At the end 1940-x of years in several countries of Europe, a dilapidated Second world war, gradually began to recreate the automotive industry. On the streets there are inexpensive micro cars purely personal use: trehalase German “Messerschmitt” with a body that resembled the fuselage of an airplane of the same name, quadruple “Zundapp-Janus” with doors in the front and rear body panels, three-wheeled double “Heinkel kabine”, quadruple “BMW-600” and Italian is a four – seater FIAT 500 and the double four “Isetta” with a narrowed rear track.

At the end 1940-x of years in several countries of Europe, a dilapidated Second world war, gradually began to recreate the automotive industry. On the streets there are inexpensive micro cars purely personal use: trehalase German “Messerschmitt” with a body that resembled the fuselage of an airplane of the same name, quadruple “Zundapp-Janus” with doors in the front and rear body panels, three-wheeled double “Heinkel kabine”, quadruple “BMW-600” and Italian is a four – seater FIAT 500 and the double four “Isetta” with a narrowed rear track.

The abundance of “aviation” titles in this list are not accidental, but due to the fact that in that period the aircraft manufacturing plants in Germany and Italy it is strictly forbidden to produce aircraft, and therefore, instead of bombers and fighters, these plants began to produce inexpensive subcompact cars.

All these machines have a low weight, economical fuel consumption and small size.

During the same period attempt to create a domestic small car has taken and the Soviet automotive, bringing on MZMA (Moscow small car factory) “Moskvich-400 and Moskvich-401” as two drops of water similar to the pre-war German “Opel-Kadet”.

Quite affordable for wealthy domestic buyers, the car was well received by motorists – in fact, it was the first Soviet passenger car intended primarily for individual use. Let me remind you that a significant part of the earlier Soviet car was delivered exclusively on departmental raznaryadke enterprises and institutions, including for work in the parks. The same few drivers-“individuals” with considerable difficulties machines were bought through the trade Union organizations of the enterprises in which they worked or through specialized consignment shops. However, parthenogenetically doctrines, it was assumed that Soviet citizens will use mainly public transport vehicles – trams, buses, trolleybuses or, at least, by taxi cars.

The emergence of the domestic automotive industry “Moskvich” car of the individual use – inspired not only motorists, but also the Soviet of automakers – they had hoped that the release of a minicar of this class – it’s a hint at future changes in the policy of acquisition of passenger cars by individuals.

In the country there were a lot of outstanding engineers and designers (note, the latter term at that time still did not use), which was eager to take on the Soviet drawing of compact cars for personal use. Among them is one of the most experienced and well-known Soviet artists-autoconstruction (happy to remind you: for many years a regular contributor and member of the editorial Board of the journal “modelist-Konstruktor”.

So, Yuri Aronovich Dolmatovsky. Born in 1913 in Moscow, the son of a prosperous lawyer. School Yuri chose certainconditions with a gradient (at that time there were some). And the teenager was attracted to cars.

After school, Yuri entered the Moscow polygraphic Institute, faculty of book. After graduating, the young man entered the Moscow automotive Institute and promptly received the second higher education, passing examinations without attending lectures for the entire course MAMI.

The makings of a automotive designer he showed Yuri Dolmatovsky very early – from childhood he loved to draw cars and growing up, became the author of illustrations in the magazine “Technics-youth”, “modelist-Konstruktor” and “Behind the wheel”. In the technical literature there is even a special style Dolmatovsky – copied it for him and studied his works were admired by fans of automobile aesthetics.

Design activity by Y. Dolmatovsky started in NATI (Scientific-research tractor Institute), then continued in NIIAT (Scientific research center in the field of motor transport operation) and US (Scientific research automobile and automotive engines Institute), and in the latter he had the opportunity to participate in the design of compact micro cars, which later became the prototype for future domestic small car.

Compact three-wheeled German car “Messerschmitt”

Tricycle “Heinkel kabine”

In 1938, Yuri Aronovich completed work on fundamental work “Automobile body”, marked the beginning of domestic design school, and in 1939 at the automobile plant named after Stalin (ZIS) designer engaged in designing the bus bodies, while examining the American experience of designing cars.

In October 1941, when the German occupiers came close to Moscow, the VMS were evacuated from the capital and along with a plant in the Urals left and Dolmatovsky. However, in 1943 he was summoned to Moscow and offered to work in US by the head of the design office.

After the great Patriotic war A. Y. Dolmatovsky in the group of design engineers was sent to Germany to study the German experience autostructure. That’s where the designer got acquainted with the car wagon and established their prospects. In 1949 Dolmatovsky started to create his first large-scale concept.

In the early 1950-ies of the mass production of micro cars in the USSR began to think and Industrialists, who saw in the small car relatively inexpensive to manufacture vehicle designed for the mass buyer with average incomes.

So, the leaders of the Irbit motorcycle factory, which produced during the great Patriotic war and after its end, a heavy military motorcycle M-72 with sidecar, initiated the serial production of cars of especially small class on the basis of manufactured motorcycle components and assemblies. Key Advisor and partner of the factory were made by US.

The result of this collaboration was to create a car very small class of prospective design, which allowed to release the car without modification and upgrades for quite a long period. Great attention when creating such a machine was ordered to be given how unassuming it to the Russian road and acceptable for the driver and passengers comfort.

The development of Italian double sidecar “Isetta” – compact German four-seater BMW 600

The development of Italian double sidecar “Isetta” – compact German four-seater BMW 600

The constructive scheme of the new vehicle, called NAMI A50 Belka, was partially borrowed from the US-013-1951 – experimental concept car wagon (minivan) layout with a rear engine and three rows of seats, which in 1949 was attended by Y. Dolmatovsky. Of course, to copy the proportions and design of the seven-seat of the car while creating a compact quadruple was impossible, however, to use the principles of layout of the car body US-013 was quite acceptable.

The main phase of the micro-car, only took not too much time – from the first contacts between the heads of Eames and US before the commencement of testing of two experimental machines NAMI A50 Belka – about a year. And acceleration of further works on operational development of cars contributed to preparing in the summer of 1955 showing the state and party leaders of micro cars purchased in Europe. Preparing to the demonstration and domestic compact car Y. Dolmatovsky AND US-50 “Protein”.

As later recalled Yuri Aronovich, showing the latest novelties of the foreign car industry was organized at the highest level, so that the Chairman of the Council of Ministers and General Secretary of the Central Committee of the CPSU N. With. Khrushchev could not only inspect the equipment, but also to give designers guidelines for the selection of analogs for the generation of domestic micro cars and their further production in the USSR. By happy coincidence, at this time, Eames was the photos with fragments of the test suspension layout “Proteins”. On one of the images caught in the hands of N. With. Khrushchev demonstrated the buoyancy of the agricultural version of car.

Khrushchev liked the car, and he ordered to speed up the work on fine-tuning the “Whites” and the inclusion of its release in the state plan. Just a week on IMZ were sent to the tinsmith, master plumbers and deployed the finish work on final fine-tuning “Proteins”.

Options wheels and tyres inputs to directly affect the designers were chosen in accordance with loads on them. Another selection criterion was the external diameter of the tire in relation to the “Squirrel” he was not supposed to exceed 500 mm, otherwise because of the limited height of the vehicle to place the seat inside the car, above the wheel niches, it would be difficult.

As it turned out, suitable for “Whites” tires in our country in those years was not allowed. Bus from the “Moskvich-401 with a diameter of 650 mm was for “Whites” too big, and the rubber motorized С3А not suitable for the load. Had designers to special order the tire manufacturers tires with dimensions 5.00 – 10. Interestingly, almost the same bus was later set on the legendary British car “Mini” Alec issigonis ‘ design.

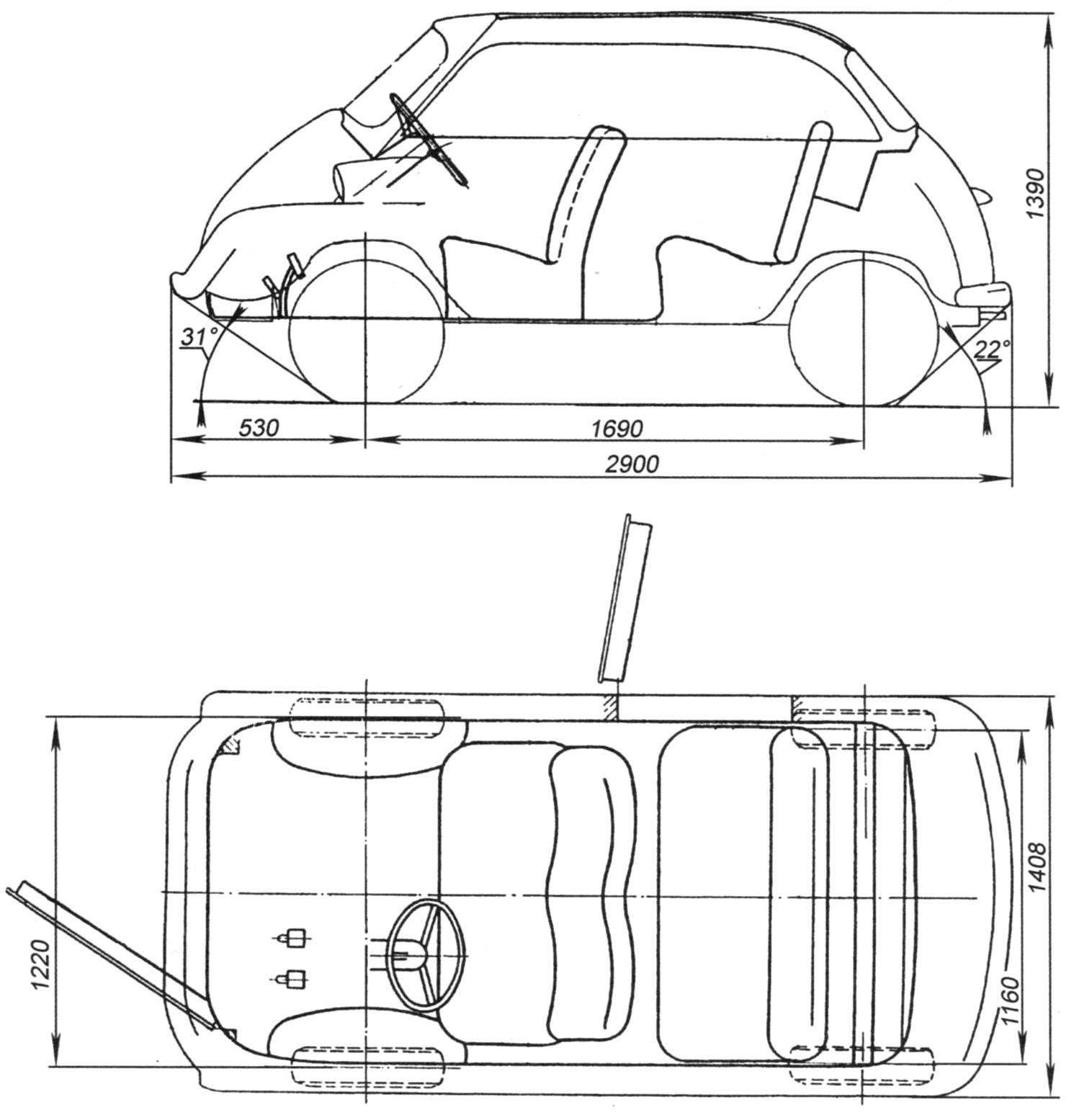

Comparison of dimensions “Proteins” and “Moskvich-400”

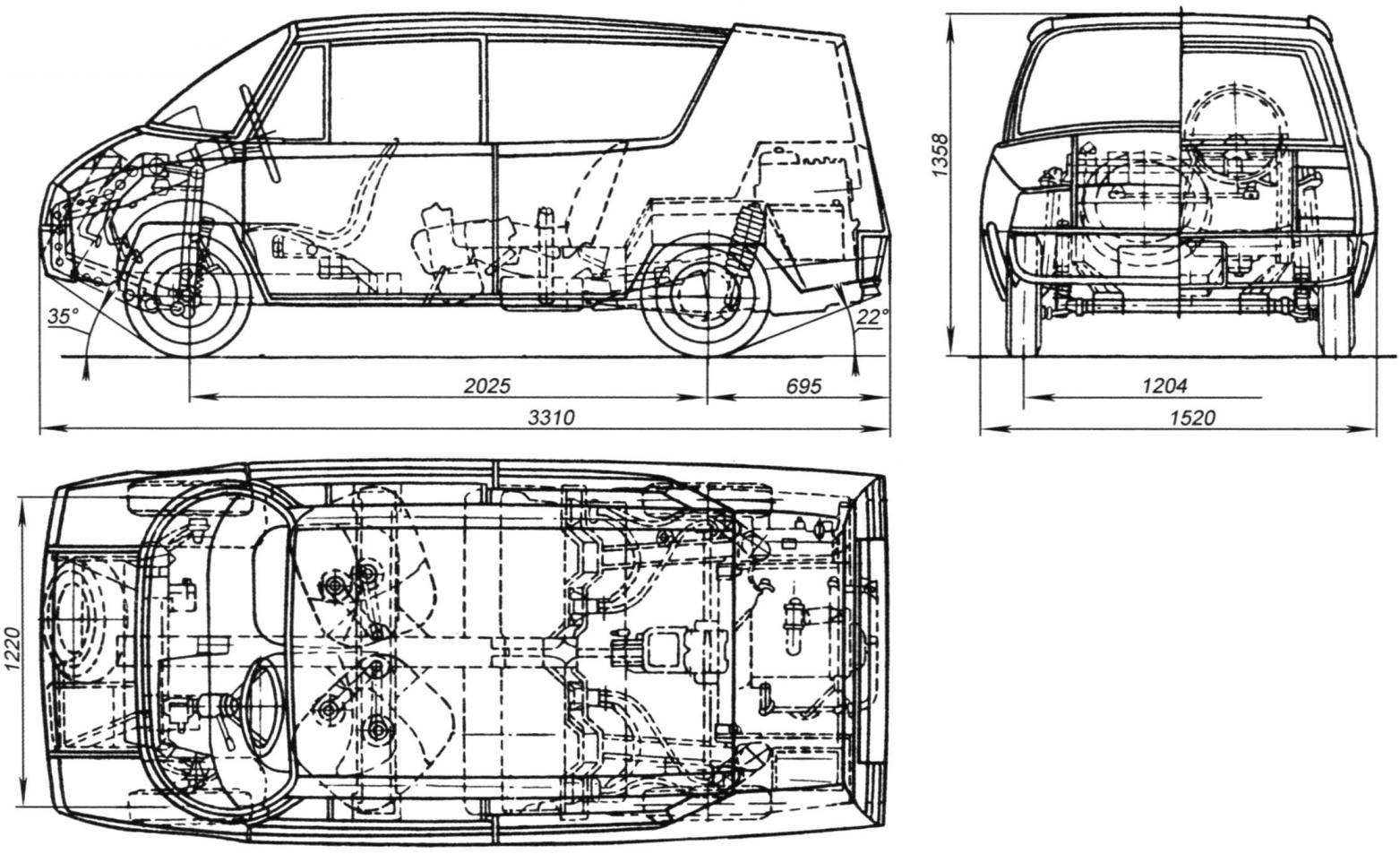

The layout and dimensions of the car “Squirrel”

New wheels with such tires it came brake drums from the motorcycle M-72. However, instead of the motor cable brake pads “Protein” has received a more modern hydraulic. The hydraulic actuator is provided to control the clutch mechanism.

Shock absorbers for “Whites” also came from M-72 – they only had a few to strengthen. Stamped suspension arms performed swinging, placing them in relation to the longitudinal axis of the vehicle at an angle less 90 degrees. Shifting gears was also supposed to carry out with the help of hydraulics, but for some reasons, the drive transmission had to make a mechanical.

The engine and clutch mechanism for “Proteins” used modifications of the M-72 intended for movement at low speed and therefore have a air cooling system.

Transmission on “Protein” from the car “Moskvich-401” as regular motorcycle had no reverse gear, and were not designed for automotive gear ratio and load.

For joining flanges of the housings of the engine and gearbox designers had to use the adapter plate. To make it, on a piece of cardboard made prints of Carter combined the centers of their shafts, and then the plate to cut the holes for the bolts that connect it on one side with the engine, but the transaxle. In turn, the box with the main transmission is also connected through the plate. It should be noted that in the later samples, “Whites” was established specially designed for her gearbox, main gear, differential and the driveshaft oscillating axle was borrowed from the car “Moskvich-401”.

In the early 1950-ies in the world automobile become fashionable panoramic windshield, the setting on the sidewalls of the car body. Since such glass is weakened the body structure of the vehicle and reduced doorways, in the domestic automobile industry this style has only touched upon a Executive cars (Chaika and ZIL-111). As for compact cars with a body carload type, the problem of combining a good overview with the stiffness of the body was less acute. The solution to this problem – the merit of the beautiful avtodizayner V. I. Eramova proposing to use for the driver and front passenger a single, forward hinged door with an oversized windscreen, with whom I leaned back and the steering column. The entrance to the front of the cabin was carried out left and right, and the driver and passenger when it was not necessary to bend over. Access in the rear of the cabin provided only on the right, through a wide, coming to the roof door. The designers decided that the use of the left door is unsafe for passengers when boarding and disembarking. In addition, the exit of passengers from the cabin directly on the roadway is prohibited by the rules of the road. To all, the rejection of the left doors has allowed designers to get rid of the ledge of the tunnel in the middle of the cabin – the “Whites” all communication control mechanisms of the vehicle passed through a reinforced left side of the body.

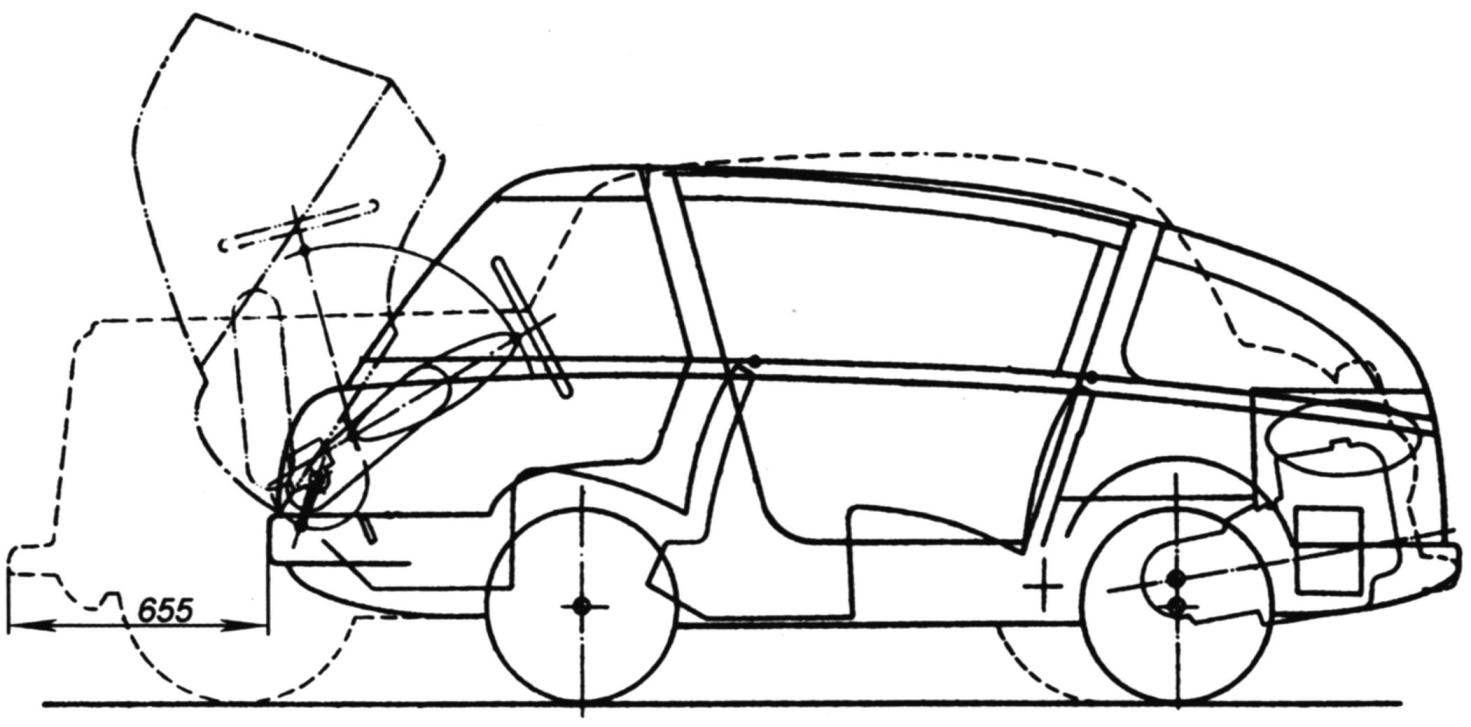

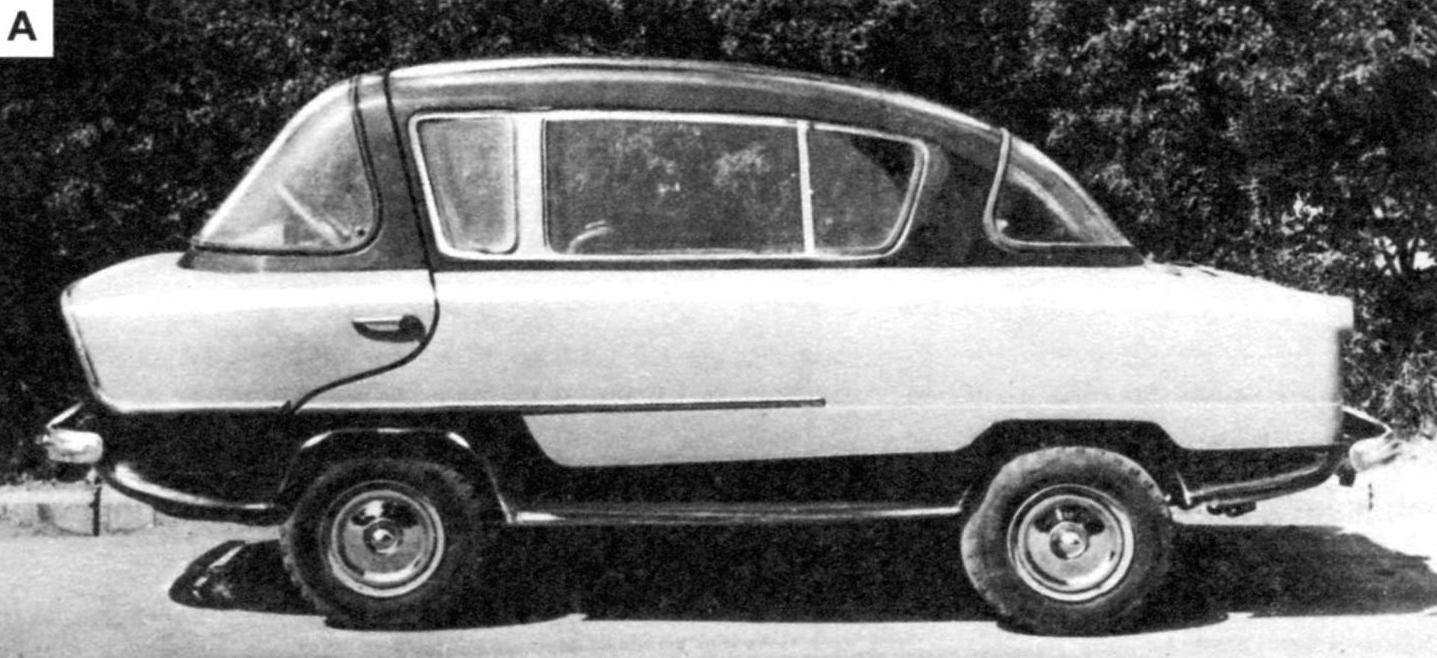

Compact car “Protein” (And “urban option”, B – “rural option”)

Taxi “VNIITE”

Seat car the first was a light steel frames, seats with springs tight fitting rubber bands. However, this design was not acceptable; more suitable for Proteins recognized anatomical Cup-shaped “shells” made of fiberglass, covered with molded foam. These chairs provides not only the convenience of boarding the vehicle driver and passengers, but also delivered them from occurring in the process of moving mechanical vibrations. In addition, these seats are well was built over the wheel housings of the machine.

We collected five copies of the car “Protein”: experienced chassis platform; the above-described basic model with a body of type “sedan” (later it was transferred to the factory Museum); outdoor (agricultural) version of the machine and two cars with universal bodies and removable roof type hardtop and tipping up side doors made of fiberglass. Unfortunately, the recent break in failed – their powertrains on orders over transferred to Zaporozhye automobile plant to install those on the chassis layouts of the future “Zaporozhets” ZAZ-965 and wheels – at the Serpukhov automobile plant, to install them on the prototypes of the wheelchair sidecars.

Before answering the question of why “Protein” did not go in the series, it makes sense to acquaint readers with the rating of this car, given in the official report on her trial : “…”On the compactness, convenience of the interior, and maneuverability “Protein” is superior to most of the class, and other qualities (weight, dynamics, fuel consumption, reliability, engine, comfort front seats) requires fine-tuning…”

In summary it was noted that “car design “Protein” can be recommended for further development and construction of a batch of prototypes”.

As mentioned above – start this work has already been laid, however, in accordance with an ancient but still revered in Russia wisdom that says that there is no prophet in his own country, prevailed “proven foreign design” – a prototype of the first Soviet “CD” “Zaporozhets” ZAZ-965 was not a domestic car “Protein”, and the Italian FIAT-600.

FIAT “Multipla” – Italian compact car wagon

– Failure to start serial production of the car “the Squirrel”, which became, however, an important step in the development of cars of especially small class, had not only immediate, but also long-term effects.

As it turned out, the designers of “Whites” were almost in the same way as their foreign colleagues. A characteristic example is the release of the American company “Chrysler” farm vehicle “Permobil”, much like the agricultural version of “Proteins”.

It appeared, moreover, that not even-driven “Protein” has accelerated the launch of a series of compact car “Zaporozhets” ZAZ-965. The fact that 965, as “Protein,” was rear-engined, air-cooled engine, with the same diameter wheels. And don’t be in the presence of prototypes of engines, designed for the “Whites”, model samples “Zaporozhets” there would be at least six months later.

As for “mini-vans” – compact passenger car wagon, 1950’s- 1960’s years, the automakers seemed we just forgot about them. On machines of this type is recalled only in the Fiat, who from 1957 to 1970-th year released van “Multiple”, and then – similar in design to “Familiale”. Well, super cars, created on the basis of motor units in the burgeoning post-war Europe was quickly forgotten.

In the late 1960-ies a lull broken only by a specialized vehicle, a taxi with a body carload type created in VNIITE (all-Union scientific research Institute of technical aesthetics); in the development of this machine were made by the designers at the time created a “Squirrel.” Was designed “Maxi” is an interesting little micro-car wagon-type design which was used used when creating car-taxi VNIITE items: fiberglass exterior, sliding doors, anatomic seat, adjustable pedals, and original steering.

Meanwhile, at the Zaporozhye automobile plant has developed production of a new subcompact. The first two models of this car (ZAZ-965 and ZAZ-965-A) has proved to be economical and agile car, who had quite a decent cross. But not all buyers are satisfied with their cramped interior, small boot space, lack of comfort, low dynamics and unsightly appearance. All this was the reason for the urgent creation of improved cars with a more modern look.

New CD ZAZ-966, popularly nicknamed “big-eared”, to some extent, fulfilled the task, but, unfortunately, its main difference from the “hunchback” was increased to 400 mm length and big 110 kg weight. So, I may say, “modernization” has allowed designers VNIITE to conclude that on the basis of units of the ZAZ-966, you can design a car with the same interior, much larger trunk, but with size and weight as the “ZAZ-965, popularly nicknamed “Brokeback”. Wagon layout promised a more rational distribution of mass between the axles, increasing machine stability, reduce tyre wear and improve the flow of the body. As a result, in VNIITE began the development of a new alternative version of “Zaporozhets”, which received vnutrijeludockova the name “Maxi”. In contrast to the “Whites”, the new “mini-van” seat of the passenger and the driver placed inside the wheelbase, as close to the housings of the front wheels.

During the design of “Maxi” in the magazine “Tekhnika-molodezhi”, “Knowledge is power”, “modelist-Konstruktor” and “Behind the wheel” on this compact little car was published many intriguing and sometimes ridiculous articles like the novelty of the domestic automobile industry. The fact that at that time the Agency has chosen not to reveal their plans until, until you have implemented them the basic solutions.

A simple comparison “Maxi” and “Zaporozhets” ZAZ-965 shows that two cars with virtually the same dimensions have different capacity – car wagon passenger cabin was much more.

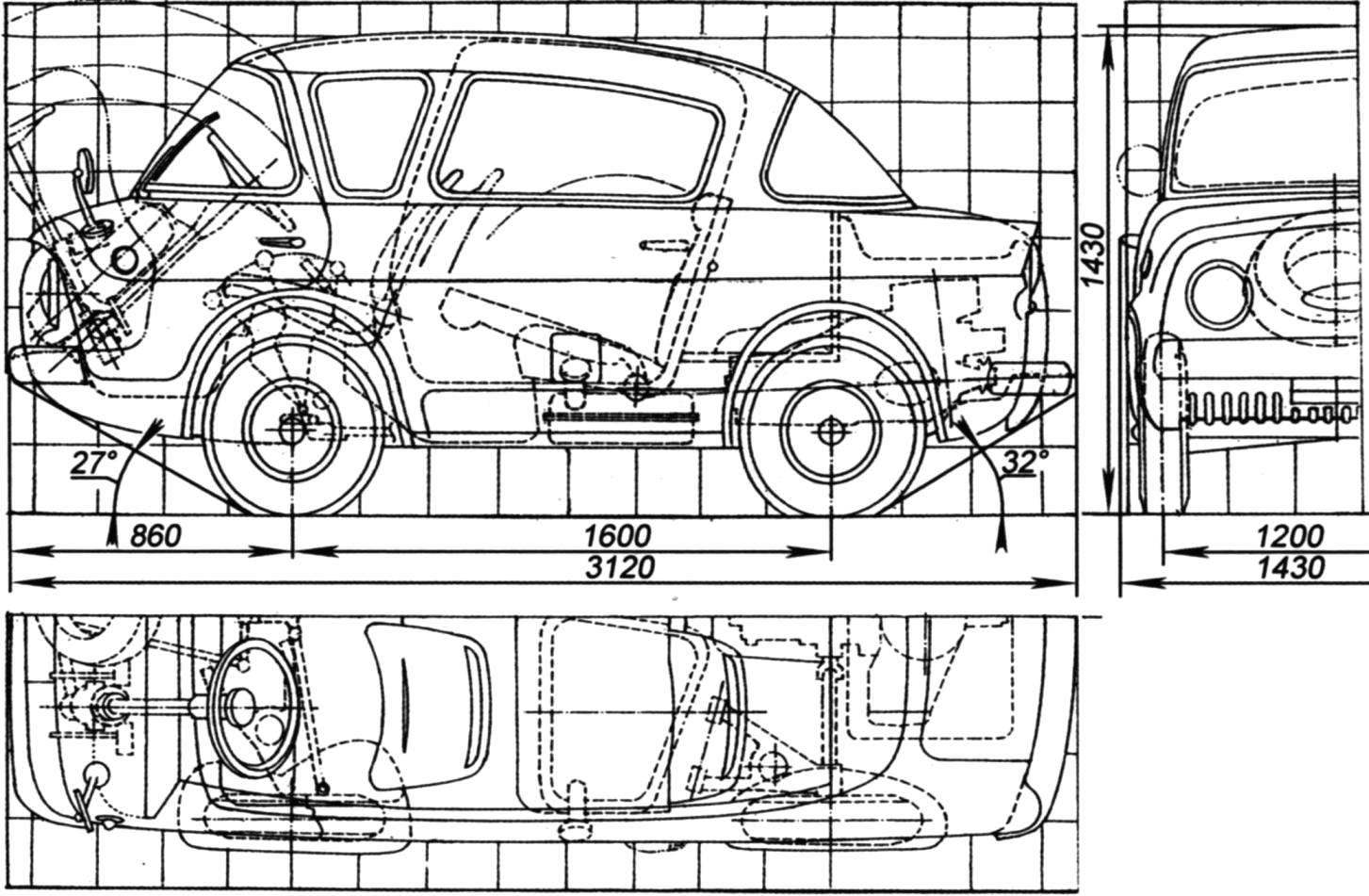

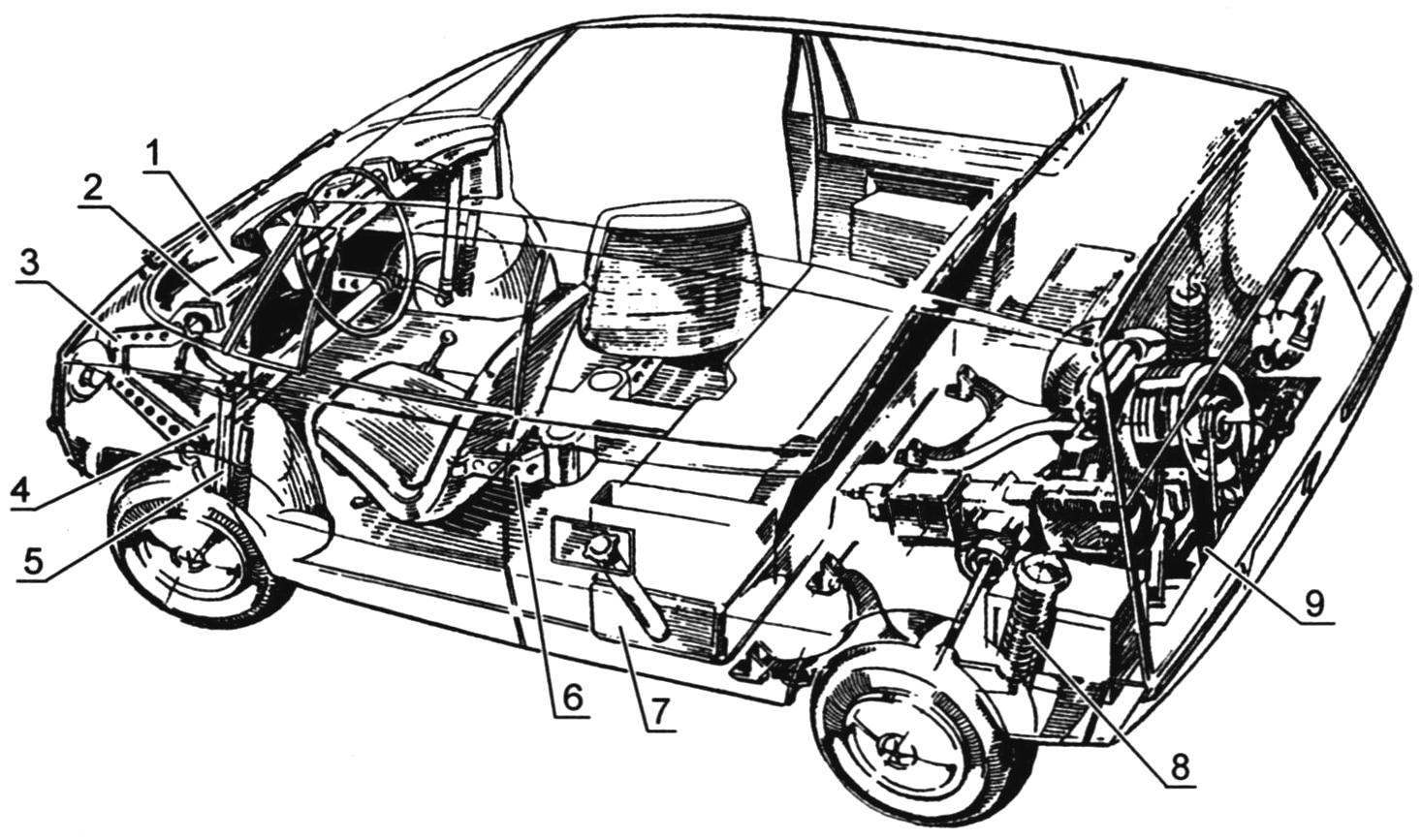

Maxi – compact car car layout

The layout of the car “Maxi”:

1 – shield of devices; 2 – the upper torsion bar; 3 – power profile; 4 – lower torsion bar; 5 – pivot strut front control arm; 6 – a rotary crank; 7 – tank; 8 – rear; 9 – engine

Maxi – compact car car layout design Dolmatovsky and Aramova

I wonder did the designers when choosing the optimal placement of the driver’s seat and mechanisms. “Maxi” this problem was solved unconventional for the landing of the driver and front passenger used laminated foam fiberglass seat anatomically shaped, is pivotally mounted on brackets. When you turn this chair its raised lateral portion passed over the wheel housings and the chair, therefore, was nominated in the doorway. And a couple of borrowings from the “VNIITE Taxi” – this is an adjustable pedal unit and sliding door. The latter, along with a significant decrease in the area intended for car Parking, provide convenient access to the rear seats.

Among the other features of the “Maxi” should also include the original body structure, steering and front suspension.

To ensure sufficient space for the driver upper torsion bar suspension and a steering linkage from the ZAZ-966 were raised to the level of the windscreen. Thus was formed a sort of cross frame covering the inner body panel and serving as additional protection in a frontal collision of the vehicle. And the short steering shaft from the Pitman arm on the front end, and to trapeze in accidents could have prevented injuries to the thorax of the driver.

The front seats on the “Maxi” was moved to 345 mm forward compared to the basic “Zaporozhets”, the rear is 150 mm, and as a result, he received the promised increase of the cabin and trunk.

The body was a shell of glass reinforced plastic, steel spine beam and cross-beams were just molded into the platform floor.

It should be noted that the shape and layout of the “Whites” and “Maxi” is very close to that accepted today and they can focus as automakers Amateur and professional – of course, adjusted for modern materials, machinery and technological capabilities. And those cars-homebrew a lot – alone engines for vehicles of small and very small class – at least five options. To all of the automakers greater opportunities in purchasing components for the generated car elements suspension, electrical, transmission, controls, control devices, and individual elements of the body.

A feature of the form “Maxi” is a strongly sloping and rounded in its anterior part and steeply cut rear end. Modern trends in the aerodynamics of the car suggests that this form of resistance and the aerodynamics are close to optimal.

The most characteristic element of design solutions “Maxi” is a pair of wide rear pillars, reminiscent of the aircraft keel United over the roof of a bridge. The leading edge of the bridge and stands are openings of the air intakes: side – to supply air to the engine and the top – air discharge from the roof to the rear glass, which protects it from dirt. It is also worth mentioning that the bridge was not so much a designer a design element, but an element of passive safety for driver and passengers, protecting them during a crash rollover of the vehicle.

In conclusion – the story about the failed car Y. Dolmatovsky – a kind of Testament to the great car designer as a professional designers of cars today, and designers and Amateurs.

“I don’t want to impose on the automakers (both professionals and Amateurs) their opinion and taste. Allow only myself to dream, what will be the car in a few years. I should note here that the volume of the body gives greater freedom of placement of chairs, machines, appliances and units, as the location for the largest car Assembly – engine and Luggage is not strictly defined. It is only important to observe the following:

– comfortable fit and access to the seats;

– good visibility for the driver and passengers;

– security;

– optimal load distribution on the wheels;

– convenient access to the mechanisms for their maintenance;

– pleasant climate and low noise level in the cabin.”

Notice that to comply with all of the above quite difficult, and the designer will have to use textbooks and handbooks as well as publications on these topics in the journal “modelist-Konstruktor”. Here will give their views directly relating to a hypothetical car of the near future, as mentioned above.

On most modern cars with an one-volume body are used wide-base tires, and on cars with rear engine – and even different outside diameter tire front and rear wheels. On some mini-vans using such design solutions as raised floors and located in the middle of the steering column. All this is the desire of the designer it is possible to more fully use the area of the body, given the close proximity of the driver’s seat and the wheel casing; can reduce the length and therefore weight of the vehicle; to reduce fuel consumption and harmful emissions of the engine. At the same time to improve the view of the road and reduce drag of the front end, as well as to facilitate access to the seats.

And yet – about the layout with the Central location of the steering column: it is not necessary to install it strictly in the plane of symmetry of the machine, better still a few to shift the column to the left, to improve visibility when overtaking. Not necessarily to move the column forward far enough to move it for 250 – 300 mm, to provide favorable for the stability of the car and to grip the mass distribution as in front and at the back of the engine.

As experience shows, automakers-goers mainly use for homemade car series motors. Thus, when choosing a motor for your car, they determine its most advantageous location in the body volume and, therefore, the layout of machines in General.

So, the engines from the models from ZAZ-965 to ZAZ-969, complete with clutch, transmission and the main transmission it is advisable to place rear as the base of “Zaporozhets”. Install them in the front, as, for example, Loiza, odnoimennom car unprofitable – in this overloaded front wheels tyres, demanding increase in their diameter, and stands far to the front overhang of the body. Might even be broken and its one-volume form.

The use of motorcycle engines entails their blocking of the transmission of “Zaporozhets” with the help of bridge plates, as it had to do when creating a power unit for “Whites”.

The engines of cars VAZ models from 2101 to 2107 well linked when you cross their location, as it was in his time made on an experimental car created in VNIITE. For this purpose we used a shortened driveshaft associated with a pair of helical spur gears with the output shaft of the box and bevel gear – main gear axle. It is very important to ensure a minimum (not more than 7-10 degrees) angles of the gimbal work. You can certainly do without the extra pair of gears, replacing the conical crown gear is cylindrical, however, this will entail the production of a complex crankcase the main transfer.

And, of course, for the rear location is quite suitable engines from all domestic FWD cars. In principle, well-composed and front bridges completely, just need to adjust them at the rear of the car.

I could be accused of excessive partiality to the rear-engined layout, however, it is quite reasonable considerations.

First, practice has proven that RWD cars are more simple in manufacture and operation compared to FWD in the same class, so this arrangement is more suited for inexpensive cars of a small class. That is why rear wheel drive cars so actively produced in the 1950 – 1960s years when the world was overcome post-war economic difficulties, in General similar to those in recent years, and pursue our country.

Secondly, the undoubted advantages and the wide spread of front wheel drive cars is not excluded from the production rear-wheel drive vehicles small and very small class. So, quite successfully continued to produce these cars for the companies FIAT, Volkswagen, Subaru and others. And most sports cars that have always been harbingers of most promising design solutions, engine have for and before the rear axle.

Thirdly, the rear and middle engine was used even on the newest mini-vans, BMW and Toyota.

Fourth, rear-wheel drive seemed to be especially suited for a one-volume car, which is inevitably greater than that of any other machines, the load on the front wheels due to the forward displacement of the mass body and passengers. In cars with rear wheel drive a more uniform mass distribution, which is optimal for the clutch wheel with the road in a variety of situations.

Fifth, the initial submission about the lack of safety of the car car layout has undergone significant changes. In particular, the statistics clearly showed that under identical conditions of operation of the RAF minivans and cars GAZ-24 “Volga” first experienced one-third fewer accidents than the second – mostly due to better maneuverability and excellent visibility of the road.

Sixthly, it is impossible not to take into account the impact on the layout of the car such things as demand, fashion, advertising, profit, prestige of the owner, etc.

Along with technical progress and the development of operational requirements, “non-transport” factors play an increasingly important role in the spread of cars. At the time, the design of the cars, so appeared tires-tires, powerful motors, indoor and all-metal body, and then the body more streamlined, electric starter, automatic transmission and much more. And nowadays, thanks to such “non-transport” factors and held a massive shift in the “front-age.” I believe that if not for the influence of “non-transport” processes and phenomena, the monocab quite able to spread earlier and in the near future surely is a rightful place for them in the objective of their qualities and clearly the emerging trends in the global automotive engineering”.

I. EVSTRATOV