Kharkiv residents have a long tradition of love for technology. Since the construction of the legendary Tractor, since the first graduations of the Aviation Institute, since the first pre-war work of the Kharkov DTS and the Palace of Technical Creativity.

The city, saturated to the limit with industrial enterprises, research and educational institutes, could not but give rise to a mass passion for design and modeling.

There was, perhaps, not a single exhibition of technical creativity of young people, not a single serious modeling competition without the participation of Kharkov residents.

Several points where pre-war guys were engaged in design, learned the basics of technology, several centers of searching for ways of industrial progress have sown many creative sparks over the past years. Clubs and clubs, stations and houses of technical creativity – everywhere you will find enthusiasts, dream-obsessed discoverers, future inquisitive experimenters, innovators, experts in their field.

Here’s just one – indicative! – number. In the circles of VOIR, NTO, in production and technical schools and other educational institutions and non-school institutions of the city, tens of thousands of people are now engaged in technical creativity. From this mass, from hundreds of rationalization proposals, original designs, models, we chose two. Two cars, widely known to our readers from their exposition at VDNKh, according to press reports. Two cars that our readers asked us to publish descriptions and drawings of. Both were preparing for an exhibition of technical creativity of young people. Both are notable for the boldness of their design, the thoughtfulness of their layout, the meticulousness of their execution, and most importantly, the participation of large youth groups in their creation.

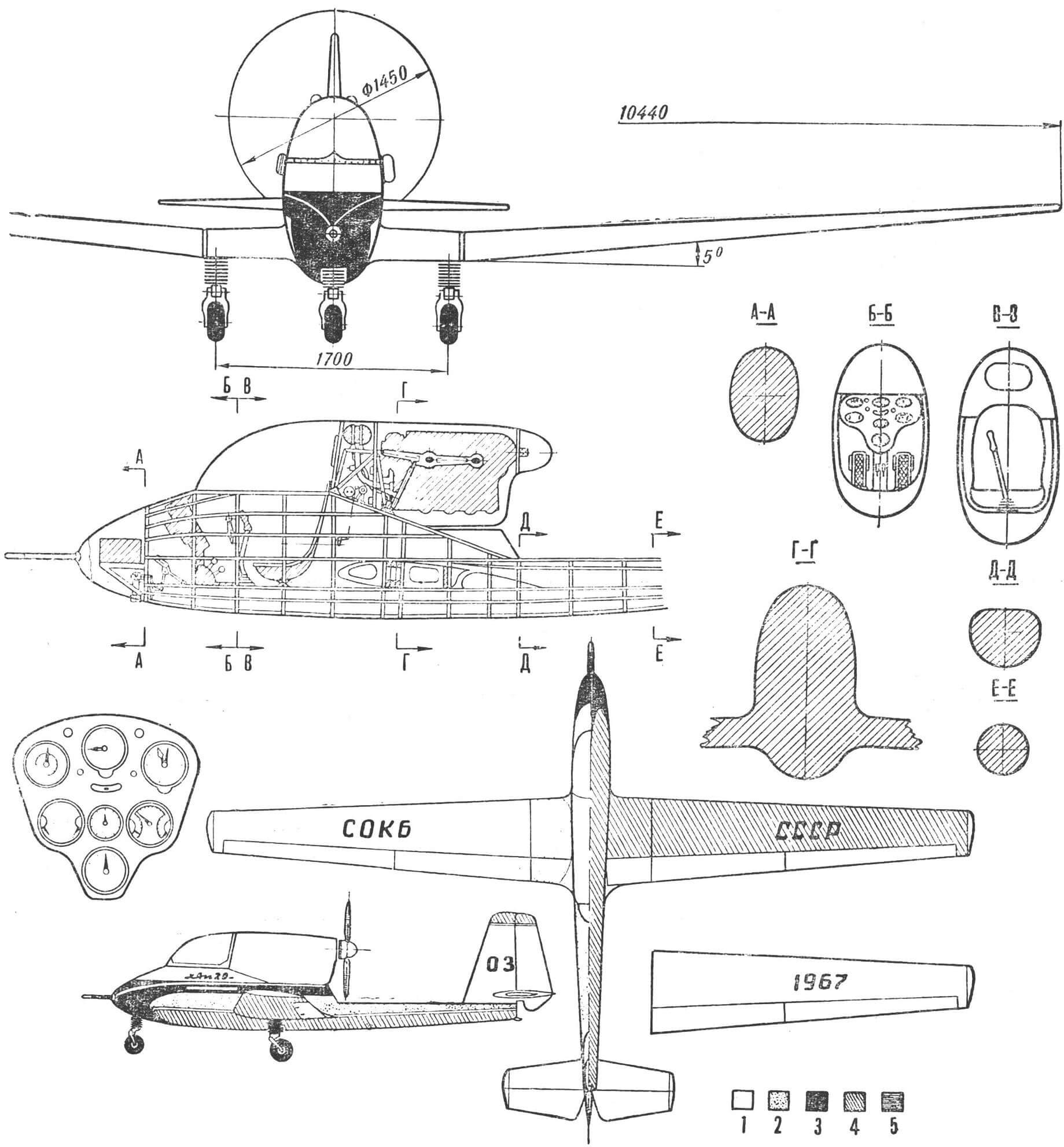

1 – white, 2 – yellow, 3 – black, 4 – orange, 5 – blue.

“There is nothing more interesting for engineering students than designing, building and testing a machine from start to finish. If we manage to introduce such an interesting practice into the life of the Kharkov Aviation Institute, then our students will certainly have an exceptional thirst for learning and from the “yellow-faced freshmen” they will quickly grow into young aircraft engineers who know a lot about the real design of flying machines…” – we thought while studying at Institute. After much debate, everyone unanimously decided that we would design and build a light single-seat aircraft with the help of KhAI students. We were supported by teachers from the aircraft design department. It also helped us that the Kharkov Aviation Institute, even before the war, had a good tradition of creating light aircraft and gliders by a team of teachers in collaboration with senior students. The main organizer of our newborn student design bureau was student Valery Reshetnikov; the bureau also included Georgy Chub, the authors of this article and many other students.

Immediately after the war, we built our first aircraft, the KhAI-17, a cantilever low-wing aircraft with a low-power engine, a beam fuselage and a pushing four-bladed propeller. It was tested in flight by our own students. Following him, the next plane appeared – KhAI-19. It was a low-wing aircraft that had a three-wheeled landing gear with a nose wheel. KHAI-19 was very well suited for copying on a cord model, so many modellers and copy makers know it. Our second aircraft made a number of successful flights and is currently exhibited at the Exhibition of Excellence in Ukraine.

Finally, in 1965, we began designing the third KhAI student aircraft. If we count from pre-war times, then this third student turned out to be the twentieth, which is why it was dubbed KhAI-20. It took two full years to design and build it. When designing the KhAI-20, students completed several dozen graduation projects and about two hundred coursework based on this aircraft. Each group underwent practical training in the construction of “their” KhAI-20 aircraft. All educational, design and calculation works of students were real, tangible activities, which, before the eyes of their authors, turned into a real, and not a “paper” aircraft.

And finally, in the fall of 1967, the KhAI-20 was rolled out to the airfield. Our brainchild was taken on its first flight by its builder, who by that time had successfully completed the flight school of the Kharkov DOSAAF flying club, Georgy Chub. The plane relatively quickly took off from the ground after takeoff and quickly began to gain altitude. Georgy comprehensively checked the stability and controllability of the aircraft in the air and on the ground, made several circles over the airfield and performed a precise landing. Our test pilot’s conclusion was laconic: the KhAI-20 aircraft is an excellent training sports car.

In 1967, the KhAI-20 passed the entire cycle of factory flight tests. The flights took place at altitudes of up to 3000 m. Test flights fully confirmed the calculated data. The total flight time for the KhAI-20 is about 15 hours.

How does this plane work?

KhAI-20 is a cantilever single-seat sports training monoplane with a three-wheeled fixed landing gear. The plane has a pusher propeller, a fairly large wingspan and looks like a motor glider. The main construction material is aircraft wood. However, fiberglass and metal are also used.

The trapezoidal wing consists of a center section, tightly connected to the fuselage, and two detachable consoles with a positive lateral angle V of 5°.

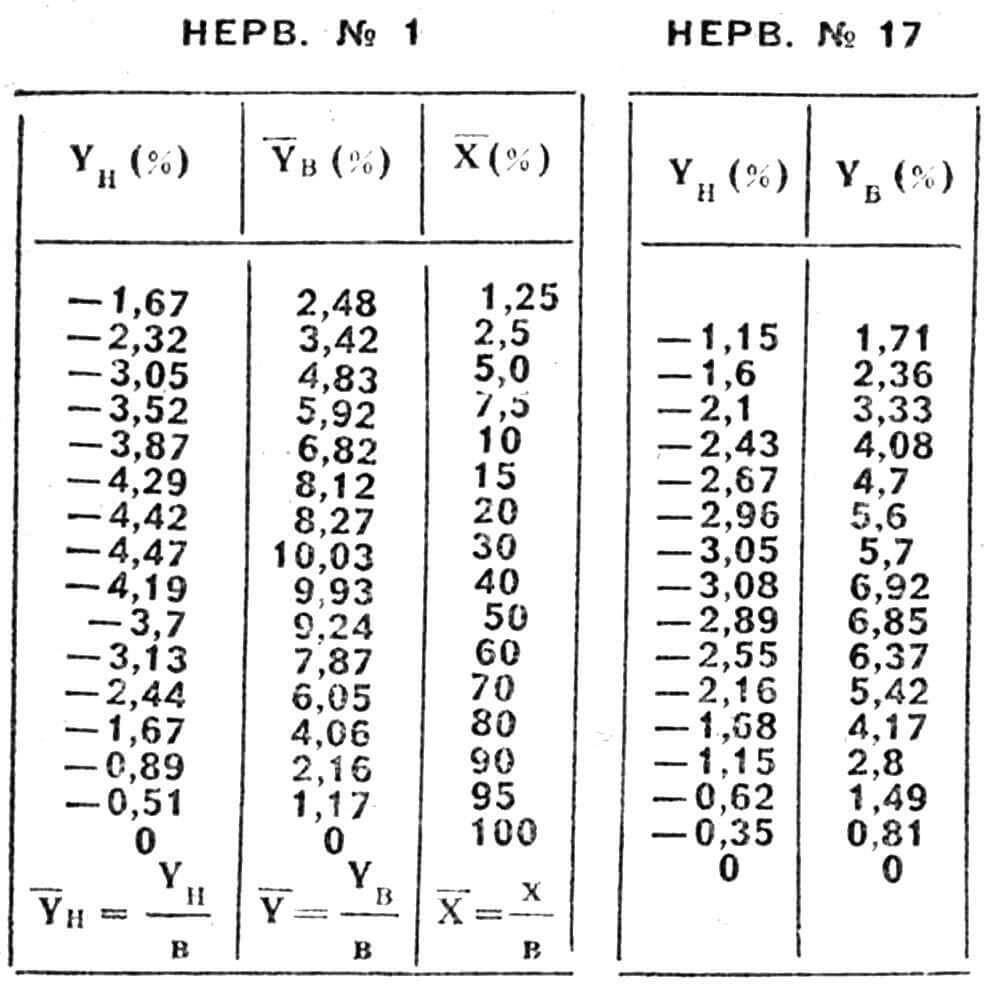

RAF-38 profile with a relative thickness at the tip of 10% and at the root of 16% of the wing chord. The detachable part of the wing is made according to a single-spar design with a torsional plywood sock and fabric covering. The tail and rudders have a similar design.

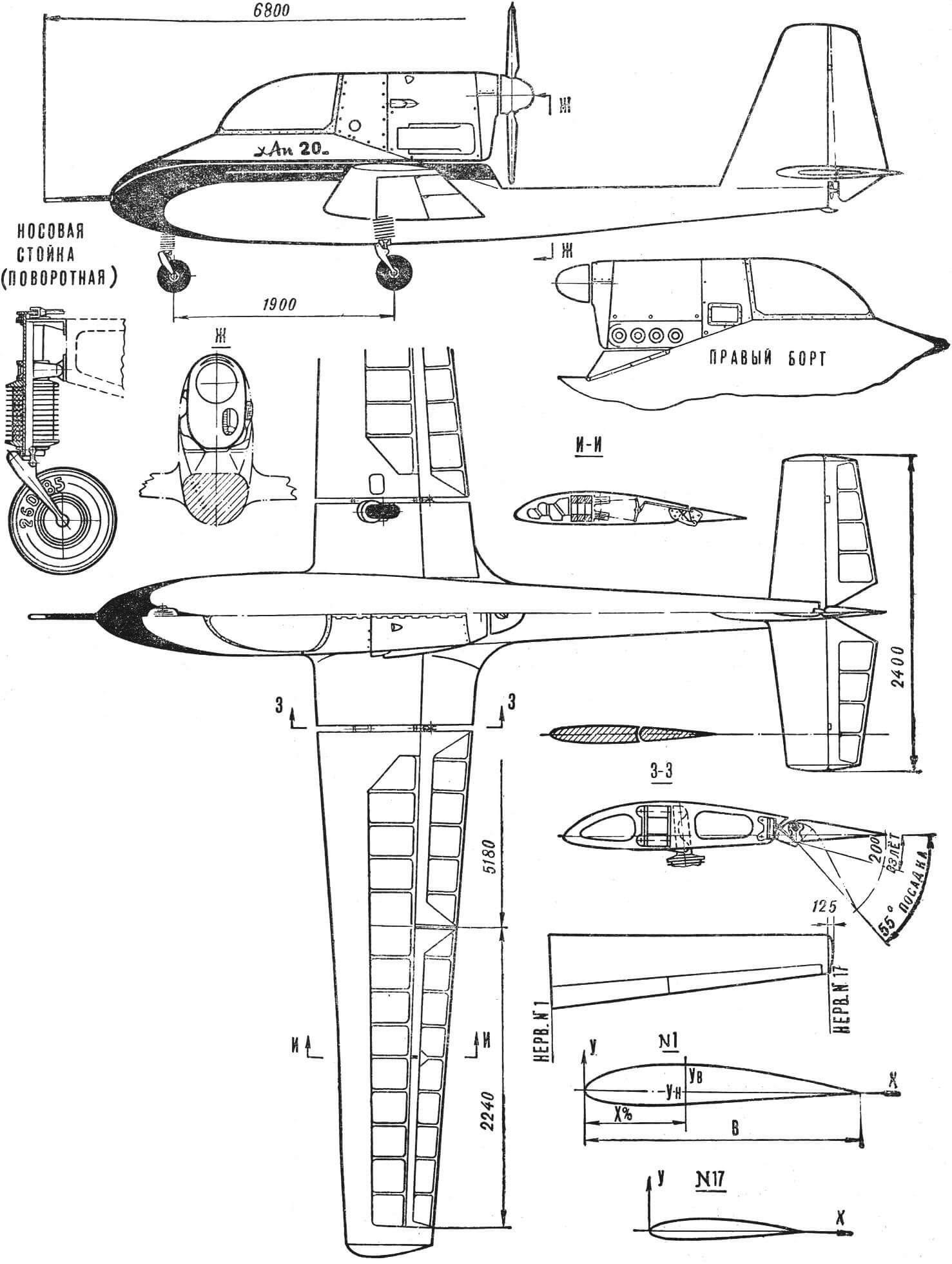

As a takeoff and landing mechanization, the aircraft uses a slotted flap located on the center section and cantilever parts of the wing. The flap is usually deflected by two positions – 20° and 55°. The aileron is slotted, with aerodynamic compensation, suspended at three points. The center section is made according to a two-spar design and is completely covered with aircraft-grade plywood. Box-section spars.

The fuselage is semi-monocoque. Its frames have an oval cross-section, and the tail boom is round. In the forward part of the fuselage there is a pilot’s cabin with a removable canopy. The contours of the canopy blend smoothly into the overall contours of the aircraft. In the tail section, the fuselage beam merges into the keel, forming a single whole.

The horizontal tail has a trapezoidal shape in plan with a cutout for the rudder. The profile of the stabilizer and keel MUNK-2 is symmetrical, with a relative thickness of 8% at the end and 12.3% at the root. The stabilizer is removable. Its attachment points allow you to change the installation angle. The elevator, mounted on the stabilizer spar, consists of two independent halves.

The aircraft is equipped with a Czechoslovak aviation engine M-332, four-cylinder, in-line, air-cooled, with a maximum power of 140 hp. With. The fuel system supplies fuel to the engine from tanks located in the center section and fuselage. On the hood there is an air intake for cooling the cylinders, a supercharger intake; in the upper part there are intakes for cooling the engine crankcase. On the starboard side behind the canopy there is an oil cooler. When operating on the ground, the engine is cooled by air suction by the propeller and the use of exhaust gas ejection. Push propeller, metal, variable pitch, reversible.

The landing gear is non-retractable. The main struts are attached to the center section spar, the nose strut is attached to the fuselage power frame. Shock absorption is carried out by a package of rubber rings (15 for the main struts and 10 for the bow). To improve shock-absorbing properties, the rubber rings are separated from each other by duralumin washers. When landing an airplane, forces are transmitted through the fork and earrings to the lower support plate, causing it to slide along the chrome part of the strut and compress the package of rubber rings.

Aircraft control is mixed. The control handle and pedals are connected to the corresponding steering wheels via rods and cables. The flaps are controlled by an electric motor. The pilot monitors the flap deflection using a dial indicator.

The cabin is equipped with all the necessary aeronautical instruments: speed indicator, slip indicator, VD-10 altimeter, variometer (vertical speed indicator) and instruments that control engine operation – tachometer, cylinder head temperature indicator, oil, fuel, air pressure gauges and oil temperature indicator. There was also a place for a radio station.

The propeller pitch is changed electromechanically, using a remote control installed in the pilot’s cabin. There are fixed blade positions for the “Takeoff”, “Rise”, “Highest speed” and “Reverse” modes. In addition, it is quite possible to install the screw in any intermediate position.

The control levers for the throttle and altitude corrector are mounted on the left side of the cabin. The control levers for the supercharger and oil cooler flaps are located on the cabin floor along the axis of symmetry of the aircraft.

We designed the KhAI-20 as a sports aircraft for setting records in the first weight category (up to 500 kg). It is also designed to perform all aerobatics.

Based on the drawings and description of the “student aircraft”, it is possible to make a cord model of it with 2.5 cm 3 and 5.0 cm 3 engines. Due to the fact that the fuselage has a rather complex shape, we recommend making it from fiberglass.

AIRCRAFT BASIC DATA

wingspan – 10.44 m,

length – 6.8 m,

height – 2.085 m,

wing area – 10.2 m 2 ,

take-off weight – 500 kg,

empty weight – 350 kg,

wing load – 49 kg/m 2 ,

track width of the main wheels – 1.7 m,

take-off speed – 86 km/h,

landing speed – 74 km/h,

highest speed – 270 km/h,

cruising speed – 190 km/h,

vertical speed at the ground – 8.3 m/sec,

practical “ceiling” – 8600 m,

take-off length – 145 m,

run length (without the use of a reversible propeller) – 110 m.

V. LYUSHNIN, S. ELISTRATOV, engineers, Kharkov