Anyone who has had to pour any fine powder through a funnel with a narrow neck, knows that this is not easy: the powder stick together and clog the hole. However, if you tap on the funnel, it will go faster: vibration disrupts the adhesion between particles of matter.

Anyone who has had to pour any fine powder through a funnel with a narrow neck, knows that this is not easy: the powder stick together and clog the hole. However, if you tap on the funnel, it will go faster: vibration disrupts the adhesion between particles of matter.

This principle has been used to solve similar problems in a production environment — where you want gradually feeding into the working area, for example, cement, fine and humid sand, chemical or metal powder, lime, graphite. For these purposes, employees of the State Institute prikladnoi chemistry developed a simple but effective hopper is in which the main role is played by the vibration.

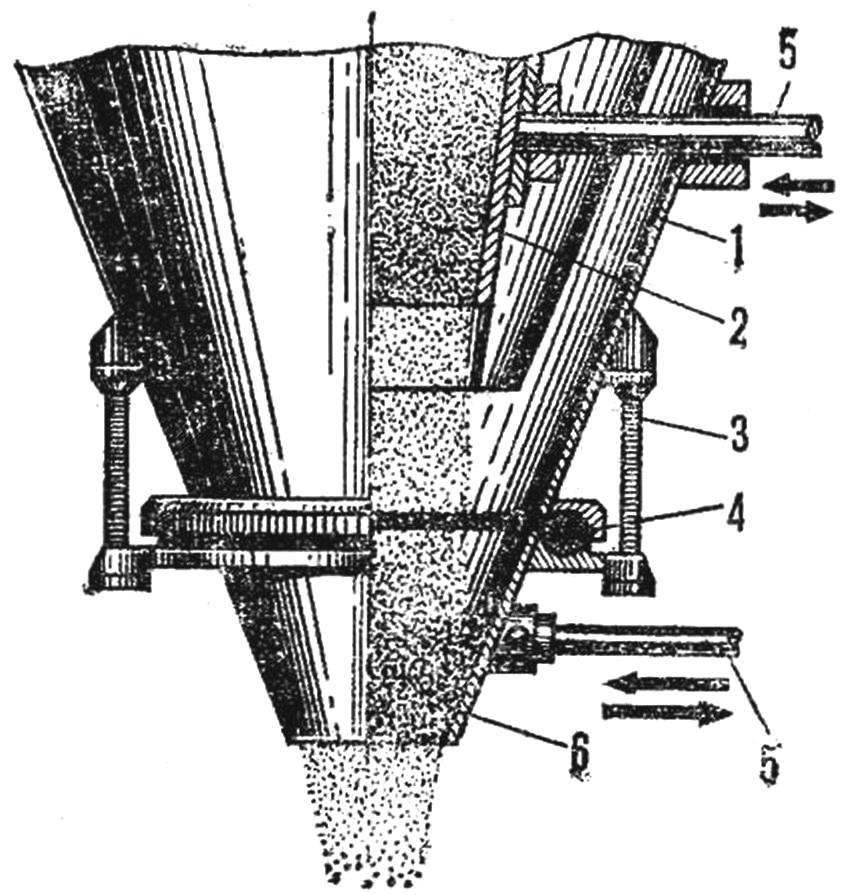

Hopper is:

1 — silo tank 2 — vibration insert, 3 — flat spring, 4—, sealed-junction, 5 — vibrating rods, 6 — fibrinogenic.

The tapered part of the hopper provided with a vibrating tip, suspended on a flat spring and having a rubber sealing gasket at the junction with the hopper. Inside the bunker also introduced vibrating insert. Both the vibrating element is driven via painted them stocks, sending frequent reciprocating motion. The vibration frequency of insert and tip can be different: there is a possibility to dose the amount of powder passing through them.

This design allows feeding the non-free-flowing fine powders using minimal exhaust holes up to 25 mm, providing a high quality of work.