Krysheval the trunk will be of interest to owners of cars that do not have a garage and have to leave to spend the night steel “horse” under the open sky. Most of them equip their vehicles with security alarm. However, it often works even from a passing truck or a number of powerful peals of thunder, breaking the night’s rest of residents.

Krysheval the trunk will be of interest to owners of cars that do not have a garage and have to leave to spend the night steel “horse” under the open sky. Most of them equip their vehicles with security alarm. However, it often works even from a passing truck or a number of powerful peals of thunder, breaking the night’s rest of residents.

A in addition to the alarm set mechanical anti-theft device on the controls: steering wheel, pedals, etc. For stealing these electronics and mechanics, apparently, a hindrance to small — abductions-that is not getting smaller.

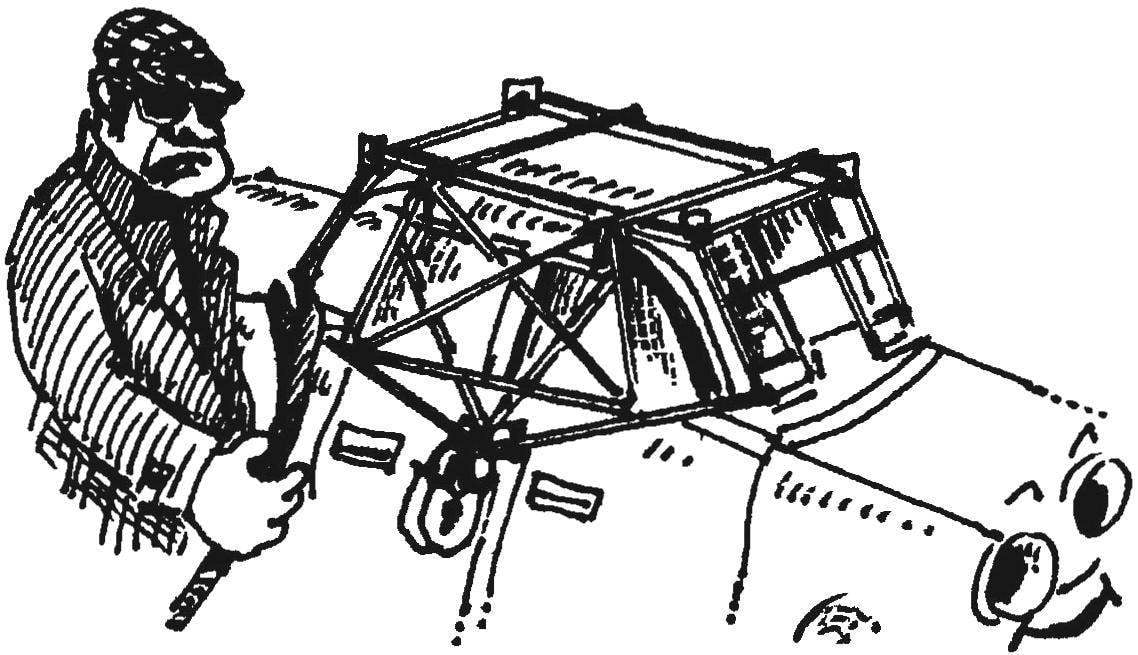

I designed and built for his “Moskvich-412” krysheval the trunk, which in addition to the direct purpose use as anti-theft (security) device. In the protective position of the side-grid surrounds the entire glazed surface of the body and prevent the unauthorized opening of doors and the penetration of thieves into the cabin through the window.

Car with the trunk, the guard does not even try to steal too much trouble and attention-grabbing noise it will create for the hijacker before he will be able to be in the car.

If you want to make a similar design, and krysheval trunk (standard or improvised) you already have, you can use it for suitable items for the new security.

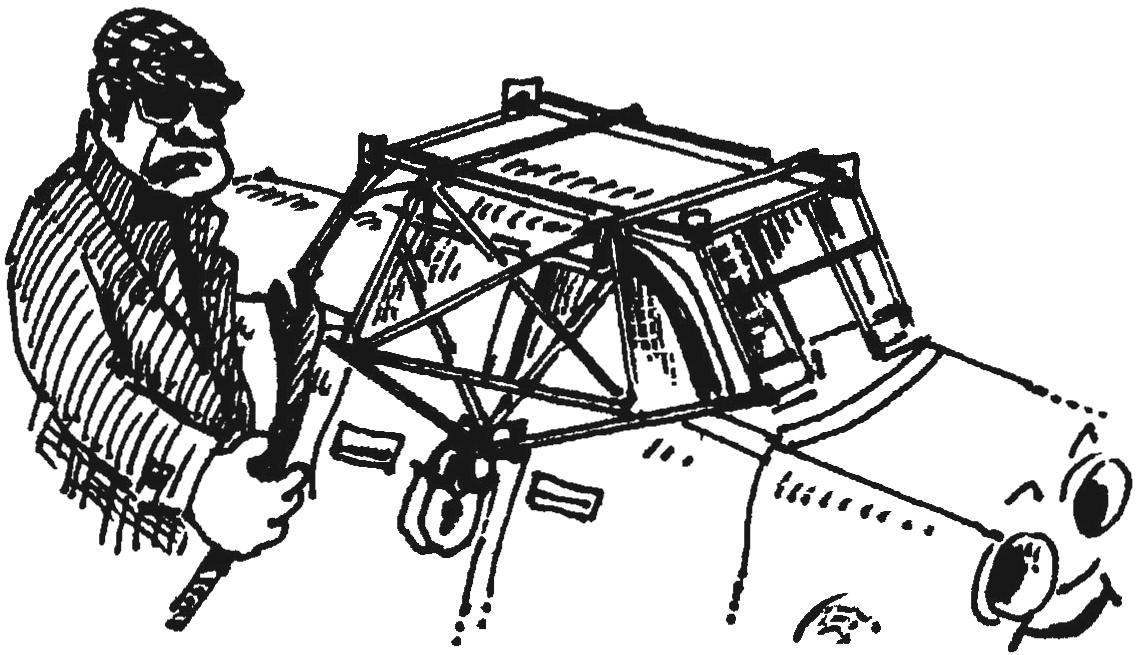

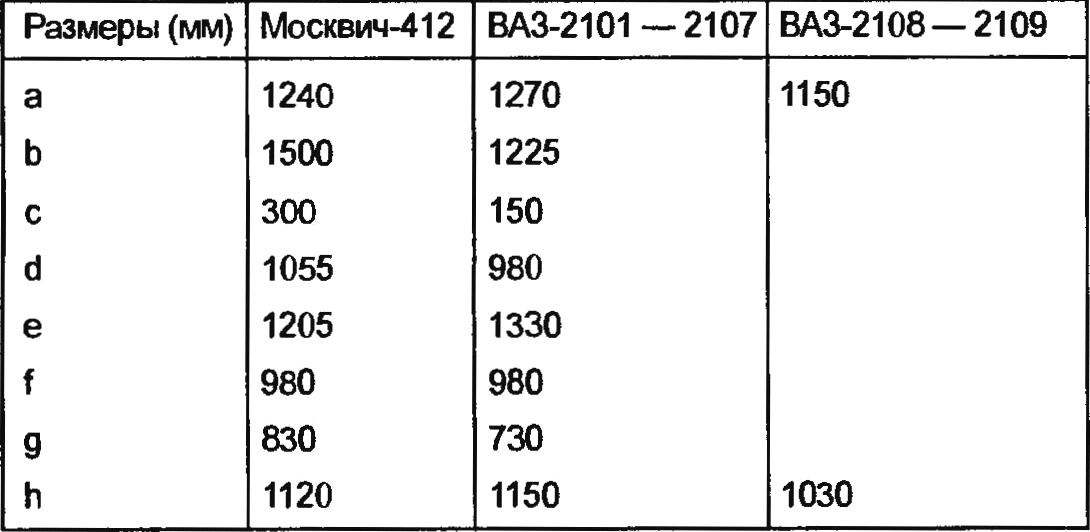

The main (middle) part of the trunk frame consisting of two longitudinal beams (area 25×25 mm) and a pair of crossbars. Each cross member is welded of dual in the vertical plane of rods with a diameter of 10 mm. This wire is the main material of the whole structure. The ends of the lower rods are bent slightly downwards — they form the struts, increasing the cross member.

In order not to burden excessively the product, the longitudinal elements of the flooring on the frame not mounted: his (or, rather, grating) form the folding side — two side and two end, each of which is a is also a lattice design.

Trunk guard (part 2,3,4,6,10,11,13,17 made of steel rod Ø10; details 5,7,8,12,14,15 made of St3, sheet 3):

1 — longitudinal beam (steel angle 25×25, L = b, 2); 2 — cross (L = h, 2); 3 — tying the end side (L4800, 2); 4 — crossbars (L1180, 4 pieces); 5 — stud earring (8 PCs); 6 — thrust (8 PCs); 7 — trim (8 pieces); 8 — lug (4 PCs); 9 — clamp (4 PCs); 10 — loop Rigel (L1200, 2); 11 — rail side walls (L4250, 2); 12—solitaire supports (4 PCs); 13 — lezhen support (L60, 4 pieces); 14 — front supports (4 PCs); 15 — fastening bolts (4 PCs); 16 — brace (2 PCs.)

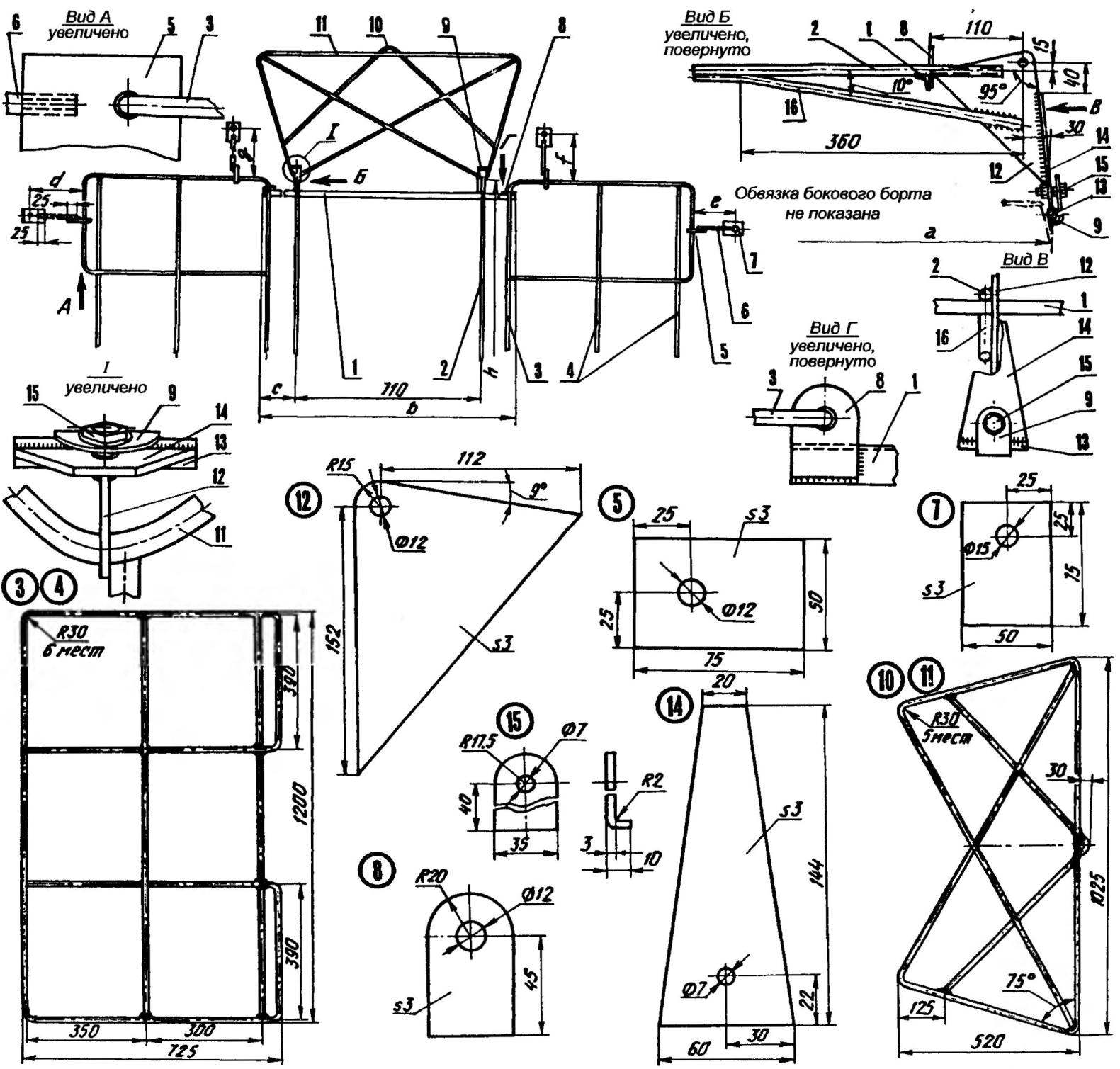

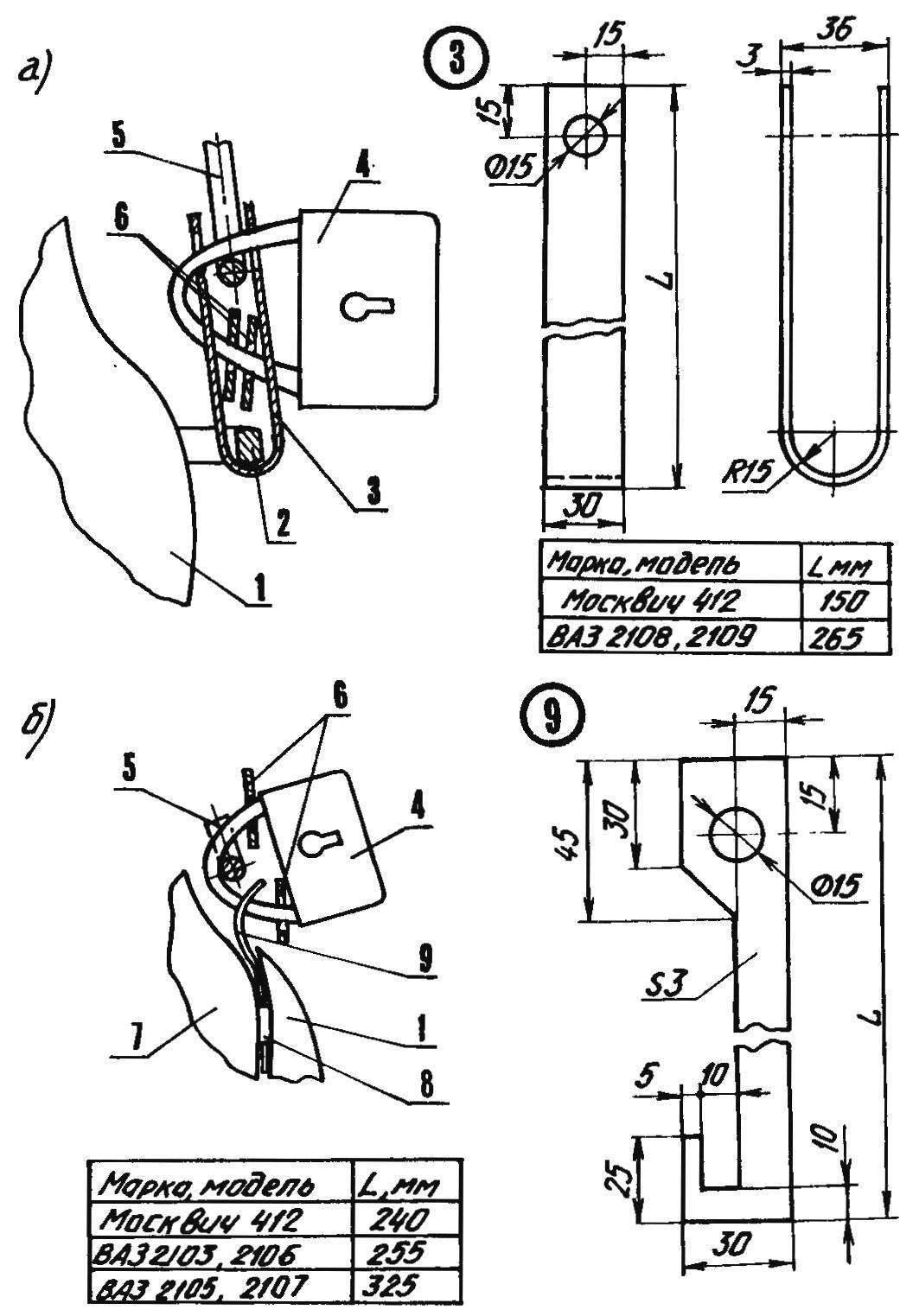

Fixing trunk in a position of protection (a—side sides, b — with additional rods instead of the side):

1 — car; 2 — lateral side; 3 — a lateral Board; 4 — the main thrust; 5 — auxiliary power

In order to standardize both the lateral side is made identical, as well, and end (front and rear). The configuration of the side walls is trapezoidal, approximately the glazed doors of the most common cars, and front and rear — a rectangle with sides of dimensions glass (rear slightly less front).

The support frame (four of them) consists of several small parts: scarves, racks, groundsel, welded together, and a locking device consisting of a clamp and mounting bolt. The device allowed to make the trunk removable. A support fixed to the drainage grooves of the roof of the car (so the boot construction is suitable only for those systems which have such grooves are available).

A support frame (or at least scarves) must be done prior to the manufacture of the side walls. Then, turning down the rod Board binding in accordance with the required configuration, it put on (through the holes in the scarf) the supports and then the ends of the rods welded to the piping. After the sides are welded and the loop bolt. After that the ends of the cross members of the frame first, take the scarf, and after adjustment of the relative position of the elements is welded completely.

The same technology is made and end Board, but instead of bandanas they put on a pair Ushkov and earrings. First after welding flanges welded to the ends of the beams, and the other is welded thrust of appropriate length with plates. Overlays and stud details similar and differ only in the diameter of the holes in them: have lining it more. The support elements, overlays and earrings made of steel sheet 3 mm thick.

For installation on vehicle trunk with folded on the frame bars is mounted a rack on the gutter of the roof of the car so that the hinges lock in the lower side grilles located at meiderich stands four-door car or over the handles of the three-door (for example, VAZ-2108); they are fixed by clamps.

To reduce noise and protect the paintwork of the roof and gutters must be put under the ledge racks rubber pads, and the contact between the bars of the sides to put the segments of rubber tubing, previously cut lengthwise.

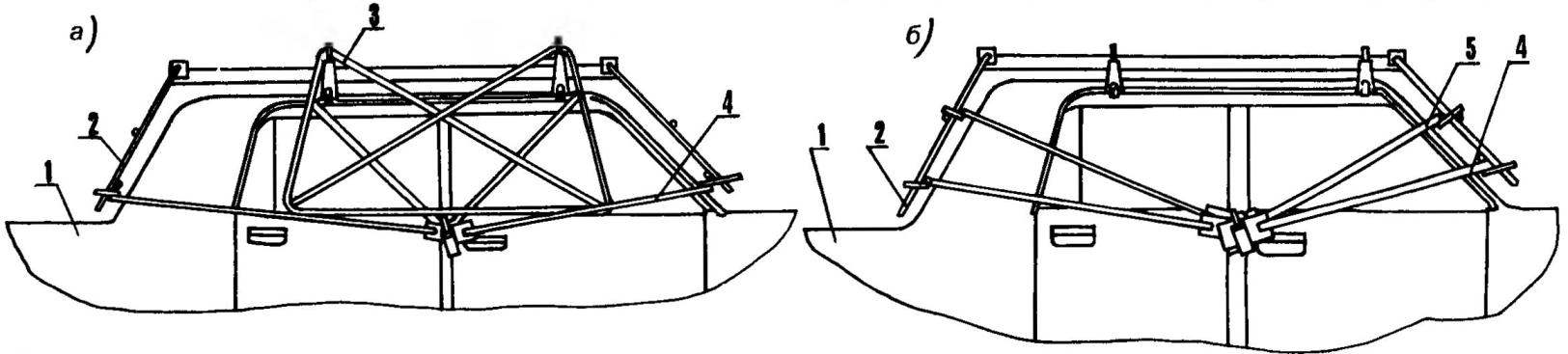

Locking of the gratings of the trunk on the car (with exposed door handles; b— with recessed door handles):

1 — door; 2 — handle; 3 — bracket; 4 — lock; 5 — loop side wall; 6 — lining rods; 7 — Magdolna stand; 8 — hinge rear door; 9 — eye

For translation of the trunk to position the protection of four-door vehicles with recessed handles, you need to open the front door to catch the eyes (bending pre-form ordernow rack) for the top hinge of the rear door and again to close the door. Lower the bars on the Windows, to tie a shackle padlock through the hole of the eyelet, the loop of the side grilles and threaded clevises.

For vehicles with protruding door handles instead of eyelets are used a special bracket, which cling to the door handles.

In transport position the side-bars are folded on the frame of the trunk and fastened between two clamps and M6 bolt. Clip represents exactly the same detail as the stand clip. In this position the trunk may be carried long cargo items. If necessary — for example, for transportation of large volume (but not mass) of cargo in a relatively small container — grid fit the same brackets in a vertical position, forming the sides and on the frame arranged temporary flooring.

Such a trunk-guard with a revised dimensions of frame parts and rods can be manufactured for other cars, both domestic and imported, with drainage grooves. These dimensions for some of the domestic machines listed in the table.

For ease of design instead of the side walls can be mounted even a couple rods on both sides of the end boards.

In the position of protection, they will block the window of each door diagonally.

The movement of the trunk-guard folded having approximately the same aerodynamic resistance as the normal serial.

V. TASKAEV, Syktyvkar, Komi Republic