In rural life, there are many laborious works, which nevertheless must be done quickly, such as a spring — sown, summer — haymaking, harvesting in autumn and finally the snow in winter When they are executed, if there are many helpers, without mechanization not do a Great help on the farm would be workaholic-a tractor, but is it “rent”? So try the hosts of the farmsteads, knowing techniques to purchase inexpensive some broken tractor and restore it But for everyone of those too lacking, and therefore the “paracasei”, try to make the tractor themselves from discarded scrap metal units and units of different machines.

In rural life, there are many laborious works, which nevertheless must be done quickly, such as a spring — sown, summer — haymaking, harvesting in autumn and finally the snow in winter When they are executed, if there are many helpers, without mechanization not do a Great help on the farm would be workaholic-a tractor, but is it “rent”? So try the hosts of the farmsteads, knowing techniques to purchase inexpensive some broken tractor and restore it But for everyone of those too lacking, and therefore the “paracasei”, try to make the tractor themselves from discarded scrap metal units and units of different machines.

On the way past and I went, when in 2001, he rented two hectares of land. Experience of designing improvised equipment I have had Since 1976, I subscribed to the magazine “modelist-Konstruktor”, store subscriptions, and, guided by its publications in 1985 for their younger sons, Oleg and Maxim made a light moped In 1989 produced a four-wheel air suspension of his own design In 1993 on the engine truck motorcycle “Ural” has used forced air cooling, included in the transmission two-stage reduction gear, and equipped the bike with a mower. Picking up in semejnyh places — at a friend’s homebrew, scrap metal, the “cemeteries” technique suitable assemblies and mechanisms from different types of machines began in December to collect them from the tractor.

Since the story about the tractor, I want to note that it was built in stages. In the first winter did the chassis with the drive only the rear wheels.

The chassis is assembled on a cropped frame from the GAZ-52. The frame is mounted on the power unit — diesel three-cylinder liquid-cooled engine with a capacity of 28 kW (35 l ) at frequency of turns of a cranked shaft 2200 per minute from the Czechoslovak loader. To the motor via an adapter ring basket docked with the clutch mechanism from the van UAZ-452 To the basket, too, via an adapter attached characterdata box changes gear (transmission) from the truck GAZ-51 equipped with transmission PTO (PTO) driveline going from the transmission to the rear wheel axle, two — stage open type. Bridge — truck off-road vehicle ZIL-157, but shortened. To the frame it is suspended rigidly by means of four ladders the Rear wheels of the car GAZ-66.

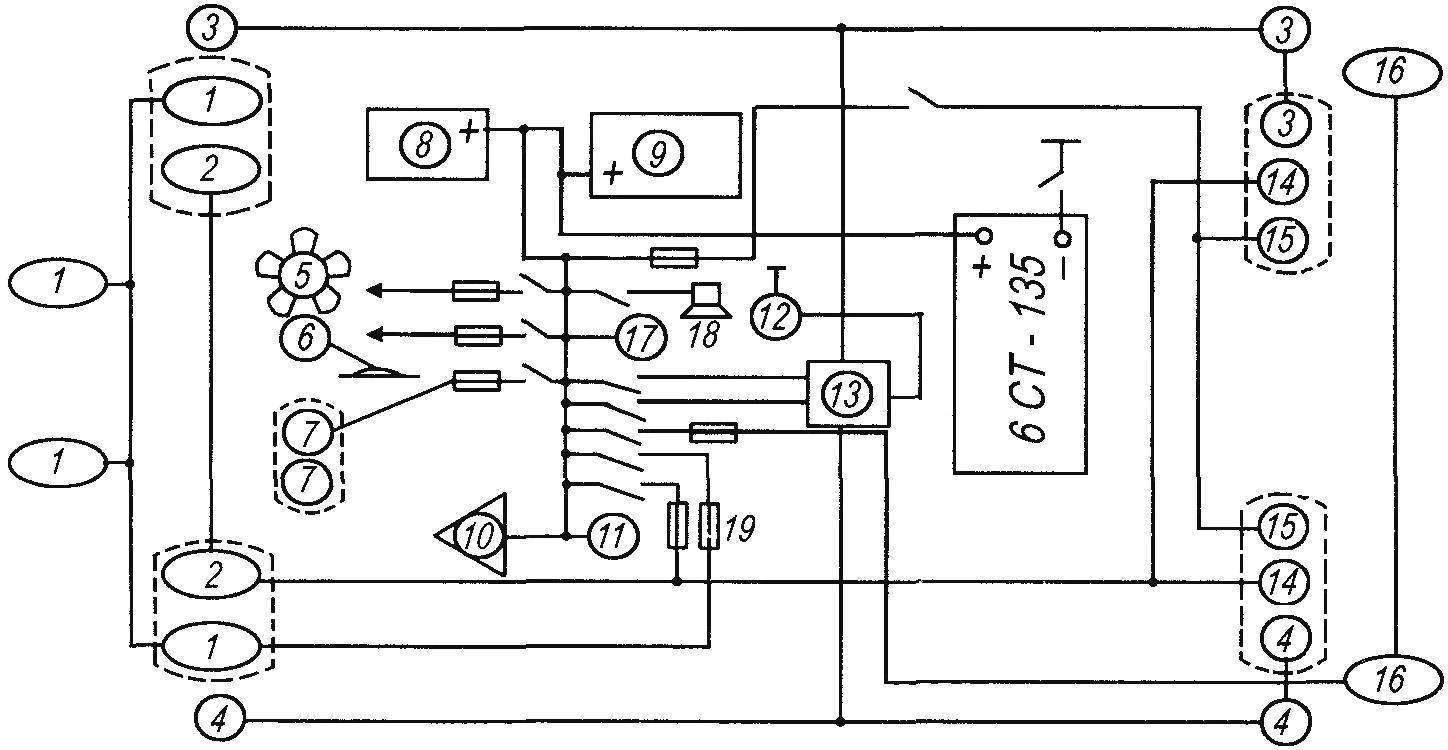

Wiring diagram tractor:

1 — beam, 2 — lamp beam, 3 — pointers right turn, 4 — pointers left turn, 5 — blower, 6 — windshield wiper motor, 7 — interior, 8 — alternator 9 — starter 10 — oil pressure sensor, 11 — oil-pressure indicator, 12 — the control lamp of indexes of turns, 13 — relay turns 14 — tail lights, 15 — stop lamp, 16 — rear lights, 17 — cigar lighter, power socket, 18 — beep 19 —the fuse (6 PCs.)

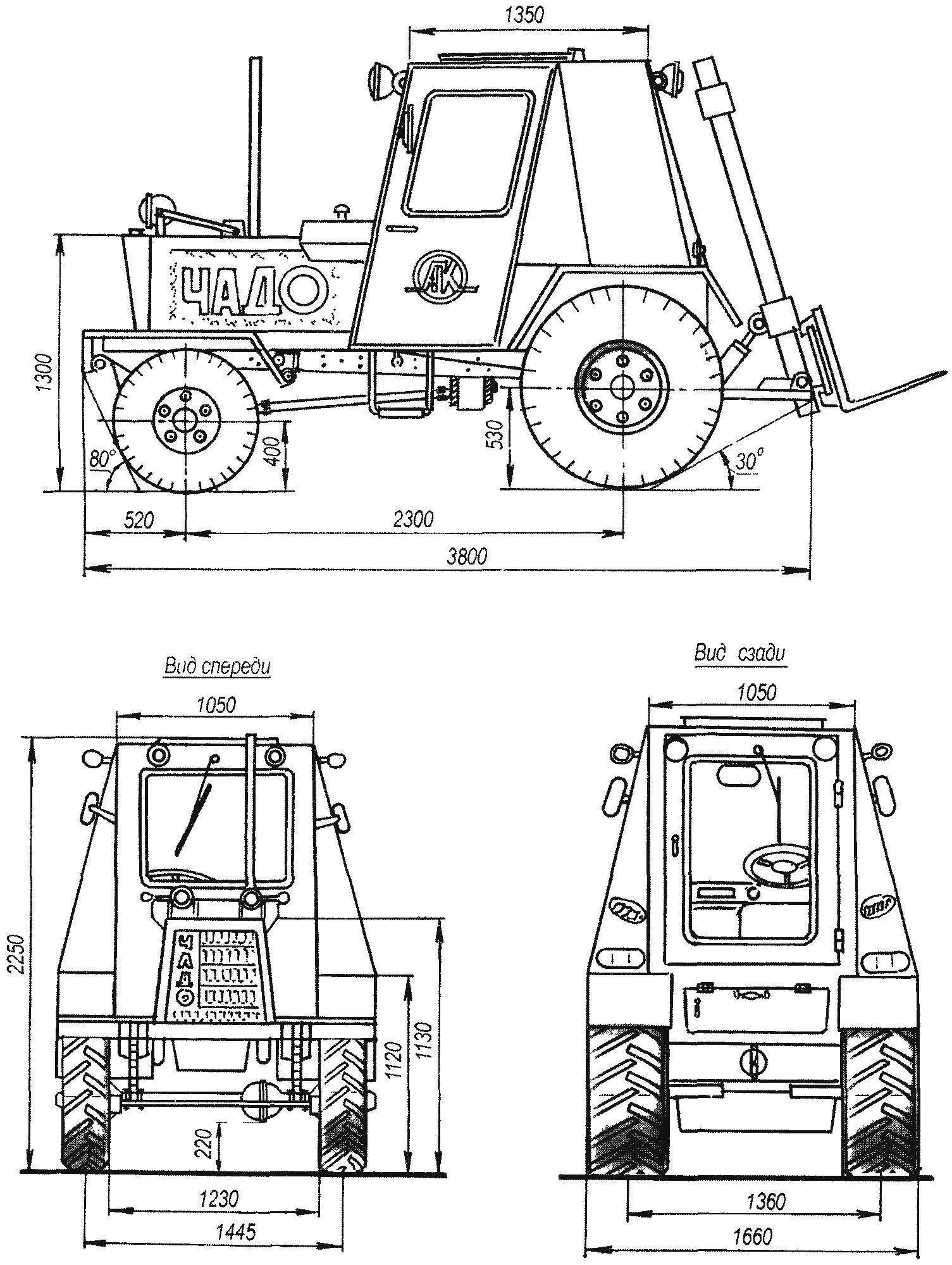

Tractor “CHILD” (in the rear view of the stacker is not shown)

Towed the truck away in the concerts of Amateur artists becomes a makeshift hardware, trimerous and coupling

Front axle used from the car UAZ-469 He, as the back, execution — leading (with the main transfer and differential) But it in the original version was not used and the front wheel size 6×15 remained only the guides of the Front axle is suspended on the frame by semi-elliptic leaf springs with no shock absorbers, the steering Mechanism from the car GAZ — 51 Brakes were mechanical and acted on the rear wheels only, although the Parking brake was available too.

Electrical — 12-volt But at the first stage installed only absolutely necessary — the alternator and starter Battery on time borrowed from a passenger car “Lada”.

Here on this chassis (called a tractor this original version not yet solved) in the spring of 2002 went “beyond the gates” and performed field planting is carried, so to speak, of testing in the case.

Then mounted on the chassis mounted mower driven by the PTO shaft and trailer (also on horseback) rake them held a harvest for hay.

The autumn, time of harvest, adapted to the chassis, the linkage for DAHLONEGA plough and with it raised on the field plowing the Whole season if necessary, used the chassis as the two-axle tractor trailer truck was carrying on her hay, firewood, crop In the following “messagestate” (late autumn, winter and early spring) continued construction of the tractor made the work on the improvement of the transmission chassis and improved comfort.

Primarily made chassis all-wheel drive complements the transmission two-speed transfer case from the truck GAZ-66 Propeller shaft is thus divided into two intermediate and rear the same Front driveshaft re-made “Stockings” (the housings of half shafts of the front axle) I had to rearrange (swap) to Carter, the main transmission with its drive shaft located to the left of the engine wheel is also supplied with brakes, but unlike the rear — hydraulic.

Even equipped the tractor with a forklift driven by a hydraulic system with gear type oil pump. In haying time the stacker successfully replace the stacker (the height of rise of about four metres) and in exceptional cases when the load cannot be lifted by hand — and as a crane For the winter I think to equip the tractor device like a dozer blade or grader blade to clear snow from the tracks.

Separate conversation about the cabin I did a few unusual with three doors, two side and one rear In the cabin arranged side niches, and from this it has become noticeably more spacious. Now it can freely fit together with a driver, three passengers (two in the niches and one on the seat next), he is not interfering with the tractor set up all the necessary lights lights, “turn signal” brake lights, as well as the washer and wiper.

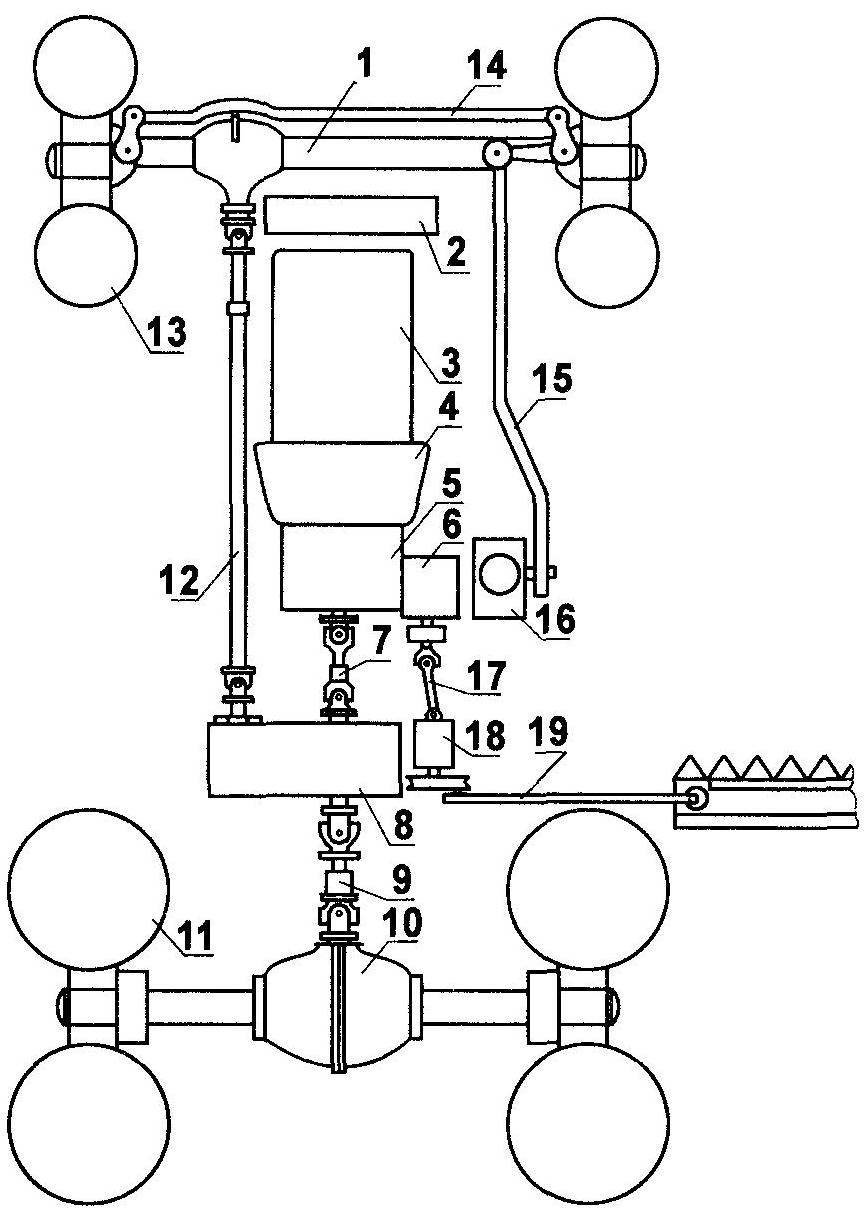

Layout scheme:

1 — front axle (GAZ-69), 2 — the radiator (from the “Moskvich-412”), 3 — engine (diesel, 35 HP from the Czechoslovak loader), 4 — linkage mechanism (UAZ-469), 5 — gear shift (GAZ-51), 6 —the mechanism of the PTO shaft (GAZ-51), 7-intermediate driveshaft, 8 — transfer case, 9 — rear driveshaft 10 — rear axle (ZIL-157), 11 — front wheel (GAZ-66, 2-piece), 12 — front driveshaft 13 — front wheel (from UAZ-469, 2 – piece), 14 — tie rod (UAZ-469), 15 — longitudinal tie rod, 16 — steering gear (GAZ-51), 17 — additional propeller shaft 18 — bearing housings, 19 — mechanism for mowers

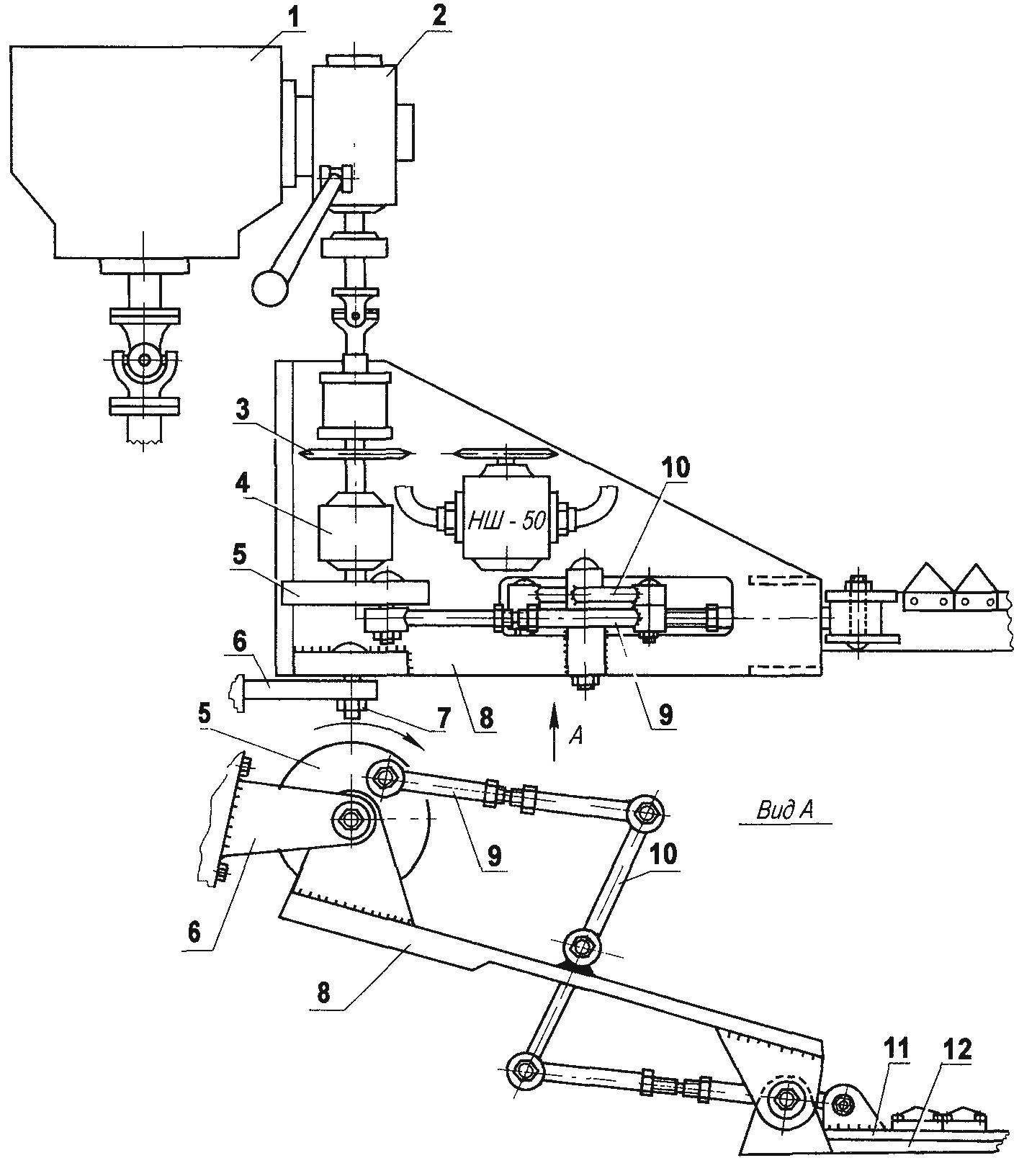

Diagram of the drive mechanism of the mower:

1 — gear shift, 2 gear power take-off, 3 — chain transmission drive gear oil pump, 4 — the case of the bearing unit, 5 — Cam, 6 — bracket, 7 — axis hinge, 8 — base area of the lever, drive the upper blade mower, 9 — rod arm (2 PCs), 10 — lever 11 — the upper (movable) sheet mowers, 12 — lower (fixed) pilot, mowers

The cab interior also tried to arrange well — made casing, placed ceiling lights and the fan But the main thing — have established here a good reciever and now have the opportunity to work with the music and songs, including those performed by Amateur ensemble “Kalinka”, soloist and artistic Director.

The tractor is called “CHADO” in honor of the beloved grandson “of the Armenian People Demid O.”, who never miss an opportunity to ride with grandpa on his knees besides so kindly in old Russia called children.

Technical characteristics of the tractor I was quite satisfied. Even a relatively large mass (about 2.2 t) works — provides good traction when plowing and on a slippery road. Fuel tank capacity 25 litres — enough for more than 150 km Speed from 3 to 60 km/h And although the machine was not created for racing, however, such a large maximum velocity still is needed when performing transport work.

I mentioned about a cargo trailer truck. By the way, it is also made by myself. In addition to transporting goods use it as a mobile stage, control room and green room for visiting concerts of Amateur artists local. House of culture of oil industry workers, whose Director I part-time are (my main job is a fireman).

P. ARMENIAN, p., Coteret, Bashkortostan