Motorists know how important it is for diesel internal combustion engines proper installation of the moment of ignition — the ignition spark of the spark fuel in the cylinder before the end of the compression stroke. In theory it should occur exactly at the end of this cycle. In practice, use a small spark advance below the maximum dissipation was carried out at the beginning of the next measure — extension. Otherwise you will not get far: the motor is getting “greedy”, but “pulls” very bad.

Motorists know how important it is for diesel internal combustion engines proper installation of the moment of ignition — the ignition spark of the spark fuel in the cylinder before the end of the compression stroke. In theory it should occur exactly at the end of this cycle. In practice, use a small spark advance below the maximum dissipation was carried out at the beginning of the next measure — extension. Otherwise you will not get far: the motor is getting “greedy”, but “pulls” very bad.

“Strays” is the ignition fairly often like due to wear of the parts in the timing system, and because of riznosortnoho gasoline even of the same brand. Therefore, to regulate the so-called ignition timing, owners of cars and motorcycles (especially is not new) more often than I would like. In a home workshop this operation requires a certain experience, if not to say, of art. There are many ways to “catch the moment”: the depth of Tangenziale, leaf tissue paper, etc., However without intuition and a lot of patience is also unlikely to work, because the installation angle should be done with extreme care.

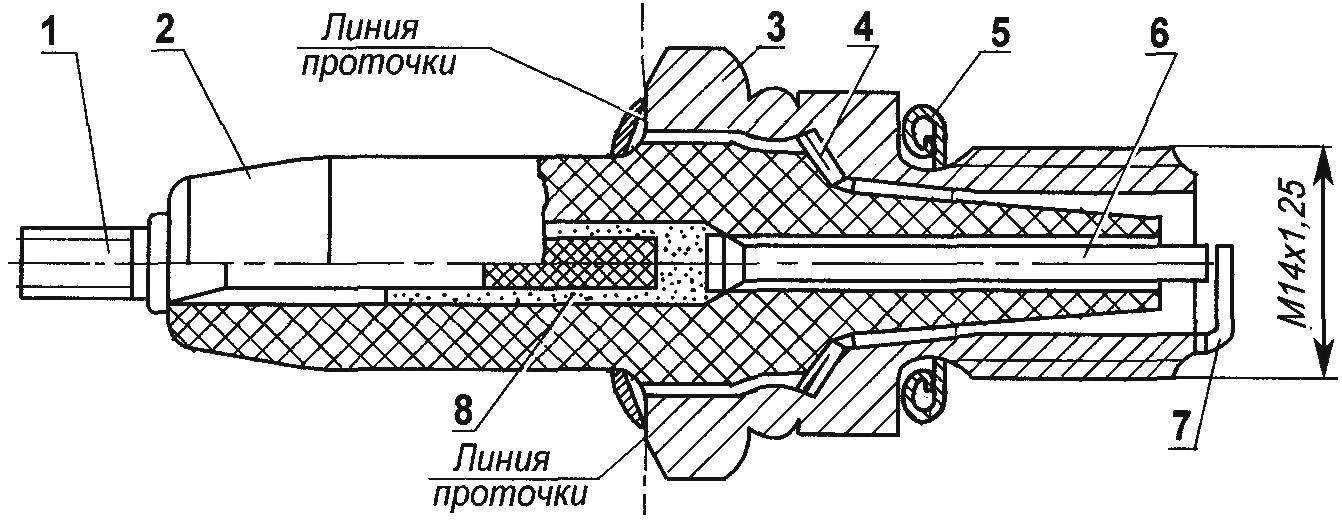

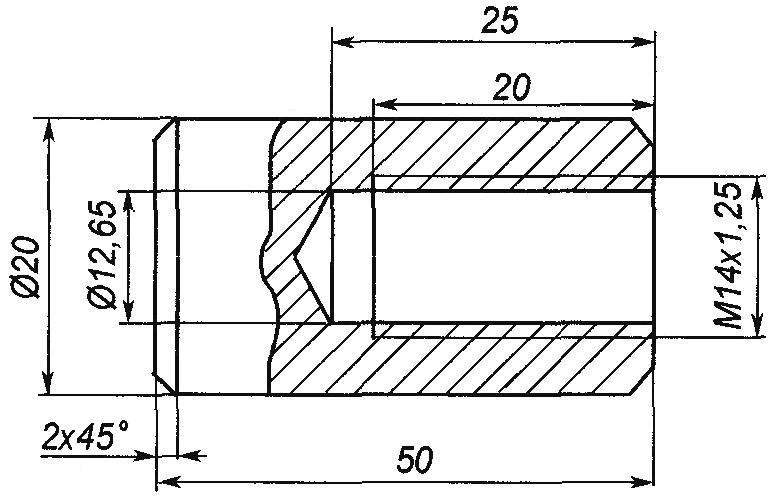

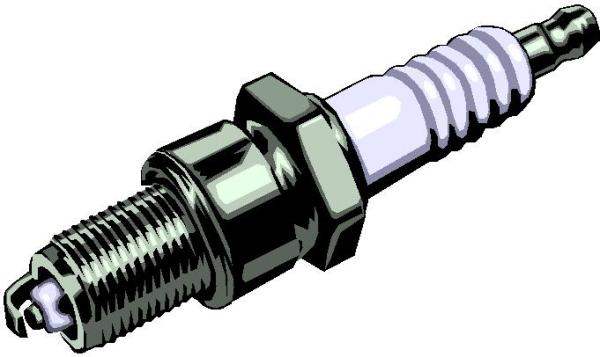

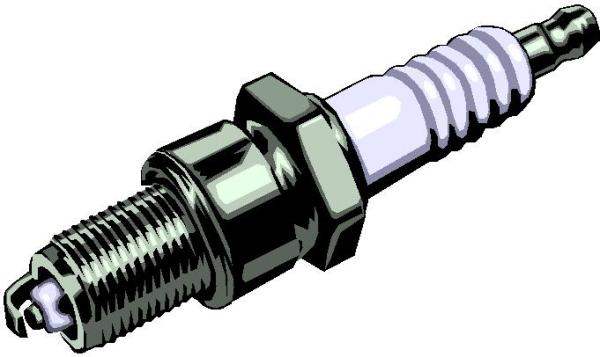

The proposed device, let’s call it the determinant of the moment of ignition (OMZ), greatly facilitates this task. It is made from used spark plugs from the same engine that you find will not be difficult, especially when a car or a motorbike already “experienced”. The upper part of the metal case candles (zahlcovany bezel) must be machined on a lathe before the start of the hexagon (nuts) to be able to pull out a porcelain insulator with a tungsten center electrode. In order not to damage the threads on the “skirt”, our candle is better by screwing it into the fixture, which is a steel cylinder, which made the end threaded hole М14х1,25, where and screwed into the candle. The insulator can be free and with a file, although the operation is in this case more time. A file it is necessary to remove and the side electrode.

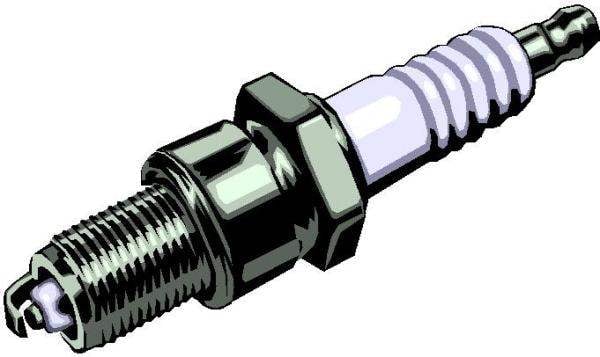

Spark plug:

1 — contact pin; 2 — insulator; 3 — body; 4 — heat-washer; 5 — a sealing ring; 6 — the Central electrode; 7 — side electrode; 8 — conductive steklokeramika

Device for grooving the body of the candle

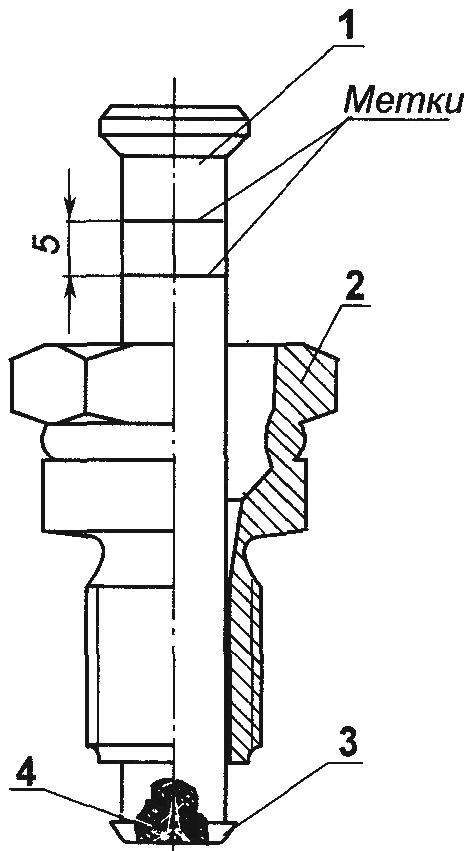

The determinant of the moment of ignition:

1 — the slider (metal, plastic, wood); 2 — body; 3 — washer (metal, plastic, wood); 4 — the screw or bolt

Now you need to make a runner of any suitable material: metal, plastic, wood. The stem diameter of the runner is slightly smaller than the inner diameter of the “skirt” of the candle, and the diameter of its head — to 7 — 8mm more. Stem length should be such that when screwed into the plug socket of the fixture and the location of the piston in the top dead point of the lower mark on the head slider slightly towered over the nut of the determinant of the moment of ignition. In order that the runner did not jump out from the casing, its lower end can be slightly flared or screwed to the face of a restrictive washer with a diameter of 10 — 11 mm. On the web runner apply a second circular risk — 5 mm above the first.

Setting ignition timing is performed in the following order.

1. Removing candle of the first cylinder, set the engine piston at top dead centre (TDC) (instructions for this engine).

2. In place of the twisted candles screwed fixture determinant of the timing — until then, until the lower risk of the slider is aligned with the top plane of the nut OMZ.

3. Now manually little by little we lower the piston by rotating the crankshaft against the direction of the labor movement, until now the top risk of the slider is aligned with the top plane of the body of the tool.

In this position of the piston should be open contact breaker that can be checked by using a probe tester or just a piece of tissue paper.

R. KRAVTSOV, the teacher of technical work, city of Yeysk, Krasnodar Krai

Recommend to read

THE RADIATOR FOIL

THE RADIATOR FOIL

Fast and simple — to manufacture heat sinks for transistors and microcircuits made of copper or aluminum foil with a thickness of 0.1—0.3 mm. Plates are cut with scissors, carefully... “RUZANKA” FOR A FEW MINUTES

“RUZANKA” FOR A FEW MINUTES

Chopper roots, so necessary to provide domestic animals with vitamins ("rezanci"), I have constructed on the basis of АТД2 charged — device Tu-Kovacevica disk, which managed to find...

Motorists know how important it is for diesel internal combustion engines proper installation of the moment of ignition — the ignition spark of the spark fuel in the cylinder before the end of the compression stroke. In theory it should occur exactly at the end of this cycle. In practice, use a small spark advance below the maximum dissipation was carried out at the beginning of the next measure — extension. Otherwise you will not get far: the motor is getting “greedy”, but “pulls” very bad.

Motorists know how important it is for diesel internal combustion engines proper installation of the moment of ignition — the ignition spark of the spark fuel in the cylinder before the end of the compression stroke. In theory it should occur exactly at the end of this cycle. In practice, use a small spark advance below the maximum dissipation was carried out at the beginning of the next measure — extension. Otherwise you will not get far: the motor is getting “greedy”, but “pulls” very bad.