For all the apparent simplicity of the hull shape and small number of add-ons to create models of submarines a very difficult job. And yet, the modelers love to Tinker with them: well done model starts steadily and rarely fails its designer. In addition, the degree of difficulty — depending on which class preferred — also very different: there are the subs, do that and beginners, and for the manufacture of which requires a specific skill and experience. These include and publish here the model of the submarine. Such models repeatedly won prizes at all-Union competitions.

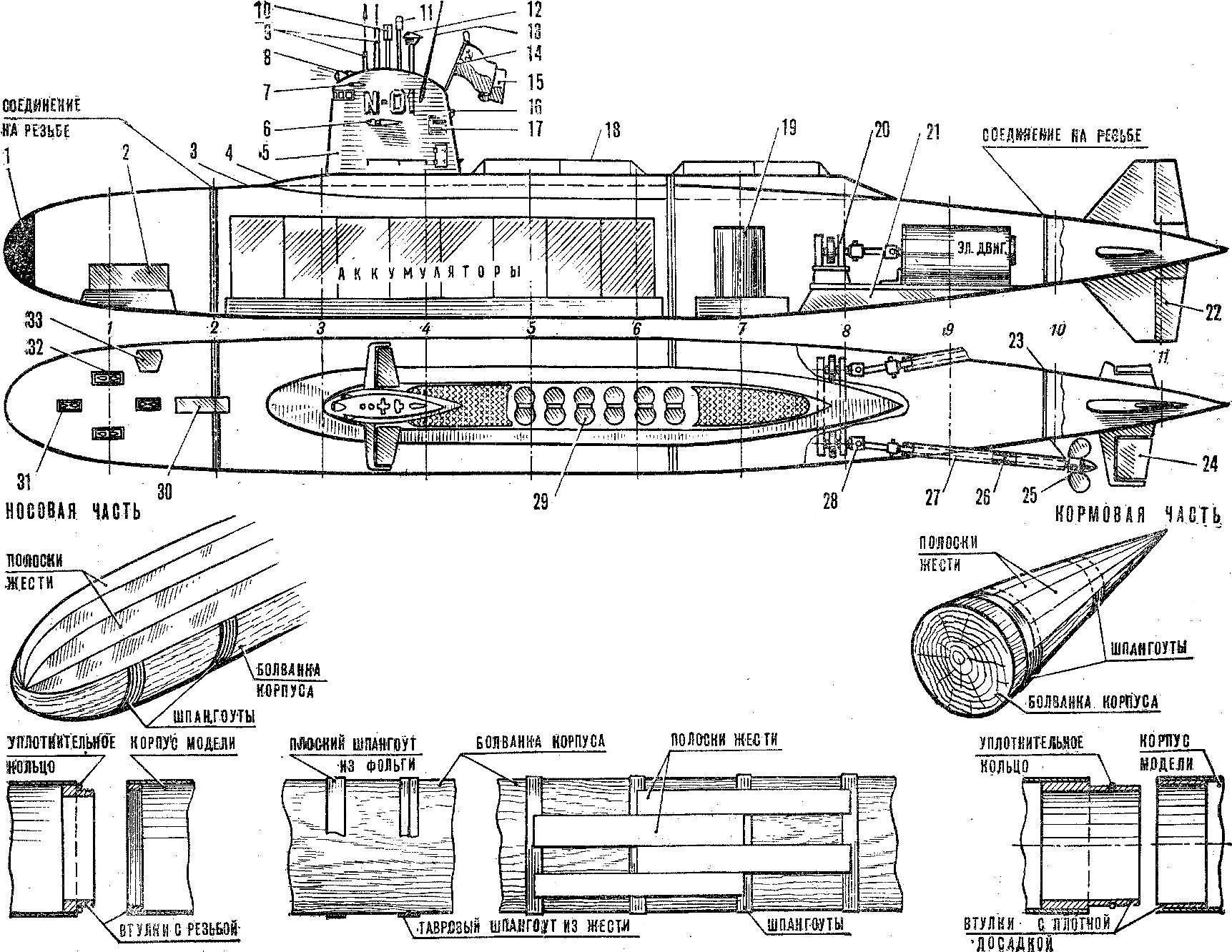

Manufacturer model starting with the case. First make a blank of wood (Linden, alder, or poplar), but can also be used pine. The wood must be seasoned and free from knots, and preferably straight grained. If there is solid timber, glue together well planed planks. Prepared timber treated with a hand plane and sandpaper. Even better it to turn on a lathe.

The case is made of tin. First on the disc are placed frames. They can be flat or t-foil made of tin. In the latter case, on the disc, make circular cuts to the frames tightly joined them and was flush with the external plane of the disc. When the frames are installed before start to solder plating. Strips of sheet metal placed along the body, carefully adjusting them so that between them there were no big gaps.

Before removing the body blanks making cuts slizovskiy in the joints. Then slizovskiy also saw the hull at the waterline, shoot him with blanks and washed with warm water with soda and soap to remove residues of acid. You can now begin installing the machinery, rudder, deadwood, etc. the Cabin of the boat perform on the same technology of tin on the disc.

When all the mechanisms are mounted, it is necessary to solder together the upper and lower sections of the boat. In the rear of the hull at the gland soldered blank bulkhead in the bow and the middle of expansion joints soldered ring with thread for Assembly of the compartments of the boat. They are machined from brass on a lathe and they cut thread with a pitch of 1.0—1.5 mm Thickness rings installed in the middle compartment, 2.5—3.0 mm, width 5-6 mm, inside it is threaded. The ring is tightly inserted in an outer diameter of the housing flush with the edge and probailout. The other ring is threaded on the outside at half the length. Smooth part it is inserted into the housing and also probailout, and the protruding portion when assembling the boat wrapped in a ring with an internal thread.

Rings fore and aft compartments have a length of 8-10 mm and the same thickness. The same as the previous one, after installation into the housing carefully probailout. For better sealing of the boat on the thread you can put the rubber seal rubber of 1.5— 2.0 mm. Below the ring is not oxidized and lighter were welling up, lubricate them before Assembly grease or with grease.

Design of connections can be simplified. This ring is made without thread, but more broad. The average compartment 20-25 mm, and in the nose of 50-60 mm at a thickness of 2-3 mm. In the middle of the ring bet flush, and fore or aft — half the length. For a better seal on the exposed part of pre-face piercing holes, the groove and lay the rubber ring so that it is slightly (0.3—0.5 mm) protrude above the surface.

More modern and convenient way of making the body — Vilejka made of fiberglass. On a carefully machined disc is applied a separation layer, which may be polyvinyl alcohol, paraffin, liquefied kerosene, or mastic for natirki floors. Polyvinyl alcohol is applied by brush, and wax or mastic — cloth.

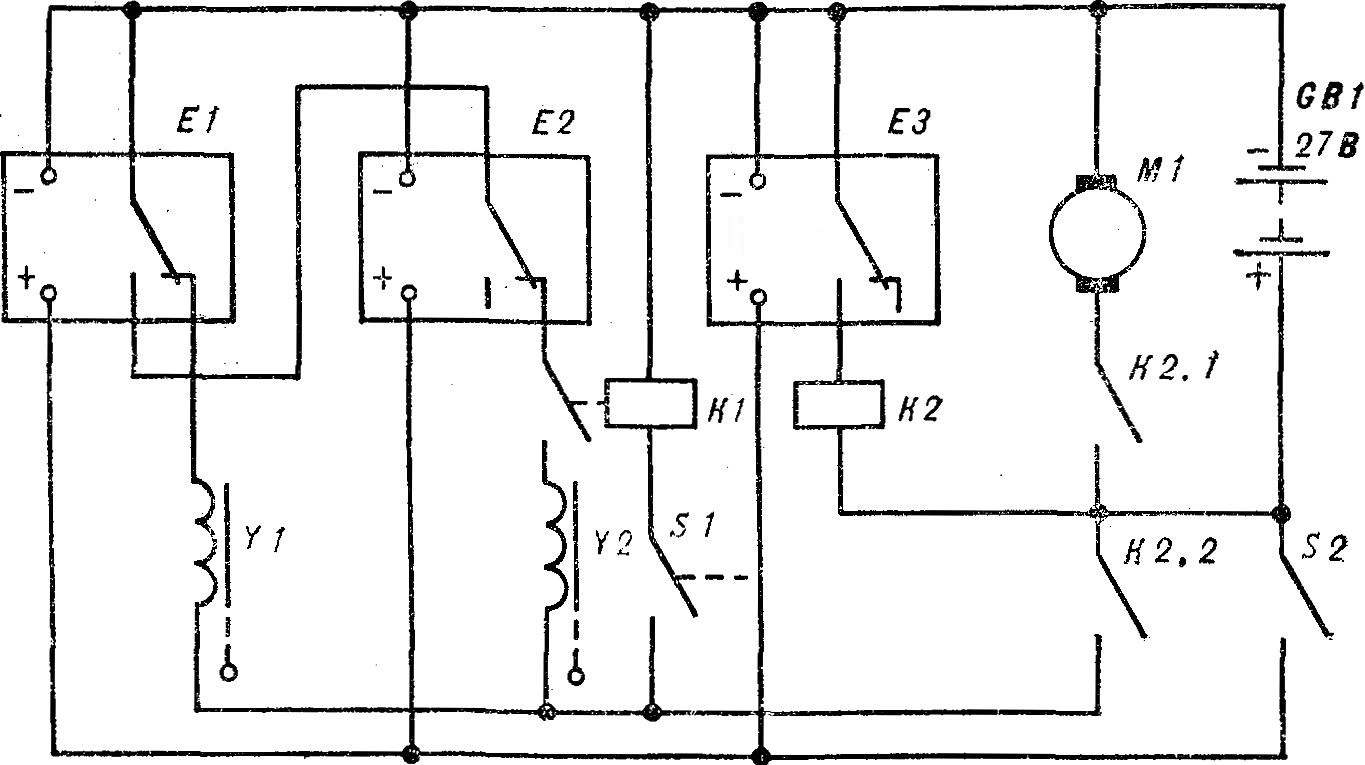

Fig. 1. Functional diagram:

E1 relay ascent time, E2 — time switch to the immersion, E3 — time relay chassis engine M — electric motor K1 relay solenoid control dive, K2 — power motor relay, K2.1, K2.2 — relay contacts K2, Y1 — solenoid dip, Y2 — solenoid ascent S11 — contact gyro or hydrostatic release S2 — switch.

Vyklevyvajut fiberglass body based on epoxy or polyester resins. Of epoxy are best ED-5, ED-25, K-153 or ED-6. Resin ED-6 before work is necessary to thin out. It is slightly heated and diluted with toluene (8-10%) or acetone (6-8%), however, from acetone, the resin becomes less plastic. To restore its plasticity add 6-8% of dibutyl phthalate, and polymerization of 10-12% of polyethylene polyamine (hardener). Work is carried out in the following order. Pre-cut three or four pieces of fiberglass (depending on thickness). Prepared resin is applied with a bristle brush on the disc. Putting a layer of fiberglass on the disc, and carefully smooth it so the resin ran through the pores of the fabric. Then, put a brush another layer of resin, lay the cloth, smooth, etc. the shell Thickness should be 1.2—2 mm. Polymerization for 14-18 h.

When the resin completely hardens, the housing is treated from the outside by applying Cracovie large files and sandpaper. Then, the surface putty epoxy putty. If at hand is not ready, it can be made independently. For this purpose, the resin diluted in the same proportions as vyklicky case, add titanium dioxide, talc or tooth powder. Putty is applied with spatula. After its polymerization the body process an emery paper. Remember that resin is toxic, so it is recommended to work in a well ventilated room, wearing rubber gloves. After work thoroughly wash hands warm water with soap.

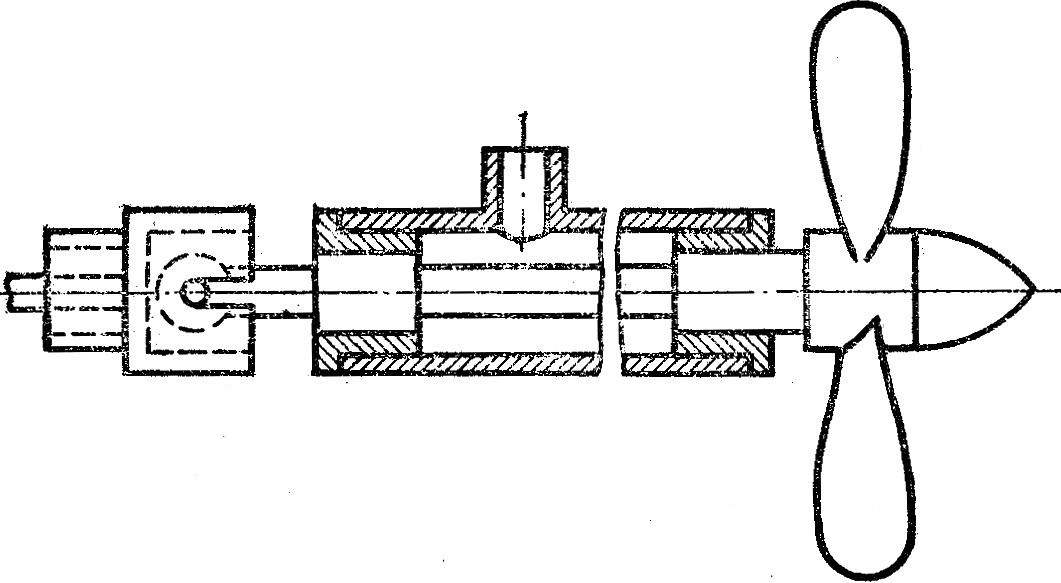

Fig. 2. Diagram of model (length — 1170 mm width — 130 mm):

1 — ballast (lead 1 kg), 2 — time switch, 3 — body, 4 — superstructure 5 — deck, 6 — chopping the handlebars, 7 lights, 8 — spotlight 9 — periscopes, 10 — finder, 11 locator, 12 — snorkel, 13 — antenna, 14 — pole 15 — flag 16 — hamborsky fire 17 — fan 18 — railing, 19 — gyro (or humidistat), 20 — reducer, 21 — Foundation 22 — aft rudders (vertical) 23 — watertight bulkhead, 24 — aft rudders (horizontal), 25 — screw 26 — shaft 27 — stern tube, 28 — gimbal articulation, 29 missile hatches, 30 — torpedo hatch, 31 — bale straps, a 32 — bollards, 33 — anchor beak.

You can now remove the laminated body blanks. No need to cut the hull at the waterline. It is necessary to cut it at the joints. Then, lightly protocal wooden hammer (mallet] on the sides, remove the case.

In the body sections assembled the necessary arrangements. When installed, the joints glued on the epoxy ring threaded or ring with a tight fit. Cutting vyklevyvajut and treated the same way as the hull.

After all, you can start painting the model. First, brush it with liquid putty nitroshpaklevok. Then treat the surface with fine emery paper and coated with the spray nitro or a black ball (gray) color. Painted model is brought to a mirror Shine. Used for polishing automotive polishing paste No. 290.

Periscopes and other devices on the cabin is made from brass tube and wire. Stacks and bollards can not produce, and to designate their plate of celluloid or incised on the body in places of their installation, as the nuclear boats they are cleaned inside.

Rudders and stabilizer it is possible to solder or applied to the wall of the fiberglass.

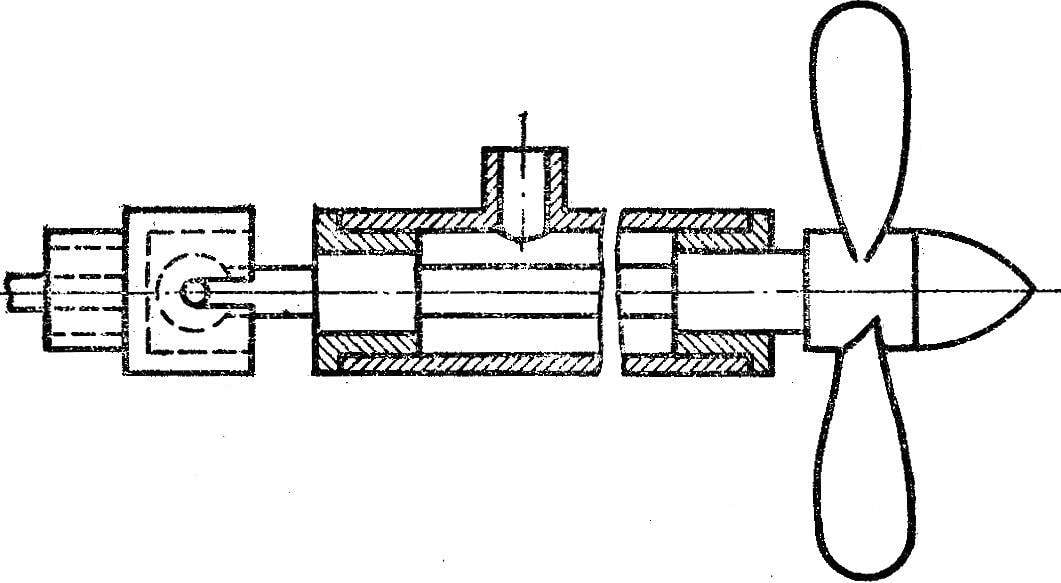

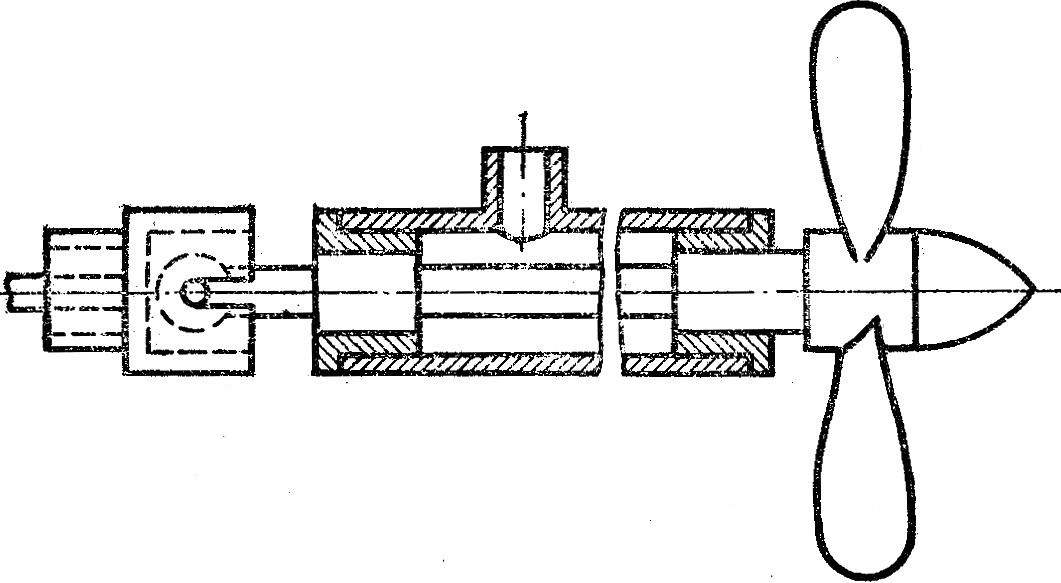

Fig. 3. Stern tube with shaft and propeller.

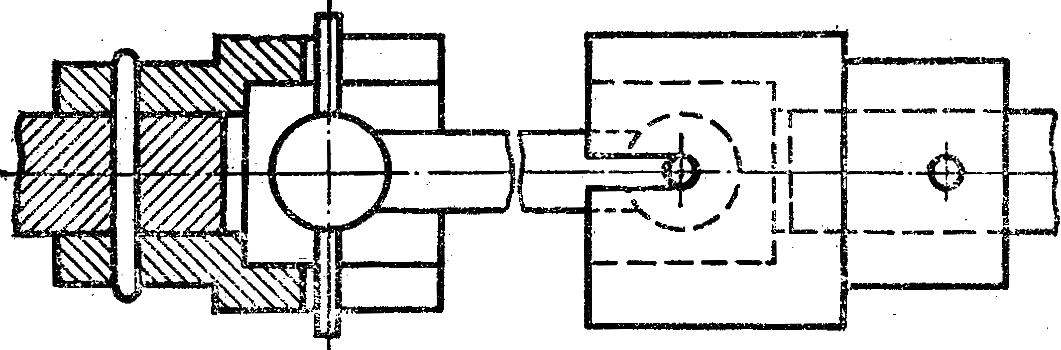

Fig. 4. The gimbal joint.

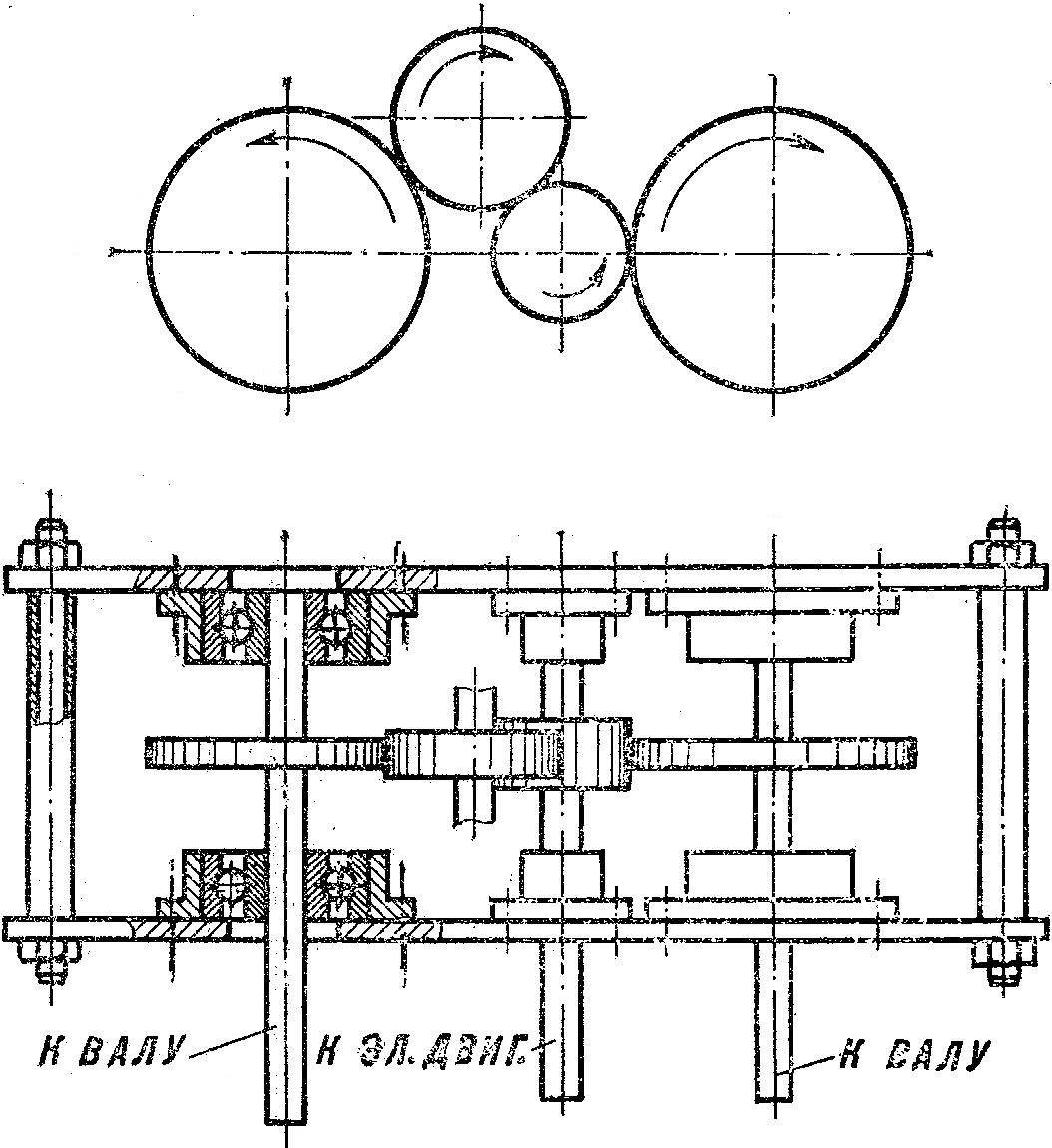

Fig. 5. Gear; positioning the gear.

In the model used by the motor MU-100. To reduce speed use gear with a ratio of 1:2. The motor shaft is connected by a hinge to the leading gear and driven gear shafts of the screws. All shafts on ball bearings.

Deadwood is made from a tube. At the ends it is put in the brass sleeves and fill them with grease. For shaft use steel wire Ø 3-4 mm. On the inner end put a Cup hinge, and an external threaded for screw mounting. For it downloaded hub machined from brass. It drilled a hole and cut threads on the shaft. Then on the hub make cuts under the blade. They should be tightly and thoroughly sealed. Now turn the nut (cone) with the same thread, wrapped around a screw on the shaft and counter it.

Both the vertical rudder is soldered to one of baller that is installed on a dense planting in heliportable pipe. This is needed for sealing, and a clear identification of the rudders. It is important to ensure careful manufacture heliportugal pipes and seals from the PCB to the horizontal rudders, or in the aft portion may enter the water. So it is not leaked to the rest of the hull in the aft compartment is a blank bulkhead.

The contest rules state the model should go with a scale speed. A few meters it is on the surface and then sinks. After passing the course, the boat POPs up and crosses the finish line on the surface. To run this program on it install a humidistat or a gyroscope, which with a relay time shift of the horizontal rudders to dive or ascent. The actuator on the rudder is the solenoid.

When debugging mechanisms it should be remembered that the boat for better stability should be loaded so that on the surface there was one cabin (position position).

V. TSELOVALNIKOV, the master of sports of international class