The Creator of light tanks. After the victorious conclusion of the great Patriotic war of the Soviet airborne connection in June 1946 he was separated from the air force and became an independent native troops subordinated directly to the Minister of defense of the USSR.

The Creator of light tanks. After the victorious conclusion of the great Patriotic war of the Soviet airborne connection in June 1946 he was separated from the air force and became an independent native troops subordinated directly to the Minister of defense of the USSR.

It was believed that one of the main objectives of the air assault will be assistance to the troops advancing from the front, overcoming large water obstacles. Before that time, the formations and units of Ground troops landing-crossing means and their number did not allow troops in full strength and with the move to force large rivers, for which, as was shown by the experience of the recently ended war, was fought a fierce battle. It was assumed that air-dropping behind enemy lines to capture bridgeheads and bridges in areas of anticipated crossings (and their subsequent retention to the approach of his troops) will not give the enemy timely to organize the defense of these sectors of the front. This will create favorable conditions for the continuous offensive. In that case, if the defense of the water obstacles will be organized in advance, troops will be able to strike the enemy from the rear towards your advancing troops.

The second important task of the airborne troops, landed in the operational depth of the enemy’s defense, was the capture of important areas and lines to assist ground troops in the encirclement and destruction of key enemy forces and reserves, as well as disorganization of retreat of the enemy and prevent the transfer to them of reserves from the depths of defence to the front line.

It was also planned to use airborne forces to capture and destruction of airfields, command posts, communication nodes, depots, bases for various purposes and other important objects.

The leadership of the Armed Forces simultaneously with the organizational activities began the systematic re-equipment of the airborne forces, including weapons and military equipment, specifically developed taking into account the objectives and the specifics of the fighting “winged infantry”. The airborne units have increased the number of automatic weapons, artillery, mortars, anti-tank and anti-aircraft artillery.

Considering the tasks of the airborne forces, and increased demands on their mobility, in the autumn of 1946 resolution of the USSR Council of Ministers, the Ministry of industry issued the technical specification development airborne self-propelled guns ACS-76 76-mm cannon. Provided landing landing self-propelled heavy assault gliders.

Decision of the government leading developer of ASU-76 was determined by OKB-40 Mytishchi machine-building plant headed by N..Astrov who designed the chassis for the new machine. Nikolai Alexandrovich Astrov, was a well known designer of light tanks and self-propelled artillery.

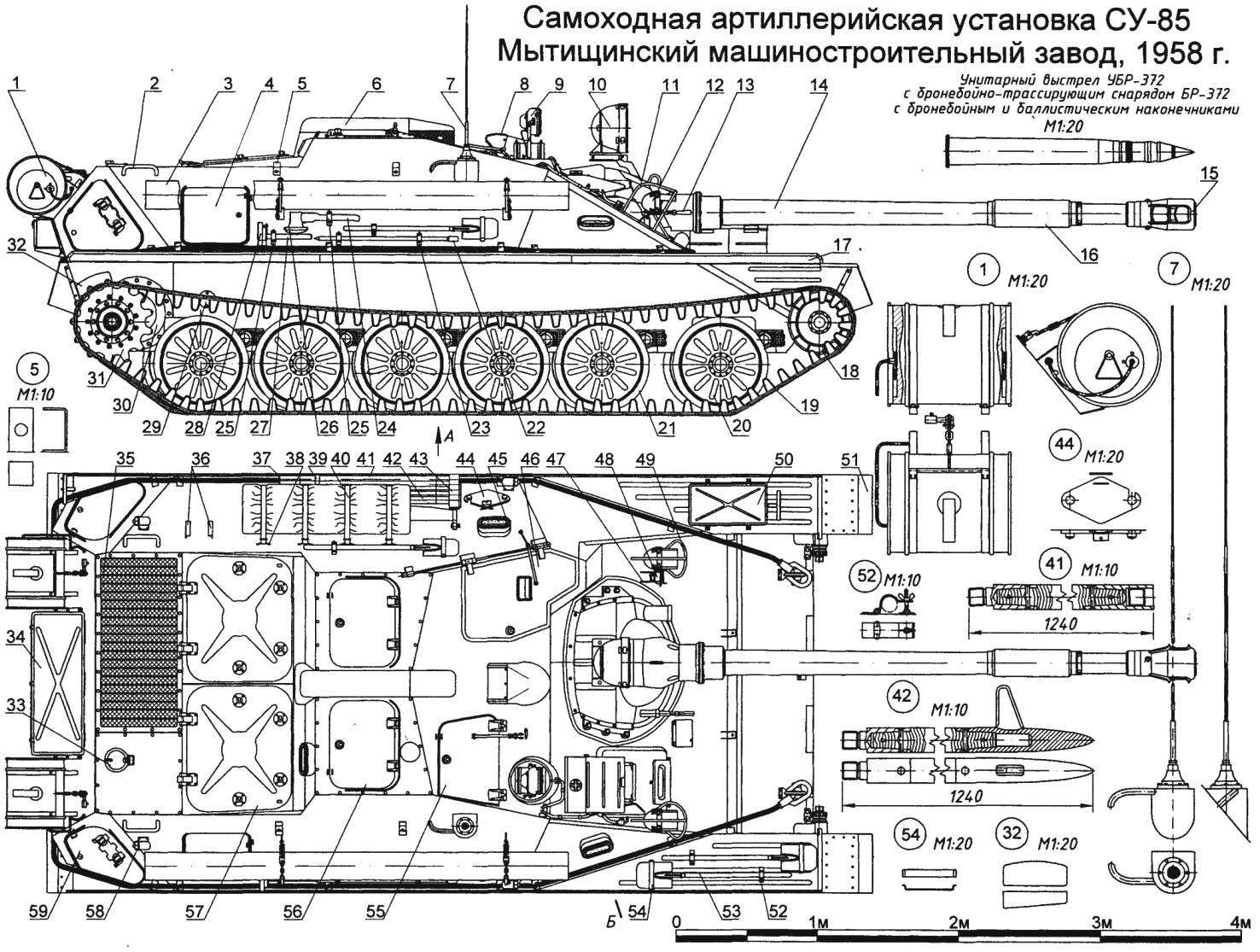

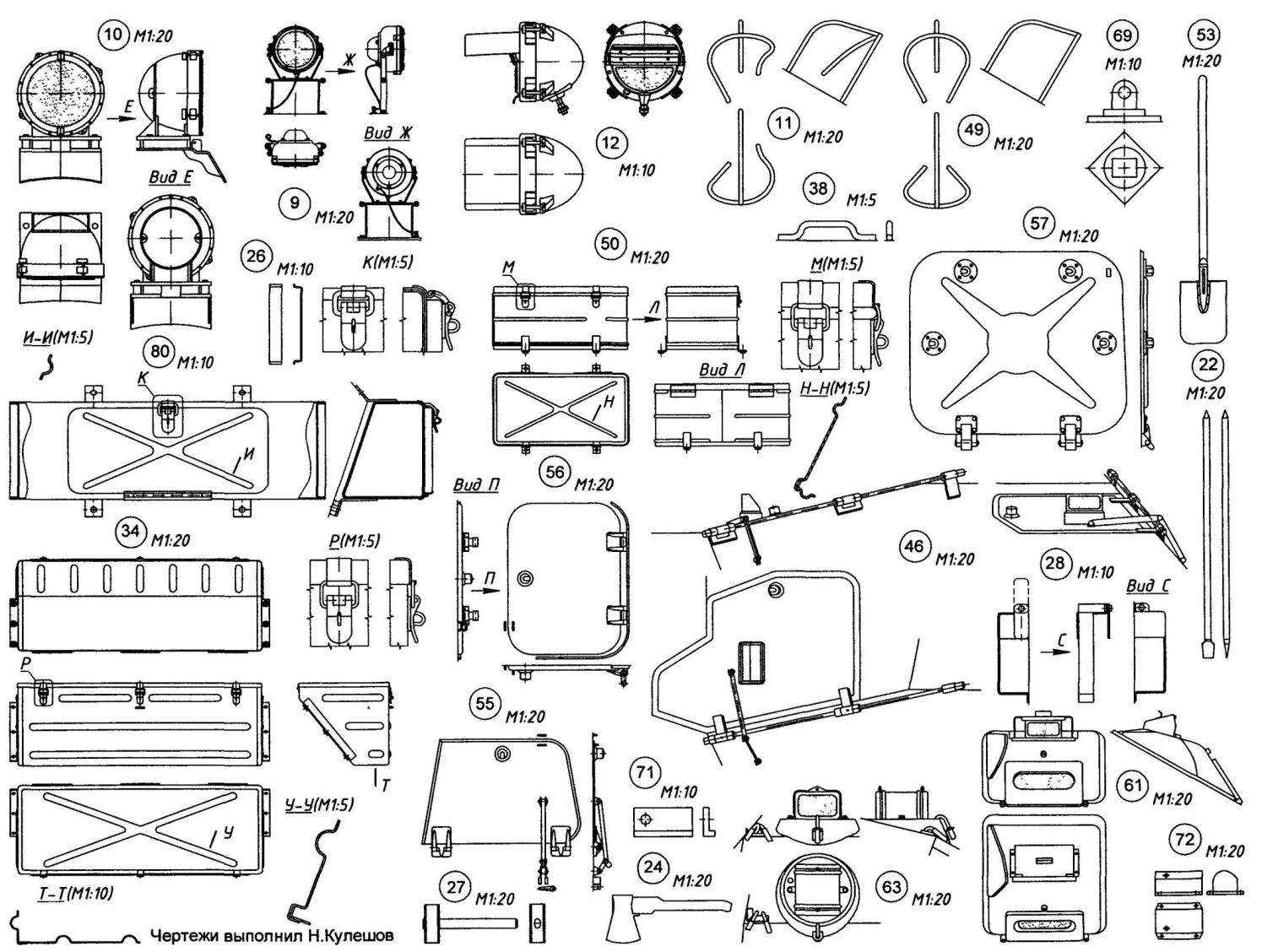

Self-propelled artillery SU-85:

1 — smoke bombs BDSH-5; 2 — rail; 3 — logs for self-recovery; 4 — cover for access to the positioning of the illuminator, L-2, the batteries of the device “Luch” and the optical elements of headlights; 5 — the brackets for laying of the cable for self-recovery winch; 6 — the case of the intake of the engine; 7— antenna VHF radio station R-113; 8 — the armored covers of fan of the fighting compartment; 9 — illuminator of the night vision device commander installation; 10 — illuminator, L-2; 11 —fencing right headlamp; 12 — headlight FG-102; 13 — 7.62-mm coaxial machine gun SGMT; 14 — 85-mm gun D-70; 15 — muzzle brake; 16 — receiver ejector; 17 — piping of the wing; 18 — guide wheel; 19 — track; 20 — front track roller; 21 —a support roller; 22 — scrap; 23 — clamp scrap; 24 — axe; 25 pin tool (axe and hammer); 26 — laying the axe bracket; 27 — sledgehammer; 28 — clip styling sledgehammers; 29 — cover technological hatch; 30 — side transmission; 31—a driving wheel; a 32 — bump; 33 — cover flap of the filler neck of the cooling system; 34 — a box of ZIP No. 3; 35 — frame air flow units with shutters for the radiators of the engine YAMZ-206B; 36 — guide bars for installation of the air-hydraulic pump guns; 37 — emphasis; 38 — bracket; 39 — lock styling milestone and rod of the swab; 40 — strap covers, tarpaulin; 41 — rod swab; 42 — milestone; 43 — packing the socket; 44 — cover flap filler fuel tank; 45 — periscope gunner; 46 — cover of the hatch of the gunner; 47 — enclosure of the audio signal; 48 — electric solenoid beep; 49 — left fence lights; 50 — drawer styling MZA-W; 51 —rubber skirting; 52 — lock shovel; 53 — a large sapper shovel; 54 — the packing brace of the shovel; 55 — cover commander install; 56 — cover loader; 57 — cover MTO; 58 — Parking light (front with green filter, rear — red); 59 — bilge hatch MTO; 60 — retainer logs for self-recovery; 61 — the armored covers for the driver with the monitoring devices; 62 — a container of washer fluid for observation devices; 63 — brunellesco with observation devices commander installation; 64 — bronenosca guns; 65 — loophole sight TSHK-2-79; 66 — periscope gunner; 67 — covers, tarpaulin; 68 front reflector (only on the machines of the Polish 6th airborne division); 69 — mooring bracket; 70 — protective Board; 71 — bracket for installation of the mechanism check the dealer link gun; 72 — bracket; 73 — tow hooks; 74 — blocks B-1; 75—rubber nalobnik; 76 — a nest of surveillance device; 77 — nut-lamb locking screw; 78 — rear reflector (only on the machines of the Polish 6th airborne division); 79 — surveillance device charging; 80 — box of ZIP; 81 — cover flap for mounting and dismantling of the longitudinal rods of the control; 82 — clip; 83 the fixing of the towline; 84 — housing of the ejector; 85 — aft hatch MTO; 86 — a towline; 87 hatch cover under the transmission case; 88 and 95 of the hatch covers under the brake drum; 89 hatch cover under the drain plug of the gear unit; 90 — manhole cover under the drain plug of the fuel tank; 91 — mooring hook; 92 hatch cover of the emergency exit; 93 hatch cover under the clutch housing; 94 hatch cover under the engine

Here I would like to Preface further description of the creation of ASU-76 story about this remarkable man and talented designer, the centenary of whose birth was celebrated last year.

1928 N. Astrov after graduation worked as a designer at the Moscow Elektrozavod. At the same time is engaged in scientific research at the Department of applied mechanics GAMIX.

In December 1930, the industrial and scientific activities of H. A. Astrov is interrupted by bodies of the OGPU. It brought to trial on trumped-up case of the so-called industrial party. After an eleven-month pre-trial detention N..Astrov without providing specific evidence of guilt was sentenced to five years probation and was sent to work in Auto-tank KB technical Department (ABTO) economic management of the OGPU, where he worked as prisoners, and civilian specialists.

From December 1931 to may 1934 N..Astroff worked as a leading engineer-constructor, then the head of ABT, where he developed krasnosulinskyi tanks: floating PT-1, PT-1A and the land average T-29-4, T-29-5. Built prototypes of tanks were tested, but not commercially built.

In 1934, ABTO disbanded, and N..When I was appointed chief designer of the Moscow plant № 37, where under his leadership there was created a small floating tanks T-38 (1935), and T-40 (1939), and semi-armored tracked artillery tractor T-20 “Komsomolets” (1937). These tanks with anti-bullet armor and the tractor, unified with the tanks T-38, were 4-cylinder petrol engine M-1 of the Gorky automobile plant. The machine was successfully tested and produced commercially. The beginning of the great Patriotic war the plant № 37, and the Gas produced 1604 T-38 all modifications, 222 floating T-40 and 7780 — “Komsomol”. The use of automotive engines in light tanks provided the technical specifications for their development, as in the construction of Nizhny Novgorod (later Gorky) automobile plant provided for its involvement in the production of military equipment.

In the early days of the great Patriotic war, after the huge losses suffered by the red Army, especially acutely the question of the production of military equipment, for the manufacture of which mobilized the entire industrial capacity of the Soviet Union.

By the time it became clear that time tanks with anti-bullet armor is gone and this war they are unsuitable. Instead of tanks T-40 at factory No. 37 was assigned to go urgently to the production of developed in Leningrad light tank T-50 with thicker armor.

This decision was accepted by the people, it is not known the possibilities of the Moscow plant № 37: the T-50 and constructively, and technologically compared to the T-40 was a very complex machine. Factory # 37, not without difficulty master a 5.5-ton T-40, could not move within the required time 14.5-tonne T-50: there was no tooling and documentation on it, the machine was not suitable for the manufacture of new parts, the square of the shops were small, hoisting means weak.

Unloading the su-85 from the An 12

In this challenging environment N..Aster decided to modify the T-40 in the ground tank with reinforced armor. Land version of the T-40S with broederlam simplified form and 12.7-mm DShK, and from September 1941 — 20-mm automatic cannon tnsh was proposed in the beginning of July. Almost a secret from the Directorate, who was in a state of shock faced with plant problems, Nikolai Aleksandrovich with the specialists of the plant for two and a half weeks drew and executed in metal another example of a modified tank. The thickness of the front hull plates and turret increased almost two times, brandelli became simpler in form and easier to produce, and the inclination angles of armor plates more rational. Suspension remained the same, and the car, potjazhelevshie only 300 kg, was lower by 15 cm.

Compared to the T-40 tank, that is, looked good. N..Astrov with the senior military representative of the plant by Colonel V. P. Okunev in mid-July 1941 addressed a letter to Stalin. Omitted late in the evening in the mailbox at the Nicholas gate of the Kremlin, it was read the same night, and the next day on behalf of the head of state inspected the car, the people’s Commissar for tank industry V. A. Malyshev. Endorsing the initiative of the designers, Vyacheslav Aleksandrovich was advised to replace the DShK machine gun aircraft auto-cannon, and reported to Stalin. 17 July 1941 issued a decree of GKO No. 179/SS on the issue of light tanks T-60 at the plant № 37 Archostemata, and resolution No. 222/SS from July 20, the production T-60 was instructed, except the plant number 37 already and Gorky automotive, and Kharkov tractor with the overall purpose of supply of 10 000 tanks until the end of the year. The resolution was determined providers: bronelista, hulls, turrets, weapons, instruments and rubber products. Only the hulls were made from several plants: Podolsk, Kolomna, Novo-Kramatorsk and Voroshilovgrad machine building, locomotive Murom, Vyksa tobelerone equipment and Taganrog “Krasny Kotelschik”.

The t-60 was a very simplified vehicle with a single engine GAZ-11 (in tank version of the GAZ-202 with a capacity of 70 l/s instead of 85 for improved reliability). He had a good cross, was equipped with pre-heater, especially helping out in the harsh winter of 1941/42. In the hardest for our country the days when the major manufacturers have relocated to the East, the Gorky plant employees until the end of 1941 made 1323 T-60, many of whom took part in the counteroffensive near Moscow. T-60 fared well and at the break of the siege of Leningrad in the Sinyavino swamps and other battles. In addition to Gorky city, 45 tanks T-60 was released shipyard in Zarephath. Moscow factory No. 37 to the evacuation to the Urals managed to produce 20 of these machines and 467 T-40C. During the period from 1941 to early 1943, the industry has produced 5920 tanks T-60.

In the autumn of 1941, Nikolai was transferred to the GAS by the Deputy chief engineer Andrei A. Liphart. At the same time addressing current issues in the production of T-60, Astrov designed a new tank based on the needs of the front and of the production capacities of the Gorky automobile plant.

In the same way as for the T-60, has proactively developed a two-seater car engines GAZ-203 and on its basis created a light tank T-70 with a mass of 9.2 t with 45-mm cannon 20K, 45 mm frontal armor of hull and turret with an optimum tilt angles. 140 horsepower Sparky gave the tank good mobility.

N..Aster recalled: “the Disease of waiting, the fears, the often flimsy, not yet owned people. The designers believed everything — from the plant Director to the last janitor and worked selflessly, do not settle with his forces, nor time. T-70 was planned in October 1941 and in January 1942 the Director of Gas I. Loskutov presented to the Supreme Commander ready sample already passed preliminary tests. A new tank was approved and recommended for service, and serial production was ordered to begin three months later in March 1942”.

Soviet tank industry deadlines mastered the production of war machines and put the red Army 8226 T-70 and T-70M. Tanks T-70 took part in the battle of Stalingrad, in battles on the Kursk bulge, breaking the siege of Leningrad.

From the tank to the vehicle

For the summer campaign of 1942 the red Army opposed the new and modified German tanks. To fight them not only light tanks developed in the beginning of the war, but also more secure and more powerful armed was not easy. Before the Soviet designers had the task without reducing the serial production of tanks, to strengthen their weapons and the reservation to the required level. One solution that allowed to maintain the established production of T-70, was the creation of the self-propelled artillery more powerful than the basic machine, weapons. The need for self-propelled artillery pieces were huge. On the basis of “Ostrovsky” machines, self-propelled guns were created before, but this was more improvisation, not a serial machine.

In the fall of 1942 at factory No. 38 in Kirov, where they settled and produced T-70 evacuated Kolomna machine-building plant, under the leadership of chief designer M. N. Shchukin by S. A. Ginzburg has developed a self-propelled gun SU-76 with a gun ZIS-S using units and assemblies of tanks T-60 and T-70.

A similar setup was developed and at the Gorky automobile plant. Unlike the T-70 on which the power unit consisted of two series coupled engine-propelled these motors worked in parallel on a common shaft, each through its transmission. The installation of the SU-76 has passed field tests and was adopted.

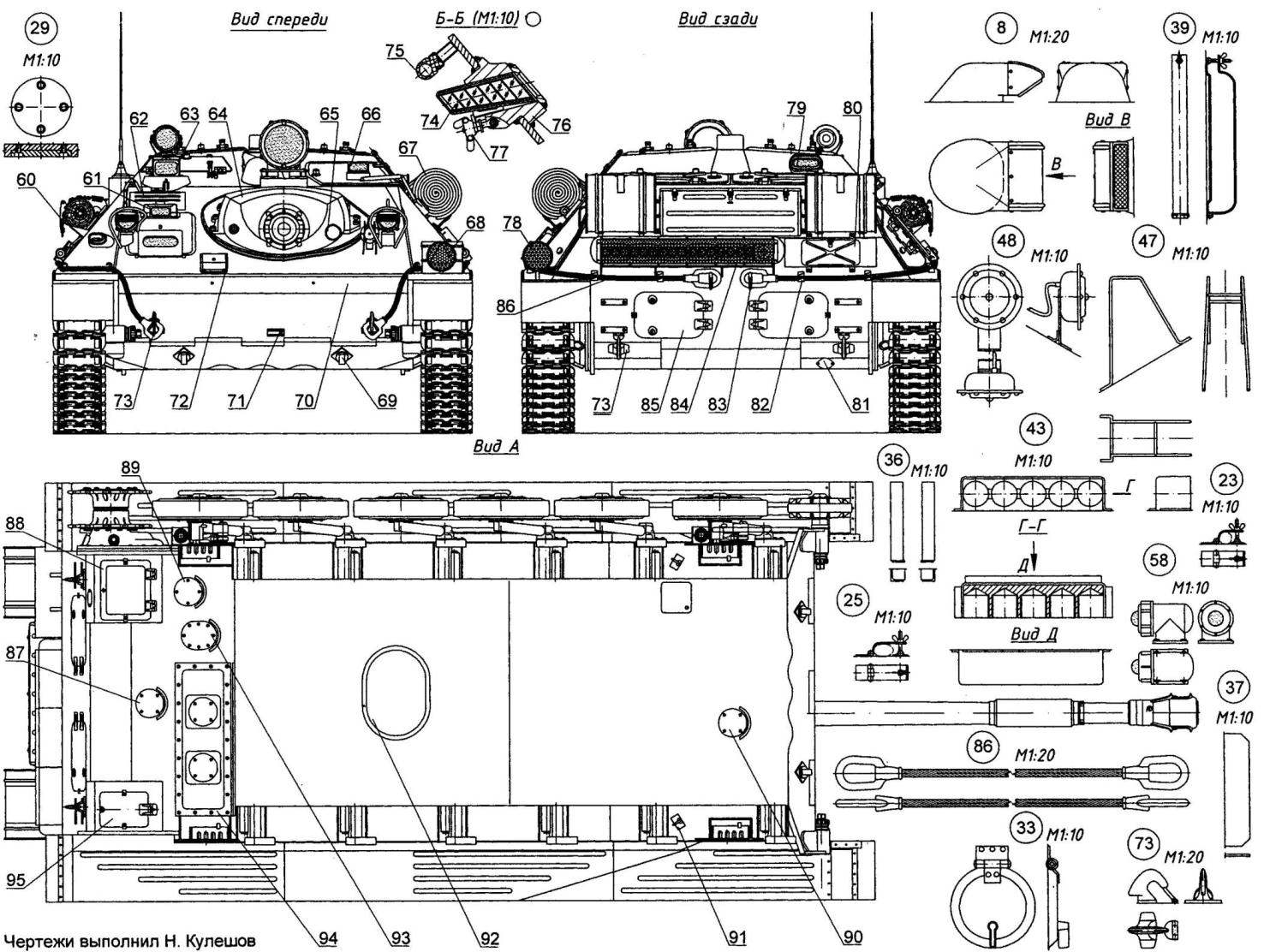

Self-propelled artillery SU-85:

4 hatch cover to access the pilings of the illuminator, L-2, the batteries of the device “Luch” and the optical elements of the headlights, 9 — illuminator of the night vision device commander installation; 10 — illuminator, L-2; 11—fencing right headlight; 12 — headlight FG-102; 18 — guide wheel, 19 —track; 20 — front track roller; 21—a support roller; 22 — scrap; 24 — axe, 26 — laying the axe clamp, 27 — sledgehammer; 28 — clip styling sledgehammers; 30 — side transmission; 31 — a driving wheel; 34 — a box of ZIP N 3, 38 — bracket, 46 hatch cover gunner; 49 — enclosure of the left headlamp; 50 — drawer styling M3A-H; 53 — a large sapper shovel; 55 — cover commander install; 56 — cover loader; 57 — cover MTO; 59 — bilge hatch MTO; 60 — retainer logs for self-recovery; 61 — the armored covers for the driver with the monitoring devices; 62 — a container of washer fluid for observation devices; 63 brunellesco with observation devices commander of the unit; 68 front reflector (only on the machines of the Polish 6th airborne division); 69 — mooring bracket 71, the bracket for the engine setup check the dealer link gun; 72 — bracket; 78 — rear reflector (only on the machines of the Polish 6th airborne division); 80 — box ZIP, the 81 — cap flap for mounting and dismantling of the longitudinal rods of the control 82 of the bracket; 83 — retainer towline; 84 — housing of the ejector; 85 — aft hatch MTO, 87 hatch cover under the transmission case; 88,95 — manhole covers under the brake drum; 89 hatch cover under the drain plug of the gear unit; 91 — mooring hook; 93 hatch cover under the clutch housing; 94 hatch cover under the engine

When operating in the army in early 1943, the artillery showed major defects associated with the failed scheme of the power plant. Work to eliminate them in the spring of 1943 instructed N..Astrove, who proposed to use a modified self-propelled gun tested by the power unit of the T-70, and perform a number of other improvements. Advanced self-propelled gun was successfully tested in July 1943, she was adopted.

Production of the SU-76 was carried out in three factories: the Gorky road, No. 38 in Kirov and No. 40 in Mytishchi. Just before the end of the great Patriotic war has produced 11 494 SU-76. The number of armored vehicles produced during the war, tanks and self-propelled guns N..When I was in second place after the legendary “thirty” and self-propelled guns on its basis.

In 1943 by order of people’s Commissar for tank industry of the N..Astrov was appointed chief designer of the Mytishchi machine factory No. 40 without the release from office of the Deputy chief designer of Gas. For his work during the war he was twice awarded the title of laureate of the State prize of the USSR in 1942 — for the development of light tanks T-40 and T-60, in 1943 — for the improvement of the design of the tank. Among his awards for selfless labour during the war including the order of Lenin, red banner and Patriotic war.

Tank gets wings

Armor N..Astrov “mastered air,” before entering the decree of the government in the autumn of 1946. In the winter of 1941/42 the famous aircraft designer Oleg Antonov has developed a cargo glider A-40 to transport light tanks the guerrillas. The apparatus consisted of biplane box and tail farm with feathers, which were fastened to the hull of the T-60. In August — September 1942 this hybrid of the tank and the airframe has passed the examination in LII (test pilot N. With.Anokhin).

In March 1947, the OKB-40 has completed the draft design of the airborne self-propelled guns ACS-76, has received factory designation “570”. In June developed a technical project, and in December assembled the first pilot plant and spent its factory testing and shooting the gun LB-76С.

After passing the field tests on the NIAP in June 1948 and the deficiencies identified four pilot plants in July — August of the following year have successfully passed military tests in one of the artillery battalions of the 38th airborne corps. At the end of the year ASU-76 was adopted. In serial production the installation was not run due to the lack of a suitable tug for a heavy landing glider Ilyushin Il-32 designed to transport including ASU-76. Suitable piston transport aircraft Tu-70 and Il-18 were built in one piece, and attempts to tow a glider two Il-12 failed.

In parallel with the testing of ASU-76, weighing over five tons, the OKB-40 work was carried out to create a lighter, more compact self-propelled guns for the airborne troops with a mass of about three tonnes with modified 57-mm aircraft automatic gun 113П and a crew of two. This option did not satisfy the military, and then OKB-40 proposed ASU-57 gun 4-51, constructed in OKBL-46 under the leadership of chief designer E. V. Charnko. This offer customer endorsed, although other observations they indicated that incomplete reservation of the fighting compartment increases the vulnerability of an installation crew.

The first eksemplar experienced ASU-57 (“572”) collected in 1948. Next spring she passed the field tests, and in the summer the military.

ASU-57 belonged to the type of semi-closed units with front-mounted engine compartment. The fighting compartment located in the rear of the hull, was combined with the Department of management. In the conning tower housed the crew and mounted a long-barreled 57-mm gun.

Right from the gun was the driver and loader on the left is the commander of the machine. Gun ammunition consisted of 30 rounds. Shots were fired three types of ammunition — armor-piercing, cumulative and high-explosive.

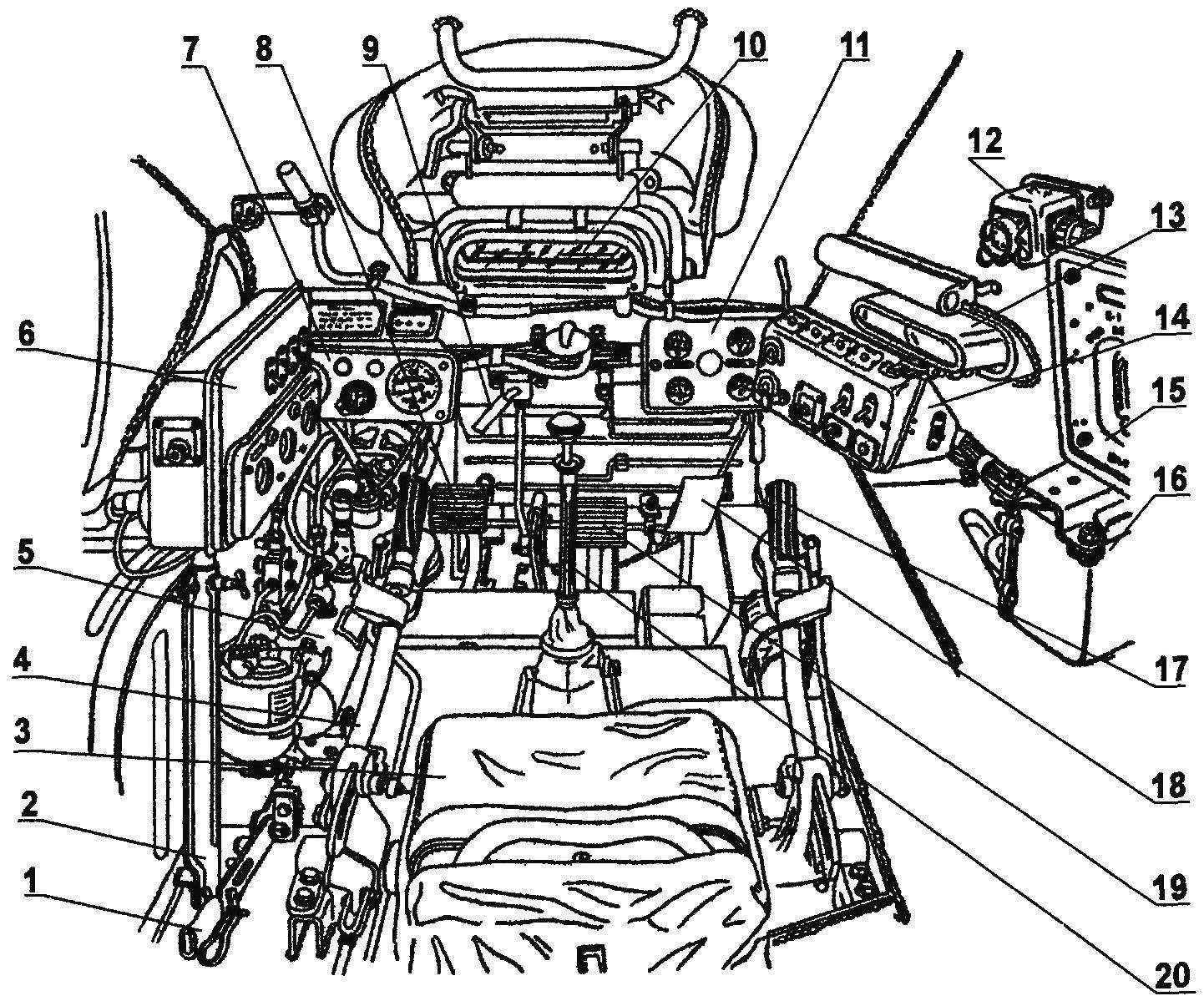

The office:

1 — lever control oil valve and stop the engine; 2 — fuel gauge; 3 — the seat of the driver; 4,17 — control PMP; 5 — the hydro-pneumatic accumulator, 6 — Shi-heaters; 7 — left front instrument panel; 8 — pedal the main clutch, 9—arm latch brake pedals; 10 — device monitoring; II —right front flap; 12— device TPU No. 3; 13 — surveillance device; 14 — lateral instrument cluster; 15 — camera TPU № 1; 16 — power supply TVN; 18 pedal of submission of fuel; 19 — a brake pedal; 20 — a gear lever

Armor-piercing projectile with an initial velocity of 1250 m/s, punched vertically oriented armor thickness of 72 mm at a distance of 2000 m. the direct fire Range of this projectile was 1,060 m. cumulative projectile pierced the armor thickness of 100 mm, located at an angle of 60° from the vertical. The car was attached to a 7.62-mm machine gun that was in the styling.

Armor protection ASU-57 was bulletproof. The hull was made of steel and aluminum armor plates with a thickness of 6 mm.

The movement of self-propelled gun was operated 4-cylinder automotive engine M-20E (as in four-wheel drive jeep GAZ-69), located across the housing and is formed as one power unit with a manual transmission. In cushioning system applied to a tubular rod torsion bar suspension with hydraulic shock absorbers on the front nodes. The extreme nodes of suspensions blocked to the body when transporting the machine through the air. On each side there were four reference and two carrier rollers, track roller and the last was at the same time and the guide wheel. The two-step gearing of track with sprocket wheel eliminated it buckling in the brake mode. A small average ground pressure (0,35 kgf/cm2) provided the car excellent traction and agility even on marshland, and its low silhouette fit well into any surrounding landscape. The machine was armed with a relatively powerful anti-tank gun. ASU-57 was used for landing parachute separately from crews.

In September 1951, the ASU-57 was accepted into service airborne. In the same year, the Mytishchi machine factory started its serial production.

Thus, ASU-57 took first place in the ranks of the airborne forces.

Success N..Astrov is not accidental, it is the result of twenty years of work, the talented designer over light armored vehicles. Work N..Astrov to create ASU-57, recognized by experts as the best in its class, awarded the State prize of the USSR.

Taking into account tendencies of development of tanks in the postwar period, in 1953, the OKB-40 has begun to develop a lightly armored self-propelled 85-mm cannon, called the SU-85, which was created in the mid 1950-ies.

Over the next three decades under the leadership of N..Astrov design Bureau of MMZ was developed by a few cars, brought him international fame. This famous self-propelled anti-aircraft gun ZSU-23-4 “Shilka” (“575”) who have distinguished themselves in many regional conflicts of the second half of the twentieth century. And it is unified with the chassis of self-propelled launchers “Cube” (“578”), standing on the arms of the Soviet Army and armies of Warsaw Pact countries, as well as many third world countries. In the mid 1970-ies was adopted the state programme for the unification of tracked vehicles for military use in four weight categories. Machine is the intermediate weight category (“569”), developed under the leadership of N..Astrov, was recognized as the best in the competition. On the basis of its chassis has been created by fire installation of anti-aircraft missile complex “Buk” self-propelled antiaircraft rocket and artillery complexes “tor”. Nikolai Alexandrovich Astrov led KB MMZ until his retirement in 1985.

A quarter of a century in the airborne ranks

For self-propelled artillery SU-85 designers Mytishchi engineering works (MMZ), headed N. A. Astrov, developed a special chassis with front placement of the fighting compartment under the factory oboznachenie “573”. The installation was completed with 85-mm gun and were intended for infantry, armored and airborne units. Its main objectives were the destruction of enemy manpower, firepower and artillery, armored and mechanized means as well as the destruction of field shelters light type and embrasures pillbox and BUNKER.

As self-propelled gun was also designed for airborne, the designers tried to lighten the machine while maintaining the required level of crew protection from armor-piercing shells of small and medium caliber of the opponent But because protection has been provided not so much by the thickness of the front, side and top armor plates of the hull, how many rational angles of inclination. To impart the necessary rigidity to the bottom of it done with a top hat cross section with a strong corrugated from the front, the lower frontal armor plate to the area of the bottom under the engine-transmission compartment (MTO) Flat sheet bottoms under MTO for increased rigidity intensified inside the hull transverse beams and longitudinal ribs. To reduce the weight of the hatch covers over the engine and right rear roof sheet MTO made of aluminum alloy.

Right in the nose of the car was in the office working place of the driver the Middle part of the wheelhouse was occupied by the fighting compartment, to the right of the gun where each other was located a loader, and the commander of the machine, and the left gunner placed If necessary the car could leave through the emergency exit located at the bottom of the housing for the breech part of a gun under the wooden flooring

In the fighting compartment mounted an 85-mm gun D-70 (symbol GRAU 2А15), developed by the Sverdlovsk OKB-9 under the leadership of chief designer F. F. Petrov Gun with the barrel-monoblock and vertical, wedge gate with semi-automatic opernogo type equipped with effective two-chamber muzzle brake ejector for purging the residue from the barrel of powder gases after the shot.

The gun barrel was placed in a cast cradle aboulnaga type. When you roll back it went over the front and rear brass inserts, mounted in the housing cradle. To cross the tide at the bottom of the cradle is attached to the rods recoil devices. Cylinder hydraulic brake rollback was left of the trunk (from the gunner), and the hydropneumatic cylinder nachalnika on the right. Normal rollback of the barrel when fired — 490 — 520 mm. aiming the gun at the target was performed by the lifting mechanism of the sector type with the donate link and a screw mechanism in the horizontal plane. The cradle is attached to horizontal axles within a rectangular frame, which served as the basis of the oscillating part of the gun. In turn, the vertical axle of the frame was fixed in the upper and lower supports of the breach in the hull. To ensure smooth movement of the barrel with the tip and balancing the swinging part of the tool equipped with a compensating spring mechanism.

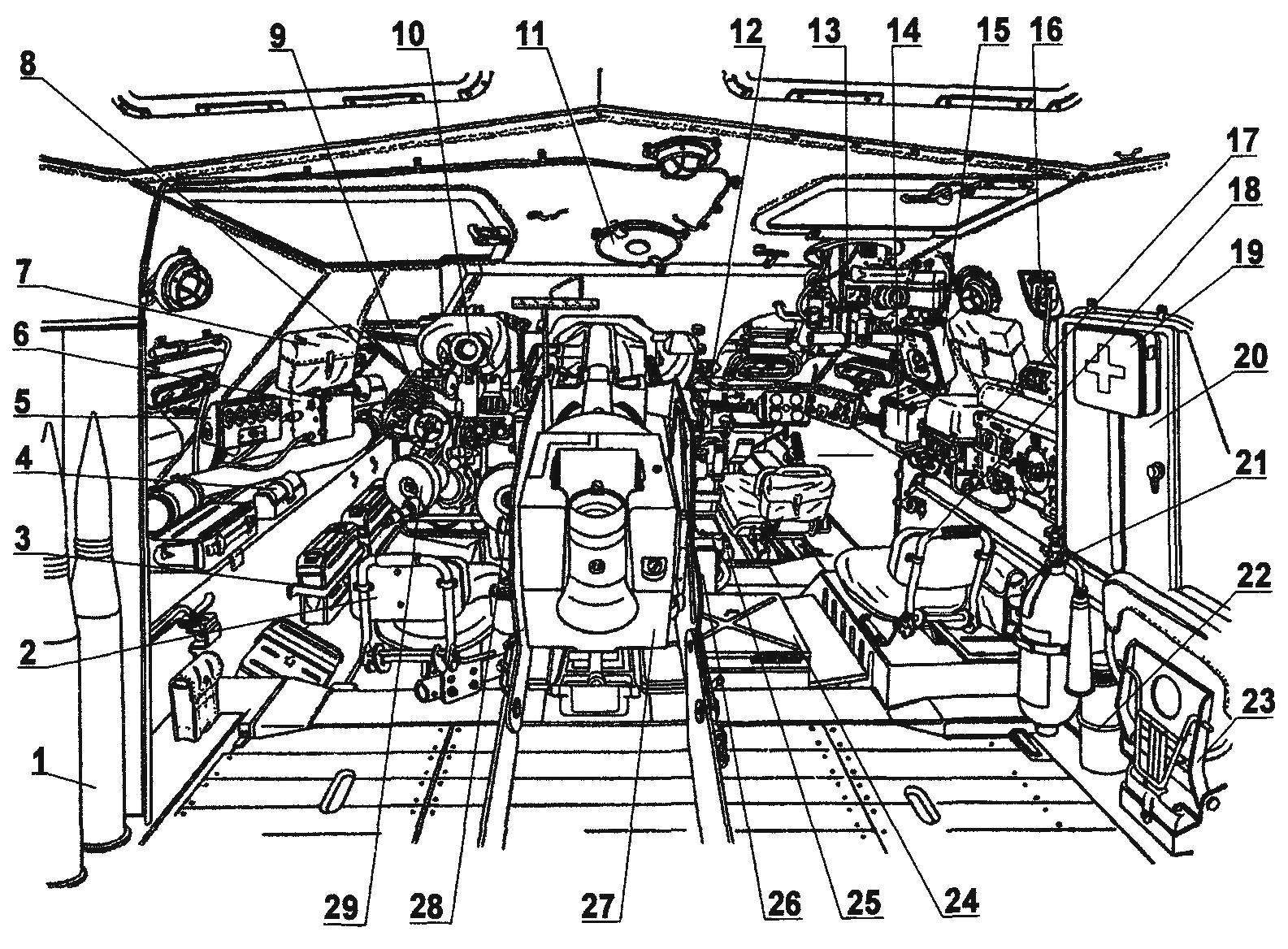

Fighting compartment:

1 —ammo for seven shots, 2 — seat gunner; 3 — magazinchika for machine gun, 4 — bag of grenades; 5 — switch Board gunner; 6 power night sight, 7 — bag headset gunner; 8 — the device TPU gunner, a 9 — sight C-71-79, 10 —sight TSHK-2-79, 11 — fan, 12 — gun; 13 — surveillance device commander ACS; 14 — power supply unit of the observation device TKN-1; 15 — device TPU № 1; 16 — antenna input; 17 — radio; 18 — seat commander SAU, 19 Cabinet, 20 — drawer stacking TKN-1; 21 —a fire extinguisher; 22 — tank for potable water; 23 — seat charging; 24 — box of ZIP; 25 – the switch of batteries, a 26 — battery 27 — gun 28 — lifting mechanism of the gun; 29 — rotary mechanism

To ensure the angles traverse gun mounted in the recess of the upper front plate, up to 15 degrees right and left from longitudinal axis of the machine gun barrel shifted 150 mm to the left of it, and in the upper part of the front plate on this side has made the cut, closed welded to the edge banding For protection of branches (combat and control) from dust and dirt falling through the gaps. the paired installation of the gun and machine gun, the contour of the embrasures was welded profiled sides, which were fixed cover, dressed in moving us In the stowed position the gun was fixed by a stopper, mounted on the cross beam of the bottom of the fighting compartment To test prototypes of the ACS began in the middle 1950-x of years, after which, in July 1958, it was adopted under the index SU-85. Serial production of self-propelled guns was started in 1959

The ammunition for 85-mm guns were part of a unitary shots from antitank gun D-48 ground to 21.9 kg with shells of several types. To destroy the vultures and the destruction of the fortifications was meant for high-explosive grenades OF 372К weight 9.6 kg. Maximum range of fire high-explosive shells at a maximum angle of elevation of the barrel was 13 400 meters When firing at moving armored targets used armor-piercing-tracer shells of the BR-372 weight of 9.3 kg and an initial velocity of 1005 m/s with armour piercing, or ballistic tip opening at a distance of 1000 m armor thickness 180 — 200 mm at an angle of 60 degrees. Cumulative shell ЗБК7 weight of 7.22 kg pierced the armor thickness of 150 mm in Addition to the ammunition of the artillery had smoke shells UD-372 steel buildings. With their help, closed the visibility of the observation and command posts of the enemy, his batteries, individual guns and firing points. They are also used for targeting their artillery.

Self-propelled gun was equipped with sights for various purposes: telescopic swivel TSHK-2-79-11 for shooting day to direct fire, C-71-79 gun with a panorama of PG-1 for firing from concealed firing positions, as well as a night tank ESRD-1-79-11.

Crew members in the operation of machines used every their instruments of observation – the commander of day — TNPK-240А night — TKN-1T, driver day — observation devices with the glass block B-1, installed in the armored covers and the front right cheekbone, TVN-2, installed in the mine armored covers; gunner — day of the B-1 with glass block on the left side of the fighting compartment, and at night — TKN-1T in the hatch; a loader — B-1 with glass block in the rear wall of the fighting compartment.

Serial guns supplied machine-building factory No. 75, located in the city of Yurga, Kemerovo region.

In A. Malyshev, then Deputy Chairman of the USSR Council of Ministers, demanded that, as in ASU-57 and ASU-76 was applied automotive units, although N..Aster wanted to install the SU-85 is a horizontal version of the engine In-6, representing one unit well spent V-shaped diesel tank. To provide the desired specific power of 210-horsepower two-stroke diesel engines YAMZ-206B, had to introduce cumbersome, but does not require extra energy ejection cooling system. MTO made more compact by installing the engine transversely of the housing There is located a mechanical transmission consisting of a main clutch, gearbox, propeller shaft, gearbox, two planetary rotation mechanism and final drives

Lack of rigidity of the shafts five-speed automotive transmission required substantial alteration, after which preserved some of its original features.

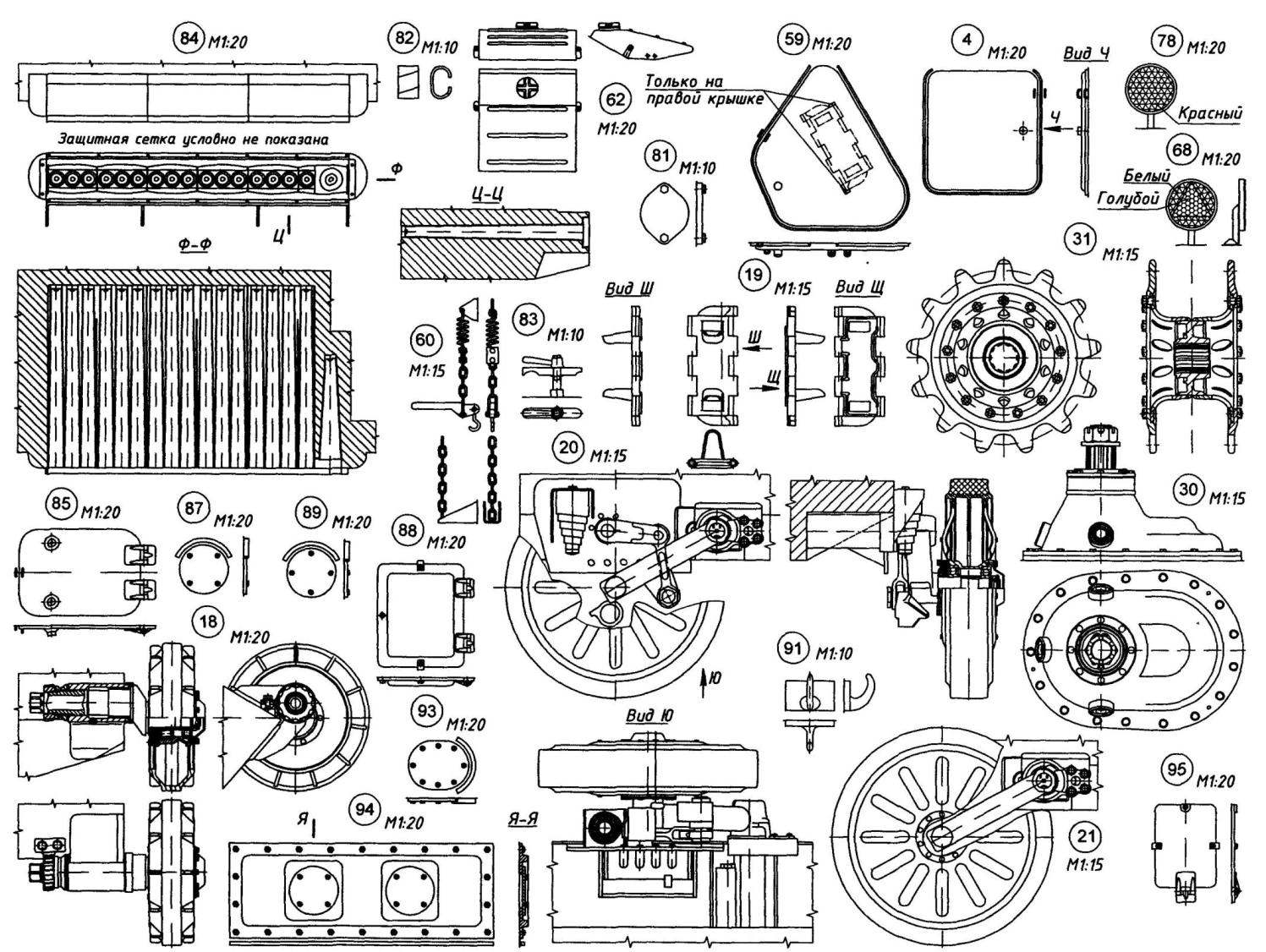

Caterpillar mover consisted of a metal track chains with open metal hinge, two wheels at the rear, two guide wheels with mechanical tension of the chains and twelve single row with rubber rollers of medium diameter. Suspension — individual torsion bar with hydraulic shock absorbers piston type front and rear sites.

Self-propelled gun SU-85 was equipped with TPU P-120, radio station R-113, filtering system, a headlamp with camouflage tips for driving in low visibility conditions and two infrared lights (one was over the gun barrel, the other driven from inside the vehicle — in front of the commander hatch) To create a smokescreen used two smoke bombs BDSH-5, located on the aft hull. Checkers ignited elektrozapalom by clicking on buttons, opening locks, holding BDSH-5, was manufactured by arms from jobs commander and gunner. The commander of the SAU was set on fire and dropped his right sword, the gunner left. To increase the reserve supply on the frame in rear of the artillery, attached to two additional fuel tank.

Dropping a relatively heavy self-propelled gun was produced from aircraft An-12 and Il-76 landing method, limiting the main tactical advantage of troops by surprise. So in 1964, SU-85 was discontinued “due to low efficiency and limited application.” In the same year, KB Volgograd tractor plant has submitted the mock-up Committee the layout of the object 911, which in some years led to the emergence of a fundamentally new combat vehicle of the airborne troops BMD-1 However, armed with airborne SU-85 remained until the middle of 1980-ies. With the advent of the transport aircraft An-22 and parachute platform P-16 this self-propelled artillery could be landed in the parachute way.

Experimental work on the landing of heavy equipment was carried out in 1967 on the aircraft An-22 (serial No. 01-06 at the site of the 7th guards airborne division in the district of Kėdainiai (Lithuania) in the Beginning were dropped from heights of 1.5 — 2 km layouts of equipment and cargo weighing up to 20 t on platforms with paper and foam shock absorbers. And then, after the testing process, parachuted equipment weighing up to 18 tons with a height of 800 — 1000 meters. The platform stretched from the fuselage parachute 14 m2. 60 m long when the speed of the aircraft 310 — 340 km/h.

Aviatransportirovke torsion bar suspension bogie wheels off using the installer from ZIL SU-85, and the machine was moored for the nodes located on the body of the machine.

Self-propelled gun was modernized several times First over the fighting compartment installed to improve habitat conditions of the crew of the armored covers with a fan to reduce the dust content of the air entering at the air filter of a diesel engine yaz-206B, engine air intake was moved closer to the upper frontal hull.

From October 1963 on the vehicle instead of the single-plate main clutch, with a Central conical spring mounted dry multi-plate friction steel on steel with 12 coil springs and modified gearing.

According to the results of the fighting in the middle East in the summer of 1967 has decided to rearm the SU-85 12.7 mm anti-aircraft machine gun DSHKM, which is mounted on the turret on modified hatch loader.

In 1960 — 1970-e years the Soviet airborne troops represented an impressive force. Six airborne divisions and ten independent airborne brigades and regiments, separate brigades and battalions of special purpose, was ready to perform combat tasks in any area of the globe. Confirmation of this can serve as a landing landing in 3 hours 15 minutes 21 August 1968 in Prague airport Ruzhin of the 7th guards airborne division, and early morning its the SU-85 has taken the intended position in the center of the Czech capital. At the same time in the airport Slatina in Brno landed 103 guards airborne division.

Eleven years later, on the evening of 27 December 1979, in Kabul the capture of a prison Puli-Charkhi prisoners commando battalion and self-propelled-artillery battalion of the 103rd division was blocked in the barracks, the crews of two tank brigades of the Afghan army. And then one SU-85 assault team rammed the prison gates, break through the Marines broke into the territory and disarmed the guards

However, designed for maneuvering of hostilities in Europe, the SU-85 proved to be unsuitable for action against the spooks in goroutines terrain Armored vehicles were sent to Afghanistan, it was unsuitable for mine warfare, which is inherent in Oriental ingenuity were the Mujahideen. Antitank grenade launcher RPG-7, which is rightly proud of its creators, has created a deadly threat for tanks T-62 and T-54, lightly armored vehicles and can not speak And if the tanks were modified, adding to the booking, the paratroopers were transplanted with BMD-1 and BMP-2 cannon, which had a significantly larger elevation angles. The crews of the SU-85 artillery battalion of the 103rd division in 1982 we changed to a modified T-54АМ.

The performance characteristics of the SU-85

Curb weight of the car, t…………………………………………………..15,35

Type of propulsion …………………………………………………………………………..crawler

Length with gun, m………………………………………………………………………8,435

Length of body, m………………………………………………………………………..6,24

Full width, m ……………………………………………………………………..2,97

But the height of the roof, m ……………………………………………………….1,935

Ground clearance, mm………………………………………………………………………………..420

Engine type…………………………………. 6-cylinder V-shaped liquid-cooled YAMZ-206B

Engine power @ 1800 rpm, HP …………………………………….210

The maximum torque of the engine

at 1400 — 1600 Rev/min, kgf x m……………………………………………………76

Average speed of movement, km/h:

on a dirt road……………………………………………………………………..15 — 25

at chosse……………………………………………………………………………………..30 — 35

Maximum design speed on highway, km/h ……………………….. 45

The reserve fuel, km

on a dirt road……………………………………………………………………..230

at chosse……………………………………………………………………………………..360

Fuel capacity, l………………………………………………………………………….400

The stock of oil in the lubrication system, l…………………………………………………..40

Booking, mm:

Borta…………………………………………………………………………………………..13

feed, roof, bottom …………………………………………………………………. 6

Weapons:……………………..85-mm gun D-70, 7.62-mm machine gun SGMT,

7.62-mm automatic AKMS, 15 hand grenades f-1

Ammunition:……………..45 rounds for the gun, 2000 rounds for the machine gun,

300 rounds of ammunition for machine guns, 20 bullets to the signal pistol

Overcoming obstacles

maximum angle of elevation, deg………………………………………………….30

the maximum roll angle, deg………………………………………………………20

the width of the ditch, m ………………………………………………………………………………2,5

fording depth, m…………………………………………………………………………..1,0

wall height, m…………………………………………………………………………… 0,7

N. JAY