When carrying out installation work related to installation of structures on mortgages supporting parts of foundations, as a result of violation of technological process or as a result of its imperfections may be difficulties caused by irregularities in the supporting surfaces (local distortions, holes, etc exceeding permissible limits). Such situations often arise in the installation of industrial equipment, but such cases are not uncommon in everyday life. For example, the use of embedded items in the Foundation in the construction of different buildings on a country or a plot.

When carrying out installation work related to installation of structures on mortgages supporting parts of foundations, as a result of violation of technological process or as a result of its imperfections may be difficulties caused by irregularities in the supporting surfaces (local distortions, holes, etc exceeding permissible limits). Such situations often arise in the installation of industrial equipment, but such cases are not uncommon in everyday life. For example, the use of embedded items in the Foundation in the construction of different buildings on a country or a plot.

In some cases, with relatively small deviations practiced by the installation of shims between the mating surfaces or processing the support flange newmotor-binkey with a possible subsequent scraping. However, these operations require a very laborious additional work, which also can have a negative effect of low ambient temperature and poor working conditions.

If significant deviations do not allow to correct the position of the above ways, the question of dismantling the defective Foundation and replace it with a new one, which in turn is connected with the time, and with the additional consumption of scarce materials, and increased costs. In such cases, new solutions to the problems through which you can fix (“cure”) the defects of foundations. One way is to use plain wedge-shaped rings with a specified angle (figure 1A), a support surface which is processed on the machines. These wedge rings are placed on a reference surface (flange) of foundations and turning around a vertical axis, is forced into the position meets the requirements of the installation. After that, the wedge ring is fixed and carried out the mounting operations, including bolted connection designs.

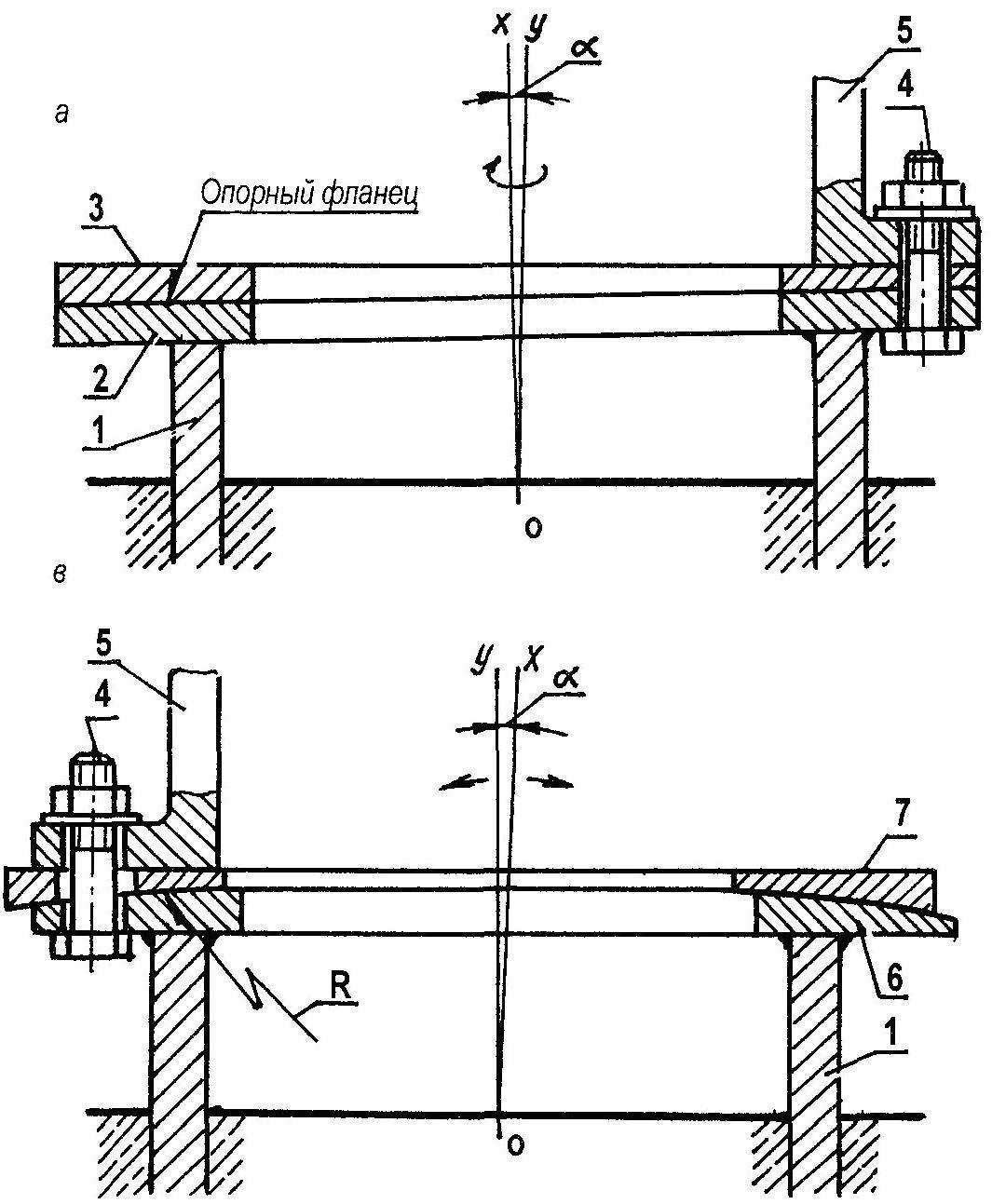

Embeds the foundations of (a — flat flange and the transitional wedge-shaped ring with a spherical flange and a spherical transition ring):

1 — Foundation base, 2 — flat flange, 3 — wedge-shaped adapter ring, 4 bolt mount, 5 — mountable design, 6 — spherical flange, 7 spherical adapter ring, Oh — the actual centerline of the laying of the flange, Oh — vertical axial line, the angle of deflection of the centerline of the laying of the flange

The proposed option may seem a bit complicated, but when you consider all the work on fixing the defective bearing surfaces or producing new, we should accept it more appropriate. The more that the wedge ring is not subjected to welding operations and, therefore, do not change their mechanical characteristics and able to provide have a positive effect. Those may be relatively few cases when it is necessary to provide a sufficiently high accuracy of the reference planes, we recommend the use of flanges and transition rings on a spherical surface (Fig.1B). The essence of this decision is that to advance under-mounted design make embedded reference part with a spherical flange and a spherical adapter ring with the same radius of the sphere. To provide the required parameters on the horizontal supporting surface of the adapter ring to be moved along the area of the flange. Then adjusted in position and then the mounting structure in accordance with the existing procedure and specifications.

Horizontal installation is wedge-shaped and spherical transition rings can be controlled, for example, using a level or optical quadrant sets out options for technical solutions has proved its value in practice.

S. CHERENKOV, Saint-Petersburg