In our middle latitudes, there are years when fruit trees stand as if in construction scaffolding: they are not visible due to a palisade of supports saving branches overloaded with fruit.

Gardeners know how difficult it is to grow a good harvest, but no less a problem is to preserve it, to make maximum use of autumn’s generous gifts. Fruits are stored, preserved, made into jams and jellies, and processed into juice. However, the juicers and juice extractors offered by industry are far from perfect: working with them is labor-intensive, and in a fruitful year—inefficient. In addition, these devices require high consumption of electricity or gas, and also require preliminary processing of fruits: grinding, removing cores, seeds.

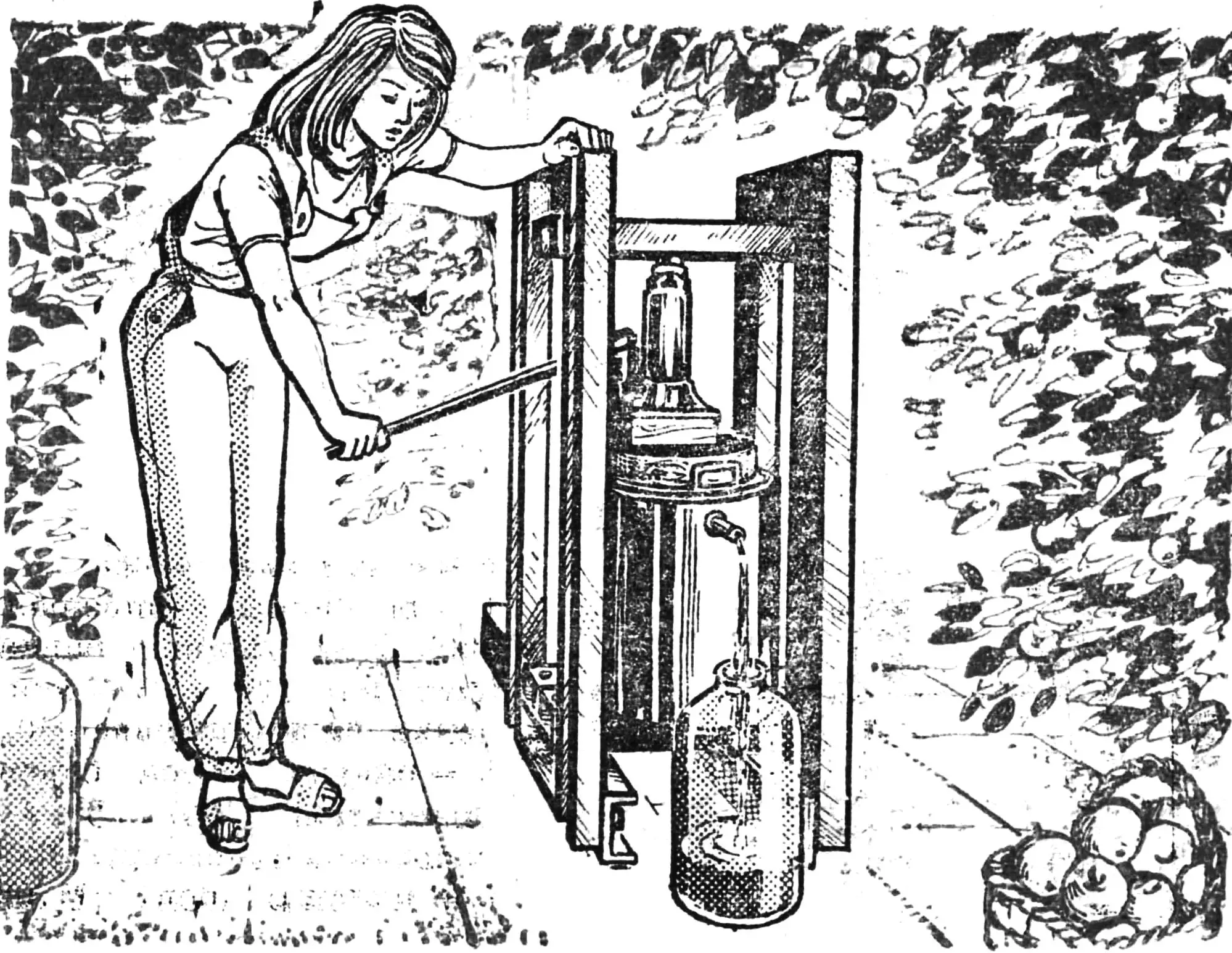

It is no coincidence, therefore, that such great interest among TV viewers was aroused by a simple and productive press for obtaining fruit juices, developed by innovator from the Moscow region, engineer I. Maslov, and shown in the popular television program “You Can Do It.”

I have only seven apple trees in my garden, and on windy autumn days, every morning under them—a colorful carpet of fallen, and therefore bruised, fruits unsuitable for storage or sale. It is best to process them into juices. And I decided to mechanize and simplify this work as much as possible.

This is how a homemade press appeared, which I want to tell about in detail, responding to numerous requests from TV viewers and readers of “Modelist-Konstruktor.”

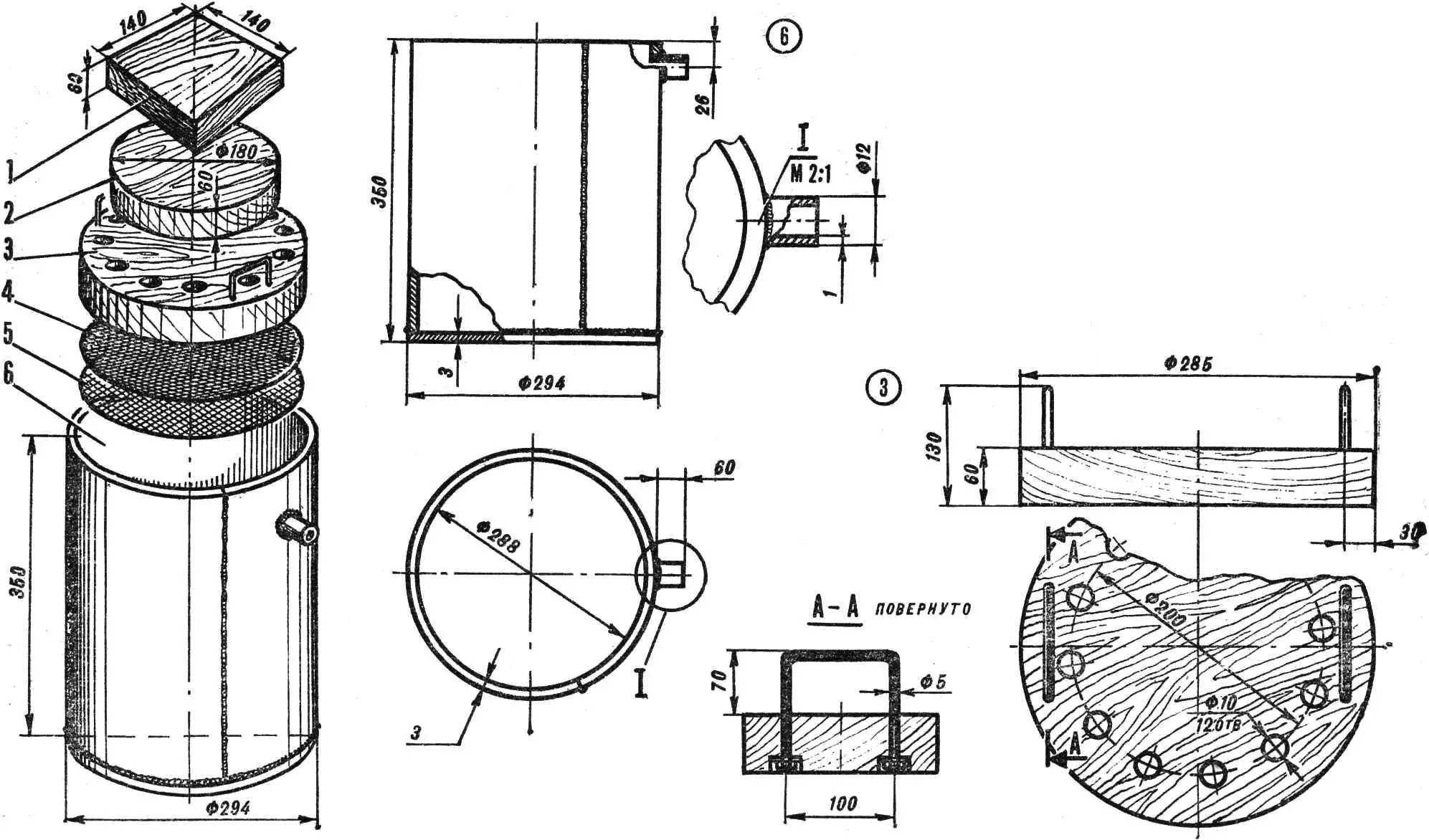

1 — spacer block, 2 — jack base disc, 3 — punch disc, 4 — fine mesh, 5 — coarse mesh, 6 — tank with drain tube.

The main part of the press is a vertical rectangular frame. A tank is placed in it, and on it, on a disc-lid, a regular car jack is installed. With such a juicer, you can process a bag of apples in just an hour, getting good quality juice.

To make the press, no scarce materials are required: I used what was at hand, resorting only to the help of a welder, since such an opportunity existed. But I think it can be done without this, as metal parts can be connected with bolts or replaced with wooden ones of corresponding strength.

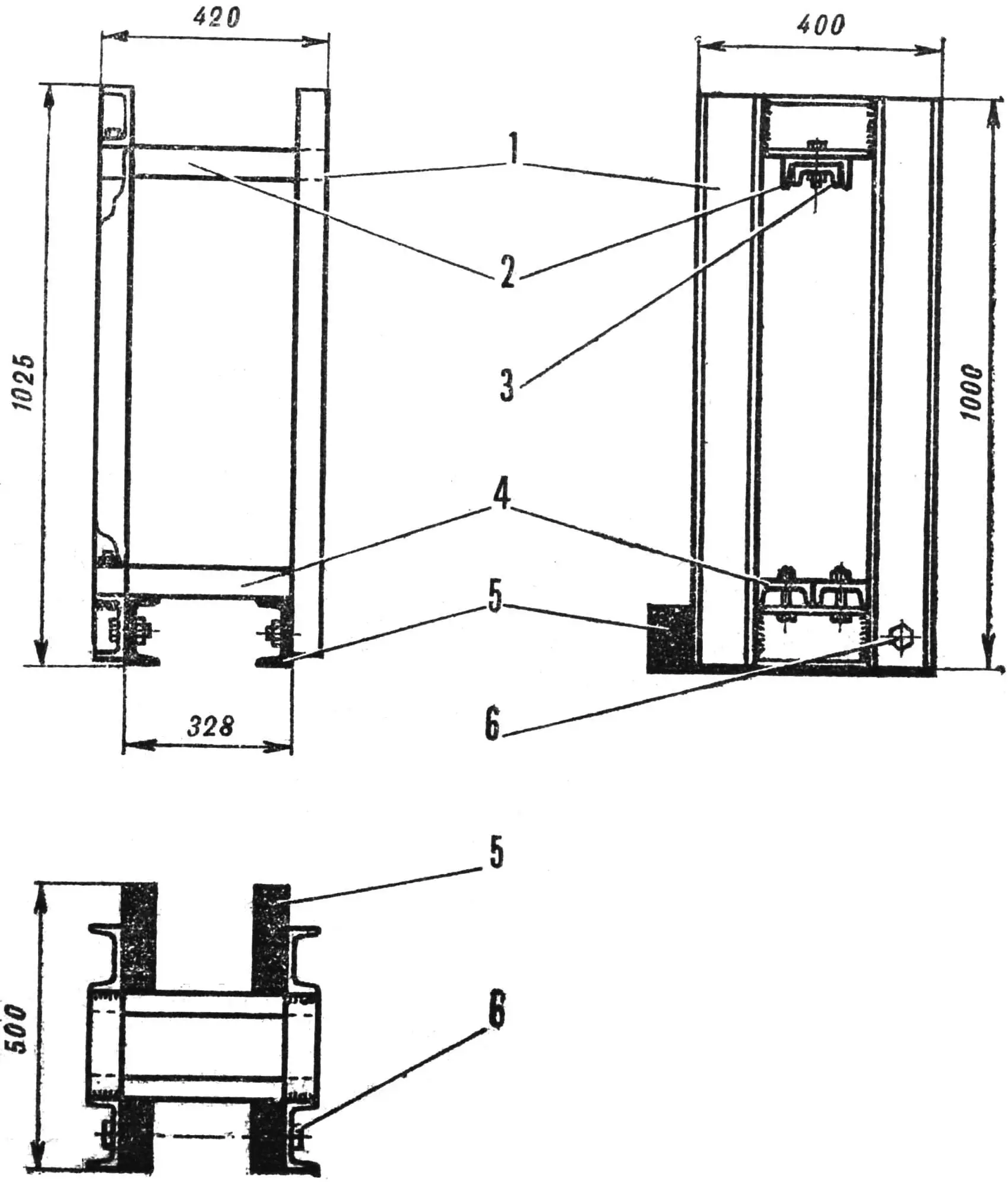

The frame is the power part of the press, so strength requirements are primarily imposed on it. I assembled it from channels, U-shaped steel profiles. Moreover, for convenience of use and storage, I made it semi-assembled: welded rectangular side panels are connected to each other with bolts by transverse beams from the same channels: a support pair from below and a reinforced (doubled) thrust—upper. In assembled form, the frame is installed on two horizontal channels running along the sides from the inside, and is connected to them hingedly—thanks to this, without disassembling the installation, it can be tilted to drain the remaining juice after pressing.

1 — side panels (channel 100), 2 — thrust beam (channel 100), 3 — beam reinforcement (channel 80), 4 — support pair of beams (channels 100), 5 — base (channels 100), 6 — hinge (bolt M10).

The tank is installed on a support pair of channels. It is welded from a 3 mm thick stainless steel sheet; if using carbon steel, the container must be tinned inside. In the upper part of the tank, approximately 20 mm from the edge, a drain tube 60 mm long is attached.

Many will be surprised: why is the drain located in the upper, and not in the bottom, as usual, part of the tank. This is the novelty and feature of the device. After all, practice shows that the squeezed juice always collects at the top—which means it is more convenient to drain it from here, and the pomace remains at the bottom.

The tank kit also includes two round metal meshes placed on top of the apples: the first with a mesh size of 1 mm, the second—0.5 mm (so that the meshes do not fall apart, they are soldered around the perimeter); a wooden (oak, beech) punch disc with holes for juice passage; another disc of smaller diameter (so as not to block the punch holes) and a spacer-block from a wooden beam, used when the jack stroke is insufficient.

The car jack develops a force of up to 5 tons. It is installed on a filled (2—3 buckets of apples) tank assembled with a press kit and rests against the upper crossbar of the frame.

I want to immediately mention some limitations regarding possible part replacements. They concern primarily the punch disc: not so much the material for its manufacture, but its thickness—it should not be less, because thanks to it, the upward displacement and “supply” of squeezed juice to the drain hole occurs. But the upper mesh can be replaced. It plays the role of a filter, so instead of it, gauze folded in several layers will work quite well. Similarly, the lower channels: instead of them, use wooden beams of appropriate cross-section, connected for stability by crossbars. The purpose of this base is to ensure the tilt of the press for draining the remaining juice.

The juice extraction process itself consists of two operations. The first is preparatory: apples are preliminarily crushed in a small barrel with a pestle, so that more of them fit into the press tank and juice extraction passes more easily. Then meshes, a punch disc, a smaller jack base disc are placed in the filled tank, and the jack itself is installed with a stop against the upper crossbar of the frame. Next, the jack is activated, as usual, with a lever extension, and the juice begins to rise to the drain hole. As the punch descends, if necessary, a spacer block is placed under the jack. When juice extraction stops, the installation is tilted thanks to the hinge at the base—and the remaining juice is drained. Then the cycle repeats.

“M-K” 7’85, I. MASLOV