Czechoslovakia justly called the center of Europe: at its plants at different times was created by the machines and equipment are well known throughout the world and is characterized by high reliability and original design solutions.

Czechoslovakia justly called the center of Europe: at its plants at different times was created by the machines and equipment are well known throughout the world and is characterized by high reliability and original design solutions.

With the advent of jet aircraft required a training aircraft with fuel-efficient turbojet engines for mass training of future pilots. In Czechoslovakia, has developed a training aircraft (TCB) since the mid 50-ies of the last century under the guidance of the famous aircraft designers Zdenek Rublic and Karel tomáš. Debugging and run this machine into production under the designation L-29 “Dolphin” headed by engineer Jan vlček, who took over from his senior colleagues. In 1962, the national company “Vodochody”, which was part of the Central Bohemian region of the machine-building factories began mass production of “Dolphin”. In 1963 he was joined by the company “Years.” Until 1973 these businesses built 3568 L-29. The creation of this aircraft was a major success for the Czechoslovak aviation industry and contributed to the continuation of the work in this direction.

Design Bureau headed by Jan vlček, and a leading designer Karl Dlouha proposed in August 1964, two more projects prospective TCB.

The first was a deep modernization of production of L-29 variant L-129 intended for initial and basic training. The aircraft was the basis of the educational complex, which included more flight simulators and ground test equipment (KPO). It is complemented by supersonic TA L-39М1 “Machtrainer”.

The second project — UTS L-39 versions, differing equipment. The training complex of its complement of training equipment, flight simulator and KPO.

In the proposed draft UTS constructive solutions consistent with typical single-engine fighter with a turbojet engine (TRD) of the air forces of Warsaw Pact countries. The crew were housed in tandem: cadet — in front of the cabin, followed by the instructor. The plane was designed for possible operation from unpaved runways, which led to the placement of the air intakes above the wing to exclude the ingress of solid particles and water in a turbojet engine on takeoff. The wing had a pronounced sweep. Subsequently, it has established end fuel tanks, and all fuel was in the fuselage. Under the wing housed the main landing gear with brake wheels allow for a rough landing. All units were designed to provide easy access for replacement. The motor attached to the front part of the fuselage and the rear section together with the tail acted as a cover.

The plane was designed under Soviet or Czechoslovakian turbojet engine thrust of about 2000 kgf axial compressor. After discussion, chose Soviet serial double-circuit turbojet engine AI-25, prepared under the leadership of General designer A. G. Ivchenko for passenger Yak-40. A modification of this engine, known as AI-25V for UTS L-39, were performed by the enterprise “Motorlet” (formerly “the Walter”), which is reminiscent of the index From the base V. AI-25 AI modified-25V differed mainly oil system modified to perform aerobatics, and later released from the AI-25TL — a smaller number of stages of the high pressure compressor. During bench testing of the AI-25V on the “Motorite” revealed a significant sensitivity of the engine to form the supply channel. The static thrust of the engine was equal to 1400 kgf, the launch was provided by the starter generator.

With AI-25V flew the first three prototype. In 1967 — 1968 DTRD tested on the flying laboratory Il-28 flight Research and test Institute (VZLU). The modified engine was installed in the rear fuselage in place of the cabin arrow.

Aerodynamic study of the new aircraft were carried out in wind tunnel VZLU in close cooperation with the scientists of TSAGI. Help the Soviet side it was not the limit. Representatives of the Soviet air force actively participated in the mock committees to solve many questions on the layout of the cockpit, availability, and maintainability of the aircraft. Initially, the nose of the fuselage were conceived with two large hatches providing easy accession to a machine with KPO КL-39.

The main developer of the aircraft L-39 was the company “Vodochody” of a production economic Association (PHO) “Aero”, which in January 1968, completed the Assembly of the airframe first flight of the prototype L-39 — X-02. Installation of aircraft systems continued until the end of the summer of 1968.

X-02 for the front edge of the air intakes had three anti-surge doors and the guide blade at its entrance, the center section of the wing had a pronounced sideways V. 28 Oct 1968 X-02 rolled out of the factory airfield “Vodochody” to determine the characteristics during taxiing. A leading test pilot from VZLU for conducting comprehensive tests appointed Rudolf Dujana who participated in this program from the very beginning.

4 Nov R. Duhon completed and the first takeoff of the L-39 with the flaps retracted. Control X-02 when fully released the flaps he had to evaluate at a safe height and depending on the result of the check to sit down with retracted or extended flaps. The test flight lasted 35 minutes. Make sure there are no problems with balancing, the pilot gained altitude of about 1000 m and evaluated the operation of the engine, the controllability of the machine when released the flaps (they jammed in take-off position — in this position and was promoted landing) aerodynamics, brakes and chassis, as well as on minimal speed.

After small improvements in early December 1968 the aircraft presented the mock-up Committee. On the run after a demonstration flight X-02 due to excessive braking, tire burst the left front of the chassis, but the pilot managed to keep the prototype on the runway.

In early may 1969 Duhon first raised in the air a second flying prototype, the X-03. He was distinguished by a modified fairing between the wing and the fuselage. In the initial stages of testing of the prototype X-02, 03, and 05 with DTRD AI-25V small antisurge sash, located at the entrance of the air intake, manufactured from wood for their operational improvement. The stabilizer prototype was made adjustable to select its optimum position.

In early June 1969, the X-03 was transferred to the first stage factory flight tests, which lasted until November. The prototype X-03, which gradually expanded the boundaries of flight ranges in mid-may, again joined the X-02. After replacing the engine he used to check his work. A prototype of the Kh-03 had the air-conditioning system, and further testing of the engine AI-25V and intake.

Verification of flight characteristics, the L-39 was performed by the pilots branch of the flight test VZLU R. Duhon, J. Kunz and A. Oswald. During the climb one of the flights on the X-03 has occurred an unplanned reset the lamp back of the cab. Duhon with the tech gauge in the cockpit was able to successfully complete the flight.

In September 1969 on test passed X-05. At the first flight drew attention to cases surge in case of overload. Improvements made on the plane, not helped to get rid of this phenomenon. After the eighth flight test program on the aircraft, the engine was replaced, and the car passed again to the factory test that was performed on X-03.

At the end of April 1970, to test the L-39 was joined by factory test pilot Juraj Shots the following prototype X-06, characterized by enlarged air intakes of the engine, run the air starter-generator “Sapphire 5”, made in Czechoslovakia by a French license. Sapphire increased the autonomy of the machine, especially in winter.

During the test flights of the six happened unplanned inspection of the aircraft on strength: in July 1970 the factory chief pilot Vlastimil David has safely made an emergency landing on the ground with the landing gear retracted due to the absence of the left post. The reason of emergency landing was a defect of the thrust holding the shutter.

In mid-may 1970 X-05 after the restoration of the painting and replacement of the instrumentation brought to the second stage of factory tests. This stage included aerobatics, the test of control in inverted flight and in the corkscrew, defining the limits of the flight characteristics when the pilot Juraj Shots allowed continuous overload. As a result, the upper wing skin appeared wavy deformation.

Wing dismantled and sent to “Years” for the repair and local strengthening. Ahead of schedule on 15 days of the pilot Yu Shouts performed in mid-December 1970 first flight of the prototype X-07 with engine AI-25V.

By this time, according to test results, it became clear that to perform some technical requirements needed to increase the thrust turbojet engines. Of the two proposed engines — the “Walter Titan” and AI-25TL chose Zaporozhye engine and early 1971 has begun preparatory work for installing it on the plane.

Meanwhile, in February 1971, in the military test flight characteristics in Research and test center 031 passed the fifth prototype. Before the summer was performed by around one hundred experienced flight.

In the summer of 1971 moved to the next stage of testing — testing a system of salvation. Ejection seat VS-1BRI from the second cockpit L-39 was first tested at the stage of factory tests in November 1970, after the joint system has passed the factory and military tests. The chair was tested on the MiG-15UTI and on the third prototype L-39 in its original form. The entrance test in June 1971 with the X-03 in-flight ejected military parachutists-testers Suhomel K. P. and Plzak.

Pre-production on X-07 (standard zero of the series) completed the revision to reduce the driving force with the disengagement of the front wheel during the run.

The front landing gear sprung a surprise of another kind: at certain speeds, it had fluctuations, known as “shimmy”. The characteristics of the chassis have been studied for quite a long time; in December 1971, the plane X-03 additionally equipped with rocket boosters, and on the X-07 on the front bearing mounted damper. However, the problem arose again after increasing the gaps in the chassis, appearing as a result of wear and tear. One of the reasons for the emergence of the “shimmy” was the shape of the grooves of the tracks of the tire tread, it has decided the method of selection of the profile of grooves: Central groove is noticeably wider than the two lateral.

In 1971 the company “Aero Vodochody” began preparations for mass production of L-39, which according to the results of the contest – chose the name “Albatross” (the initial letter And pointed to the belonging of “Aero”). The first five of the serial L-39 is handed over to the pilots of the Czechoslovak air force, 7 September 1971. Production of the aircraft is zero and the first episodes of AI engine-25V for the air force Czechoslovakia continued in the beginning of next year.

The official transfer of the aircraft of these series the military Department took place in March 1972 in the “Vodochody”. “Albatross” after a flight to Slovakia was connected to the test work in Higher military aviation school named after the Slovak national uprising in košice.

In October 1971 he finished the revision of the X-02 for the installation of the engine AI-25TL and started the engine replacement for X-07. First X-07 took off in March 1972, when I finished the factory test X-02 with the new engine.

On X-07 to mid-August 1972, performed factory and partly field testing, perform 75 test flights that assessed the new power plant. Great traction resulted in improvement of basic characteristics: increased rate of climb, decreased run time and set a predetermined height.

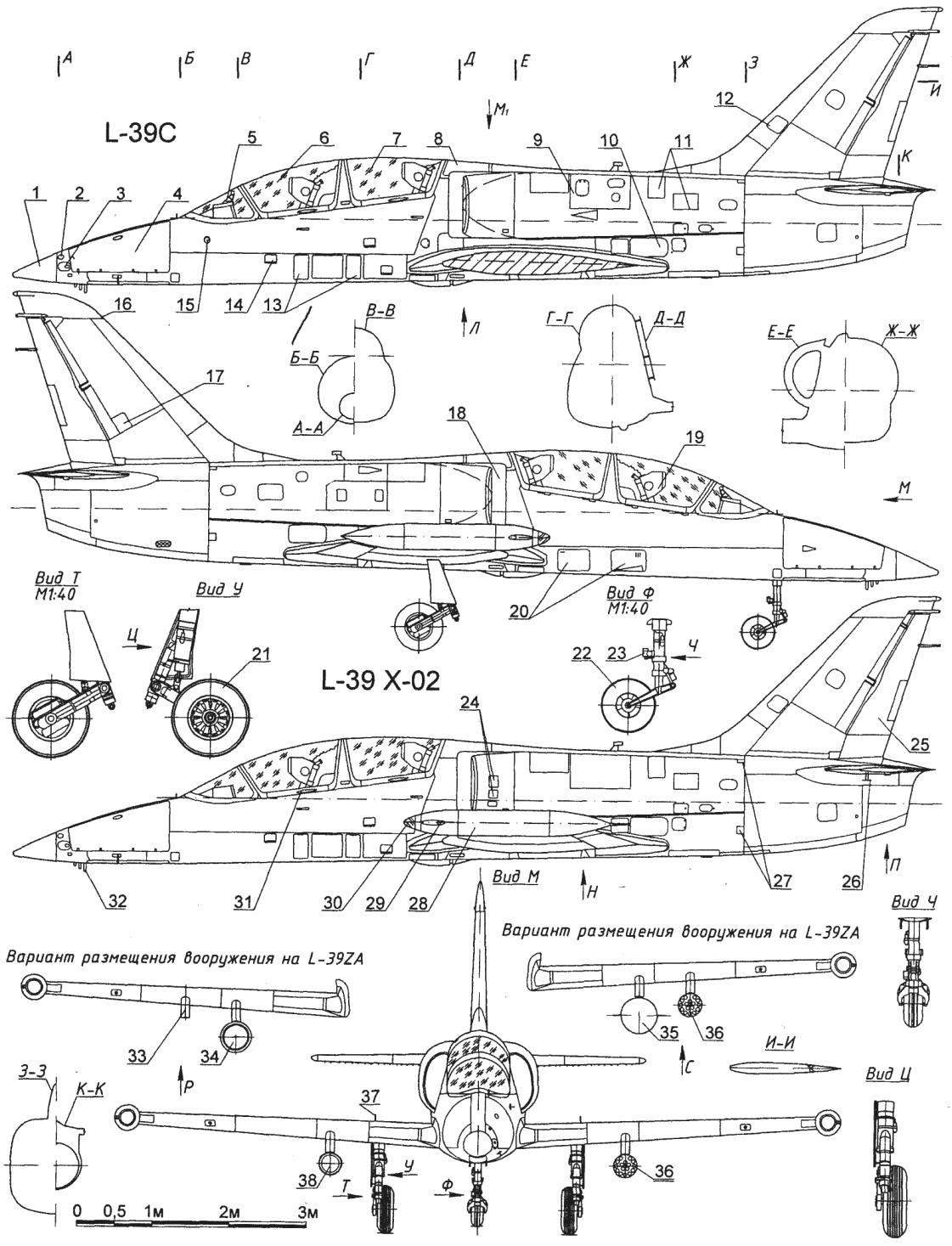

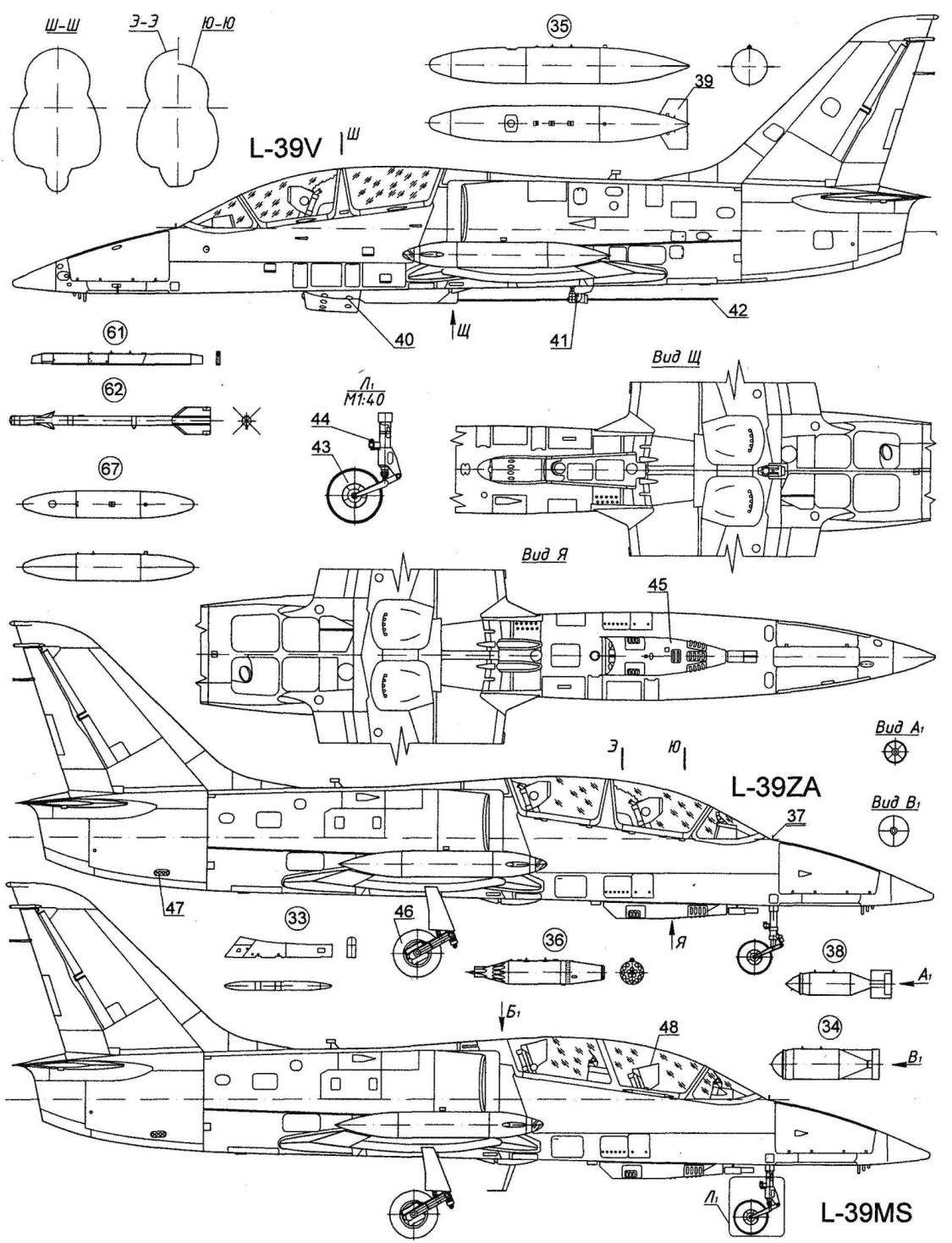

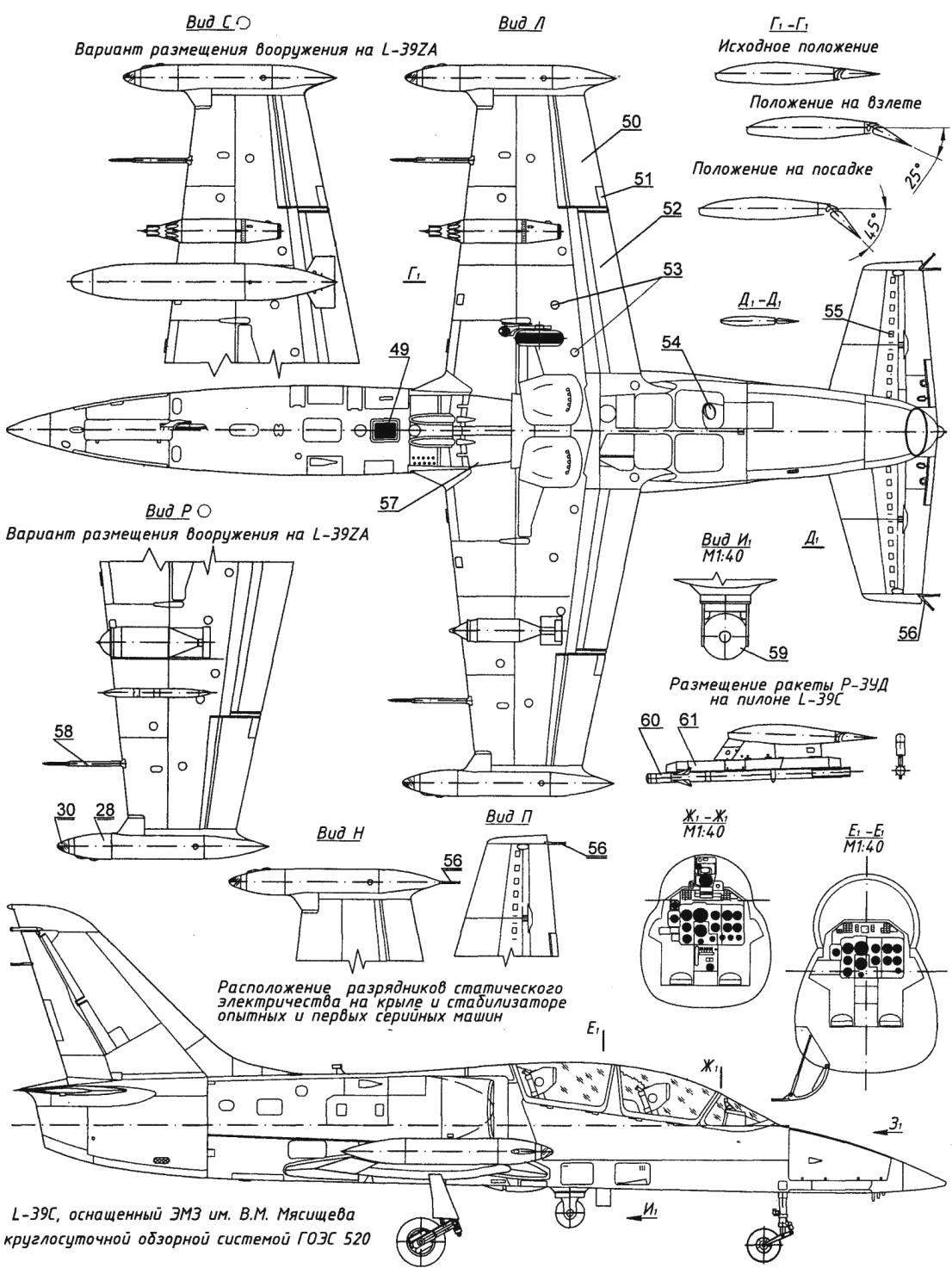

Training and combat aircraft L-39:

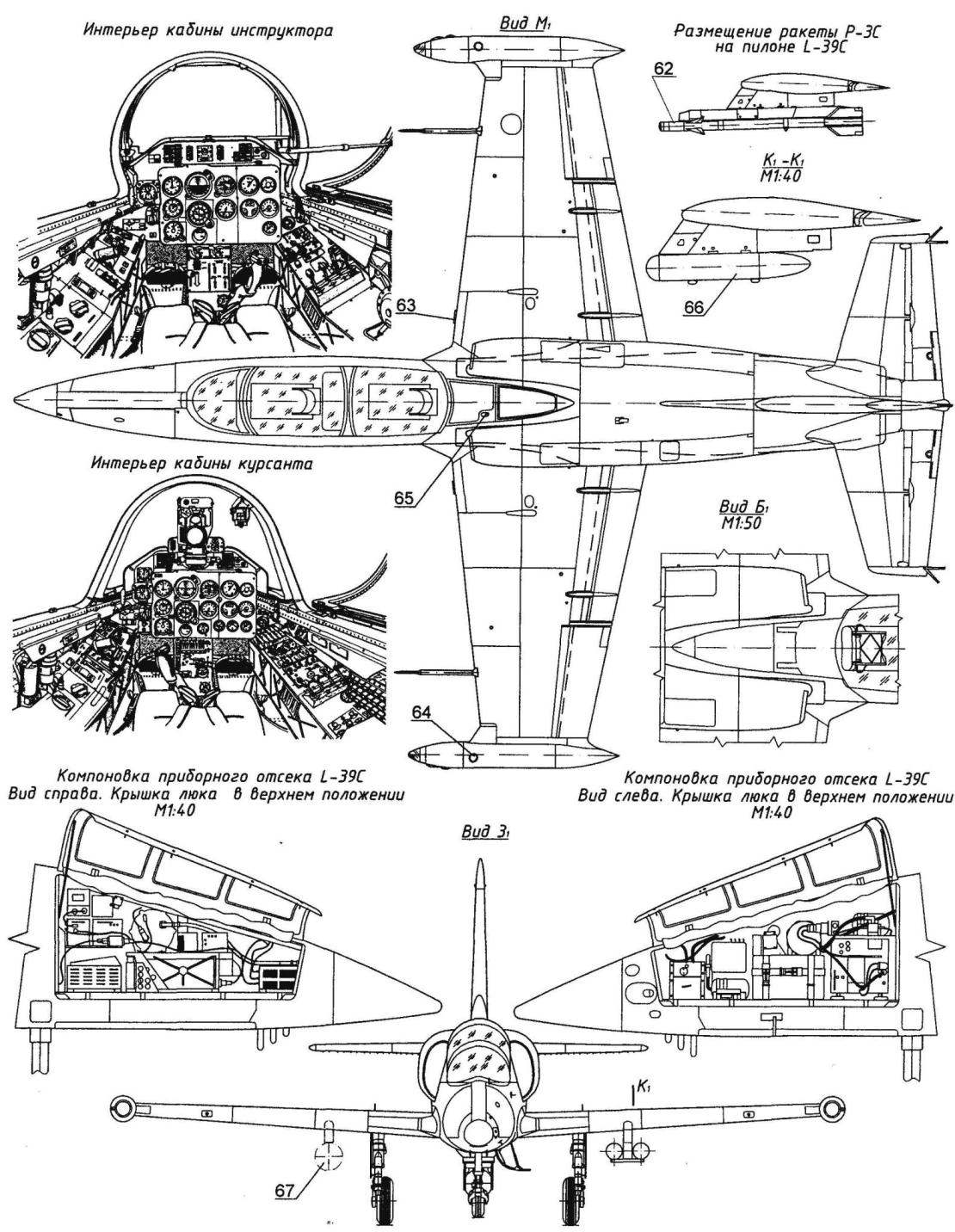

1 — Radome radar rangefinder “quantum”; 2 — the window of the pressure gauge of the pneumatic system; 3 — the hatch charging, pneumatic and oxygen systems; 4 — cover of the instrument compartment; 5 — canopy lights; 6 — cabin cadet; 7 — cab instructor; 8 — compartment radio pkkh-4 radio systems of short-range navigation РСБН5С Iskra; 9 — technological service hatch DTRD AI-25TL; 10 — technological maintenance hatch of the turbine starter “Safir-5”; 11 —technological service hatches DTRD AI-25TL; 12 and 17, a technology transaction service hatches rudder; 13 — built-in footrests; 14 — step; 15 — cap sensor of the angle of attack; 16 — cone of the antenna of the radio station R-832М; 18 — the wedge drain inlet; 19 — ejection seat VS-1BR1; 20 hatches service of radio and electrical equipment; 21 — brake wheel 650×185 mm; 22 — wheel 430×150 mm; 23 — damper “shimmy”; 24 — anti-surge air intake panel; 25 — rudder; 26 — antenna RV-UM; 27 — removal of fittings, joining of the fuselage; 28 — wing fuel tank; 29 — wing navigation light (red); 30 — landing light; 31 — handle canopy; 32 — antenna Radiotechnika SRO-2 (3 range); 33 — underwing pylon suspension; 34 — air bomb FAB 500тс; 35 — 350-liter external fuel tank; 36 — block NAR UB-16-57УМ; 37 — mechanical position indicator chassis; 38 — air bomb FAB 200тс; 39 — stabilizer fuel tank; 40 air turbine L-03; 41 — razor wire; 42 — tow rope; 43 — wheel 450×165 mm; 44 — the nose strut of chassis L-39МЅ; 45 container gun ГШ23-2; 46 — brake wheel 650×215 mm; 47 cassette flares; 48 — ejection seat U8-2; 49 — antenna MCI-56П; 50 — Aileron; 51—trimmer Aileron; 52 is a slit flap; 53 — hatches and service linkage management; 54 — nozzle turbine starter “Safir-5”; 55 and 63—turbulence flow; 56 — dischargers static electricity; 57 — brake; 58 — LDPE; 59 goes 520; 60 — uchebnaya R-ITCHING; 61 —launcher APU-13M-1; 62 — missile “air — air” R-3S(K-13A); 64 — fuel filler cap wing tank; 65 cover the fuel filler pipe main tank; 66 container apparatus; 67 — 150 litre external fuel tank

Aircraft design has undergone a fundamental change, as related to the installation of the engine AI-25TL, and in the course of evolution. After bench testing the air conditioning system has been identified the need of equipping it at the entrance of turbo-cooling unit (THU). Replacement of the power plant was forced to rework the TCA and the entire air-conditioning system the hot air coming into the system from the 9th compressor stage of the engine.

Significantly changed the radio equipment of the aircraft: one part modernized, and the other modified according to specified performance and design requirements. The prototype and first production aircraft until mid-1978 established a coherent radio station RTL1 from the plane L-29. Especially for L-39 enterprise “VUST Prague,” developed by the radio station RTL-31, a tried and tested X-03 in early 1972. From mid-1978, the aircraft was equipped with Soviet dual band radio R-832, which was first tested on the X-07. After its installation the fin tip is shorter due to the lack of a radiating antenna.

The prototype X-07 at the end of 1971 established a radar rangefinder “quantum” for testing the capture of air targets. From mid-1978 “quantum” is no longer installed on the aircraft, as the Soviet air force refused him.

In parallel, the prototype X-07 has started testing radio navigation system RSBN-5S “spark”, first single and later double. This system started to install from the sixth plane of the first series.

Since 1980 planes to the Soviet Union began to equip with a remote control system SDU-L-39. Designers of on-Board radio equipment solved two main problems: first — the actual acquisition of radio units, the second — electromagnetic compatibility to ensure their normal operation. The antenna of the radio compass RKL-4 on the upper surface of the fuselage was altered several times. Brought a lot of troubles by static electricity. Drain electrostatic charges provided comfortable accommodation for a new type of dischargers on the trailing edge of the rudder and the tip of the stabilizer.

Change the alignment of the plane after installation it DTRD AI-25TL and acquisition of the radio altimeter RV-5 required moving the battery in the instrument compartment in the forward fuselage. Further rearrangement with the transfer direction RKL-41 led to a change in the electrical system.

On behalf of the Ministry of defense of the Czechoslovak enterprise “Aero Vodochody” has developed the aircraft L-39V for towing artillery training target KT-04. Single version of the “Albatross” had a leaky cabin: in the rear cockpit mounted drum towing winch with steel cable 5 mm diameter winch Drive was carried out pressure turbine L-03, located under the fuselage. Behind her, in front of the rear fairing of the wing was the unit for emergency shutoff cord.

Development of prototype tow X-08 coincided with the replacement of the power plant. Under the modified AI-25TL X-08 was made in June 1972, and his testing was completed in 1974.

Add-ins in the lower part of the fuselage slightly affected the flight characteristics of the aircraft. The prototype in contrast to the serial of the aircraft was not equipped with aerodynamic brakes.

A prototype X-07 was considered the benchmark for a series of L-39, intended for flight schools of the USSR. In early 1973 the plane with a set of measuring equipment was transferred to the state of the control trials in the Soviet Union.

Test team in GK NII VVS was headed by leading engineer Mr Kotlyar. The leading pilot it included Alexander Petrovich Holopov. For the Soviet it was not the first and not the last meeting with the Czechoslovak technique: before they were flown L-29, and later jointly held the military trials of L-39, – special tests-sport aircraft Z-526F and Z-42. The tests have fully confirmed the implementation of laid down requirements. The aircraft received high praise, its performance exceeded that of modern foreign analogues and its predecessor L-29. The new machine is far superior to him in the first place aerobatic characteristics. There was a good review with designated instructors, sufficient equipment of the cockpit, as close as possible to the conditions of combat aircraft. Emphasizing the similarity of the L-39 and MiG-21 in the behavior on the landing and climb-out as the drawback, noted the need for a rescue crew in a wider range of altitudes and speeds. Here was the possibility of the training of cadets to the elements of combat application and the autonomy of the aircraft when the engine is started. But in fact the full list of flaws and needed fixes was two times less than after a similar test L-29.

To complete the main test programme the basic training aircraft, later designated the L-39S, conducted additional tests in 1974: life support system — the X-02 in the beginning of the year and X-06 — operation from unpaved airfields in the spring.

The first ten production aircraft for the Soviet of the customer passed in the baseline test, and after minor changes, they were handed over for operation. In 1973, the USSR has put 14 L-39 in 1974-m — 55. First started developing the L-39 cadets and instructors of the Chernigov higher air force school, received the “Albatross” in April 1974. This was preceded by the training of a group of pilots and engineers vvaul in flight school in Kosice and at the Zaporozhye engine plant. All recommended during the first year of operation improvements considered in the standard 1975, tried in late 1974.

In 1974 started to replace DTRD on the first series aircraft in service in Czechoslovakia, engines AI-25TL, and by the end of next year, not a single aircraft engine AI-25V.

To enhance the export potential of the aircraft 1.-39 and meet the needs of the national air force designers “Aero” in 1973 began developing modifications with increased combat load. It was originally designated the L-39Z and the following year it was included in the state planning Commission. In the second half of 1970-ies in this work, the aim of which was the creation of an aircraft with a reasonable price for increased pilot training and light combat aircraft focused primarily.

The work was done in two stages. On the first — reinforced wing with four pylons: outer — for combat load and internal — external fuel tanks (PTB), which summed up the fuel valve. The variant was later designated the L-39ZO. In the second stage modified the fuselage: moved a number of units and changed the cutting of the skin, mounted underneath the container with a double-barreled gun GSH-23. For testing gun mount with ammunition box in the fuselage as a ground stand used a deactivated X-03.

The plant has experienced a fire in late 1974.

The construction of the prototype X-09 was completed in June of 1974, the fly-performed Yu Shouts. The key test in the program L-39ZO was the rockets and their effect on engine performance, check the strength of a regular chassis with increased takeoff weight, as well as bombs, and standards. Required to perform static strength tests of reinforced nodes glider “Nine” was also used for testing gun mount. For testing of the variant ZO, completed in March 1976, attracted the prototype X-10. On the “top ten” has tested a new chassis with the widened wheels, which needed to increase a niche through bulls on the top wing skin at the fuselage.

In June 1976, he completed a comprehensive examination of the aircraft L-39ZO for the joint factory design and testing. Checked at the same flight characteristics, evaluated the aeroelasticity of the wing with four pylons and placed them on load: the results of the test has not been entered, no additional constraint compared with the L-39S with the old wing. In drivability and behavior of the aircraft does not appear any adverse effects, the change in the characteristics obtained was proportional to the increase in mass and resistance. Certain difficulties emerged during reset PTB 150 and 350 l, both empty and filled with water, simulating the fuel. After separation from the locks 350 liter tanks turned around the transverse axis and at a certain speed, faced with the rear edge of the wing near the flaps. In another case of PTB after reset pressed against the front edge of the wing and falls off from her on the landing. The defect was eliminated by installing the aft tanks stabilizers.

When firing GSH-23 at high angles of attack and overloads occurred overheating of the engine due to a pressure change at its entrance. Installation of various localization of the powder gases on the cut stem did not give satisfactory results, so chain firing the main gun turned on the sensor of the angle of attack. He provided blocking firing at extreme regimes. In these tests used a prototype X-11 that was built in the spring of 1977.

For use aircraft L-39ZA as a reconnaissance aircraft it tested photocontainer PFK-5. Control military test aircraft was completed in late 1977. After they conducted a thorough inspection of the machine in the USSR and the plane was ready for production.

UTS L-39 was a major achievement for the aviation industry of Czechoslovakia. In 1976, its founders, headed by Jan vlček said the state prize Clegg ment Gottwald. “Albatross” was awarded gold medals in the 15th International engineering fair in Brno (1973) and the International fair in Leipzig (1979). The plane was purchased for its air force, 23 countries of the world. The Soviet Union in 1973 -1990 years of acquired 2080 L-39S from 2784 built machines, of which 2244 — L-39S.

The whole concept of the aircraft was the basis for further modifications. Still in the design phase of the L-39 in the 60-ies as the future prospects were considered more advanced version of the aircraft, L-39S with the engine thrust of 2000 kgf, with blowing boundary layer with the front edge of the front flaps and ailerons. This significantly increased the maneuverability of the aircraft. This option remained unfulfilled.

The emergence of a new generation of aircraft was the signal for the development of modern systems with an increased share of electronics, providing a more effective solution to navigation and combat tasks. A General trend of increase in combat load has inevitably led to a more powerful power plant. Its development started in cooperation with the Czechoslovak specialists company in Zaporozhye. The work eventually led to the emergence of modernized L-39MS, first flying in September 1986. At the same time created a version of the aircraft, towing targets L-39MS. The maximum program for L-39MS provided for the creation of aircraft for basic training of military pilots since 2000.

Jan Vlček was not able to see the maiden flight of L-39MS. Since 1981, his work was continued by chief designer Vlastimil Havelka. Directly supervised the development of the project engineer Alois Benetke and lead designer Emilian Postle. The desire to preserve the good qualities of the L-39 helped to create the aircraft level requirements.

In serial production, the aircraft received the designation L-59. Its shape did not change much, but the toppings and the airframe upgraded. Thus improved manufacturability, increased the resource, used new construction materials and technical processes. From L-39 he was distinguished by a reinforced airframe, new avionics (including collimator indicator on the windshield), and a more powerful turbojet engine DV-2, developed jointly by the USSR and Czechoslovakia. The aircraft had the extended nose cone and a slightly modified form of the vertical stabilizer. Three L-39MS were delivered to the Czech air force in 1991 and two in 1992.

In comparison with the L-39 the main advantage of the L-59 is primarily an engine DV-2, the thrust of which remains at 500 kg. It was developed by order of the Czechoslovak government at the plant “Progress” (Zaporozhye) and is commercially available company, “Považská strojarne” in Slovakia.

Political change and the failure of the Russian air force from single-engine aircraft, unfortunately, had a negative impact on our cooperation. The decline in production at the turn of the 90-ies and loss of the main customer had a significant impact on the subsequent program of activities of the company, which began to focus our development on the Western partners.

Two thousand aircraft delivered to the USSR, about 800 remain in service, the Russian airmen and 300 — Ukrainian. There are several programs safeguard the normal flight operation of the “Albatross” until the Russian TCB of the new generation. The Russian program provides for the restoration and spare parts supply L-39 forces of the Russian aviation industry. This work since 1994 is engaged in EMZ named after V. Myasishchev. The program provides two stages:

in the first Czech obsolete components are replaced by domestic, at the same time develop technologies for repair of imported products at the Russian enterprises;

the second — provides for the replacement of the Czech equipment and assemblies of modern domestic equipment and carrying out structural improvements to improve safety and performance.

There is an interesting program offered by the “Desaware-service” together with the Israeli company IAI. The aircraft presented at Le Bourget in June 2003 at the pavilion of Israel, equipped with modern avionics, satellite communications system and onboard computer. Israeli avionics allows you to tailor the cockpit L-39, su-27 and MiG-29. Zaporozhye engine builders are prepared for this new aircraft modification DTRD AI-25ТЛШ that on 13 June 2002 first tested in flight on this plane test pilot Gasvianis of the armed forces of Ukraine Eduard centurions. The installation of more advanced and powerful engine made it possible to appreciably improve the dynamic characteristics of the aircraft and flight safety at low altitudes. Given the complexity of the funding of the armed forces in the countries operating the L-39, it is possible and other alternative proposals. Therefore, the history of this aircraft is still far from complete.

N. JAY