul purchased the manor house, it was found that to check have not only a “bare walls”, but with almost empty pockets. I think that in such a situation may be some readers of the respected journal, so I want to share with them my experience (From my life experience I know in Russia do not earn so much, how many you can save) So I had to switch to the manufacture of furniture And started with a headset for the hallway, or rather, with the individual items that formed subsequently to complete the set.

The first produced a wardrobe, which can be called a hanger because it is open, without doors, he’ll start a story about a headset.

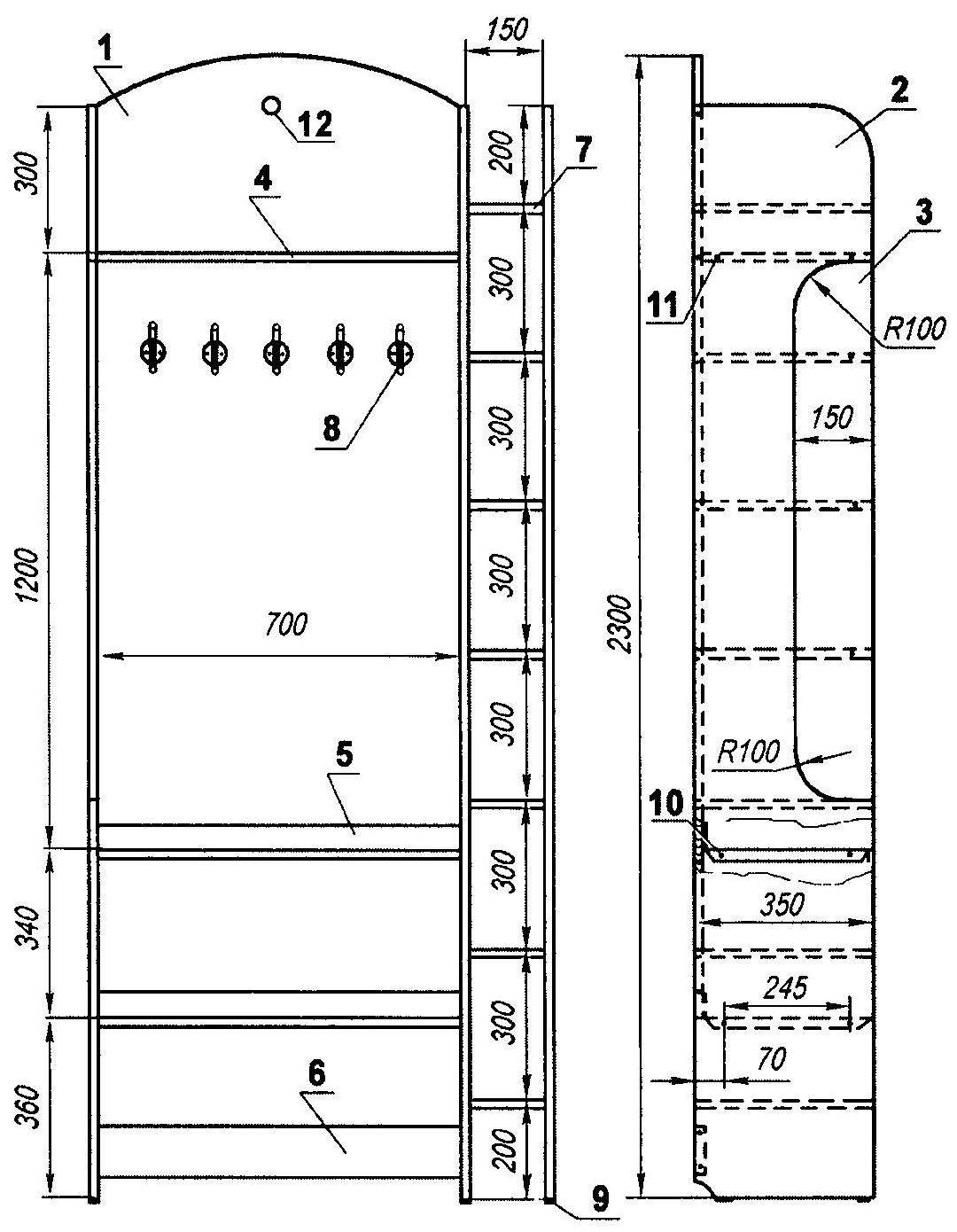

Cabinet design, size and shape was dictated by its predefined location — not far from the front door, However, and the width of the hallway was here a little more than the door itself.

The dimensions and shape of the Cabinet as a whole and all its parts are quite clear from the Assembly drawing, the design is the same — and this applies mostly to methods of joining of materials, specifics of manufacturing technology and Assembly — I will try to explain with words.

For the manufacture of Cabinet was used mainly “laminated” (lined with foil) chipboard (DSP). Cut scroll saw edges (ends) of parts papered the special “push button” belt, matched the texture of the laminate From the back side of the tape has been coated with a layer of dried polyvinyl acetate glue (PVA). Could only apply tape to the edge and smooth it with a hot iron Tape was slightly wider edges, so one edge of them combined, and the other neatly cut OST-roztochany knife Edges slightly dulled by fine-grained emery paper.

Note that trimming the blanks to size using the circular saw (as stationary and manual) is more the quality of the edges (the smaller the chips and the absence of “withdrawal” tool) But I have at the moment, unfortunately, “circular saw” was faulty.

Form details — mostly simple All the shelves and shelves — rectangular Hull parts although they have the fillets (and one side — cut), but they are quite large radii in their implementation impact the benefits of the jigsaw in front of disk (and other) saws jigsaws If not it is rounded and cut to saw through the saw without going over the lines of the fillets and radii to Refine rasp, and for the internal need of the round.

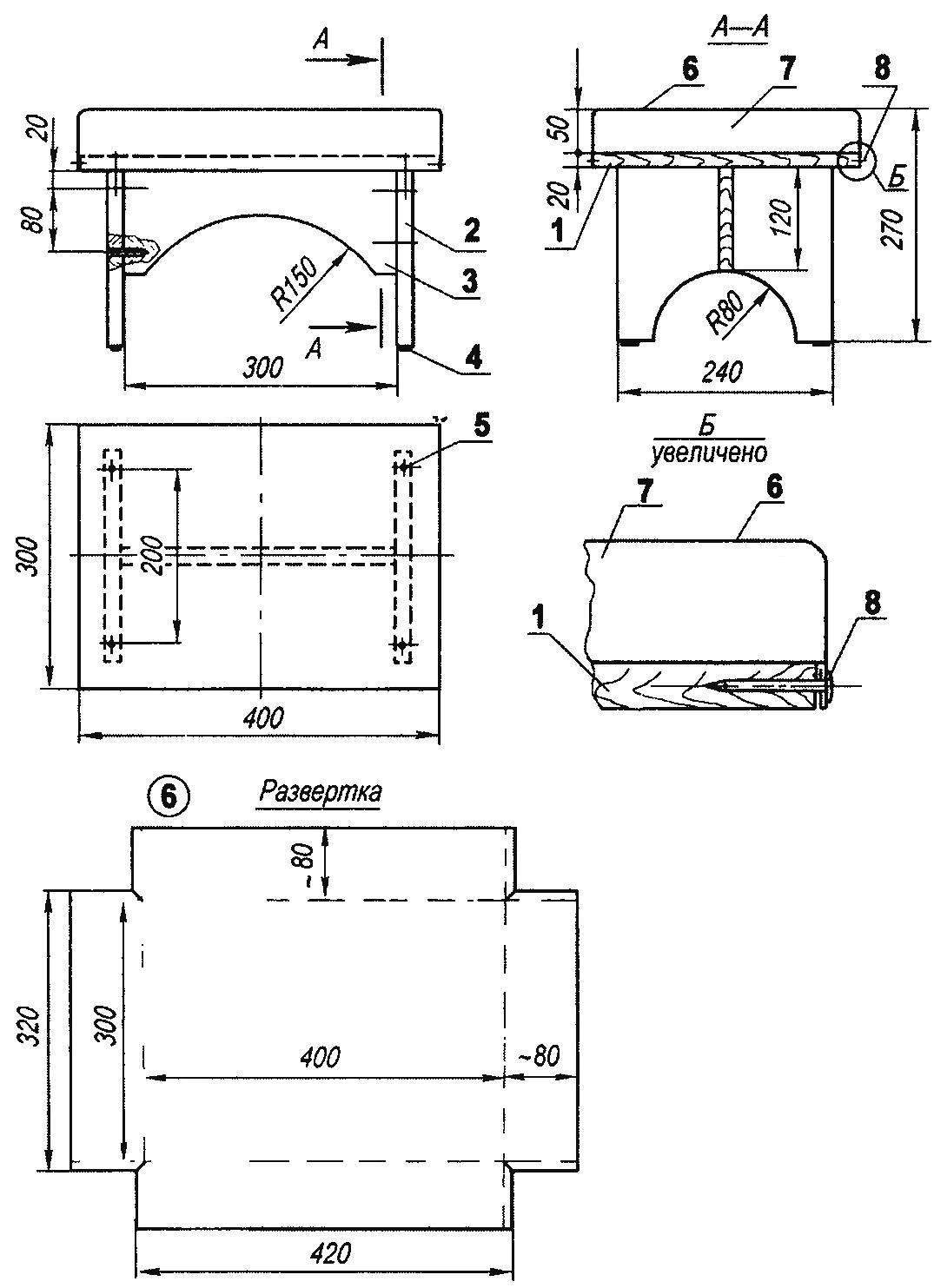

Clothes rack for hallway (all parts except specifically stated, is made of laminated chipboard 16’s):

1 back wall, 2 — side panel with cutout, 3 — side wall, ordinary (2 PCs), 4 — shelf for hats, 5 — Shoe rack (steel sheet s1,5, 2-piece), 6 — lower jumper, 7 — shelf “cell” section (7 piece), 8 — hanger-hook (5-pack), 9 — thrust bearing (6 PCs), 10 — bolt M5 (8 PCs); 11 — furniture screw (as required)

Bedside table (all items, except as stated, are made of laminated chipboard s16):

1 back wall, 2 — low side wall, 3 — high side wall, 4 — shelf-sector, 5 — top, 6 — bottom, 7 — front wall, 8 — hinged door; 9 — handle 10 — thrust bearing (nylon, 4 PCs), 11 — screw coupler (as required), 12 — hinge (piano hinge)

Cut out one of the side walls are made with the purpose of easy entrance in a narrow hallway or a full broad-shouldered man. In addition, the cutout facilitates the design of the Bottom is a cutout for the plinth can be done, and rectangular — it is still not clear.

Cabinet Assembly was carried out in the furniture screw couplers with a length of 50 mm two types of heads under a Phillips-head screwdriver and a hex key “4”. There was both — only thing lacking was the number the same each side is only used to raznosortitsa not conspicuous.

The holes in the screed in detail drilled with the aide of the son Pastikova shelf at a 90° angle to the wall in the right place, first drill with a diameter slightly larger (by 0.1 — 0.2 mm) than the inner diameter of the screw cutting ties (5 mm), through hole drilled in both parts the depth of the holes in the shelf should not exceed the length of the straps 10 — 15 mm Then in the wall of the hole drilled to the diameter of the tie rod (7.5 mm). Countersink the hole for the head tie is not required, it will aglobitse when screwing.

In my case, Cabinet installation solved another problem — it covered radiator In turn, the radiator heated up the bottom couple of shelves in the closet and the space between them So these shelves are made from 1.5 mm steel sheet, turning down the perimeter flanging for rigidity (and made a high back and bent up) and painted them the color of the texture of the chipboard (they dry them, if necessary, shoes). Metal shelves attached to the side walls by bolts M5, picking up heads with similar Grooves in the walls passing under the heating pipes was carried out at the place (in the drawing not shown).

To the lower edges of the side walls tightened the screws on a pair of plastic glides To the rear wall at an appropriate height attached five hangers-hooks.

Since the wardrobe tight and not as stable at the top of the rear wall drilled a hole and nailed the wardrobe to the wall of the hallway dowel.

Furniture for your

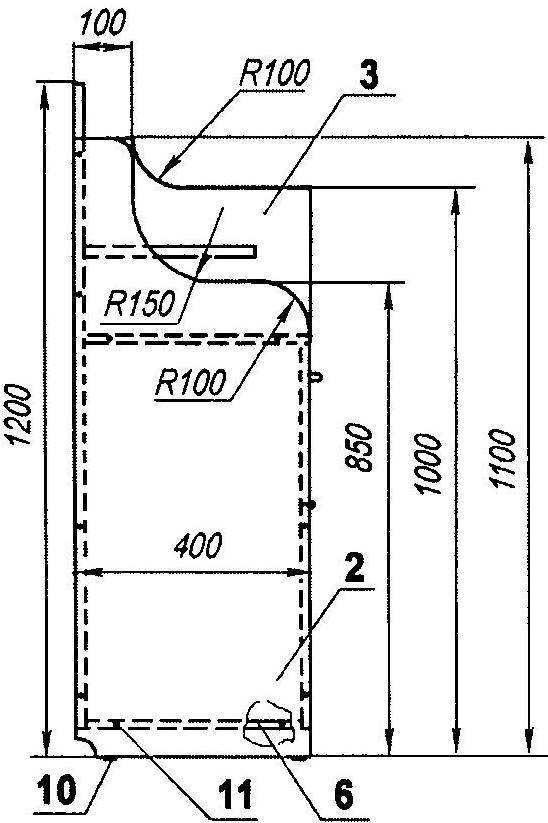

An empty corner in the hallway with a phone on a stool a few months reminded that for a complete set of this front room not enough tables like secretaire had to design and make and it, typing in the style previously made wardrobe-hanger But it was easy because the material for the tables was still the same chipboard 16 mm thick laminate with the same texture.

The width of the tables remained almost the same as that of the Cabinet, but the depth of its slightly increased as the width of the hallway in the place where it was supposed to position the table, was already more unlike wardrobe bedside table made of a closed — provided the front wall and door is the Door connected to the front wall by a hinge of the piano hinge itself and the front wall attached furniture using cable ties to the side walls and the bottom, the Very bottom as the top, connected to lateral walls (and the last of the rear wall) also furniture screw ties the Shelves to the bedside table no, since there is expected to store large items or footwear (high boots, boots).

Above the worktop in the corner there is a small shelf in the form of a sector — it fits the phone, and under it even a thick reference book.

The technology of manufacture cabinets exactly the same as that of the Cabinet, and to repeat it makes no sense Design as tables, as well as the configuration and size of all its parts clear even from the Assembly drawing.

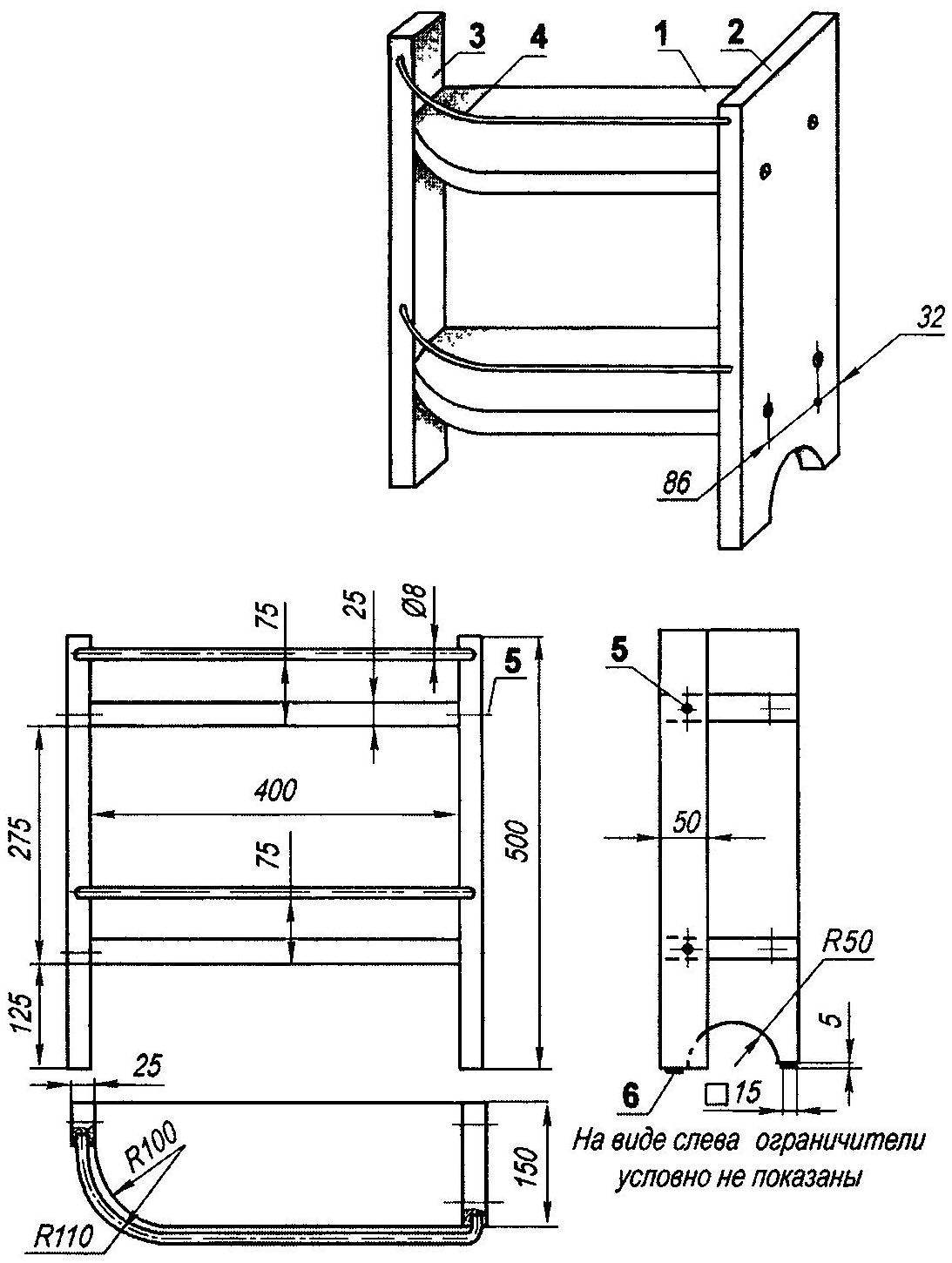

The chair-Ottoman

Another piece of furniture for the hallway — a small and low chair-Ottoman And it is necessary not so much children, how many elderly people for dressing up shoes.

The design of the chair and the sizes of its parts, clear Assembly drawing. Of course, it can also be made of the same particle Board wardrobe and bedside table, but it is better (will be stronger) plywood or boards, painted them the color of the laminate Even greater stiffness will give the high chair a shaped cross Bond of wooden parts — the usual long screws.

The chair-a beanbag (material unspecified parts—Board or plywood s20):

1 — seat, 2 — leg (2 PCs.), 3 —cross bar; 4 —thrust bearing (nylon, 4 PCs); 5 — screw (as required), 6 — cover (fabric); 7 — a lining (foam rubber s50), 8 — a nail with a decorative cap (as required)

On the finish, making chair type benches But it will be much easier if the seat is to make a soft, laid on it a thick layer of foam and closing the soft upholstery fabric upholstery is Attached to the bottom of the seat brackets But you can nail her nails with decorative hats to the side edges of the seat.

Bookcase

As it turned out, the hallway took another piece of furniture — a small outdoor shelf bookcase for various items, as well as for Newspapers and magazines. Its size is determined by the remaining free space in the hallway between the drawer under the telephone and a wardrobe-clothes rack.

The material for the shelves was a pine Board thickness of 25 mm From one Council’ do not throw away immediately cutting them, at least a few of them that are — they are still useful.

Of course, the complexity of manufacturing furniture from solid wood is much higher and requires sufficient experience of the contractor in finishing (finishing) of parts But the wood furniture has such properties, which do not attach articles of fiberboard it is not only environmentally safe, but she exudes the healing odors.

For beginners also the home of craftsmen, the manufacture of such furniture will be a good lesson to advance to the heights of skill of cabinetmakers.

Technology of processing of wood is described in detail in various publications, including the journal “modelist-Konstruktor” Stop focusing on her again doesn’t make sense.

Bookcase (details naukarani positions made of boards s25):

1 — shelf (2pcs), 2 — wide front, 3 — narrow front, 4 — limiter (wire with a PVC coating Ø8, 2 – piece), 5 — screw coupler (6-piece ), 6 — thrust bearing (nylon, 3 PCs.)

But the specifics of the Assembly of the wooden parts using screw clamps, I think will not be superfluous to highlight and detail.

Such features a bit first, the hole in the shelf, you can (and should) check the inner diameter of the screw cutting on the web of the screed secondly, since the fixing screw in the body of the wooden parts is made along the fibers (direction of least strength of the wood), before assembling hole well greased with glue is Good to use almost obsolete joiner’s (bone) hot glue It in the roots of the wood penetrates better, and seizes immediately in the freezing — lowering the temperature to room.

The third feature (one might say, and complexity) is in the collection of Kohler products to match the finish of the environment.

A great choice for construction markets and tinting of paint and varnish materials allows to solve very easily this problem to make Sure that this is the Kohler, you can try a few of them, causing the coating on the remaining scraps of boards.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.