Manufacturer of air screw requires special precision and accuracy. The proposed device will greatly facilitate your work: processing of the pressure surface of the screw with sufficient precision and surface finish takes no more than 10 min. Fixture mounted on the lathe TV-4, common in school workshops and on suit. The mounting base of the copier fixed with two screws and the caliper longitudinal feed of the machine. Copier consists of base, gon and coperni line, bolted. The copier is moved right and left against the part and the fixing bolt screwed in the back.

Manufacturer of air screw requires special precision and accuracy. The proposed device will greatly facilitate your work: processing of the pressure surface of the screw with sufficient precision and surface finish takes no more than 10 min. Fixture mounted on the lathe TV-4, common in school workshops and on suit. The mounting base of the copier fixed with two screws and the caliper longitudinal feed of the machine. Copier consists of base, gon and coperni line, bolted. The copier is moved right and left against the part and the fixing bolt screwed in the back.

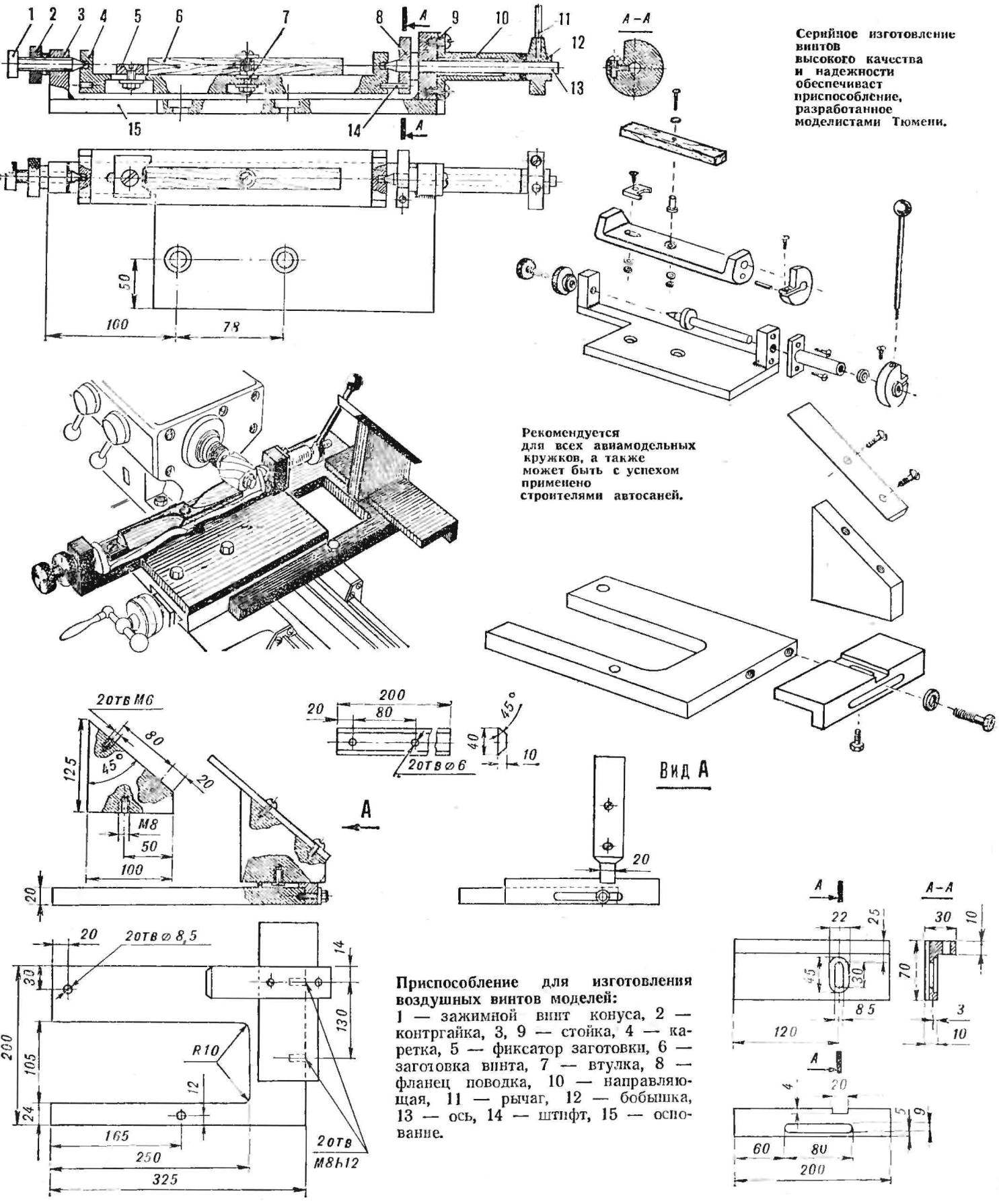

Item 15 mounted on the uprights 3 and 9 forms the base for the installation of the rotary carriage. On the axis 13 fixed In the flange, which is pressed on the pin 14. This pin enters the hole in the side of the carriage and fixes the latter relative to the axis 13. Item 10 — additional bearing axis. It is secured with screws and the rack 9.

On the axis 13 with the lugs 12 fixed to the lever 11 can provide a focus copyrow line.

Rack 3 wrapped cone 1 threaded, with which the carriage is mounted on the base. From the reversing of the cone is fixed to the nut 2. The carriage 4 is to consolidate will be able to prepare in the device; the workpiece is placed on the axis 7 and is fixed by a screw and washer. From turning about the axis during the treatment, it is additionally with items 5 and screw-nut, which can move in the groove of the carriage.

Special attention should be paid to the alignment fixture. The working surface of the cutter, mounted in the machine spindle must be at the level of the center of rotation of the carriage. The position of copier choose roughly as follows: the copier using the screw mounts on the bracket and set so that dimension a corresponds to the selected step. For example, for a step of 200 mm

A=N/2π=200/6,28=32mm,

where h is the screw pitch, mm;

A — the distance from the axis of the rotary carriage to the line of copier.

π is 3.14.

The position of the copier to the right or left of the axis of the carriage affects the direction of twist of the blade. The cross-feed screw of the caliper install the carriage so that the distance from the axis of the workpiece to the axis of the cutter And the plan was equal to 80 mm. the Lever carriage push Kopiraj the ruler and measure the angle of the surface of the carriage relative to the horizontal plane, which in our example is 22°. Moving the copier back and forth, it is necessary to ensure that the angle of inclination of the carriage correspond to the calculated angle, i.e. 22°. The workpiece is mounted on the carriage and is then processed starting from the end. After this operation the measured pitch in different sections. Its value must be constant. Adjusts the position of the copier by moving the square forward or back.

Only then you can permanently fix the position of the polygon relative to the base pins. The second side of the workpiece is processed after reversal of the carriage at the centers. Fixture designed and manufactured in Tyumen oblsud in the laboratory of auto modeling sport.

V. KALININ, master of sports of the USSR