When I hear the word “dubbed”, it is a sun-drenched Playground, dry asphalt paths, summer-dressed children… unfortunately, autumn, winter and spring avtogorodok contraindicated. What should I do? Where to engage with students?

When I hear the word “dubbed”, it is a sun-drenched Playground, dry asphalt paths, summer-dressed children… unfortunately, autumn, winter and spring avtogorodok contraindicated. What should I do? Where to engage with students?

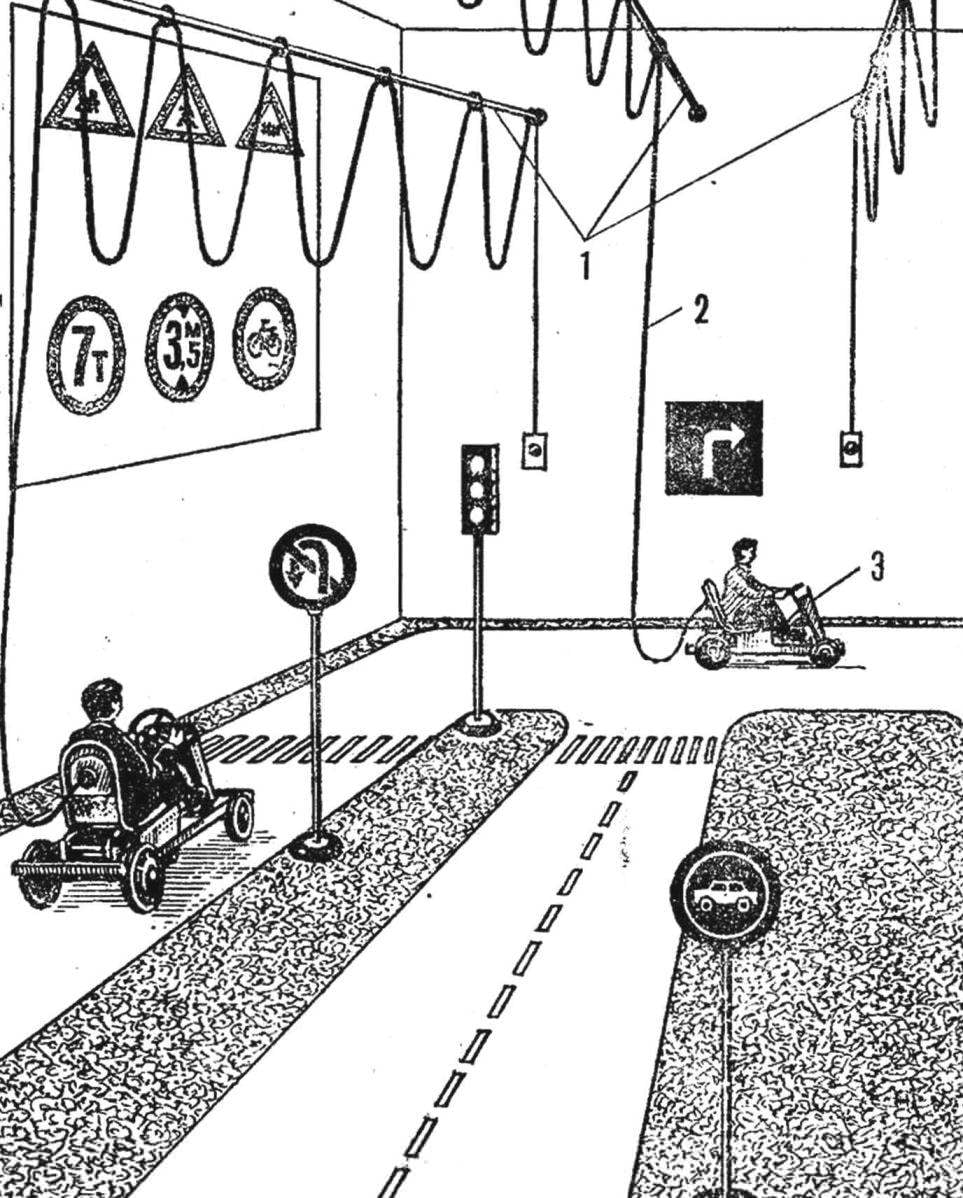

Meanwhile, there is a solution. Learning to drive can be done in the premises: in the Assembly or sports halls of the school, in the wide corridors. A workout machine should be electric.

But does it make sense, thought my teacher E. Kakuma, put on the car, which obviously will be used in the room, heavy and expensive battery? Is not it easier to bring to it the power cable, as is done in industrial lifts-hoists?

We made this electric car, and it turned out that the power lead at a relatively small closed area is not a hindrance! Even if the miniature vehicle moves along the marked notched track.

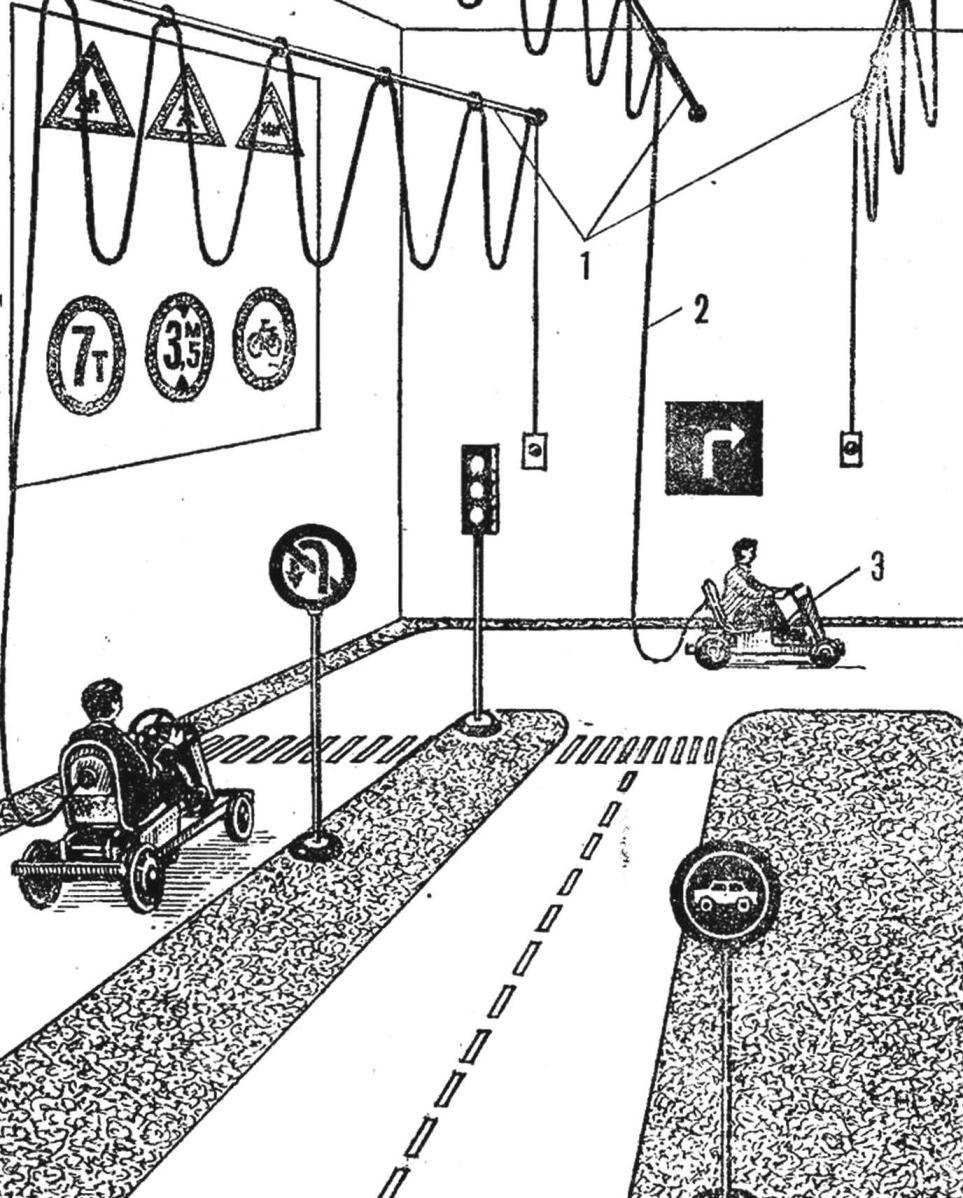

To build “the car on a leash” was easy because we used the best available parts and components. For example, the chassis was taken from a children’s pedal map, the motor from a bench grinder, and gear used a manual sharpener.

When working out of the machine revealed a detail: the starting torque of the motor was insufficient to make the vehicle move, so I had to introduce a frictional grip. But as they say, there would be no happiness, Yes the misfortune has helped — it gave the ability to control electromobility as real.

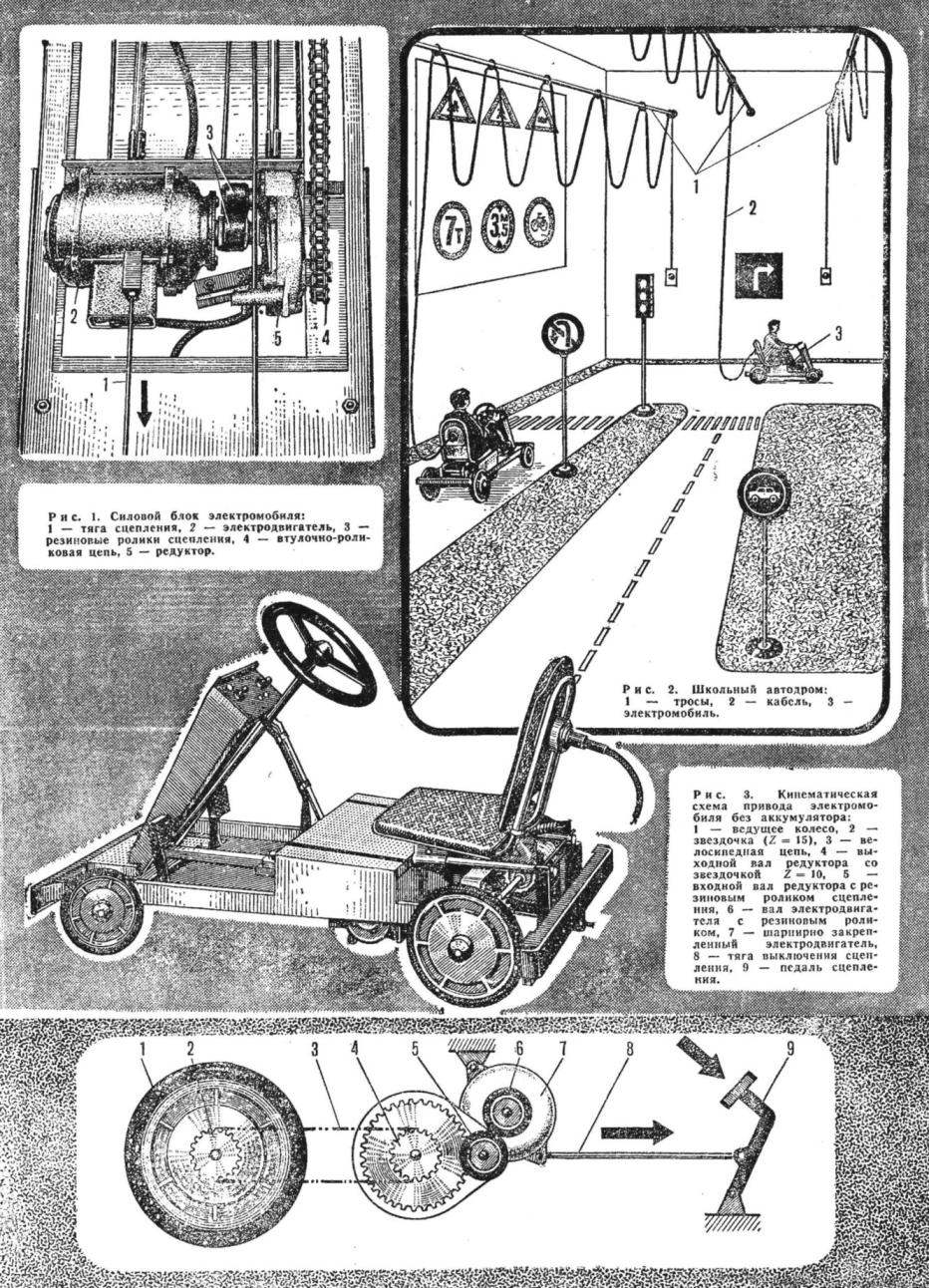

The actuator is arranged as follows (Fig. 1 and 3). On the shaft of the former winepress instead of the abrasive wheel is installed, a hockey puck, the engine is pivotally mounted on the frame and is connected by a rod with the clutch pedal. The same hockey puck is on the output shaft of the manual sharpener instead of the arm adjusted a Bicycle sprocket (Z = 10). Further torque is transmitted to the chain sprocket (Z = 15) of the rear axle.

The rear bumper hung on two hinges and a rod associated with the pedal it is a brake. In this reducer, sprockets and engine our electric vehicle moves at a speed of about 4.5 km/h, which is enough for “room facilities”.

The car mounted the following controls: toggle reverse (front to back), switch engine (by the way, it would be nice to take the form of a pedal of “gas” that we intend to do), the pedal clutch and brake pedal.

The sequence of actions of the driver when setting off the following: squeeze the clutch, start the engine, then the clutch pedal is gradually released and the car starts moving.

The power cord is hung, as shown in figure 2.

BRIEF TECHNICAL CHARACTERISTICS

Dimensions, mm:

width 540…

length 1050…

height 690…

Base, 800 mm…

Track, 450 mm…

Weight, kg 24…

Speed km/h 4,5…

Engine – three-phase, asynchronous, power of 440 W

The gearbox is a manual sharpener RT-16 (ratio 1:16)

Chain transmission – with the help of stars with Z=10 and Z=15

Reversing motor – switch of the windings

D. FERBER, teacher school No. 4, Valmiera, Latvia