Compact car KIM-10-50 release 1940. Economy cars have always been interested in the mass market for its relative cheapness, compactness and simplicity of design. They attracted automakers such as low cost, processability and high demand.

Compact car KIM-10-50 release 1940. Economy cars have always been interested in the mass market for its relative cheapness, compactness and simplicity of design. They attracted automakers such as low cost, processability and high demand.

In Russia the first experience of creating a small car was a car US-1, designed by the Central Scientific research automobile and automotive engines Institute Konstantin Sharapov and produced in small quantities at a Moscow factory “Spartak” from 1927 to 1930. Compact four-seater car with a tubular spine frame equipped with a 22-horsepower engine and can accelerate to a speed of 75 km/h. However, the production of such vehicles is mainly for individual buyers, were clearly not at the time in the period when the entire state ideology was focused, primarily, on the products of collective use. And the possibility of factory “Spartak” (until 1917, it was a car-crew factory Peter Ilyin) was allowed to produce cars only in small series (in three years the plant has produced only about 400 cars).

The idea of creating a small car for the buyer-an individual in the Soviet Union returned to a relatively stable — from the point of view of the economy — the prewar period. Production base for the manufacture of such a machine was elected to the Moscow automotive plant named KIM — Communist youth international (up to 1938 he was engaged in assembling the “trucks” FORD-AA and GAZ-AA from the kits supplied by Gorky automobile plant) — the decision in January 1939 was taken by the Glavavtoproma of the people’s Commissariat of medium machine building.

In order not to “reinvent the wheel”, the domestic small car took the tried and time-tested English car Ford Prefect of the sample 1936.

The prototype of the first Soviet mass of a small car was an English Ford Prefect

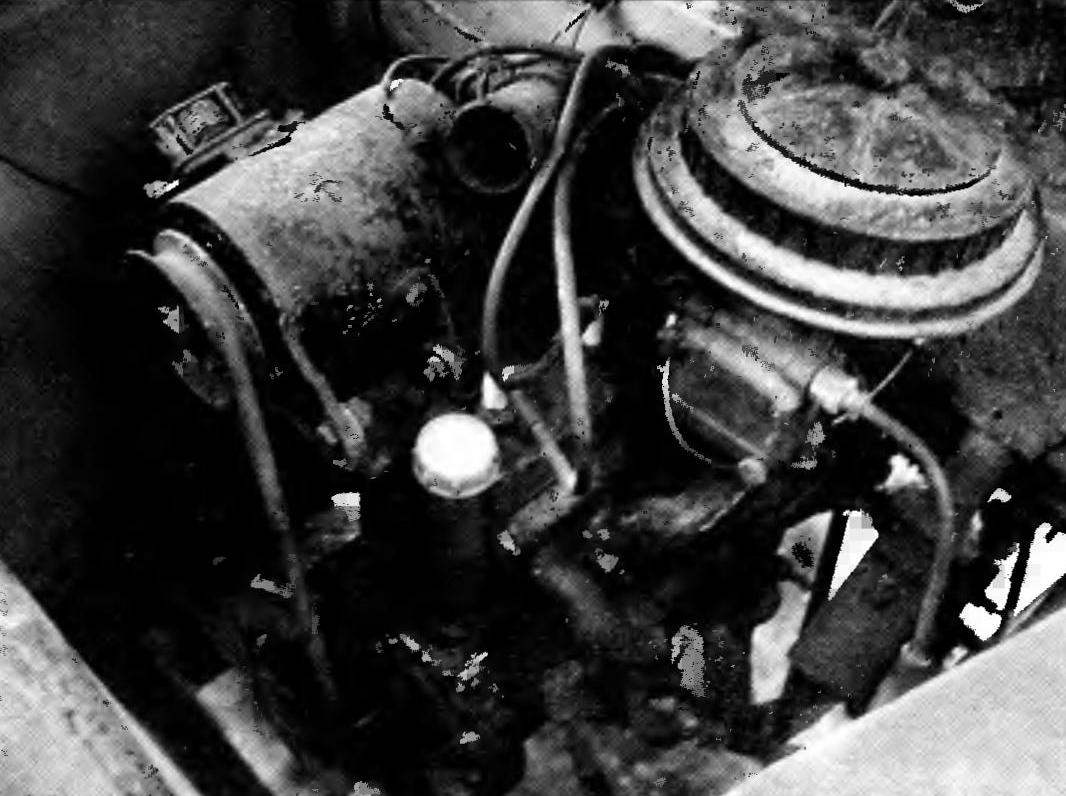

Car-the prototype had a frame construction and solid axles on transverse leaf springs inverted. Engine Ford Prefect was in-line, 4-cylinder, nineleven, with a displacement of 1,172 liters capacity it was 26 HP and a maximum vehicle speed reached 98 km/h I Must say that the Ford Prefect was produced in two-door compact and a four-door version. However, for Soviet car was chosen-only two-door version — the fact that doors represent a fairly complex element of the car, not to mention the fact that fitting them to the openings in terms of mass production — the operation is difficult and much hard work.

The construction of the chassis and engine of the new car was entrusted to group of designers NACHI, which was headed by A. N. Ostrovtsev, chief designer of the Moscow automobile plant named KIM, and the design of the body has engaged experts of the Gorky automobile plant.

The body design developed by the artist group body Gas V. Y. Brodsky, who created the generalized image of “explanation” of Ford Prefect and Buick Roadmaster by Many experts of the time claimed that in the process, the artist-designer was able to design a better body than that of the prototype. So, the car disappeared already becoming archaic foot pegs, windshield from a flat turned into a V-shaped, and the hood for the first time in domestic science became alligator. Note that the latest prototype consisted of a pair of folding wings — as in “Ehmke” M-1.

And for the first time in the domestic automobile front seat separate, equipped with a mechanism of adjustment. By the way, car strip separate front seats appeared only on the “Volga” GAZ-21 in version taxi.

Stamps and debugging batch of 500 sets of body panels were ordered from an American company BUDD. In their further manufacture, as well as cast billets were supposed to be on the Gorky automobile plant. Forgings, springs, and frame was supposed to make Moscow ZIS. The production of many components needed for the new machine, was supposed to organize on 42 companies-suppliers. Well, to assemble a runabout was the Automobile plant named KIM.

The geometric scheme of the micro-cars KIM-10-50

The prototype car KIM-10 — he looks different from the production model the headlights mounted on the fenders of the car

Serial KIM-10-50

Serial production of cars was planned at the beginning of 1941, it was planned to produce 2,500 cars per month, respectively, in the year — 30 thousand! In the future it was planned to increase annual production to 50 thousand cars.

April 28, 1940, was celebrated the completion of construction of the first plant and on may day demonstration in Moscow’s red square in a convoy of GAZ employees held three brand-new prototype vehicle.

Time was running out, the factory was in full swing preparing for serial production of KIM-10 — so called runabout. By the end of September the Assembly line was installed and on October 1 was appointed to his technological tests. To do this, three prototypes Kim was dismantled in order to be able to carry out a trial Assembly of the cars on the Assembly line, defining the optimal time of installation in different Assembly positions and to coordinate the Assembly time of different units.

When the pipeline delivered the re-assembled machines to the end of the Assembly line, happened unplanned incident. Those present at the trial Assembly, the photo correspondent of “Izvestia” has made a series of shots of the main conveyor, and the next day in the newspaper on the first page there was a photograph accompanied by the caption: “Yesterday with the main Assembly plant named KIM went first subcompact”. The next morning the newspaper came to the table to “best friend’s car -” comrade I. V. Stalin. I must say that at that time no plane, no tank and no car would not start production without his personal approval, and then — “went first subcompact”, and nobody even reported…

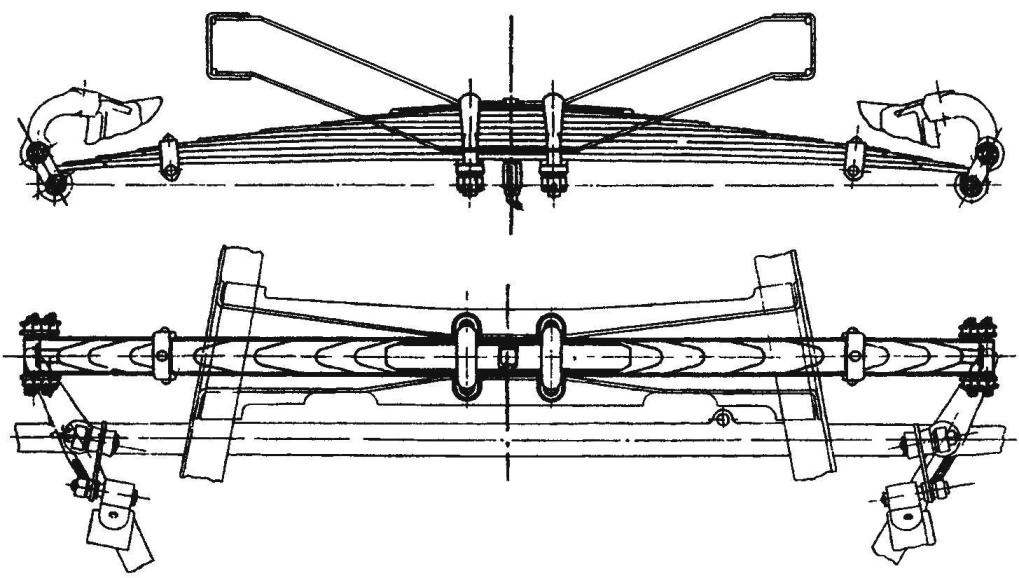

Front suspension KIM-10

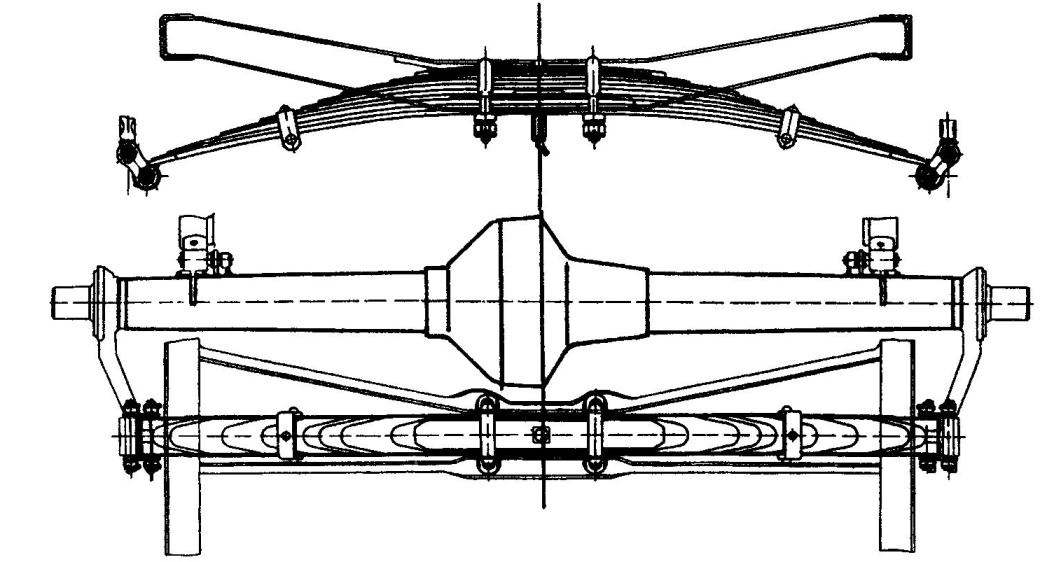

Rear suspension KIM-10

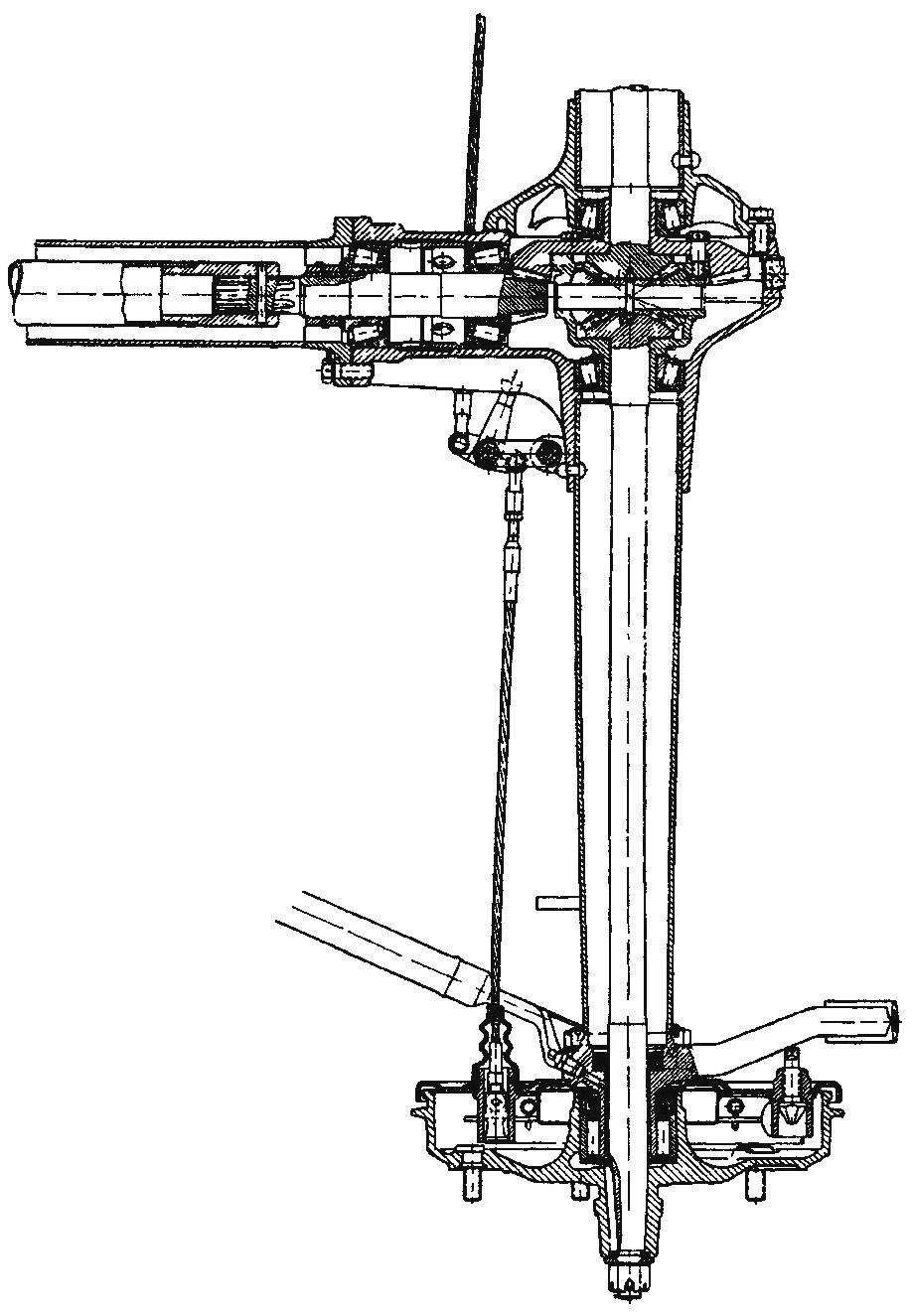

The steering mechanism of the vehicle

Rear axle

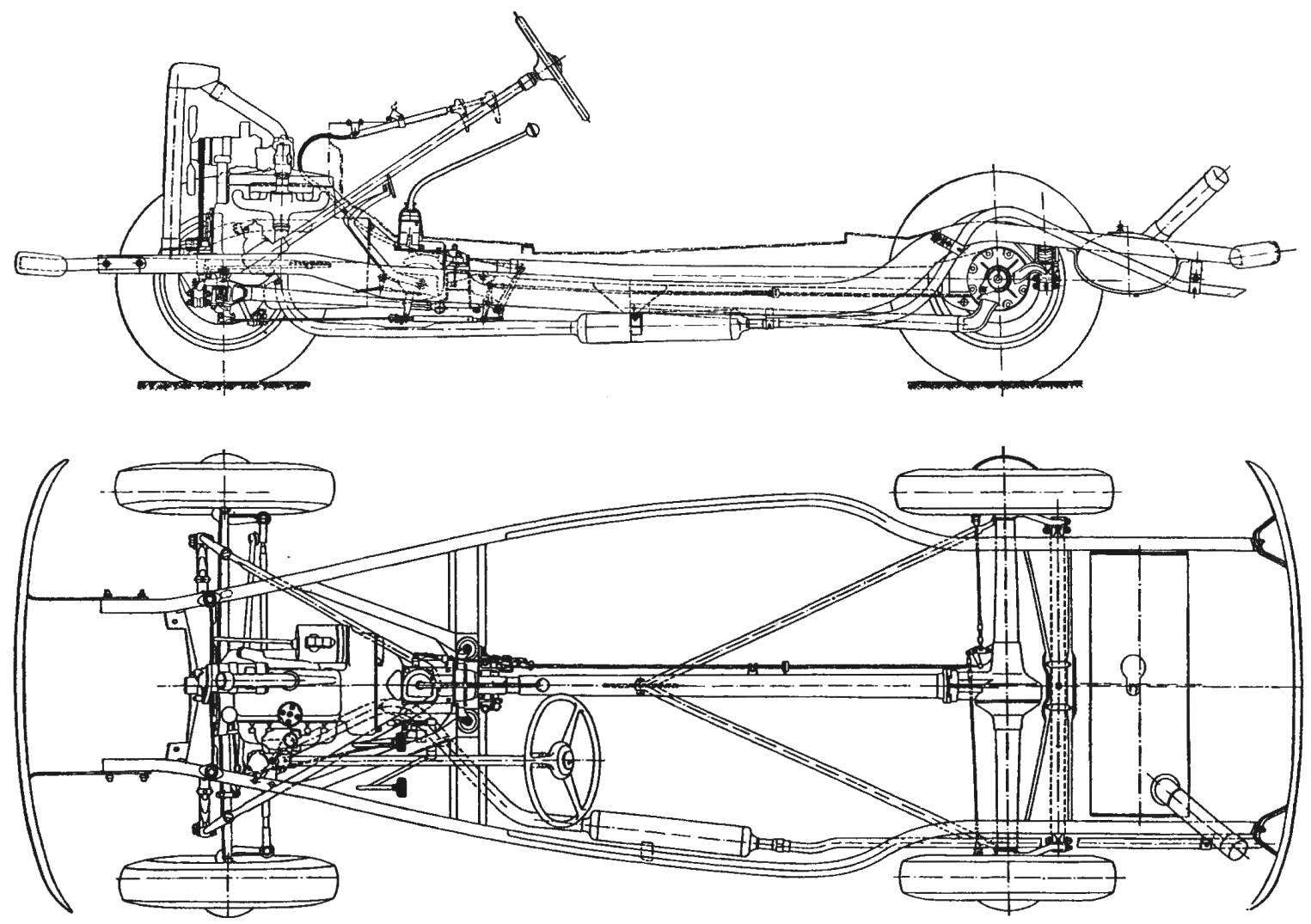

The chassis of the car KIM-10

Immediately followed by a call to the people’s Commissar of medium machine building And Lihacheva with the requirement to deliver the car to 12 hours in the Kremlin. Hasty attempts to “put the move” through the pipeline subcompact to success has not led to bring them into working condition was only in the afternoon. And, as a consequence, in this day of “best friend of car” refused to examine the new machine.

Failed inspection and had more long-term effects — the factory Director A. V. Kuznetsov was sentenced to 15 years imprisonment, and I. A. Likhachev demoted from the post of people’s Commissar was transferred to the Director of the Automobile plant named after Stalin. Later the bride at the highest level still held. However, not too successful. Two-door car did not like Stalin — followed by instructions to Refine the car, with another pair of doors. The leader gave “good” to produce 500 two-door vehicles already purchased in the USA body panels. But the alteration of the two-door four-door bodywork was entrusted to experts of the Gorky automobile plant Two prototypes of four-door subcompact KIM-10-52 on the Gas gathered — one of which you can admire in the capital’s Polytechnic Museum.

Limited production two-door KIM-10-50 began in late 1940. Unfortunately, before the war, managed to collect from American body panels only 498 sedans and a small number of phaetons KIM-10-51.

As further fate of the repressed commanders of automobile production? In 1942, when the ZIS awarding the order of Lenin for the defense order, Stalin asked Likhachev, which is needed for a smooth process of production. In response, the Director of ZIS asked to return to the factory A. B. Kuznetsov, the former head of production at ZIS. Convict Kuznetsov immediately was taken to Moscow and placed in the VMS, where he worked for his entire life. Well, Likhachev was able to return to the seat of the people’s Commissar (or more precisely — the Minister of motor industry) only after Stalin’s death. Ironically, in 1956, after the death of I. A. Likhachev, the ZIS Automobile plant named after Stalin were renamed ZIL Moscow automobile plant named after Likhachev.

After the war, when the question about deploying at the Moscow plant of small cars (that was the name of a former Automobile plant named KIM) serial production of the compact car, showed three prototypes — a captured Opel Kadett and Opel Olimpia and pre-war domestic four-door (!) KIM-10-52. Eyewitnesses claimed that the “best friend of motorists,” KIM didn’t even look, opt for a Opel Kadett, the future of “Moskvich-400″…

The design of the car KIM-10-50

Subcompact two-door four-seater car KIM-10-50 was the most progressive domestic pre-war car, the design of which has incorporated the most advanced technical and technological solutions in the global automotive industry.

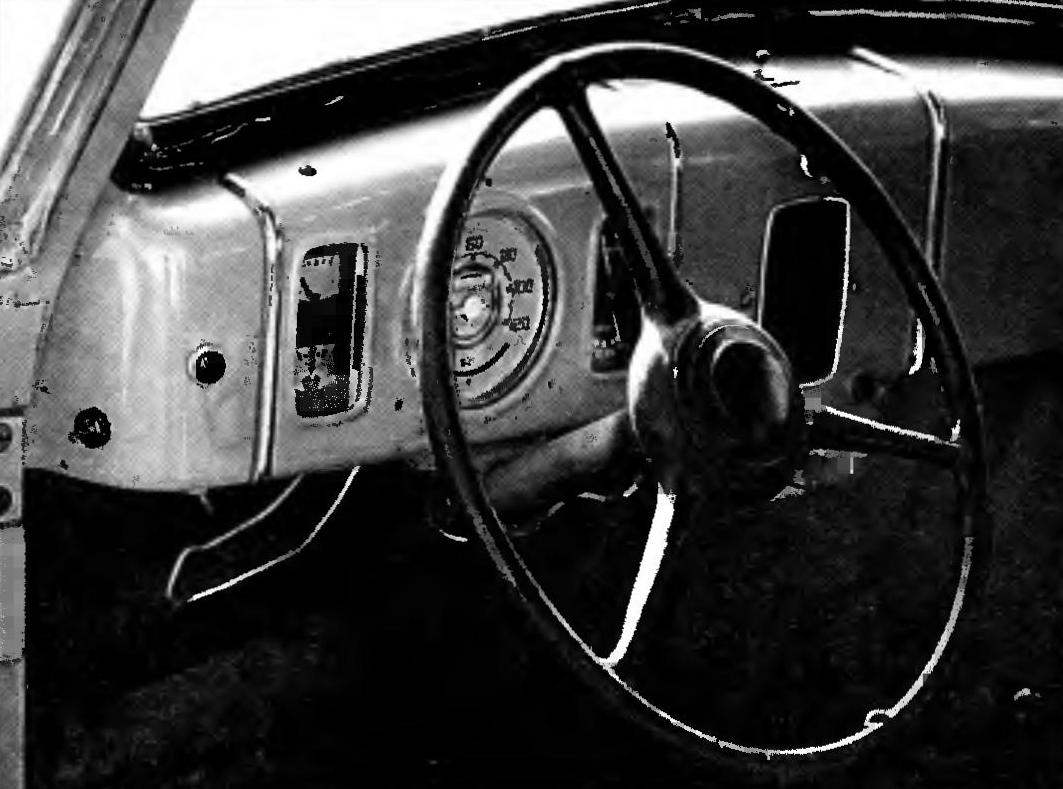

So, the new machine was an all-metal “polonesse” body with a lightweight frame, which receives the necessary stiffness only after connecting it with a body that brought modern design to the supporting bodies. For easy access to the rear seats the doors were made wider, and the backs of the front seats leaned forward. The chair is equipped with mechanism for adjusting their position. The machine is equipped with direction indicators of the semaphore type.

Dashboard KIM-10

Engine compartment of the car

The only extant pictures of the Phaeton KIM-10-51 was made in the besieged Moscow in late 1941

The prototype four-door cars KIM-10-52, designed in the design Bureau of the Gorky automobile plant.

KIM-10-50 completed a three-speed gearbox with synchromesh on the third and second stages, the ignition system had a centrifugal mechanism for changing the advance angle and the engine almost the first time in the USSR were equipped with bushings in the bearings for the journals of the crankshaft — before the neck was just filled with low melt babbit. Pistons made of aluminum alloy, and candles — for the first time in domestic science — had a 14 mm thread.

Unfortunately, Nizhnekamsky motor had significant shortcomings — its valvular mechanism did not have devices for adjusting gaps, the cooling system is not provided for the water pump — it worked for obsolete with modern machines thermosiphon principle. The spare wheel of a small car was located not outside, but in the special niche of the trunk.

The first samples of KIM-10 teardrop-shaped lights are fixed on the wings, and on production machines they were integrated in the body.

The brakes on the KIM-10 was a mechanical drum. The pedals, unlike modern cars, was not suspended, and outdoor. Suspension front and rear axles were dependent on the transverse semi-elliptic leaf springs.

Specifications subcompact KIM-10-50

Body…………………………. ……………2-door

Length, mm…………………………. ……………3960

Width, mm……………………… …………….1480

Height, mm……………………….. …………….1650

Base………………………………………………….2385

Track, mm………………………….. …………….1145

The number of seats, man………………… ………………….4

Curb weight, kg……… ……………….840

Maximum speed, km/h……………….90

The number of cylinders of the engine ………………….4

Diameter of cylinders, mm……. ………………63,5

Stroke……………………………………….92,5

Working volume, cm3…………… ……………. 1172

Power, HP …………………………………..30

Transmission………………. manual, 3-speed

Suspension…………..by transverse leaf springs

Brake…………………………….drum, mechanical

I. EVSTRATOV