A thrifty owner, especially a rural resident, does not have too much household equipment. So I got another mini tractor. As usual – homemade (you can see about my previous work in “M-K” No. 1-2023 ). This time, in addition to functionality, increased attention was paid to aesthetics and ergonomics. I wanted to get not only a reliable, but also a comfortable, beautiful car. To be “better than from the factory.”

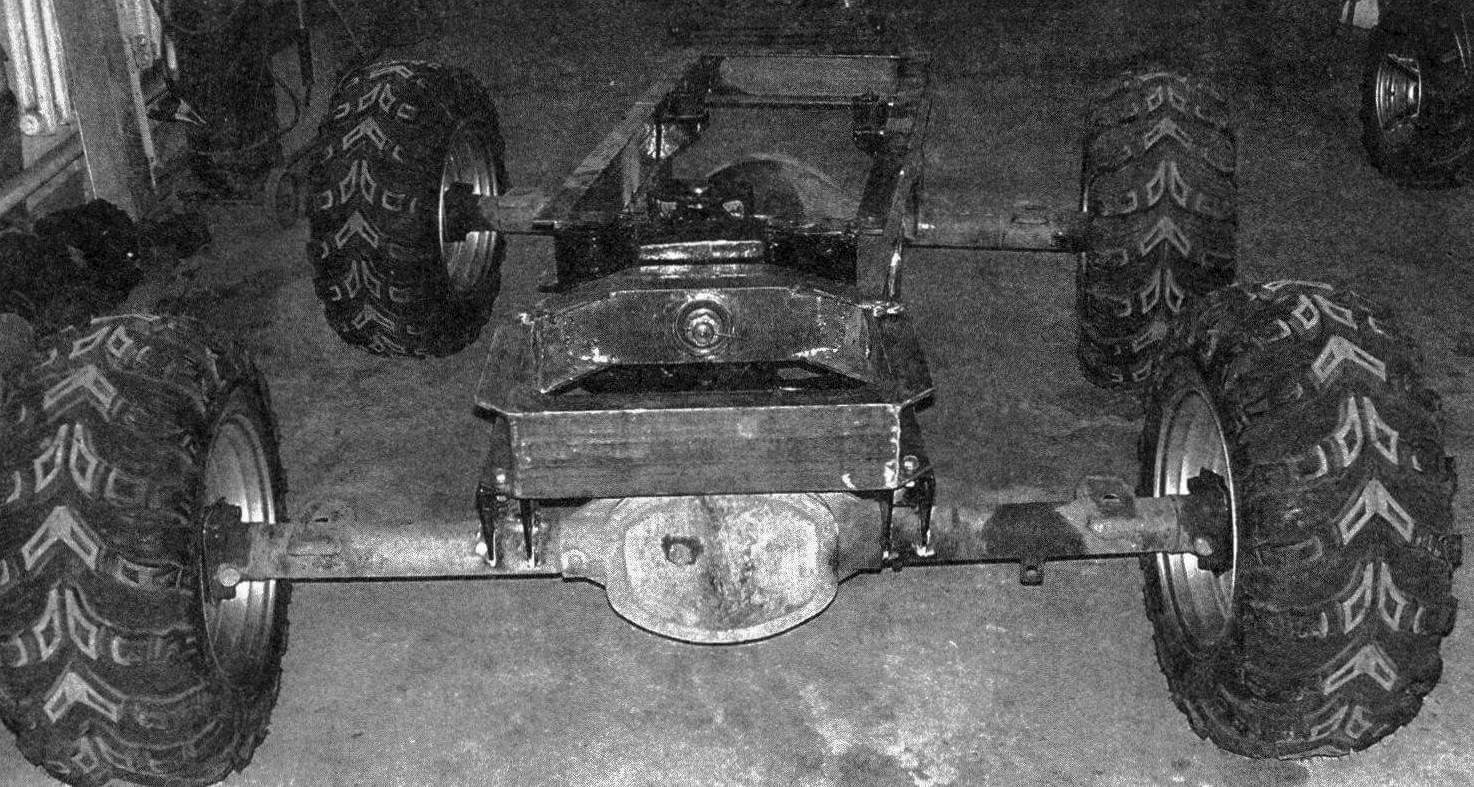

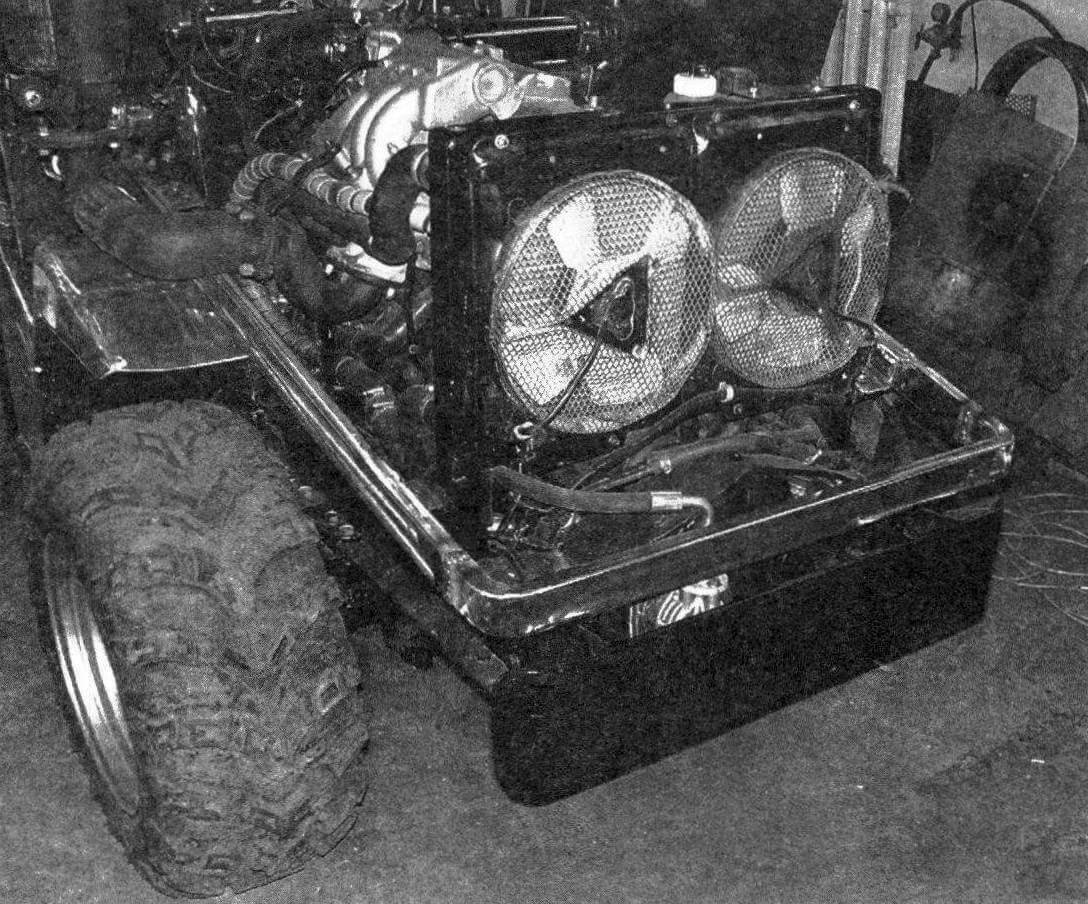

The layout is traditional for amateur “break” designs. Both half-frames are made with a large margin of safety – welded from 120 mm channel. The articulation unit with three bearings is modeled after the Kirovets K-700 tractor, only small. The axles are shortened from the Volga GAZ-3110, but the main pair in them is from the Gazelle with a gear ratio of 5.125. I took the rims from a Mitsubishi Delica and modified them to install ATV tires.

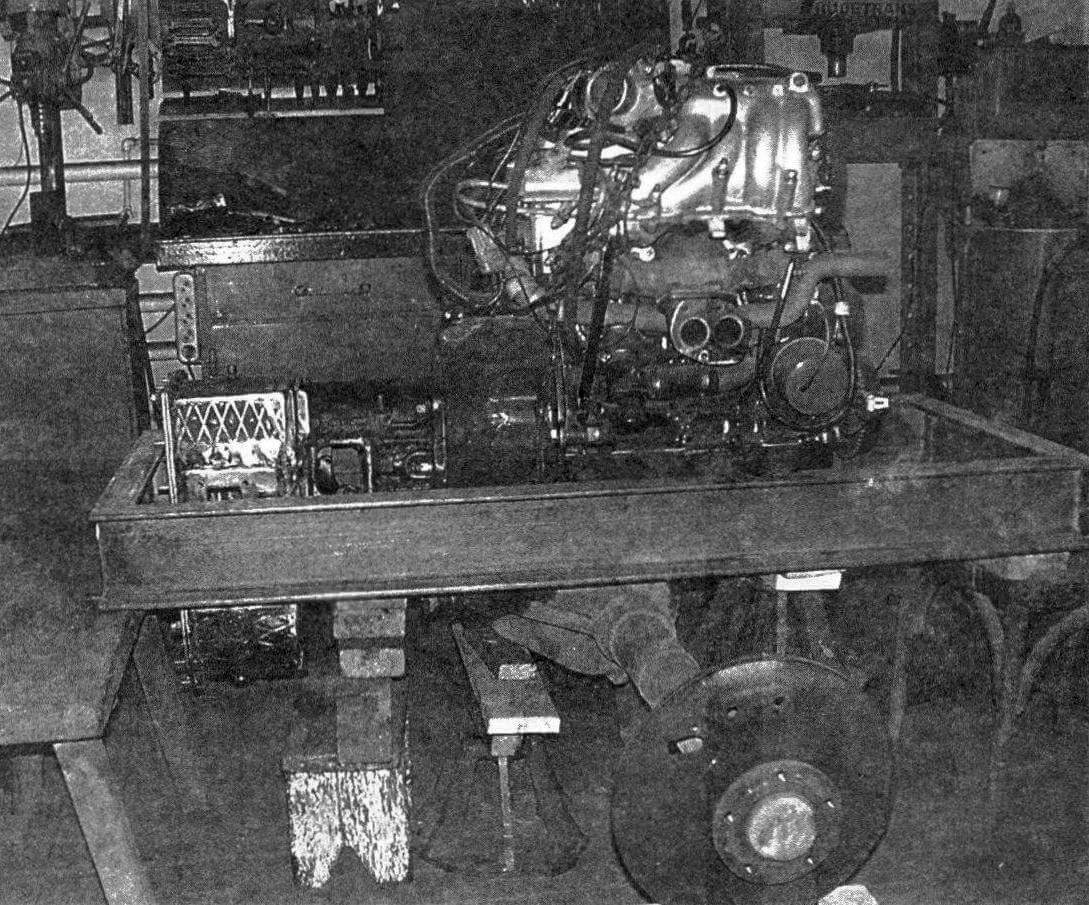

The power unit is installed on the front half-frame. The engine used an injection VAZ-2111. The radiator is from a VAZ-2109 with two electric fans from Toyota. The clutch basket and release bearing are from a VAZ-2109, the driven disc is from a Moskvich-412 car. The clutch pedal is driven mechanically using a rod.

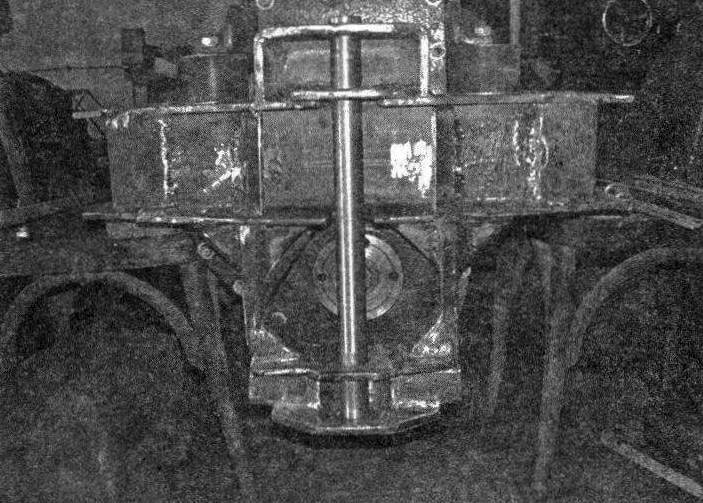

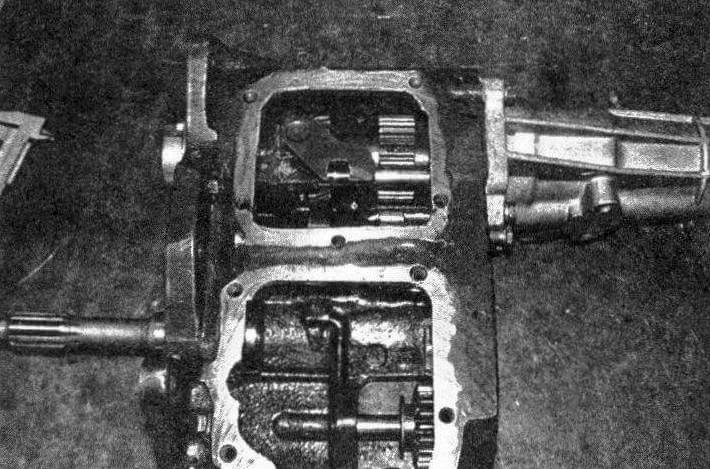

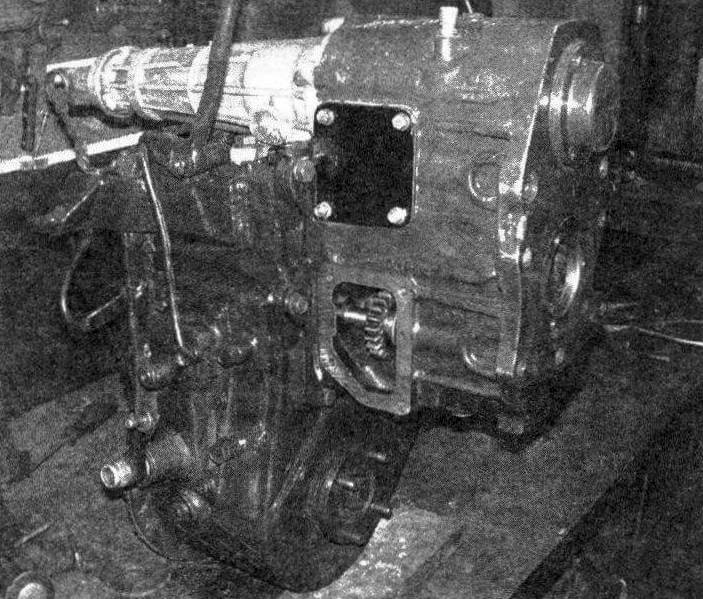

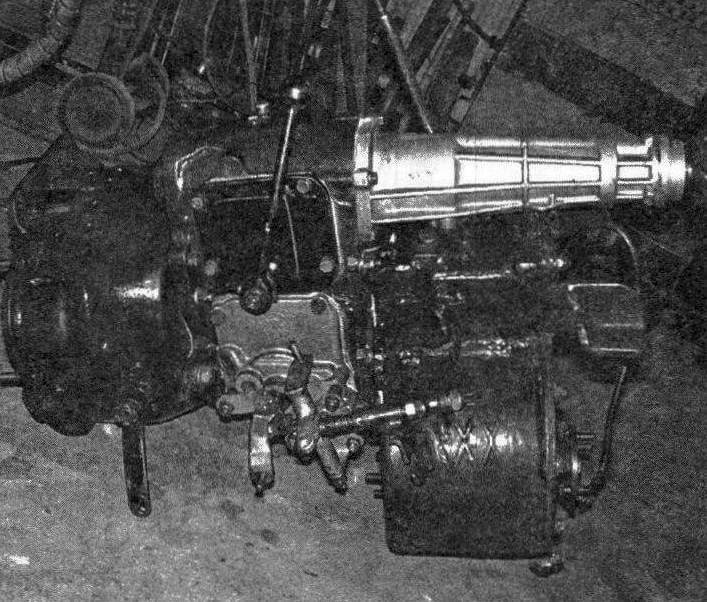

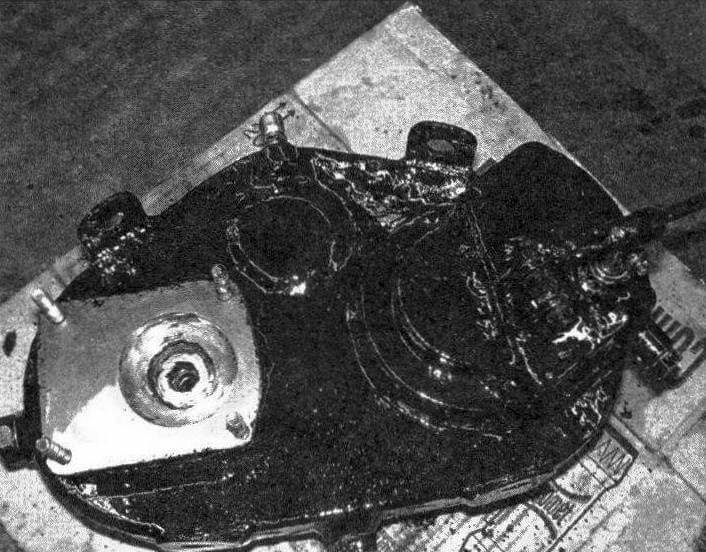

The highlight of the design is the homemade transmission. The gearbox housing is welded from two housings from a Moskvich-412 gearbox (I used it as a basis because it is the most compact of the domestic ones). The main one is the lower gearbox – “Moskvich” assembled. A power take-off (PTO) is installed in the upper part of the housing. The output from it (can be switched off) goes to an additional gearbox, which has four forward gears and one reverse gear. From the main gearbox, torque is transmitted to a homemade transfer case with reduction gear and reverse. And from the transfer case, with the help of cardan shafts, traction goes to the front and rear axles.

Since the tractor’s steering loads can be very large when performing heavy work, I installed a rack and power steering from a powerful Toyota Prado SUV. I made the steering column with tilt adjustment myself. It turned out very well, you can literally turn the steering wheel with just your little finger.

The tractor is equipped with a hydraulic system necessary for working with various attachments. For this purpose, I manufactured a drive gear for three pumps: two NSh-10 and one NSh-32. The former are used in tandem with the main hydraulics for lifting the linkage and are not disconnected from the drive. Pump NSh-32 with a switchable drive – for additional equipment (for example, a hydraulic motor on a screw rotor, etc.). The normal operation of these pumps is ensured by the use of two homemade check valves. Filtration of oil from hydraulic distributors is carried out through coarse and fine filters.

The rear linkage is 3-point, driven by two hydraulic cylinders. There are also two hydraulic valves: P-40 for the main hydraulics (four sections) and P-80 for additional equipment.

The hydraulic system oil is poured into a 15-liter common tank. In the second part of the tank behind a double partition there is a fuel compartment with a volume of 35 liters. The tank is welded from 1.5 mm thick steel and is installed behind the driver’s roll bar.

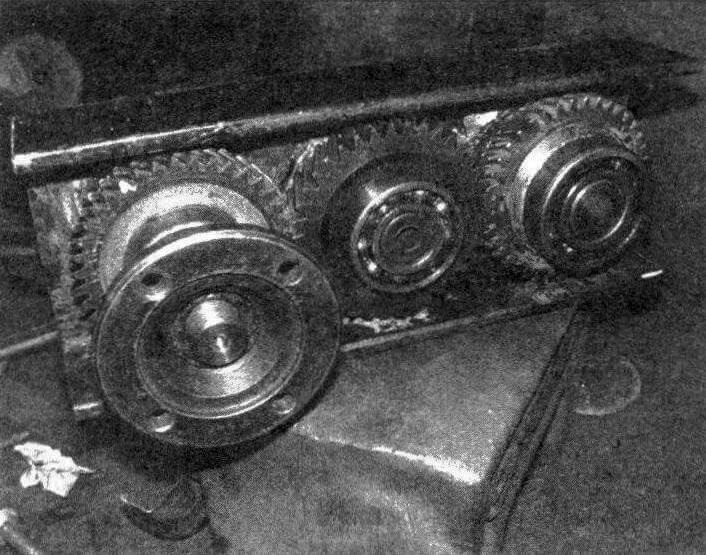

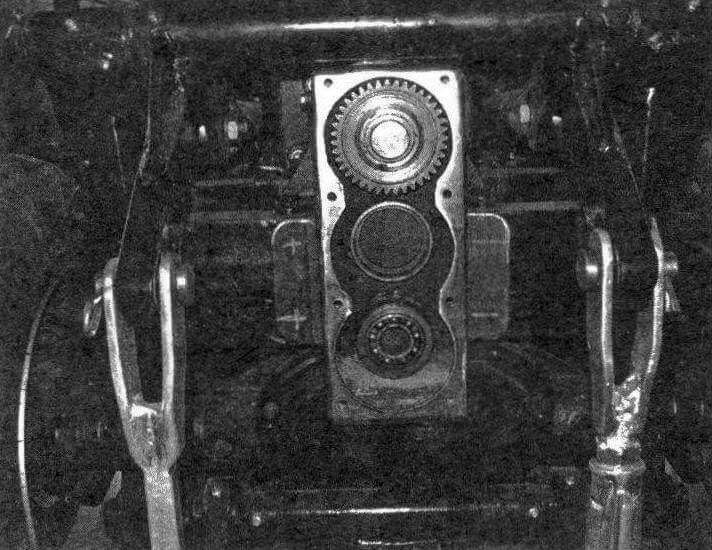

To reduce the output of the power take-off shaft (PTO) from the gearbox by 180 mm, a gearbox was manufactured using fragments of a 120 mm channel and gears of the VAZ-2109 gearbox. Initially I wanted to install a flange from the rear axle of a classic Zhiguli at the output of the gearbox, but in the process I decided to modernize the output shaft. For this purpose, the gearbox housing had to be redesigned. I machined a new lower gear shaft (I used a front hub from a Ford car as a blank). The internal splines of the hub are the same as those of the VAZ-2109, and the outer diameter is for a bearing of 39 mm. I turned the hub on a lathe to fit a 35 mm seat and a gear. I machined new housings for the bearings. I decided to make the connection to the gearbox output of the power take-off shaft floating, but as durable as possible. To do this, I used a VAZ gearbox synchronizer clutch.

Disc brakes are installed only on the rear wheels. The pedal assembly is homemade. The seat is from the “nine”. The muffler and air cleaner are welded, they are mounted on a protective arc. A beam with LED headlights is also installed there. There is an LED light on the top of the air purifier. The taillights are located on the rear of the gas tank.

Electrical equipment is standard 12-volt. Starter from Toyota, generator VAZ-2110. The 60 Ah battery is installed in a niche under the floor on the right side. Instruments on a homemade dashboard from VAZ-2105 and VAZ-2106.

Now about the external finishing elements. The hood is made of 1 mm thick metal, the wings are made of 1.5 mm steel. The tractor is painted with blue-green metallic paint. On the sides there are nameplates with the name of the car and the 4WD symbol, cut from stainless steel 4 mm thick.

Video review of the homemade mini tractor “Hummingbird”:

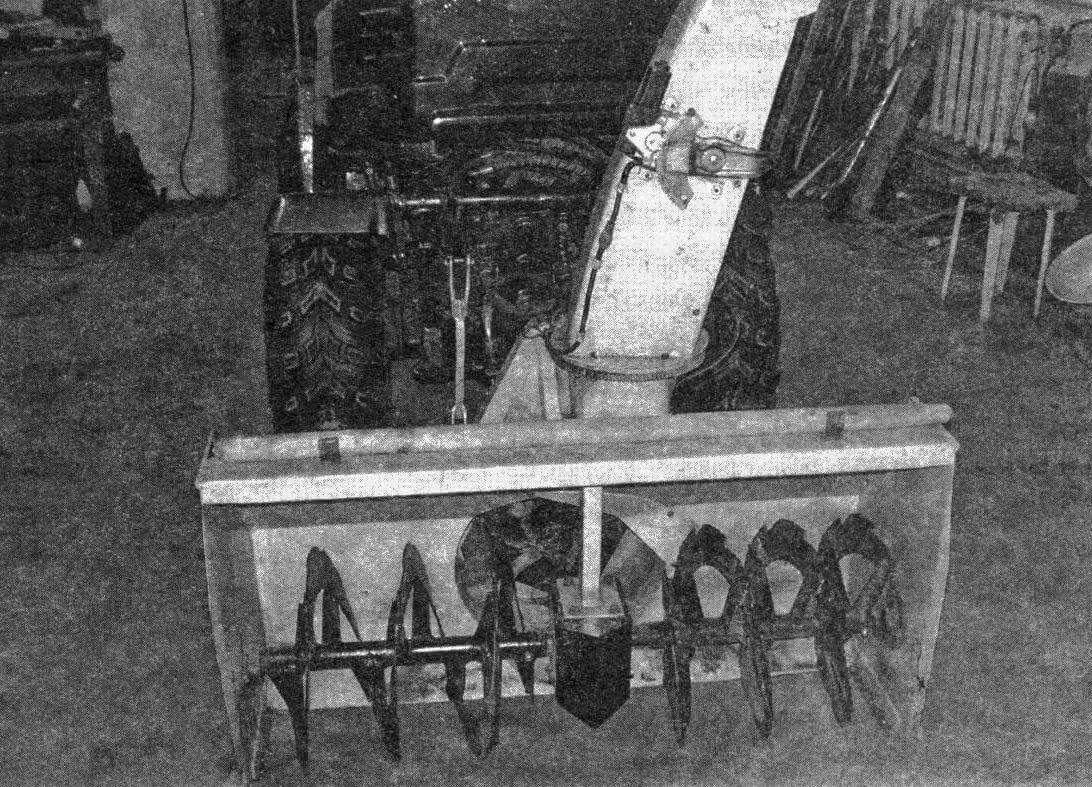

In this form, the tractor was successfully operated during the winter-spring season of 2023. In winter, I cleared snow using a rotary auger and a bucket. In the spring I cultivated the garden with a milling cutter. The machine performed well, but there was one drawback – it was not very convenient to clear snow using the rear blade. In preparation for the winter of 2024, we had to modernize and design a front linkage with hydraulics. Now work has become much easier and more efficient.

Yuri ZHURAVLEV, Kulunda (Altai region)