Europe’s “Super Sabres” were exploited by the French air force until 1976, after which he was transferred to Denmark and Turkey, where they served until the 1980s.

In 1960, 80 aircraft version “And” altered version “D” and transferred to the Taiwan air force.

A few cars F-100F converted in towing aerial targets, giving them the designation DF-100F, and 81 “Super sabre” overage — unmanned aerial target designation ° F-100.

Design description

The aircraft was a supersonic single-engine single-engine airplane had all-metal construction with swept wing and tail.

The fuselage is semi-monocoque consisted of two parts, joined at the rear edge of the wing for ease of replacement of the engine. In the front was the air channel of oval cross section, which was held under electrical and radio compartments and the cockpit, then the channel cross section smoothly into the round inlet to the engine.

The pilot was housed in the ejection seat, which provided a safe evacuation of the aircraft at all speeds up to supersonic. Air brake served located in the lower part of the fuselage is a flap that could be deflected at an angle of 50 degrees. At the top of the fuselage behind the cockpit was the auxiliary air turbine generator — in case of failure of the engine it was developed for on-Board electricity consumers.

Behind, on the left side of the fuselage was located 17 hatches that covered the straps of the braking parachute, which was placed in the compartment between the stabilizer and the fuselage. In the front part of the fuselage under the engine intake was installed rod air receiver pressure; the Parking lot is “lance” “broken” and worked my way up.

The all-metal wing with a sweep angle of 45° to the front edge had a profile with a relative thickness of 7%. Wing consisted of 36 main parts, which together with two spars and stringers formed caisson compartment. The wing was equipped with automatic slats. In the rear of the wing between the ailerons and fuselage were located flaps with a system of blowing boundary layer.

The tailplane had a similar wing design. The stabilizer was all-moving, otklonivshesj at an angle of 20°. Above the rudder on both sides of the keel were fairing system emergency discharge of fuel. Drive rudders — hydraulic, with automatic damping.

The main landing gear with wheels dimensions 856×224 mm, equipped with anti-skid devices were cleaned by means of a hydraulic system to the fuselage. There was hiding and a-pillar with dual wheels dimensions mm. 446×139 main landing gear upon their release, closed doors to prevent the ingress of dirt. The sash could be opened manually on the ground for maintenance.

F-100D with external fuel tanks

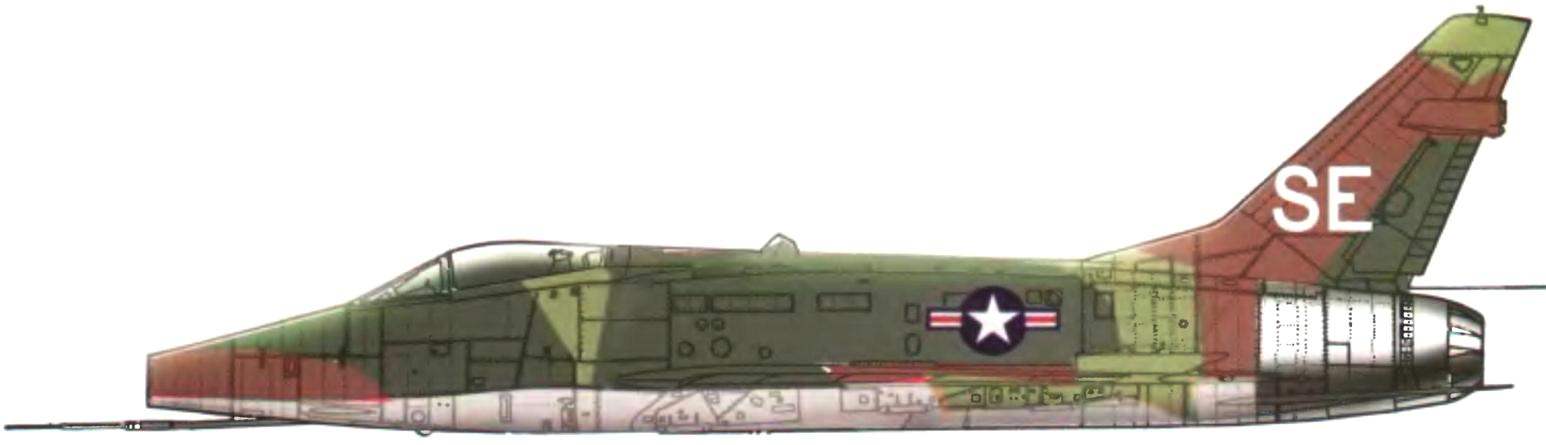

F-100D of the air force of Denmark

F-100D of the French air force, painted in the colors of the 48th tactical fighter wing of the US and installed in the Park of the American airbase, Lacanha (England)

F-100D on routine work

The cockpit of the F-100D-55

The basis of the power plant of the aircraft is twin-shaft turbojet engine “Pratt & Whitney” maximum thrust 5310 kgs, equipped with an afterburner. Afterburner thrust is achieved 7700 kgs. Fuel tanks total capacity 6582 l housed in the fuselage and wing. If necessary, under the wing of suspended fuel tanks, and could be refueled in flight by the receiver located on the right wing.

Built-in armament consisted of four 20-mm guns M-39E with ammunition, 200 rounds per gun, housed in a front lower part of the fuselage guns was Rate of fire of 1500 rounds per minute.

Various combinations of missiles and bombs total weight up to 3405 kg is suspended under the wing.

Color plane produced in different versions — depending on time and location. Machine the U.S. air force was mostly silver with black letters and signs on the left half of the wing from the top, right — bottom, and on both sides of the fuselage. Many of them attended the colored supplements and signs of aviation parts.

Planes some parts had top tri-color camo, in the form of spots of irregular shape, dark green, light green and brown. The lower surface is light gray. Similarly painted and machine French and Turkish air force. Planes Denmark are not painted either entirely covered with silver paint. They were later kamuflirovannaya paints a muddy brown and green colors on all surfaces.

Supersonic aircraft F100D Super Sabre. During the Korean war, which lasted from 1950 to 1953, in service with the us strike aircraft consisted of jet planes F-86 “saber” (“Sabre”) and the F-94 (“Starfire”) with transonic speeds. These machines served in first line until the mid 1950-ies, when they began to be replaced by new, this time a supersonic aircraft. New generation cars to be called Centuty fighters (fighters of the century) or “acres”, according to their numerical index. First among these has been the aircraft of the company “North American”, which received the designation F-100 “Super sabre”.

Supersonic aircraft F100D Super Sabre. During the Korean war, which lasted from 1950 to 1953, in service with the us strike aircraft consisted of jet planes F-86 “saber” (“Sabre”) and the F-94 (“Starfire”) with transonic speeds. These machines served in first line until the mid 1950-ies, when they began to be replaced by new, this time a supersonic aircraft. New generation cars to be called Centuty fighters (fighters of the century) or “acres”, according to their numerical index. First among these has been the aircraft of the company “North American”, which received the designation F-100 “Super sabre”.