First, second, third… Three racing car across the finish line three car team of the Soviet Union. Long-awaited success! So in 1975, ended in Minsk in the first stage of the Cup of friendship socialist countries.

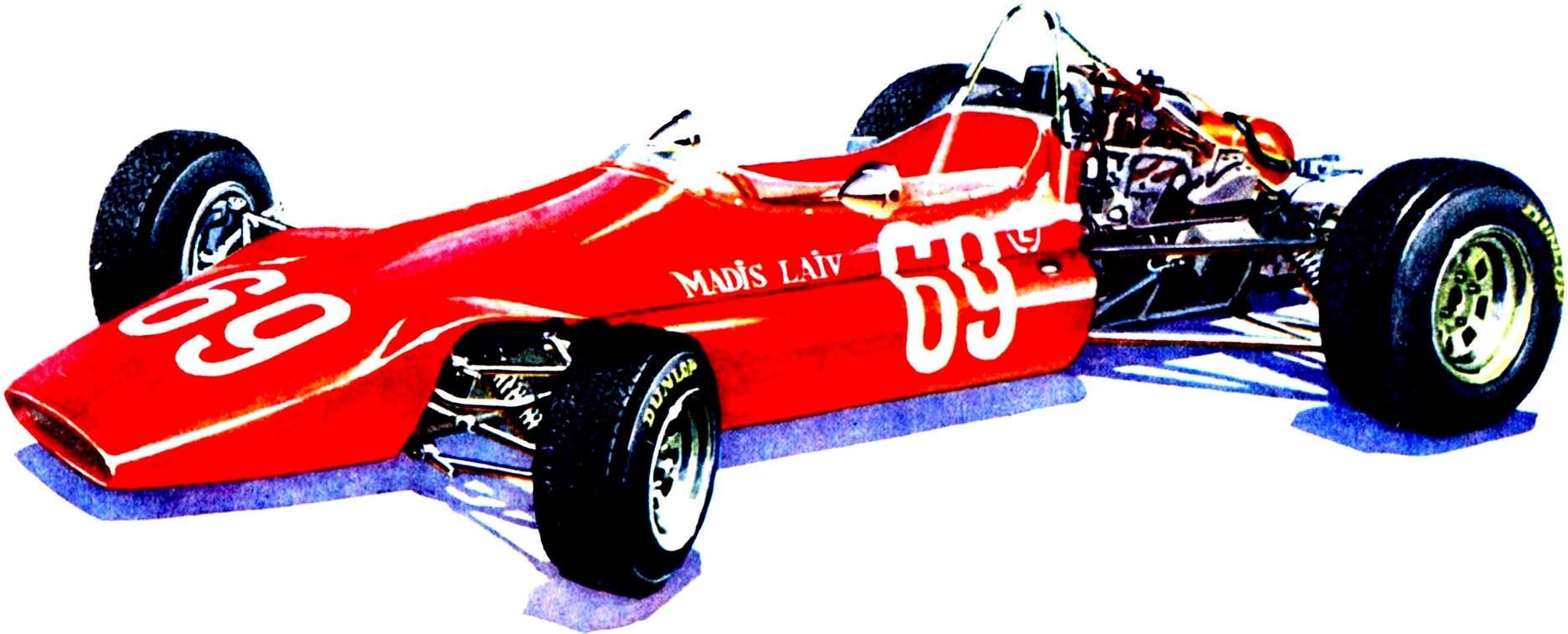

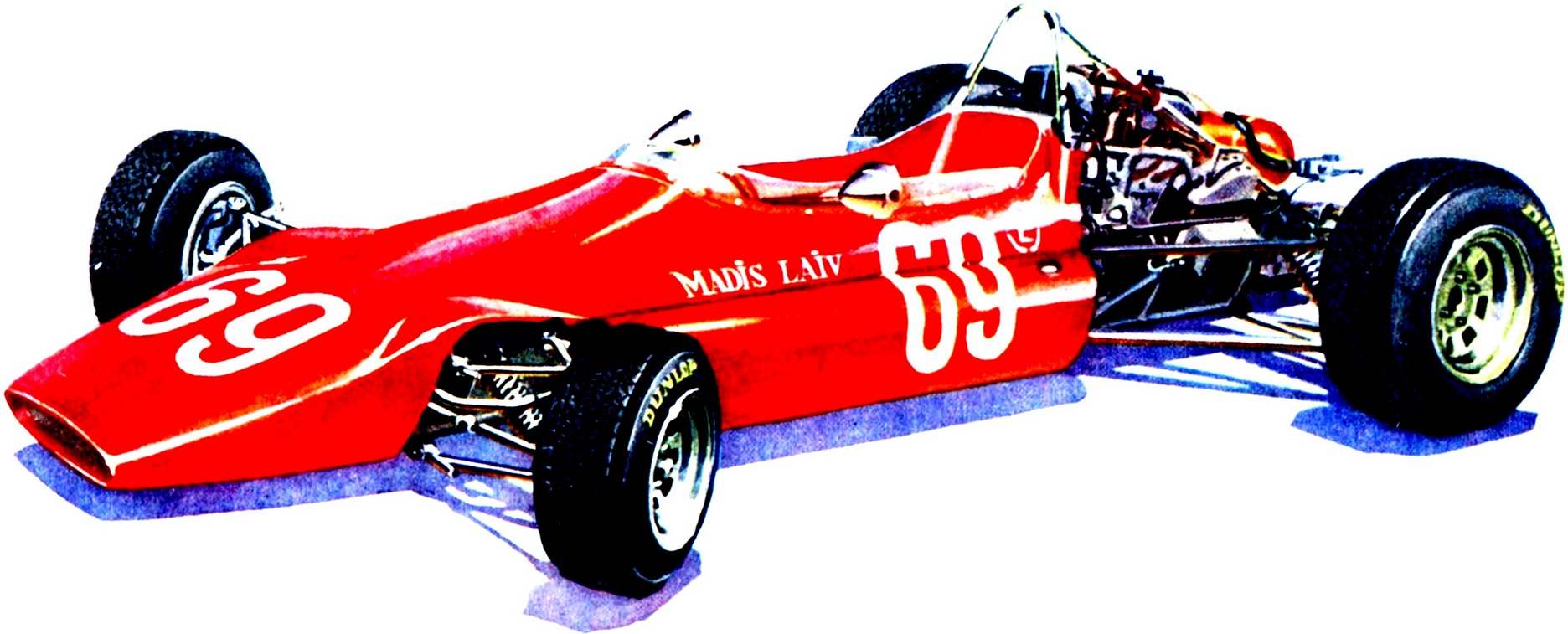

First, second, third… Three racing car across the finish line three car team of the Soviet Union. Long-awaited success! So in 1975, ended in Minsk in the first stage of the Cup of friendship socialist countries. It was played in five stages. Subsided when the motors after the final race in the Polish city of Tarun, it became clear that the sum of the points Cup was won by the Soviet athlete Madis Live domestic car “Estonia-18”.

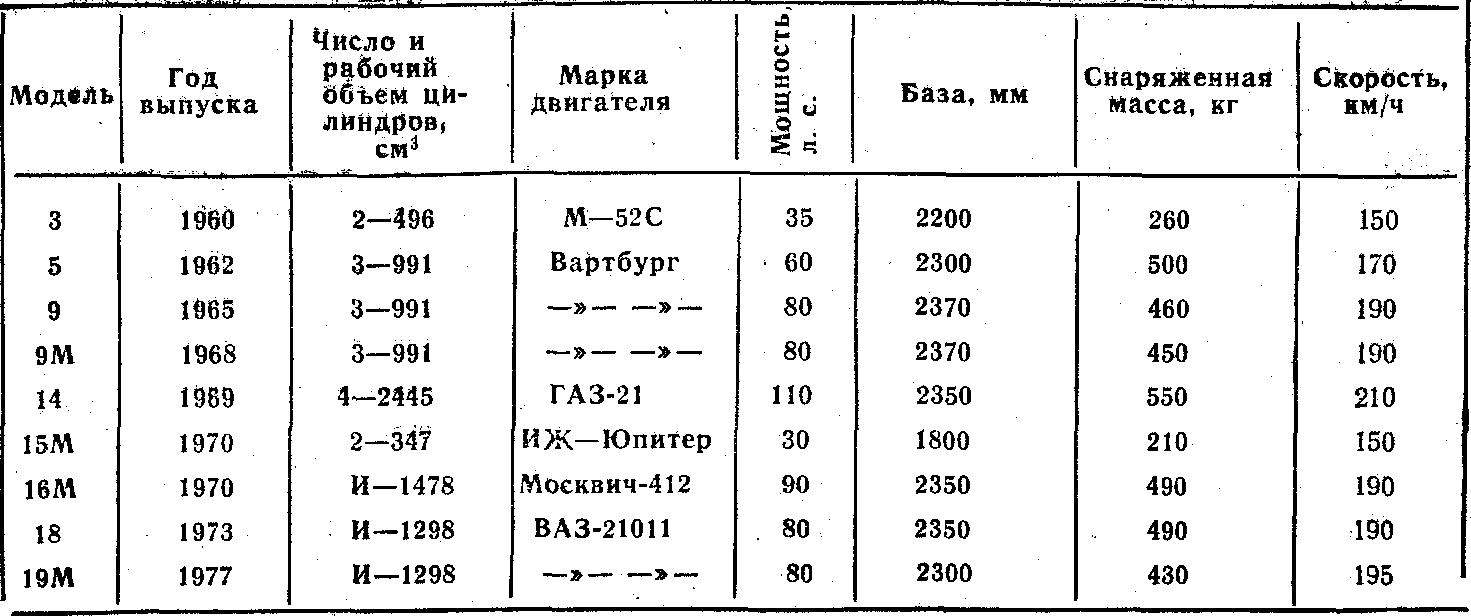

It began to produce small batches since 1974, Tallinn experienced repair plant (TOURS). The company, the main profile of which — repair of trucks and buses, has started construction of racing cars in 1958. The first machine was fitted with motorcycle engine and wheels. Enthusiasts of motor sport Ante Seyler, Peep Velbri late Eino, Loorits, Calle Keel and others tirelessly worked to create more sophisticated designs (and their brief characteristics are given in the table). All racing “Estonia” had a rear engine, independent spring suspension on all wheels (only models with index 1, 3, and 4 elastic element of the front suspension was a transverse spring], tubular frame, rack and pinion steering.

In total, 21 year TOURS produced almost 700 different racing cars, and some of them (“Estonia-3, -9, -9, -15, -15M, -16M, -18”), he produced in large quantities. Recently, the plant annually makes 50 cars. This year manufactures only “Estonia-19M”. The scale of production TOURS put on a par with well-known companies racing cars such as Chevron, RALT, MARCH, Lola, etc.

The most popular and successful among the “Estonia” has become “eighteenth”. Not to mention numerous victories in the Championships of the Soviet Union and other representative competitions, “fighting” the car, the three first, five second and four third places in the race for the Cup of friendship socialist countries.

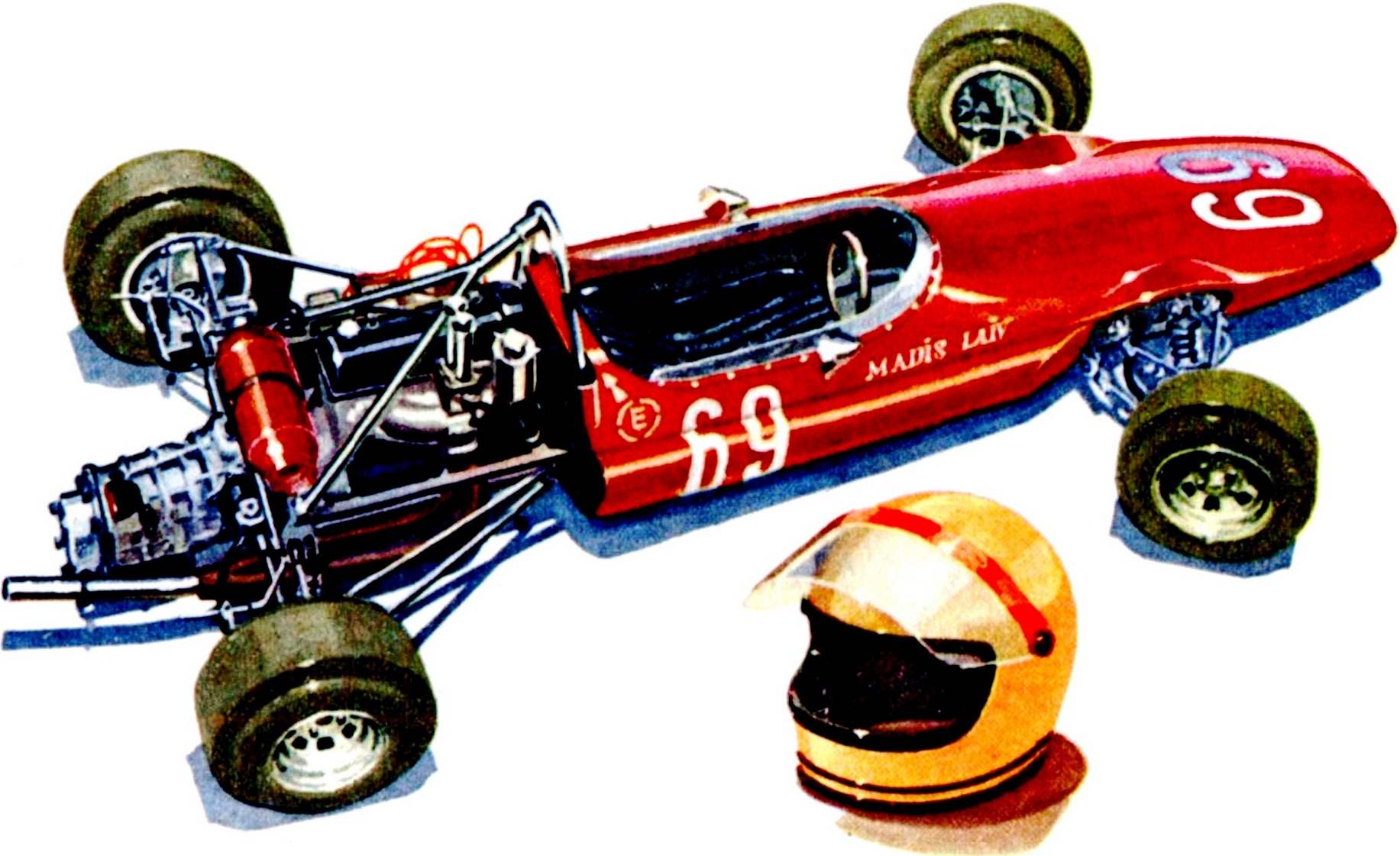

“JUNIOR-18” racing car “Estonia”.

“Estonia-18” a lot of kindred with early designs of the plant — 9M and 16M. The commonality is visible in the suspension, wheels, brakes, steering, transmission, etc.

It is this continuity has allowed in his time efficiently and with low cost to move from car 9M to 16M, and from it to 18.

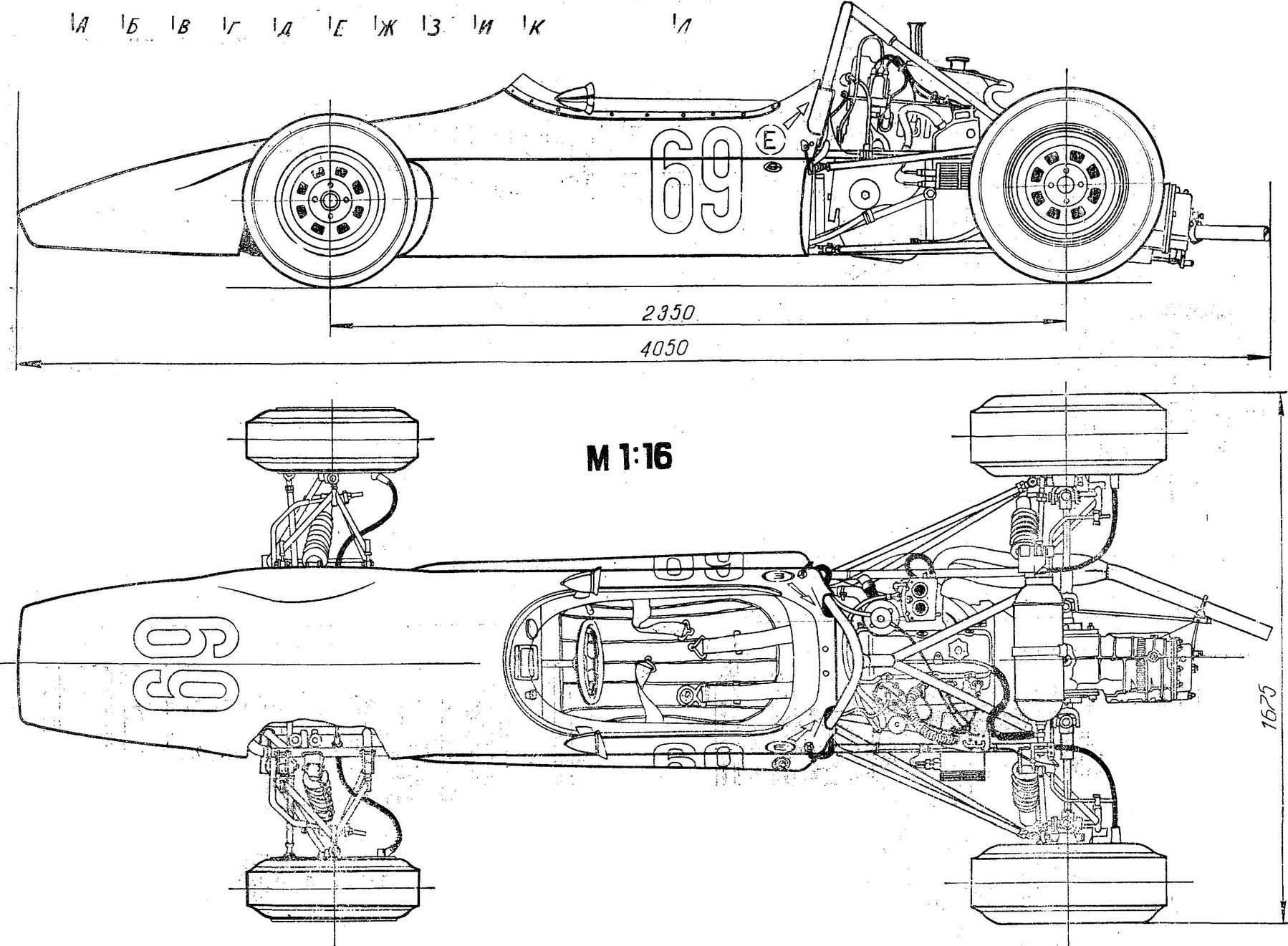

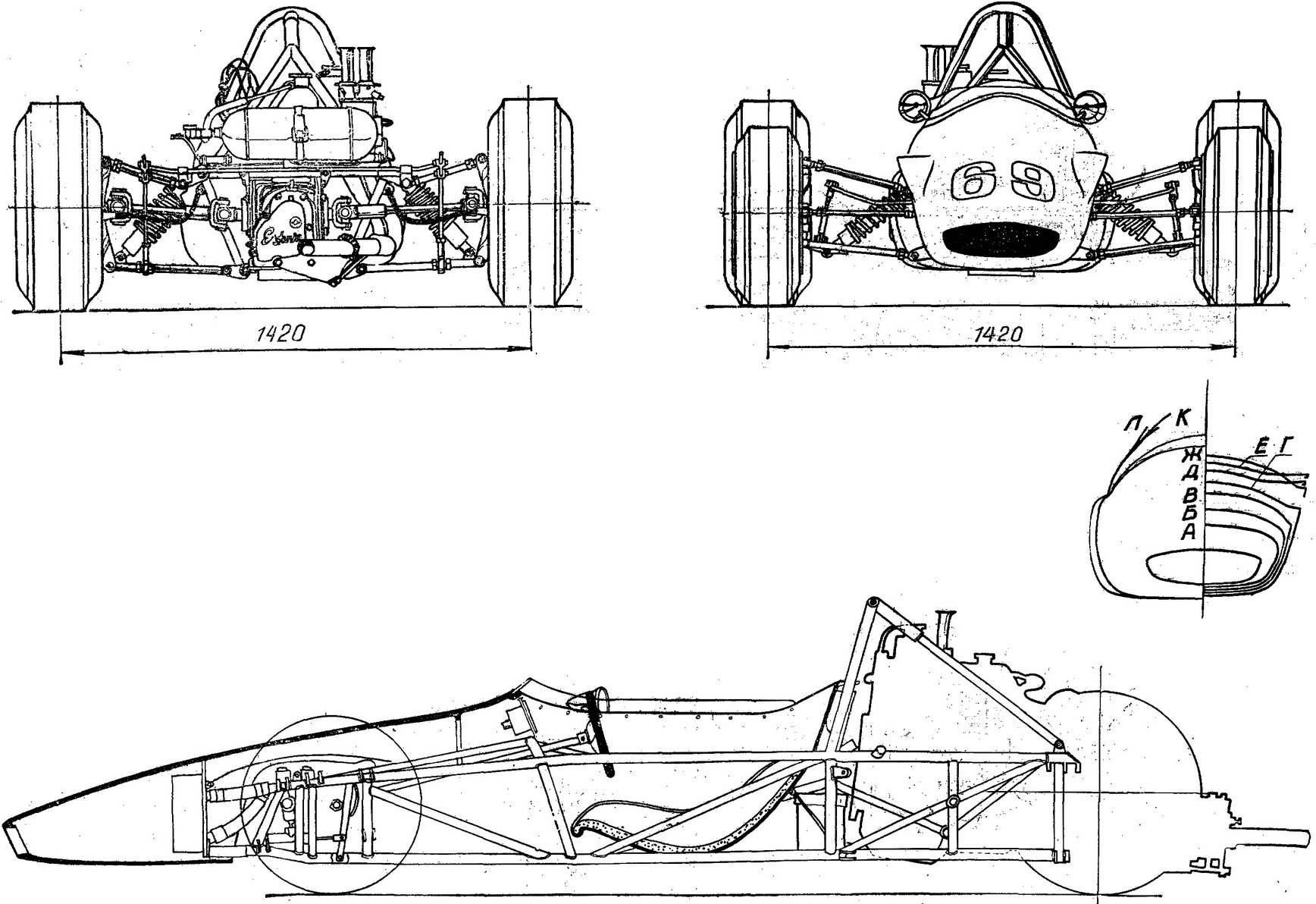

The basis of the car is a rigid frame, welded in the form of spatial farm from hromansilevyh (steel 30KHGSA) pipes with a diameter of 20 mm and 30 mm with wall thickness of 1,5 mm. Mandatory technical requirements the protective arc behind the rider is an integral element of the frame and are made from a 36-mm pipe with 2 mm walls. To the frame, weighing about 40 kg, the connected wishbone independent suspension front and rear wheels, and by means of ball joints with contact “metal—metal”. (The rubber bushing in the suspension of a race car is completely invalid — they create unnecessary elastic “layer” between the wheels and the frame, distorting the kinematics of the suspension and affect the behavior of the car on the road.

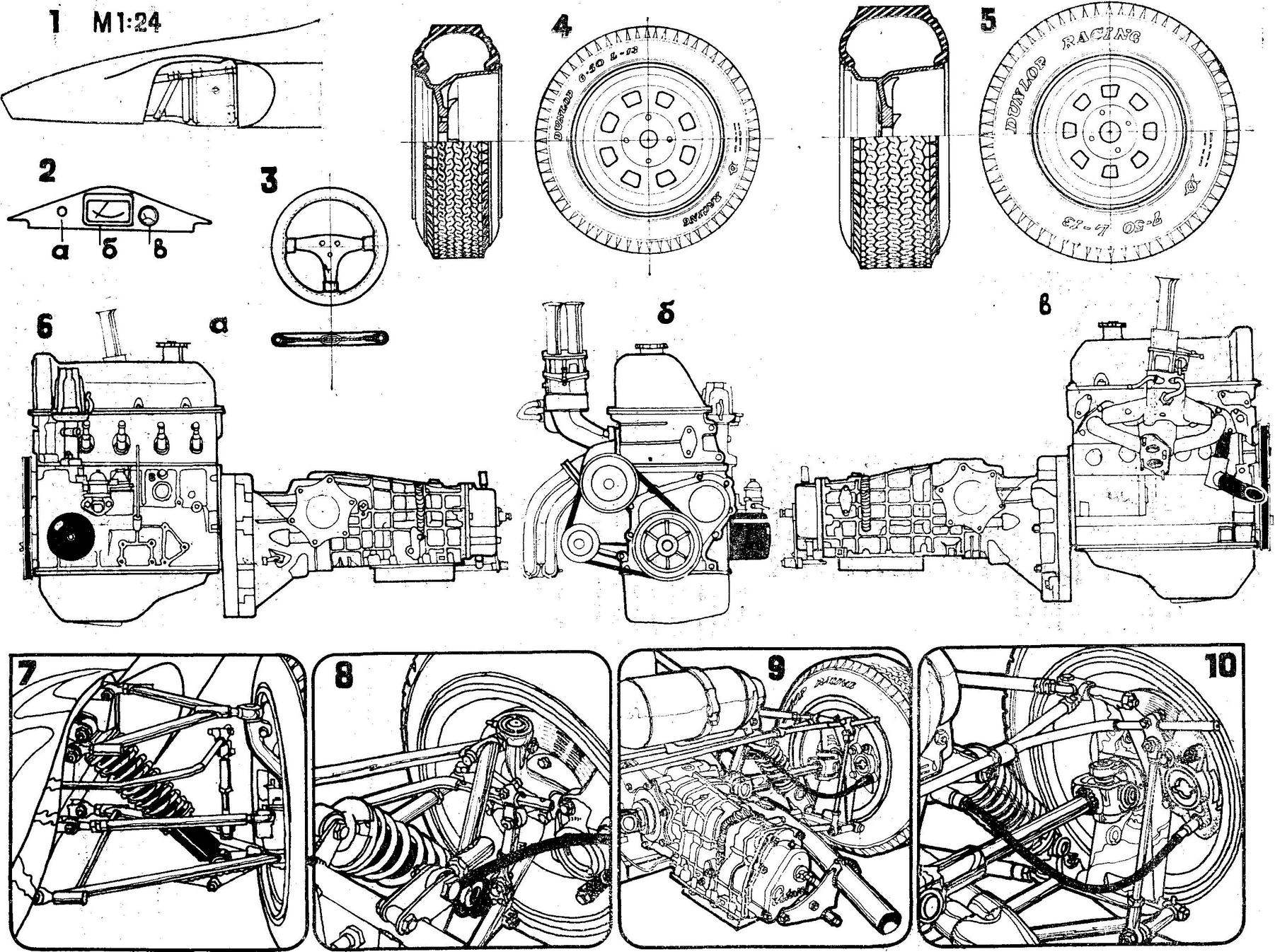

Components and assemblies “Estonia”:

1 — look at the body on the left with the removed suspension, 2 — instrument panel (starter button, b — tachometer, a temperature gauge), 3 — steering wheel 4 — front wheel 5 — rear wheel 6 — engine VAZ in the block with the box “Tours” (a — right view, b — front view, b — left view), 7 — front suspension, front left, 8 is front suspension, rear view on the right, 9 — gear box and rear suspension, 10 — link rear suspension, rear view.

For comparison, imagine a spring cutter in the lathe caliper or stretch the lead in the pencil of the artist.

To the rider to accurately “steer” the behavior of the car at each moment of its movement, you need more hard (not to be confused with the concept of “durable”) frame, with very small deformations under twisting (e.g., in a situation when the left front wheel goes up and right back down]. In addition, we need a combination of size and displacement of the moving parts of the suspension, i.e. its kinematics, so that in turn they provided conceived and specified by the designer, the behavior of the car.

Another feature: a racing car suspension components do adjustable to customize it in accordance with the individuality of each race track. And “Estonia-18” is no exception. She can simply and quickly change the gathering and the collapse of the front and rear wheels, the stiffness of the springs, dampers and stabilizer bars. The exact selection of parameters of the suspension according to the nature trails for getting good results means nothing less than the high power engine. That’s why the designers “eighteenth” paid a lot of attention to this significant features of the suspension system.

A significant part of the life of a race car is cornering, in the struggle against the centripetal force. Her struggles to side traction. The higher it is, the more speed you can go in curves, but to get the higher value of this force, we need special racing tires with wide flat tread. “Estonia-18” on the front wheels fitted with tyres in size 6,50—13, and on the back of 7.50—13. Motorists will notice that this is somewhat of a value “shoes” wheeled tractor. Yes, because the rear wheels have about 60% of the total weight of the machine.

Many drew attention to the fact that when cornering with high speed the tire “tucks”, losing traction. Racing car this phenomenon is especially harmful, and therefore the tires “Estonia” mounted on wide rims (front 190mm, rear — 230 mm) cast magnesium alloy ML5. What gives! Cast drive this car about twice as heavy as steel stamped “Lada”.

Refer to the “anatomy” of a racing car. Its powertrain — the engine VAZ-21011 in the block with transmission, made on the basis of Zaporozhskiy installed in the back. The reasons are many. Assembled in one compact unit, it is easier than a single engine with gearbox, propeller shaft and gearbox of the Main transmission. From the back, it ensures an optimal utilization of the rear wheels, and allows you to give the car aerodynamically sound shape.

The rider is reclining in the seat, backrest of which is inclined to the horizon at an angle of 50°. The sides of the seat, rigidly associated with the frame, tightly cover the body, against the car driver is like a hand in a tight glove. Thus, it conveys the slightest movement of the car, and he can respond immediately to them.

In the wedge-shaped space under the seat is the battery, in front of the steps of the legs of the rack and pinion mechanism, and a little further on, in the fore part of the body, — the radiator. Along the right side of the machine is the rod connecting the transmission with the shift lever. And on the left, between the trim body and frame, long and narrow aluminum fuel tank 40 L.

Back to the engine. As you know, racing cars are divided according to structural features into classes. Complex technical requirements to each of them is quite extensive and is called “formula”. Respectively, and the machines themselves called the cars of formula 1, 2, and so on.

“Estonia-18” applies to the racing cars of the so-called formula “East”. Technical requirements dictate that the motors they were taken from the serial cars with minimal alterations. “Eighteenth” has a motor, which removed the air filter, changed the design of the exhaust pipe, no silencer, introduced a number of other changes. Therefore, the engine power is not 68 for a serial VAZ-21011, and 80-82 HP

For gear box used “Zaporozhye” Carter, filled with the completely different gears, shafts, bearings. Transmissions do not have synchronizers, gears rotate on needle bearings and the whole design is such that, without removing the transaxle from the vehicle in less than an hour it completely “bust”, replacing all the gear. This design feature dictated by the specifics of the race. Each track requires a certain combination of gear ratios in the gearbox, and depending on the power of the engine, the tyres and other conditions, the driver must be able to quickly assemble the right set of gears.

Dry weight “of Estonia-18” (without rider, water, oil, fuel) — 490 kg and its total weight (at the start) is equal to 620-630 kg. given that the maximum speed reaches 190-195 km/h, the car needs an effective brake (not just able to stop the car, and smoothly, without overheating and other effects, operating at numerous consecutive brake applications). For this are disc brakes whose diameter front 250 mm, rear 240 mm. They allow you to stop the car going at a speed of 172 km/h, at a distance of 120 m.

Of course, when driving at high speed need steering gear with small gear ratio. To rotate the front wheels “of Estonia-18” from stop to stop (i.e. at 29° to the right and 29° to the left) have to do only 1.6 turnover steering wheel, having a diameter of 250 mm. Recall that the “Moskvich-412”, like other cars, the number of turns of helm from lock to lock and 4.2. “Estonia-18”, thus to “zero” you have to put almost three times more force, but its steering allows the driver to quickly adapt the direction of movement of the machine.

The main brands of cars “Estonia”

Of course, the “quick steering”, effective brakes, protective arc greatly ensure the safety of the rider. What else helps to improve on “Estonia-18”? A separate drive brakes front and rear wheels, four-point seat belts, outer breaker (in case of emergency) the electrical system finally, the system of fire extinguishing.

This system includes the fire extinguisher is connected by pipes with nozzles, which are installed in fire hazardous areas of the machine. In the event of an accident the system can be selected from the compartment (cockpit) of both the rider and the outside.

The first prototype of the “eighteenth” was made in 1972, and then the Yuccas Reintam won him a silver medal at the national championship. Since then, the Championships of the USSR on “Estonia” won three gold, four silver and five bronze medals.

In 1976 at the races appeared a modernized version of the car “Estonia-18M”. She had two side of the radiator, mounted just before the rear wheels. This allowed to additionally load them and give the bow of the body a more streamlined shape.

On the basis of “Estonia-18M” Moskvich V. Barkovsky, and T. tallinen NAPA has built their own modifications, called BPS and “Tallent”. They had the front fairings, aerodynamic side covers, radiators and more perfect body shape.

Since 1977, TOURS based on proven designs “of Estonia-18M”, started production of machines with index 19, with the wedge-shaped body and lightweight chassis parts.