Electric drive? For a boat? So, doesn’t our industry produce enough gasoline outboard motors? Go to a sports store and choose any one – from the lightest, suitable even for a kayak, to the heavy and powerful Neptune.

But we still need crystal clear water without an oil-and-gasoline rainbow on the surface, we need undeterred birdsong, we want to breathe air consisting of oxygen and nitrogen without any admixtures of heavy and light hydrocarbons and CO.

A boat with an electric drive fits perfectly into the environment – it does not pollute it with smoke or soot, and does not disturb the silence. Maintenance of the electric drive also does not require any special knowledge and is accessible to anyone.

That is why our selection includes descriptions of two outboard motors that are absolutely silent and do not require gasoline. They are similar both in the electric motors used in them and in the power sources, but otherwise… judge for yourself.

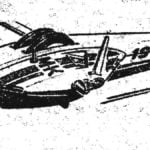

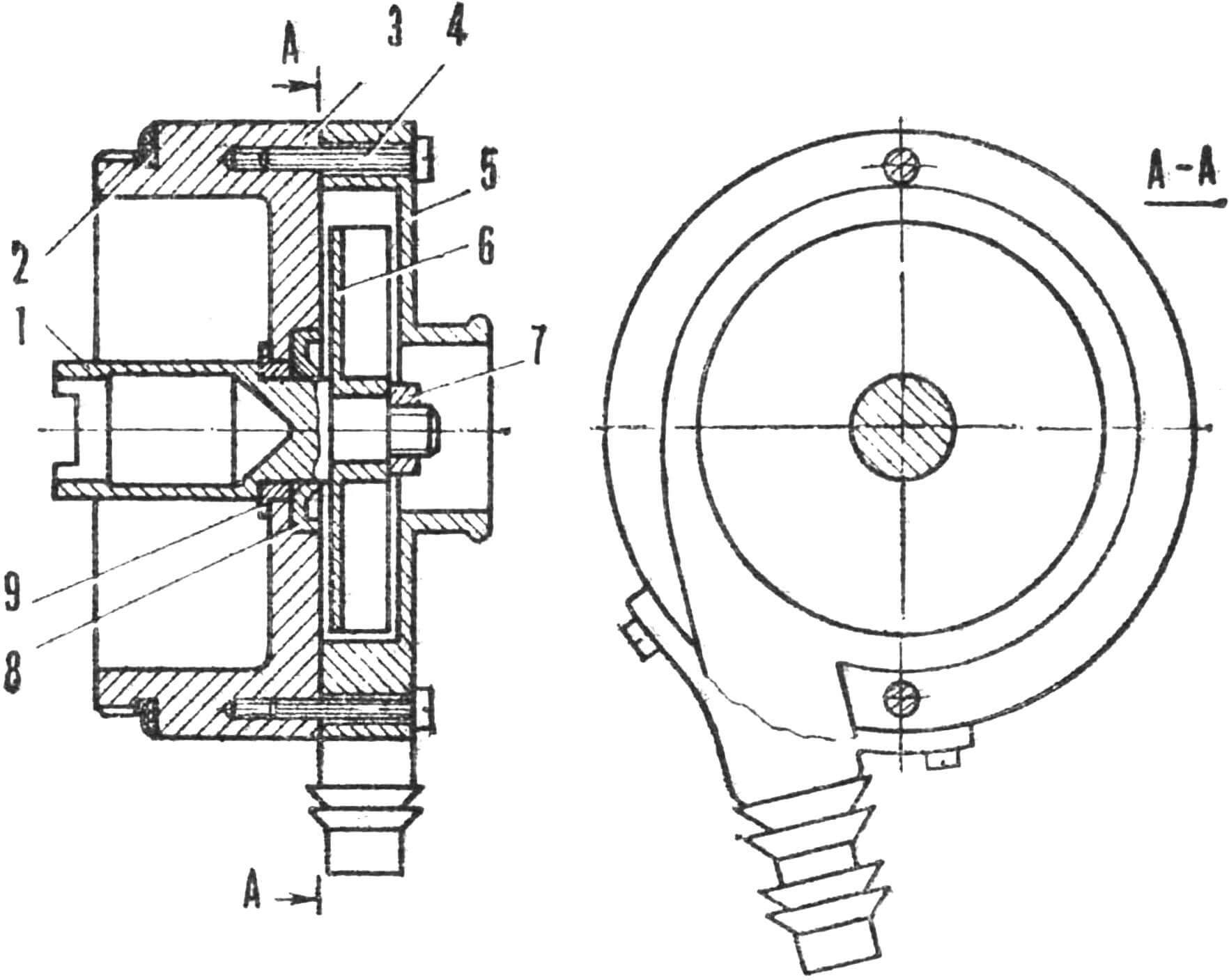

1 — control and switching unit, 2 — adapter, 3 — stern tube, 4 — connector, 5 — electric motor housing, 6 — cone gearbox, 7 — screw from the Salyut outboard motor, 8 — fastening clamp, 9 — insulating stand, 10 — three-position switch contacts.

In the Sverdlovsk region, most of the reservoirs are closed to boats with gasoline outboard motors. This is what made me switch to electric. The fact is that I am interested in fishing and spearfishing, and this hobby sometimes makes me swim quite far.

Once I came across a damaged electric fan from a truck heater – its cover was broken on one side. Instead, we had to make a new one with a larger diameter thread, which made it possible to screw all kinds of attachments onto the motor, as well as reliably seal the housing. The data from the fan electric motor turned out to be quite suitable for the implementation of my idea – to create an outboard electric boat motor. In principle, of course, any other electric motor with a rated operating voltage of 12 V and a useful power of 100-200 W can be used for this purpose. It is important that its efficiency is at least 50% – engines with lower efficiency are impractical to use due to large energy losses.

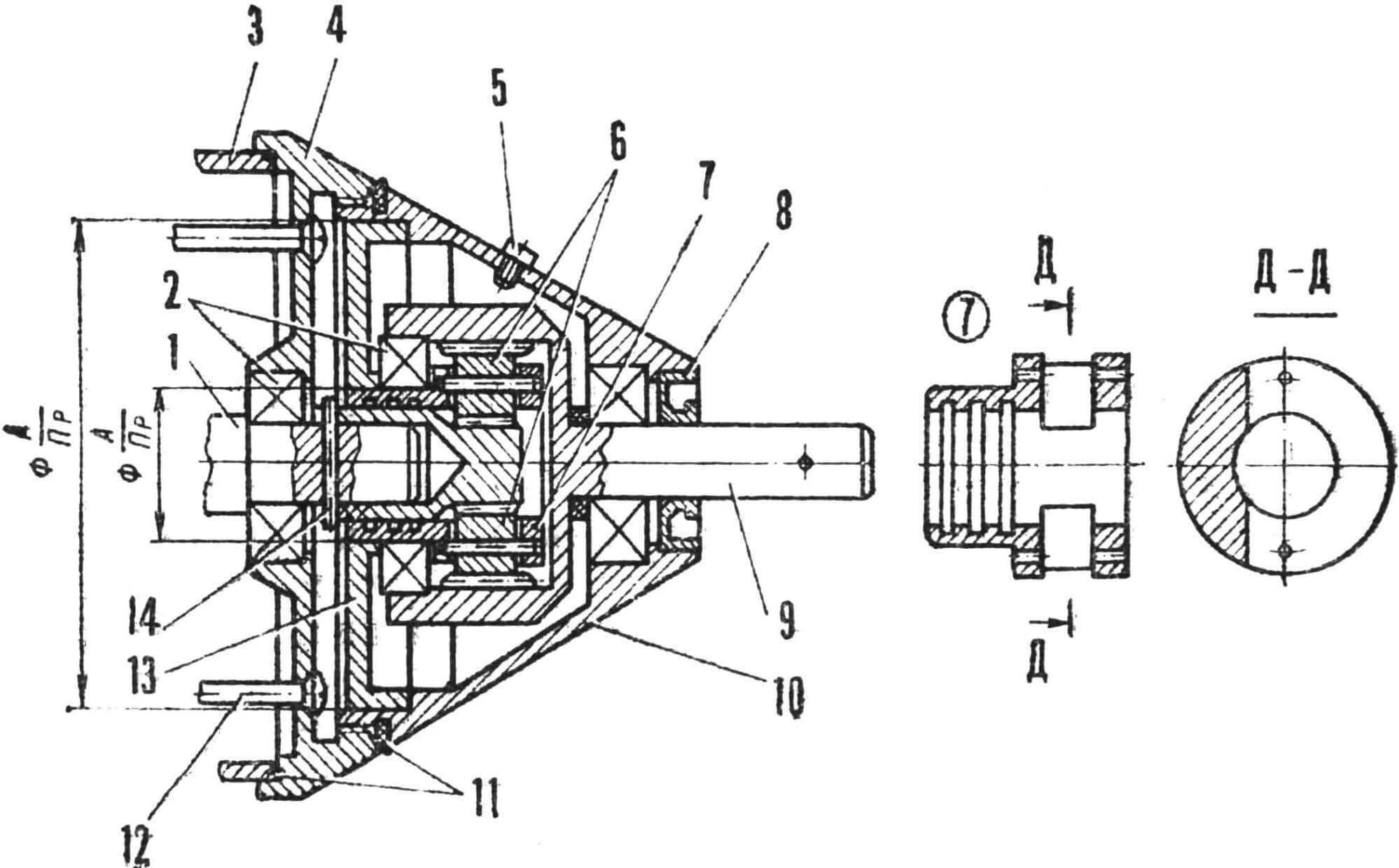

1 – electric motor shaft, 2 – ball bearings, 3 – electric motor housing, 4 – electric motor cover, 5 – screw – plug for filling the lubricant hole, 6 – gearbox gears, 7 – gear box with labyrinth seal, 8 – oil seal, 9 – propeller shaft, 10 – gearbox housing, 11 – rubber O-rings, 12 – tightening screw, 13 — gearbox cover, 14 — cylindrical pin.

After some modifications (O-rings, careful putty, painting), the motor housing becomes airtight. The wires are routed through the stern tube to a three-position switch – the engine is two-speed! – and to the ammeter. At the first speed it consumes a current of about 10 A, and at the second – about 25 A and develops a thrust of 2.5 and 5 kg, respectively. This thrust is quite enough to move a boat weighing up to 300 kg at a speed of 3-7 km/h. With a battery capacity of 88 Ah, the electric outboard motor operated at first speed continuously for 10 hours.

The propeller from the Salyut outboard motor was quite suitable for my electric one, however, I had to install a planetary gearbox with a gear ratio of 1:3 from a pneumatic drill. After a little modification, it fit quite satisfactorily into the conical nozzle on the electric motor.

1 – pump shaft, 2 – o-ring, 3 – pump housing, 4 – mounting screws, 5 – pump volute, 6 – impeller, 7 – nut, 8 – oil seal, 9 – copper-graphite bushing.

The outboard electric motor is completely silent, since everything that makes noise is hidden under the water, which also cools the engine well.

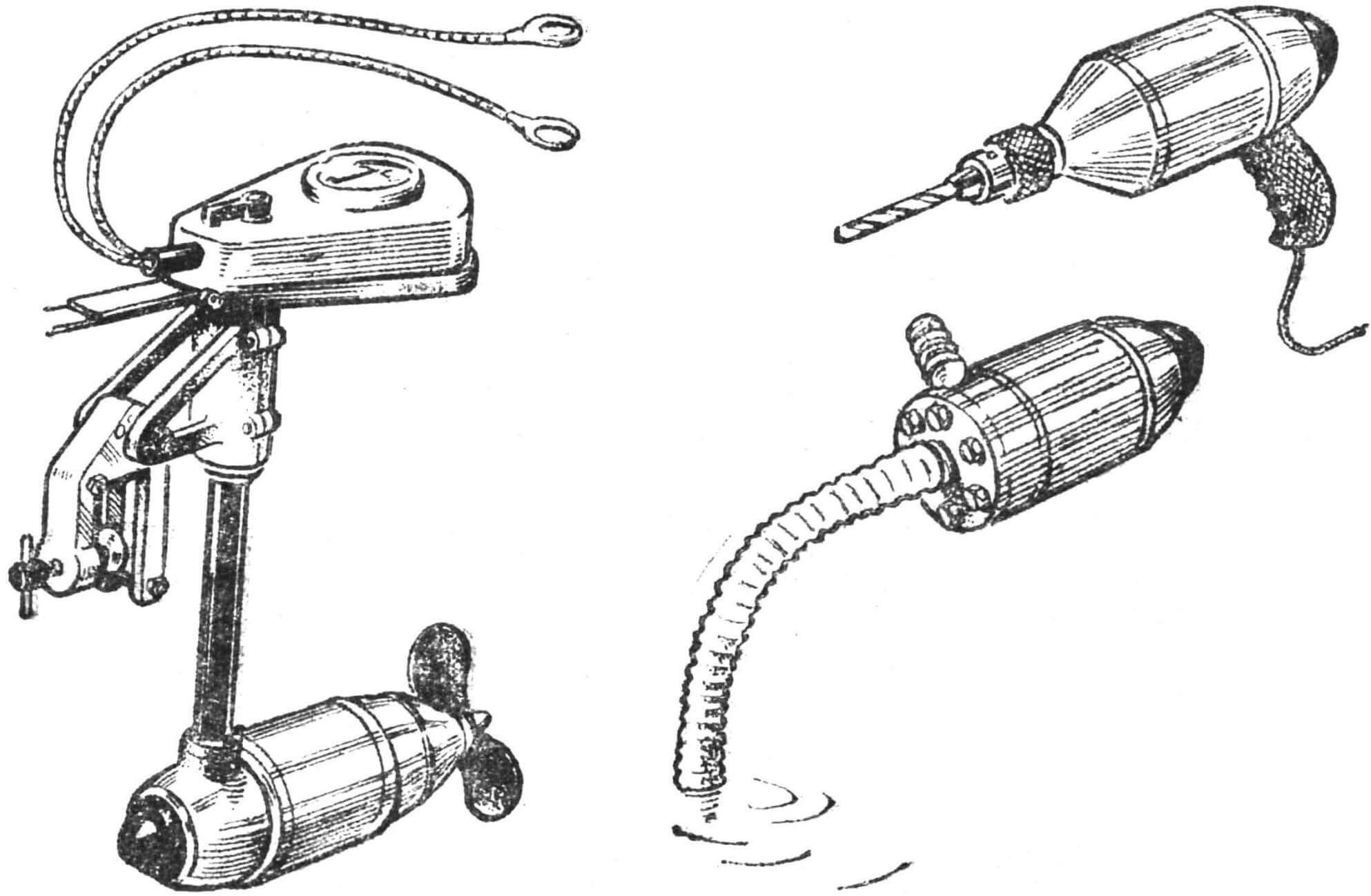

In addition to its direct purpose – to serve as a boat motor – the electric motor can also be used for household needs, for example, replacing the nozzle with a propeller with a centrifugal pump, easily watering the garden or washing the car. If you put an attachment with a cartridge on the engine, the motor will turn into an electric drill.

Now I’m developing an attachment with which the engine becomes a self-pulling winch, you just need to choose a suitable globoid worm gearbox with a gear ratio of 1:50 or 1:100, everything else will not be difficult.

E. FRANTSUZOV, Sverdlovsk