Not so quickly wear out brake disc of a passenger car. But there comes a time when this detail is replaced by new, and old simply thrown in the scrap.

Not so quickly wear out brake disc of a passenger car. But there comes a time when this detail is replaced by new, and old simply thrown in the scrap.

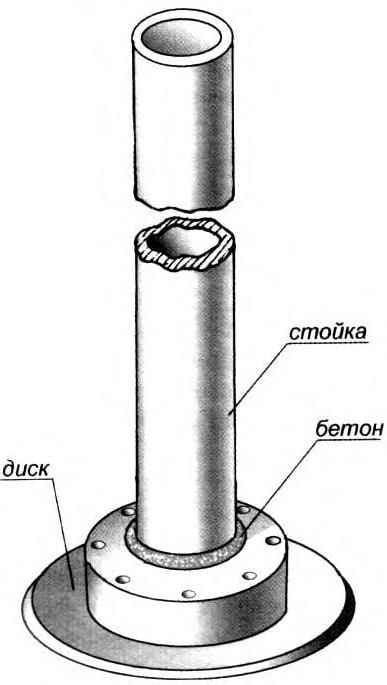

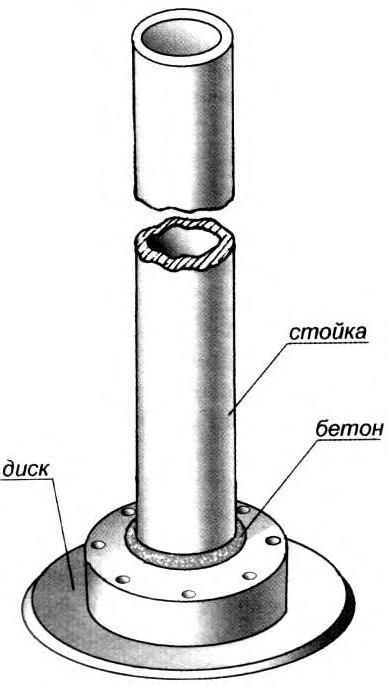

Meanwhile, the used drive can find a better use; for example, it can be used as a support for loose (free) pillars for various applications: from stand-trestles used for insurance when “Padmasana” repairs to a practical outdoor coat hangers racks.

To connect the parts, the internal cavity of the disk can be filled self-expanding or non-shrink concrete mixture, and immerse it in the pipe. If necessary, welding parts need a special electrode, since the disc material is gray cast iron. If such an electrode is not, then you can use a two-component paste “cold welding”.

When possible, a face edge of the disk to its entire height should be chamfered at an angle of 60°, so you don’t accidentally stumble over it.

A. SLEPOV