With the development of industrial building methods became widely used details of full factory readiness. However, there still remains an urgent problem mechanization of plastering and grouting works for the walls and ceilings of buildings, and especially in rural construction.

With the development of industrial building methods became widely used details of full factory readiness. However, there still remains an urgent problem mechanization of plastering and grouting works for the walls and ceilings of buildings, and especially in rural construction.

Special attention of specialists always bring a device designed to facilitate finishing works, in particular the mechanisms of universal application. This tool is a General-purpose trowel machine ZMD-10 construction innovator A. F. Demyanenko. It not only facilitates the work and improves the performance of plastering and finishing works. The machine can process the surface of the concrete and reinforced concrete structures produced by plants construction industry, facades, lined with soft stone type ingermanson, sanded, puttied up and mosaic panels as well as clean different surfaces.

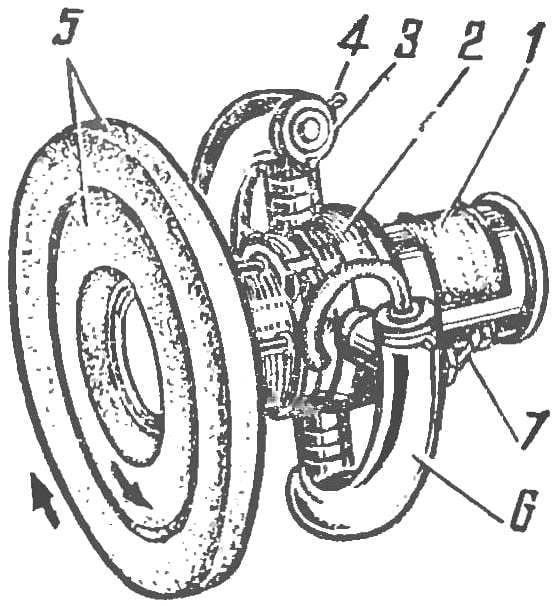

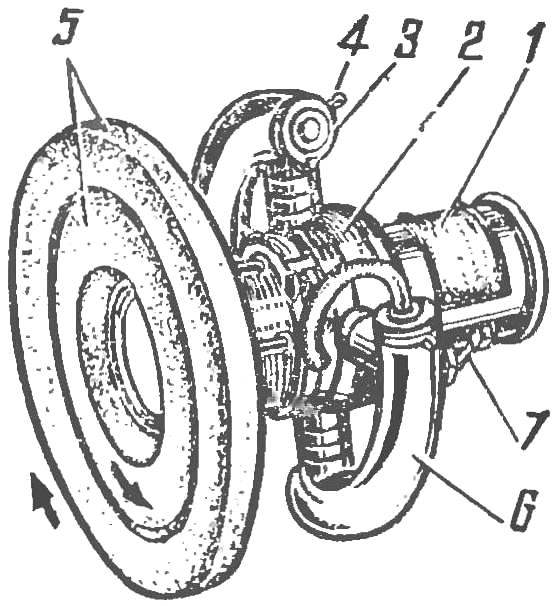

The machine consists of a motor (AP-21), volt 36, controls with switches and a water tap and the working body in the form of rotating in the opposite side of the rings. Depending on the purpose they can be just of chipboard or coated corundum or emery coatings.

Power trowel machine:

1-motor, 2 — gearbox, 3, 6 — handle, 4 — switch 5 — power trowel discs, 7 — water tap.

Water is supplied via the inner hollow shaft and through the distribution cover and the hole in the inner disk is not only to fill the surface, but also on the internal disk, and in the space between the discs to clean it from the solution.

The working disks are interchangeable, easily centered and secured with staples. The resultant of the moments of rotation is practically zero, which makes the machine stable, reduce the load on the hands of the worker. This increases productivity and improves the quality of work. The important advantage of the machine ZMD-10 and that it can be manufactured and workshops on any construction site.