DESIGN PRINCIPLES. As you know, every self-propelled model, be it a model airplane, ship or car, has a car, and, therefore, exist for them, the laws of calculation and design can be transferred on the model, taking into account the scale only. This is the first. Secondly, any self-propelled model (like any machine) includes three elements that can be considered mandatory. What kind of elements?

DESIGN PRINCIPLES. As you know, every self-propelled model, be it a model airplane, ship or car, has a car, and, therefore, exist for them, the laws of calculation and design can be transferred on the model, taking into account the scale only. This is the first. Secondly, any self-propelled model (like any machine) includes three elements that can be considered mandatory. What kind of elements?

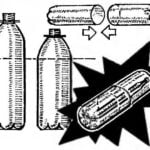

1. The very word “self” implies the model of the engine (motor). Engine type chooses a constructor based on the requirements and constraints imposed on the design. We confine ourselves to a brief enumeration of the known types of engines for models. This rubber, spring, inertial, electrical, compression (internal combustion engine), the steam engine.

2. But the engine, no matter how perfect he was, not move the model until we connect the motor shaft with the environment or the surface upon which the model moves. This link for the locomotive and car is the wheel for tractor — caterpillar, for aircraft and ship — screw. All that binds the model with the environment in which it moves, is called the mover.

3. The availability of engine and propeller, it would have been enough to get it going. In some cases the way it is: remember the plane or the model boat with a propeller. Propulsion in these cases, mounted directly on the motor shaft.

Unfortunately, in most cases, the transmission of motion from the engine to the propulsion installation required on the machines of a number of extension mechanisms. For example, the car and the tractor still can not do without a bulky and complex gear boxes, reduction gears, rear axle. Many ships and planes helical reducers as necessary as and engines.

All of these mechanisms, connecting the engine with the propeller, we call passes.

So now we know that almost every machine is accompanied by the Trinity: engine — gear — propeller. System engine transmission often called the power plant.

This begs the question: “And why, actually, sometimes you can, and in most cases it is impossible to do without the gear?” The answer to this question will be sought in the pages of a physics textbook.

For the propulsion of the car (under the car, we mean any model) on the track section AB, the engine must do work equal to Acgm. But the work, as we know, is the product of force into distance traveled, and the speed at the end of the path must be zero. So the engine with a constant thrust force will depend on the size of the traversed path. But the engine is inconvenient to measure the number of kilometers or meters, as this engine can be installed on any machine, not necessarily moving, and need to know what kind of work can make the engine always exists. And then introduced a new concept — power. Mathematically the capacity can be represented as:

N=A/t, (I)

where a — [KGM] t — time [sec], that is, power is the ratio of work to time of its Commission. Imagine the work A = F·S, then the formula I takes the form:

N=F·S/t, (II)

But the way to the time, mm know the average speed, that is, power can be defined as the product of force on speed:

N=F·V (III), where V — velocity (m/sec).

In the case of rotational motion the picture is quite similar with the only difference that the role performs a twisting force (torque) the moment and the speed is determined by the private from dividing the angle of the shaft at the time.

Let us consider these concepts.

If the point A on the rim of the disk, freely rotating around its axis OO1, applying the force P is directed perpendicular to the radius AO, the disc will rotate. The force R is called the district force and the work force, R the radius of the AO-called shoulder strength R is called torque (torque) torque MD.

Put the inverse problem.

To the axis OO1 applied torque MD. You want to define a circumferential force. Obviously, this question is ridiculous — at a predetermined torque to raise the question of finding a district effort, without specifying which shoulder (that is, at what radius) we are interested in is the circumferential force, it is impossible. If you say that this engine develops a circumferential force 20 kg, then at the same time stipulate the amount of shoulder, which is achieved by this effort. However, the technical characteristics of engines it is usual to indicate not develop circumferential force, and the value of the maximum torque and the rotation speed of the output shaft of the engine, the one that produces the moment.

Torque is the main parameter of any engine.

The amount of work for the case of rotational motion is determined by the product of the torque to the rotation angle of the shaft expressed in radians: A = MCH. Note: the dimension of the left part of the equality — of KGM, the dimension of the torque — KGM also, that is the second factor on the right side is a dimensionless quantity. Indeed, the radian is not that other, as:

[Rad] = [arc length] / [radius] = [mm] / [mm] = 1 (IV)

Power in rotational motion them, as in the case of translational motion, defined as the ratio of work to time:

N = A / t = Mkrf / t (V)

or, if you replace attitude

φ / t = w,

will get:

N = Μr·w

Engine power is constant, so M = N / w , that is, motor torque is inversely proportional to the angular velocity of the output shaft. This means that the use of engine power at various angular speeds allows you to change the generated torque. Using the power of even low-power motors at very low speeds of rotation of the propeller (e.g., wheels), you can get huge torque. Theoretically, in order to set in motion a train, enough microelectrodes, while the speed of the composition will, of course, negligible.

In practical calculations, the dependence between power, speed, output shaft speed and torque are defined by the following formulas:

motor –

MD = 0,974 N/N

where MKR — torque [kgsm], N — power [W] n — shaft speed [rpm];

for other engines:

IQR=71 620 000 N/N

where N — power [HP], M — torque [Fuel], n is the shaft speed [Rev/min].

The question may arise: “why don’t we build these engines to with given capacity it would be possible to do without gear?”

Unfortunately, we have not learned to build a powerful low-speed engines. High power is given to us at the price of high speed rotation of the output shaft and thus a small torque.

Indeed, let’s see how to relate the speed of rotation of output shafts of the motors to the rotational speeds of the working bodies of machines.

The speed of rotation of the shafts of the motors

1. Gas turbine aircraft “IL-18” — 11 thousand rpm

2. The crankshaft of the car “Volga M-21”. Maximum torque at 2500 rpm

2. Steam turbine ship — 3 thousand to 5 thousand rpm

4. Traction motors of diesel and electric locomotives — 3 thousand rpm

5. Crankshafts motorcycle engine 4 thousand rpm

The type of propulsion and the speed of its rotation

The propeller — 1100 rpm

Wheel — 680 rpm at a speed of 100 km/h

Screw — 300-500 rpm

Wheel — 600 rpm to a speed of 120 km/h

Wheel 700 rpm at a speed of 120 km/h

Of all known engines is a steam engine Yes, some very PRC”pnye marine diesel engines capable of developing substantial power at relatively low speeds of rotation of the crankshaft, which allows to install them on vehicles without reducing the speed of transmission.

So, to summarize and draw conclusions:

1. The engine model must be selected so that the speed of rotation of the output shaft was probably closer to the speed of rotation of the propeller

2. The power required to move a body depends on its velocity.

3. With the help of the programs are in fact any limits to change speed and torques of the shafts, the capacity of the power plant cannot raise by any means.

R. PETROSYAN