By the early 1930s, one of the centers of the nascent Soviet motorcycle could be the city of Kharkov. Here in the capital of Soviet Ukraine, on the territory of the former sugar factory was organized car Assembly plant – HAZ, was introduced in the “Automotiveaddicts” Association “Ukrnet”.

By the early 1930s, one of the centers of the nascent Soviet motorcycle could be the city of Kharkov. Here in the capital of Soviet Ukraine, on the territory of the former sugar factory was organized car Assembly plant – HAZ, was introduced in the “Automotiveaddicts” Association “Ukrnet”.

Deputy Chairman of the “Ukrmet” and the Chairman “Automotiveaddicts” G. P. Vodopyanov was a head of Kharkiv Garantidor – the local branch of the all-Union Society for the promotion of motoring and road improvement USSR Avtodor. In addition, all the factory workers and the President of the Council of national economy of Ukraine was the enthusiasts of motorcycle.

By this time in Izhevsk, Moscow, Tula and Leningrad have already built the first prototype motorcycles. Artisanal motorcycles created in Kharkov, but the presence of production facilities and the support of the industry and the city government gave hope for the organization of mass production of motor vehicles.

The necessary funds for the organization of an experienced motorcycle was sought by the company “Avtodor”. To review the setting of motorcycle Assembly plant “Ukrmet” in March 1931 in Kharkov were directed the team of the Central Council of the society “Avtodor”. On 26 March the brigade arrived in Kharkiv and contacted the city Department of “Avtodor”, which presented the preliminary materials for review with the motorcycling of Ukraine. On 27 and 28 March, the team toured the plant, which was built experienced a series of six motorcycles original design.

Presented to the brigade of motorcycles had “stamped frame type BMW, various configurations in each of Strumica samples” (here and below in italics the rows from documents). The results of tests intended to select the most successful frame design for serial production. Later frames were planned to with the black sea plant, is included in the Association “Ukrnet”.

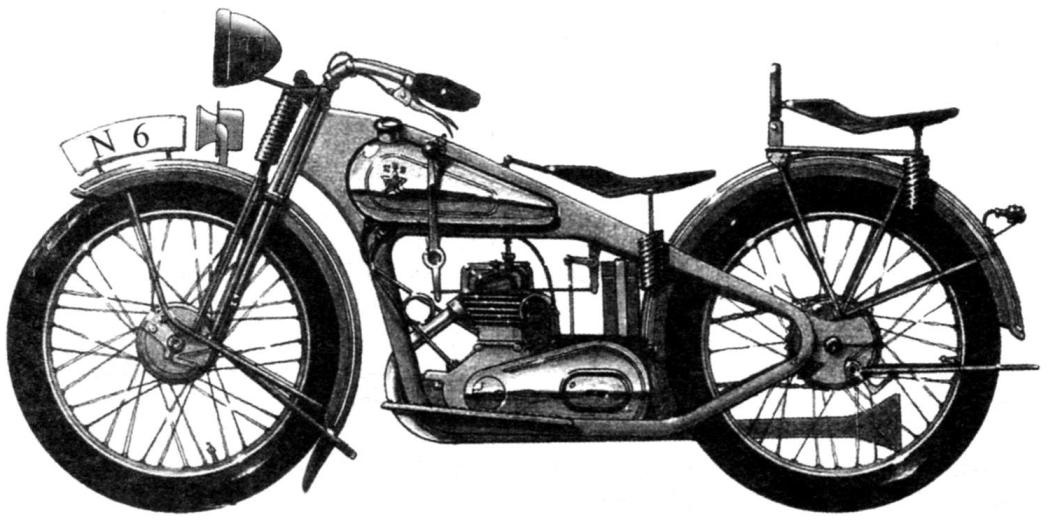

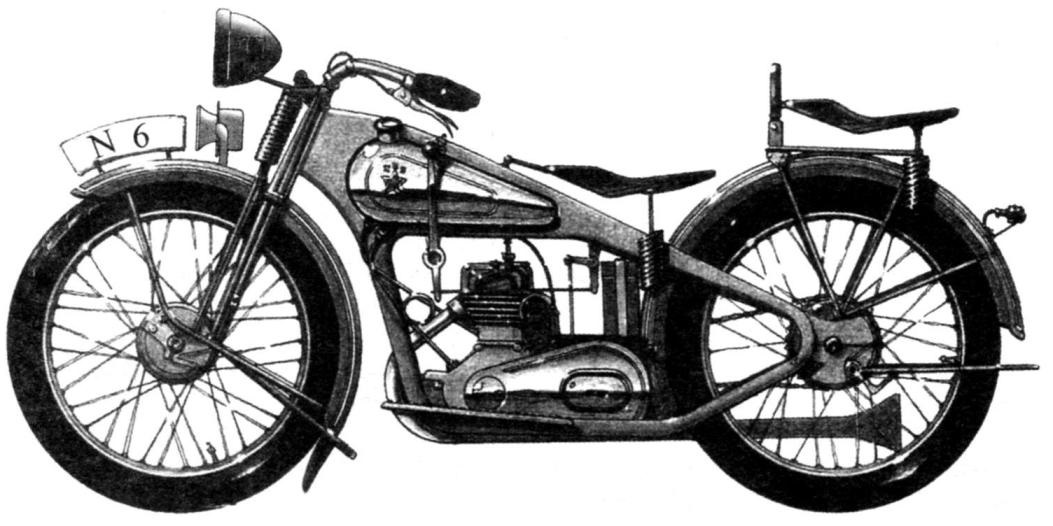

The first sample of 1M 350 motorcycle

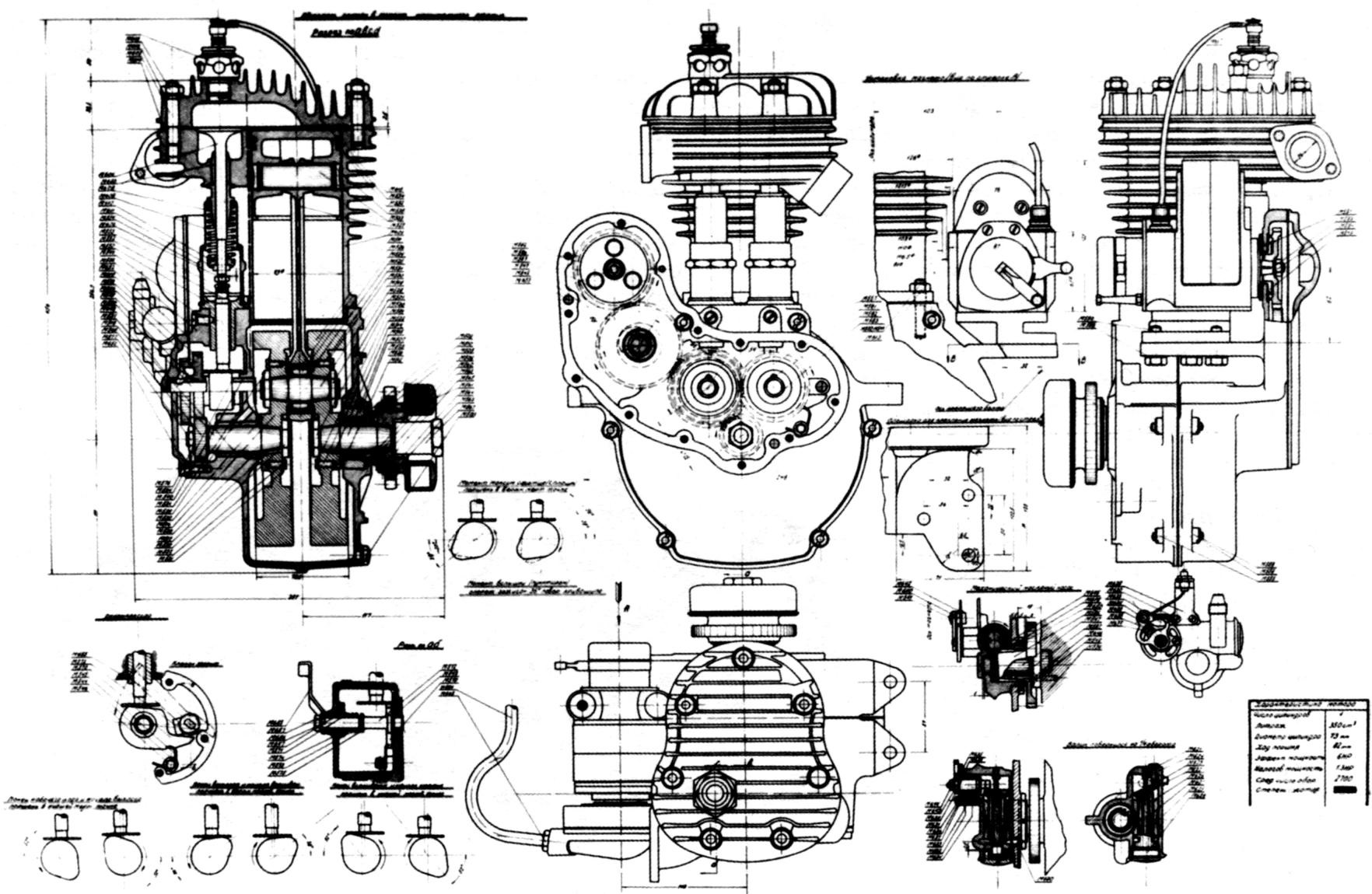

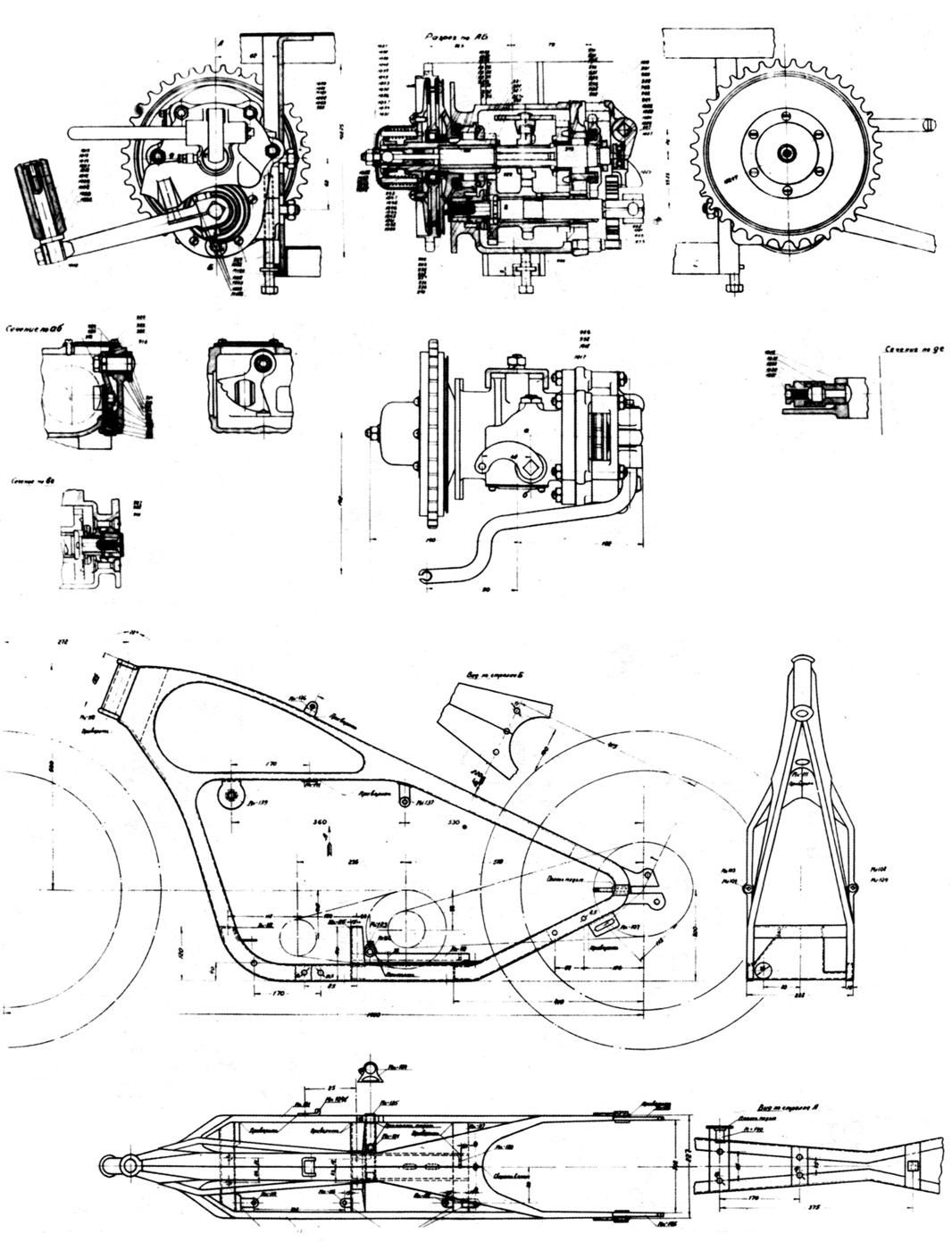

A factory drawing of a motorcycle 1M 350

A motor unit with a work cylinder capacity 350 cm3 was copied from the motorcycle “Harley Davidson 350” with some of the constructive changes. Getting a new engine plant expected “to move painlessly to the construction of a motorcycle of the same brand in 500 CC”. The clutch used a single dry plate. Transmission had three speeds.

Originally it was planned to build a motor cooperative order, receiving iron and part aluminum casting from the side. Practice has shown that plants co-operators were treated this matter lightly, breaking the supply and in the best case, giving a lot of errors – or rather, bad casting. Main parts: pistons, Carter motors, gearboxes and cylinders, the factory began to piss himself, by March they were already molded and processed. All the aluminum castings were evaluated as “satisfactory”. Some problems met with the casting cylinder, but by the time of arrival of the Moscow teams, the plant was already “on the path of eradicating this difficulty”. Gear allocation and gear box were processed at the plant, on a special gear machine with great performance.

Front fork had a depreciation type “Henderson”. “According to factory engineers, which was agreed to and the crew, Hendersonula amortization car promises greater softness and smoothness”.

The wheel consisted of one whole pipe out through two brackets (welded to it) on the main feathers of the front fork. Compared to American motorcycle, has been modified “on the contrary” management “gas” and traction control “gas” was placed in the left handlebar grip and clutch lever on the right side.

Carburetor type “, Sabler De Luxe” with an air filter manufactured at Konotop plant. When tested on a motorcycle Norton carburetor has shown “satisfactory performance”. Management of the carburetor carried by the cable, as mentioned above, from the right handlebar grips. Flow of fuel from the fuel tank to the carburetor was produced by gravity.

Production of magneto mastered was not. But in Ukraine there was a magneto Dixie “in a large number as illiquid assets”. Available their stocks part remade for the hardware of the first series of motorcycles. In the future it was planned to master in Konotop issue magneto type “BOSH”.

A factory drawing of the power unit of the motorcycle 1M 350

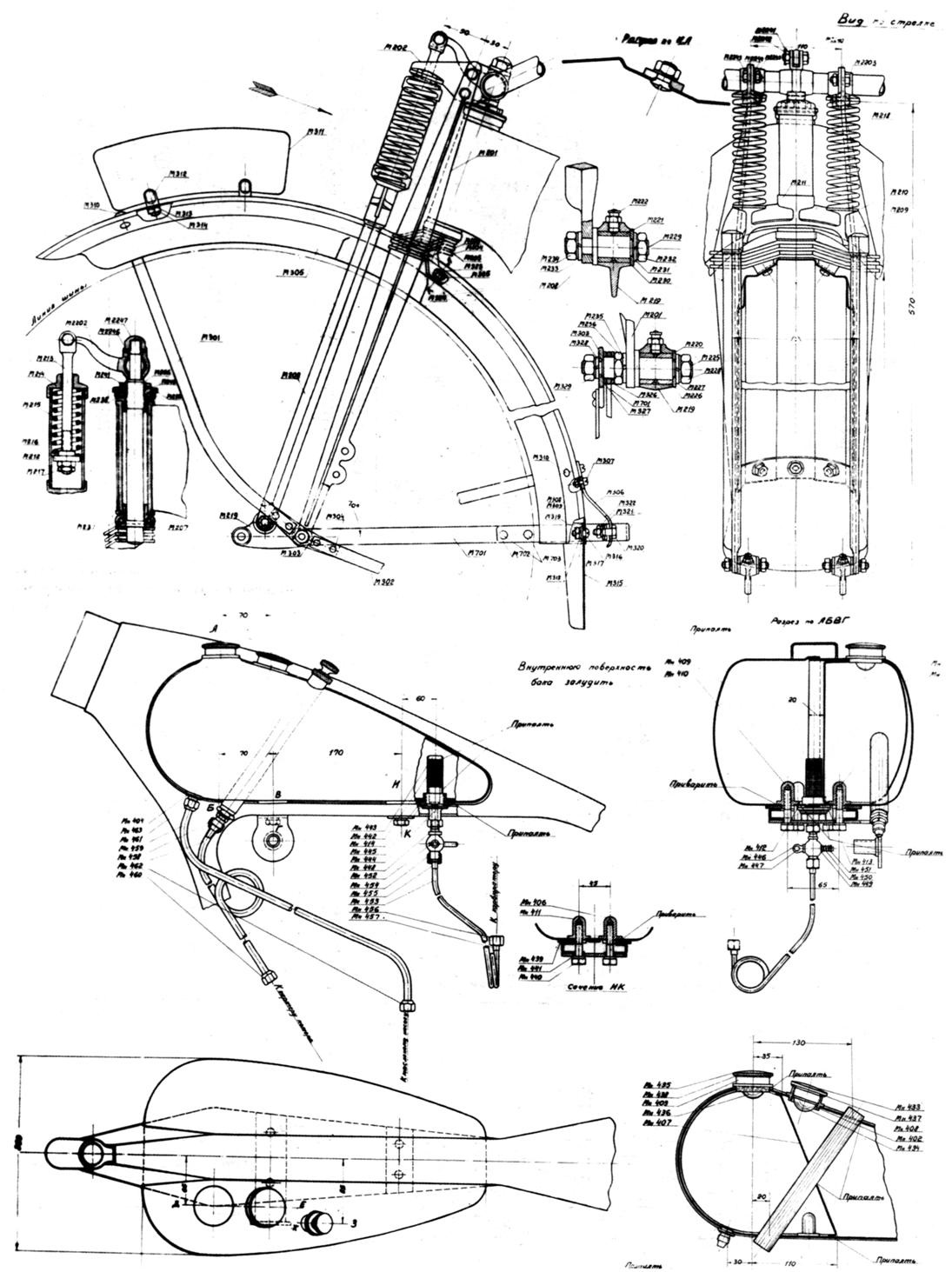

The factory drawings of the starting device of the engine and frame motorcycle 1M 350

The factory drawings of the front fork, gas tank and fuel lines motorcycle 1M 350

Lighting included the front lights, the rear control light and the flashlight on the Board. Power supply of lighting devices provided for the battery “as long as it turns out the possibility of intra-production complex magneto-Dynamo”. The audio signal was manual.

The rear wheel was rotated by chain size 5/8″. Wheels motorcycles with 40 spokes were made at the local velozavod. The forging bushings, connecting rods, valves and other parts the plant produced himself in the factory forge on unimproved low-power equipment, “through experience and perseverance of workers of the plant”. Tire size 680×90 were domestic, produced the “Rubber trust”.

Start the engine of the motorcycle was carried out a foot kick-starter. The rear brake was a belt-driven pedal mounted on the right bandwagon. Front drum brake operated by a lever placed on the left of the steering wheel. Saddle rider stamped from steel sheet of thickness 2 mm with two springs working in compression.

According to the results of inspection team of Central Council of “Avtodor” was evaluated the production capabilities of the plant:

“A) the equipment is available, but to expand the program to 1000 PCs motorcycles in 1931 insufficient.

B) Motobaro the plant has developed all design and working drawings with appropriate tolerances on all the parts of the machine. In addition, they also conducted chemical analyses of all materials required for the production.

C) Areas of the plant is provided in full, there is a special 2-storey building, allowing it to set in the ground floor up to 100 machines, and at the top to produce the final Assembly of motorcycles.

D) manpower the plant while secured and hopes to expand production such to obtain in sufficient quantity, as the chief recruiter of personnel for the motorcycle is avtodorovtsy the public.

D) financing the construction of experimental models, yet obstacles are not met.

E) the Plant puts the question of monetary allocation, t. all the places to get rid of their own based on the help of the local administration and the public.

G) the supervisor of the plant a well-placed and provides quality products.

3) There are two machines: one for testing the RAM to the load, the second for running the motor before putting on the car.”

Thus, the plant has successfully carried out test work and trials motorcycles, but to ensure mass production required the reconstruction of the company.

However, funds for reconstruction, neither the city nor the Republican leadership was not available, so Kharkov appealed to the Supreme economic Council.

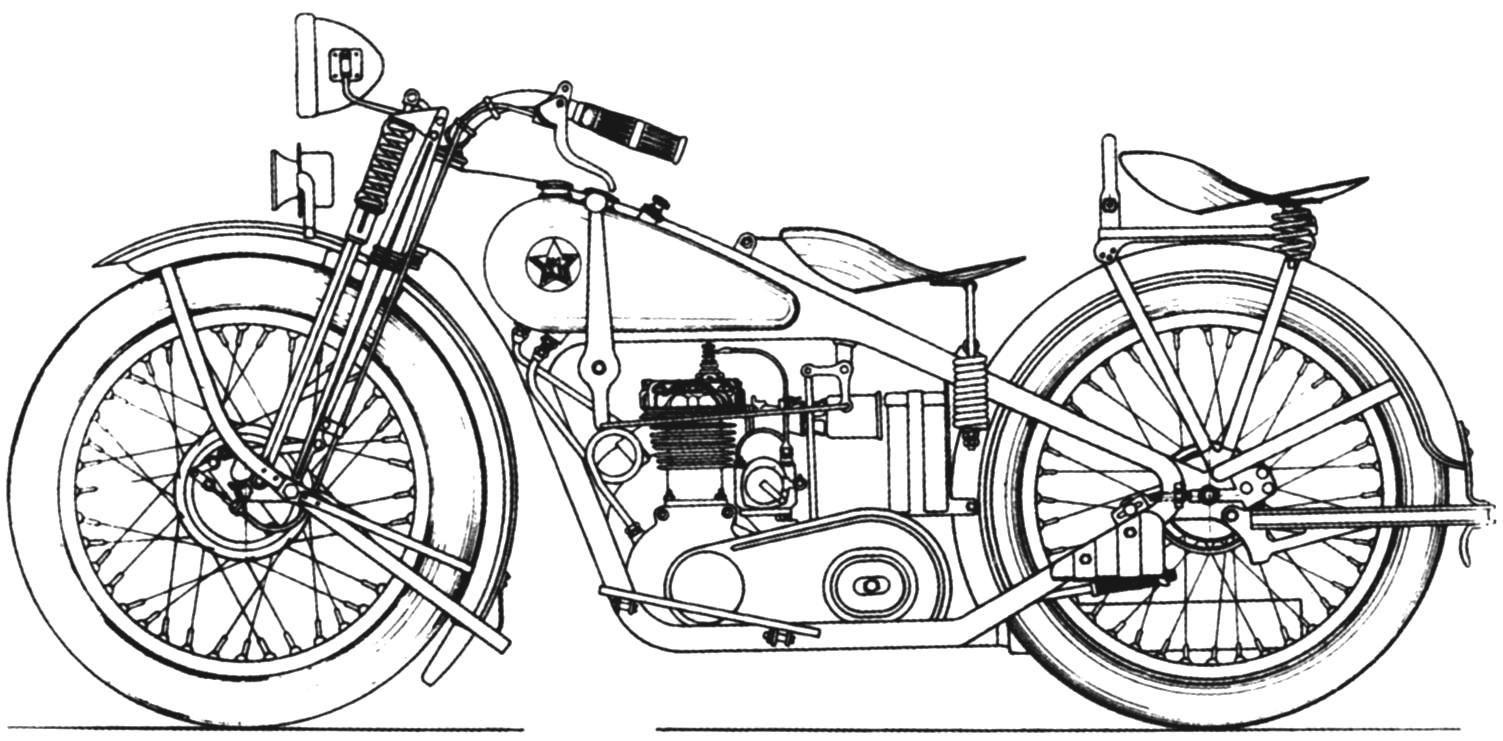

Figure motorcycle 1M 350

One of the six prototypes of the motorcycle 1M 350

In October 1931 Plasmaspray the Supreme economic Council of the USSR was a representative meeting, which is October 5, decided to consider the organization of manufacture of motorcycles in Kharkov for the needs of defense and the national economy. The plant was to be reconstructed for the implementation of the annual programme of 3,000 motorcycles.

The October, 1932, was ready reference motorcycle for the series. The frame of this bike consisted of 2 sides, pressed sheet steel, thickness 2.5 mm. the Upper strip of both sides have been brought together and welded. The motorcycle was equipped with electrical equipment of the Moscow Electrozavod. Motorcycle tank was combined with a fence dividing it into containers for gasoline and oil.

In the standard equipment of the motorcycle includes: a front and rear stand, fenders on both wheels, solid flap on a motor circuit, trunk. Additionally, leisure can play here, the motorcycle could be equipped with second saddle on the trunk and added footrests for the passenger.

November 1, 1932 motorcycle models 1M 350 has been tested by the factory inspection Committee a mileage of 50 km, and then shipped to the gift Narkomaania Clement Voroshilov. There is no doubt that the recipient has remained a happy motorcycle. The Commissar could not see the actual growth of the plant, past just a couple of years a way from handicraft workshops to modern industrial enterprise. However, motorcycles in Kharkov decided not to build.

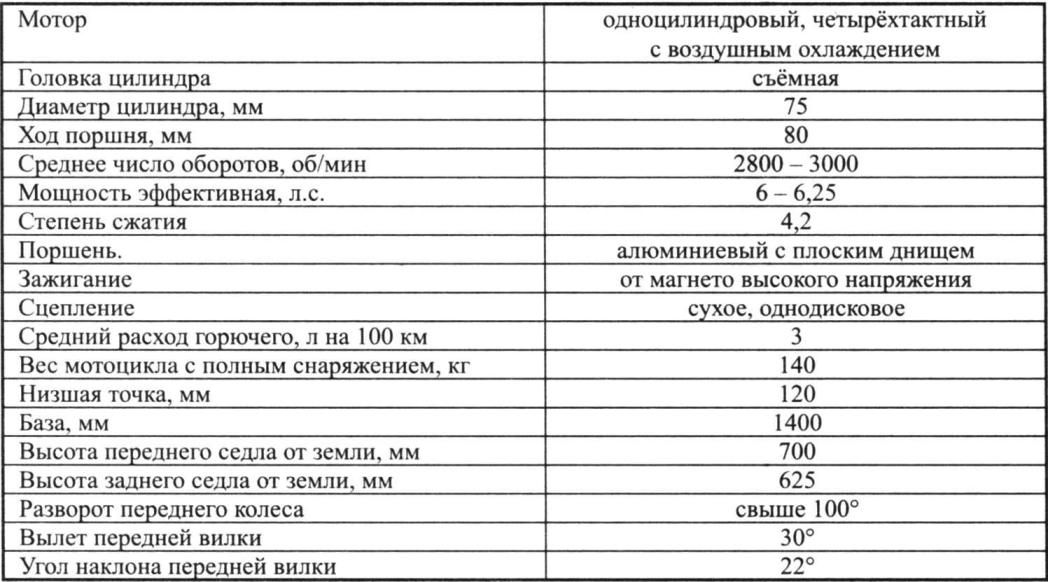

The main characteristics of motorcycle 1M 350 Kharkov Assembly plant of issue 1932

In 1932, the Kharkov Assembly plant received a mobilization task organization of armored repair facilities with the planned filing in the first year of the war (if it happens) 1454 machines. For obvious reasons, the press was informed that the plant received a task from 1933 to begin production of agricultural machines and railway platforms. The company has completed the reconstruction, and change of subordination, it was renamed to Kharkiv mechanical plant “Hammer and Sickle”. Luckily, to perform in 1933 obsadenie plant was not necessary. The order also peacetime in 1933, filed by the Office of Mechanization and motorization of the red army, included the repair of 165 tanks T-26 and T-18, 10 BT, 5 T-24 and 35 tankettes T-27.

And the question of the organization of production of motorcycles in Kharkov more seriously was not considered.

E. LICHOV