Houses built of bricks or blocks have mortar seams. Depending on the quality of the prepared solution, the time of its use and, of course, the right technology work the stitches can be long or will soon start to sleep, to breathe. The most reliable method to strengthen them is the plastering of wall surfaces. The seams for the pre-clearing to a depth of 20 to 40 mm, cleared well moistened with water. Then prepare cement-lime mortar (or one of cement to high grade) and with great force to throw back the solution a plaster shovel (or, as it is called, — with a trowel) to completely fill the seam. After that, the entire wall surface is again moistened with water and plaster.

Houses built of bricks or blocks have mortar seams. Depending on the quality of the prepared solution, the time of its use and, of course, the right technology work the stitches can be long or will soon start to sleep, to breathe. The most reliable method to strengthen them is the plastering of wall surfaces. The seams for the pre-clearing to a depth of 20 to 40 mm, cleared well moistened with water. Then prepare cement-lime mortar (or one of cement to high grade) and with great force to throw back the solution a plaster shovel (or, as it is called, — with a trowel) to completely fill the seam. After that, the entire wall surface is again moistened with water and plaster.

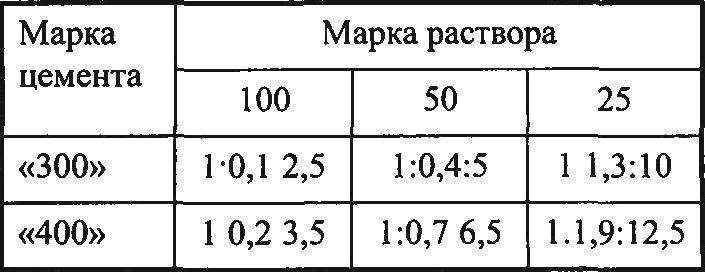

Usually, all the prepared solutions of cement should be used within the hour (as an exception — 1.5 hours): from long-maturing the mixture reduces its quality, that is strength. The solution is better to prepare from high grades of cement “300” or “400”: it can withstand in compression the load and is a long time.

However, a pure grout has a low ductility, with it harder to work with. Therefore, for convenience it is mixed with lime test lime, diluted with water until thick sour cream. All materials metered volume parts (a can, bucket).

However, many prefer not to plaster walls (although this still warms structure), and leave the updated joints as decorative elements — the natural color (gray) or painted. Bricks or blocks can be stored in its natural form, but often painted.

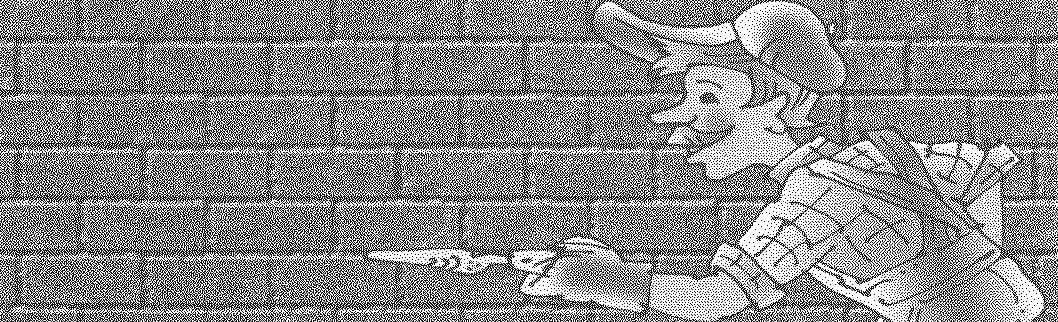

Fig. 1. Falcon—a shield for a solution

Fig. 2. Engines of wooden boards

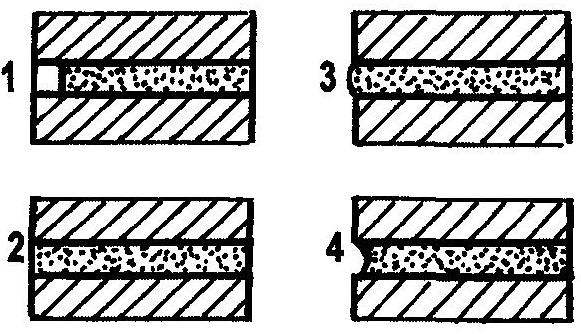

Fig. 3. Types of stitches:

1 — raked joint; 2 — Padres; 3 — embroidered convex; 4 — embroidered concave

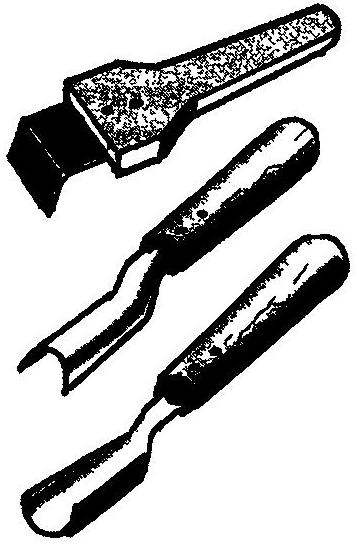

Fig. 4. Pointing

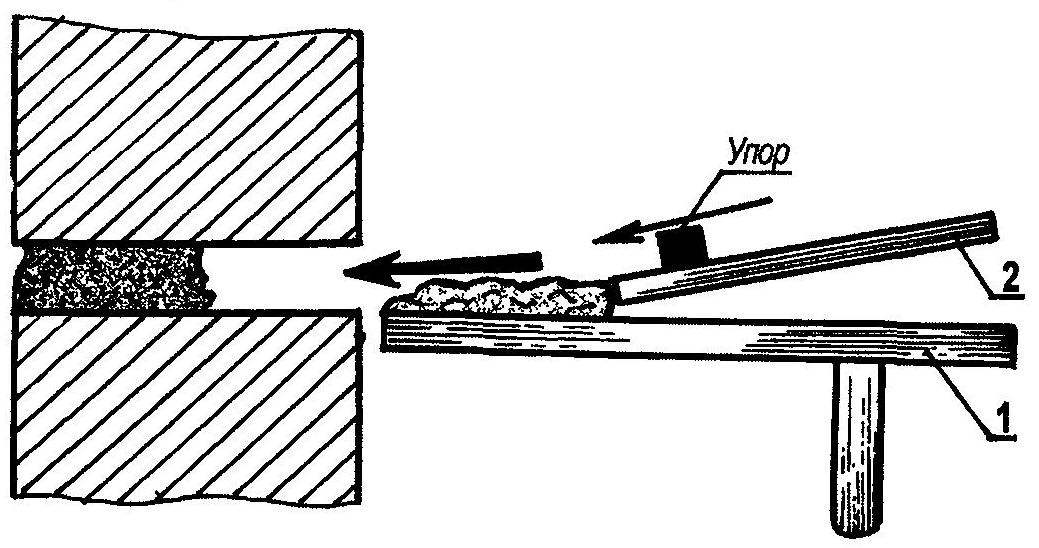

Fig. 5. Filling a seam with a solution:

1 Falcon; 2 — engine

When solutions want to paint — use alkali-resistant dry building paint (ochre, minium, carbon black, graphite), because the others quickly lose their color. The paint you have to pour in the eye, reaching the desired color. Recruitment it is produced. First, prepare a portion of the solution volume with a glass. Take a teaspoon full of paint powder, moisten it with water, added to the solution, mix thoroughly and smear on glass or tin a thin, almost mm layer. The dried mixture (e.g., fire) and check after drying. If the color fits, so 1 liter of solution need five teaspoons of paint. If the shade is too weak — add it; if it’s too rich — increase the volume of the solution. Choosing a color sample thus prepared the desired number of coated solution.

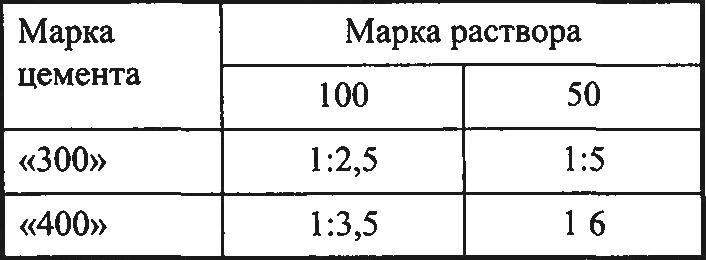

Cement mortar is comprised not only of cement and lime paste, and sand. The mixture so prepared. Measure out doses of all materials, cement is mixed with sand, lime paste, as already indicated, diluted to the density of sour cream and water, mix everything until smooth. It is necessary to add water in the necessary quantity to produce a solution of desired density. Then add the diluted (zatvoreno) in water paint and again thoroughly mixed. Then proceed to fill the joints.

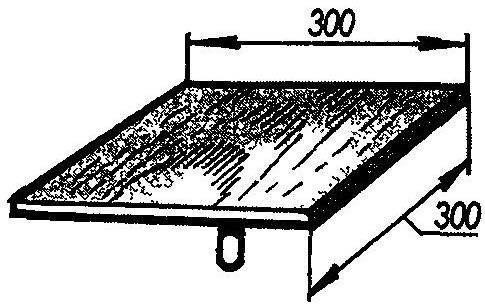

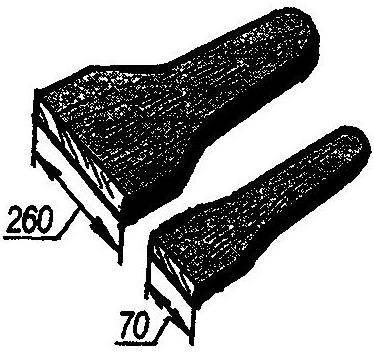

To work with the solution pre-made wooden Board (called a Falcon) with a handle in the middle (Fig.1). Then two wooden engine (Fig.2) with a width of 260 mm and 70 mm, the thickness of the weld size.

Sutures come in different forms (Fig.S): vpustoshovku, Padres embroidered with convex, concave embroidered. To give them the appropriate form of steel roofing done the pointing (Fig.4).

To restore the seams not to spoil the brick mortar, it is recommended to cut from the newspaper or other thin paper strips the size of brick: they were soaked in water and glued to the bricks. The solution, when applied to paper, does not stain brick. After filling the joints, the paper was immediately removed. Depending on its density it can be used repeatedly.

Composition of cement-lime mortar and its brand*

*In the first place — the cement, the second the limy dough, the third — sand

Pure cement mortar is composed of cement and sand

The composition of cement and its brand**

**The first position is cement, second sand Materials are thoroughly mixed among themselves (the subsequent staining procedure is the same)

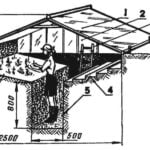

Fill seams with a solution, it is desirable to produce at a time and follows. The seams are well moistened with water, paste on the paper bricks. Put on the Falcon two to three servings (with glass) solution, put a Falcon to the wall at the level of the seam, and the engine pushed a solution into the joint, filling it to the desired depth (Fig.5). If the seams need to do vpustoshovku, the engine from the top, you can fill a rail-blank range to keep the engine on the required depth; and when it is necessary to trim this seam is used in jointing 1.

If the seam Padres, then the solution is filled edge to edge with the wall, and the excess cut off with a trowel and smooth it.

When jointing seam (Fig.H) to give it a convex or concave shape fill it with the mixture, respectively, with a protrusion from the wall or flush with its surface. Then filled the seam put the jointing tool, click on it and go along: the seam takes the appropriate form. Rasshivkoj use, fresh solution (set to level very hard).

First draw the horizontal joints, then vertical.

A. SHEPELEV, engineer