The main aircraft for training pilots in the great Patriotic war was the U-2 (Po-2) and produce the resource UTI-4. Double export fighter I-7B, Yak-9 and La-7UTI in flight schools were a rarity — they didn’t even spare regiments, and training pilots on them was expensive. In this regard, in the war years in OKB-115, led by C. A. Yakovlev, began the future development of the Yak-18, which replaced the At-2 as a “school” pilots. However, future air fighters needed the aircraft for training their shooting at air targets and bombing.

The main aircraft for training pilots in the great Patriotic war was the U-2 (Po-2) and produce the resource UTI-4. Double export fighter I-7B, Yak-9 and La-7UTI in flight schools were a rarity — they didn’t even spare regiments, and training pilots on them was expensive. In this regard, in the war years in OKB-115, led by C. A. Yakovlev, began the future development of the Yak-18, which replaced the At-2 as a “school” pilots. However, future air fighters needed the aircraft for training their shooting at air targets and bombing.

Under the “curtain” of the great Patriotic war, on 29 April 1945 at the Central airport of Moscow began the factory tests of the latest modification of the fighter Yak-3 with radial engine ASH-82FN. During the test pilot P. Ya. Petrovi reached a speed of 682 km/h at an altitude of 6000 m. during a climb of 5000 m did not exceed 3.9 minutes. However, despite such high performance, the aircraft remained unclaimed.

A year later, on its basis created training aircraft (TCB) Yak-U (which subsequently received the designation Yak-11) with a single-row radial engine ASCH-21 takeoff power to 700 HP and propeller-adjustable pitch VISH-SWISS-20. The engine AL-21 with direct fuel injection was a like half of the ASH-82 and had driven centrifugal supercharger and gearbox. Initially the engine was 100 hours, then it was increased to 150 hours. First flight and factory tests performed by the pilot G. S. Klimushkin under the leadership of chief engineer V. A. Shavrina in 1946, the Machine flew as pilots, M. I. Ivanov and F. L. Abramov.

In the same year the Yak-11 has passed the state tests in GK NII VVS (lead pilot P. M. Stefanovsky) and was put into production at factory No. 292 in Saratov. The airframe of the Yak-11 was essentially a repetition of the Yak-3. The exception was the two-seat cabin. His weapons consisted of a machine gun synchronised UBS 12.7 mm with pneumopericardium and electropneumatics-Kim descent and ammunition 100 rounds of ammunition, and two 50-kg bombs on wing holders DB2-45, located outside the plane, sweeping the air screw, at a distance of 2055 mm from the axis of the aircraft. In the first production cars in the cockpit of a cadet set sight PBP-1A and in the left wing — shot-method PAH-22 (on the right console bearing surface housed the landing light). Chassis remained from the Yak-3, but spike wheel made fixed gear.

In 1946, the plant number 292 has begun operational testing of fourth and eighth cars of the first series, and next year (planned — July 1946) — military trials in Kachin aviation school. Following this, the aircraft began to arrive in the combat units. The first year of operation training of the fighter, the air force revealed its positive and negative sides. On this occasion, in December 1947, commander K. P. Vershinin reported in the map: “the Practice of operating (…) the Yak-11 (…) showed that the technique of piloting the plane is simple, stable in flight, the rudders, the free, mechanisms of control of the aircraft are working fine. The position of the pilot in the cockpit comfortable, good review. Difficulties in development of flight crews is not. The engine AL-21 (…) reliable and economical. A lifespan of 100 hours is produced completely without derating. The main disadvantage of (…) the aircraft are a large length of run-up and takeoff distances due to the low power of the motor, and also a small vertical speed.

Therefore, at takeoff, in flight around the circle, and especially at a climb, the engine works with a higher voltage, and in the event of a missed approach with landing gear and flaps the plane barely gaining altitude. Cleaning the same flaps when it is accompanied by rapid loss of height of not less than 50 m. In the process of operation of the aircraft in the air force identified a number of design and workmanship (…), the elimination of which would make the plane not just good, but perfect.”

Production defects are treated, in particular, cracks in the spars, breakage of the attachment of the ailerons, the destruction of the kochs propellers, damaging the expendable fuel tanks and others. Pneumatic tail wheel is aged an average of 45 flights. Contrary to the conclusion of the GK NII VVS and the opinion of K. P. Vershinin, production vehicles had insufficient longitudinal stability margin, left much to be desired and the handling. Had to restrict the refueling to 150 kg instead of 268 kg. to Eliminate the latter defect was possible only through the replacement of the horizontal stabilizer. “Yak-11 — recalled test pilot A. Ants — was a beautiful plane. Blunt, sturdy and strict. Require very strict management”. This brief feature is confirmed by the statements of many pilots trained on the Yak.

In the spring of 1948, the pilots of the GK NII VVS I. M. Dzyuba and V. G. Ivanov held the state tests of the Yak-11 with a new sight ASP-1H and shot-method C-13, which were completed in those years, the fighters. Unlike previous fotopulemetov, s-13 was mounted on the visor canopy pilots.

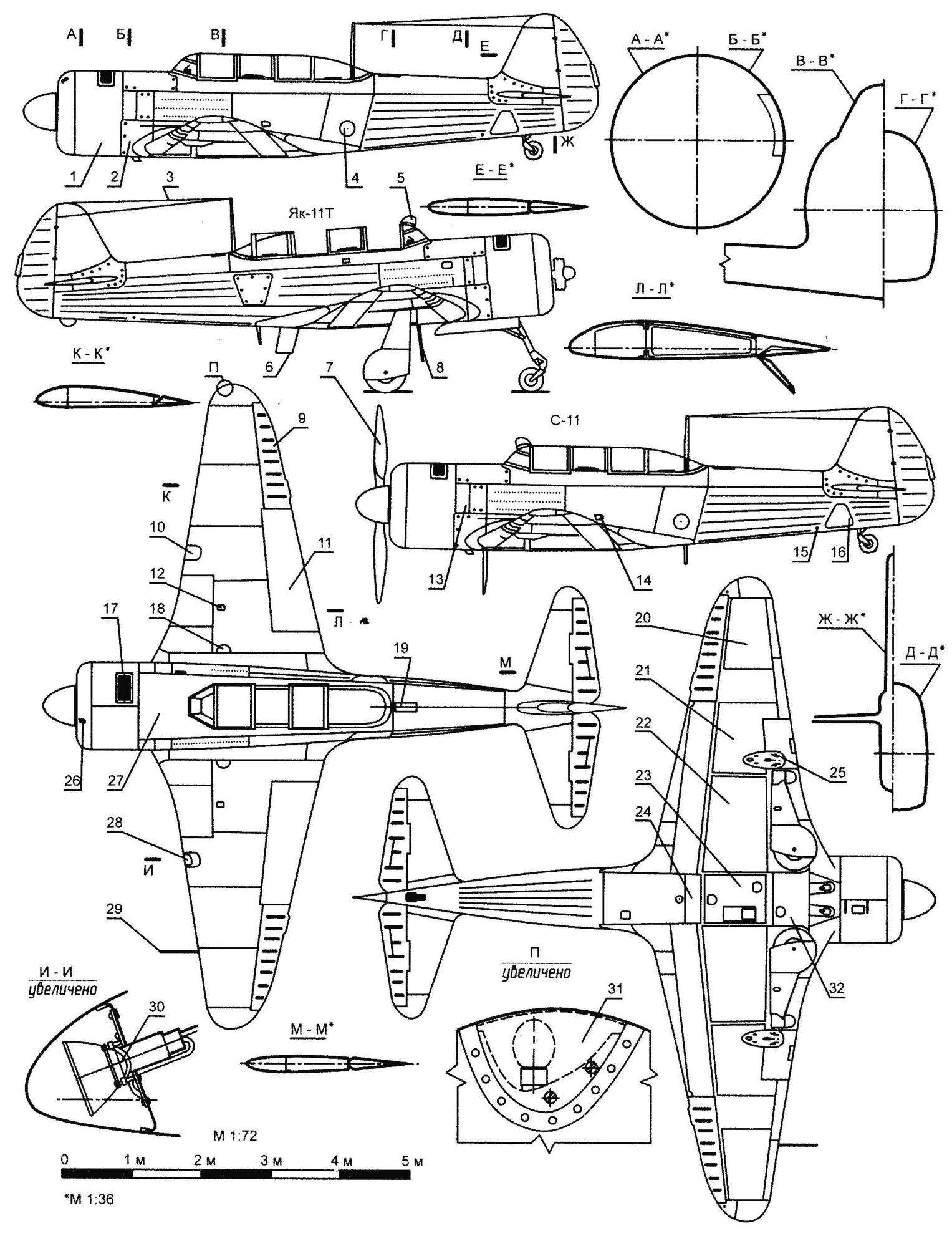

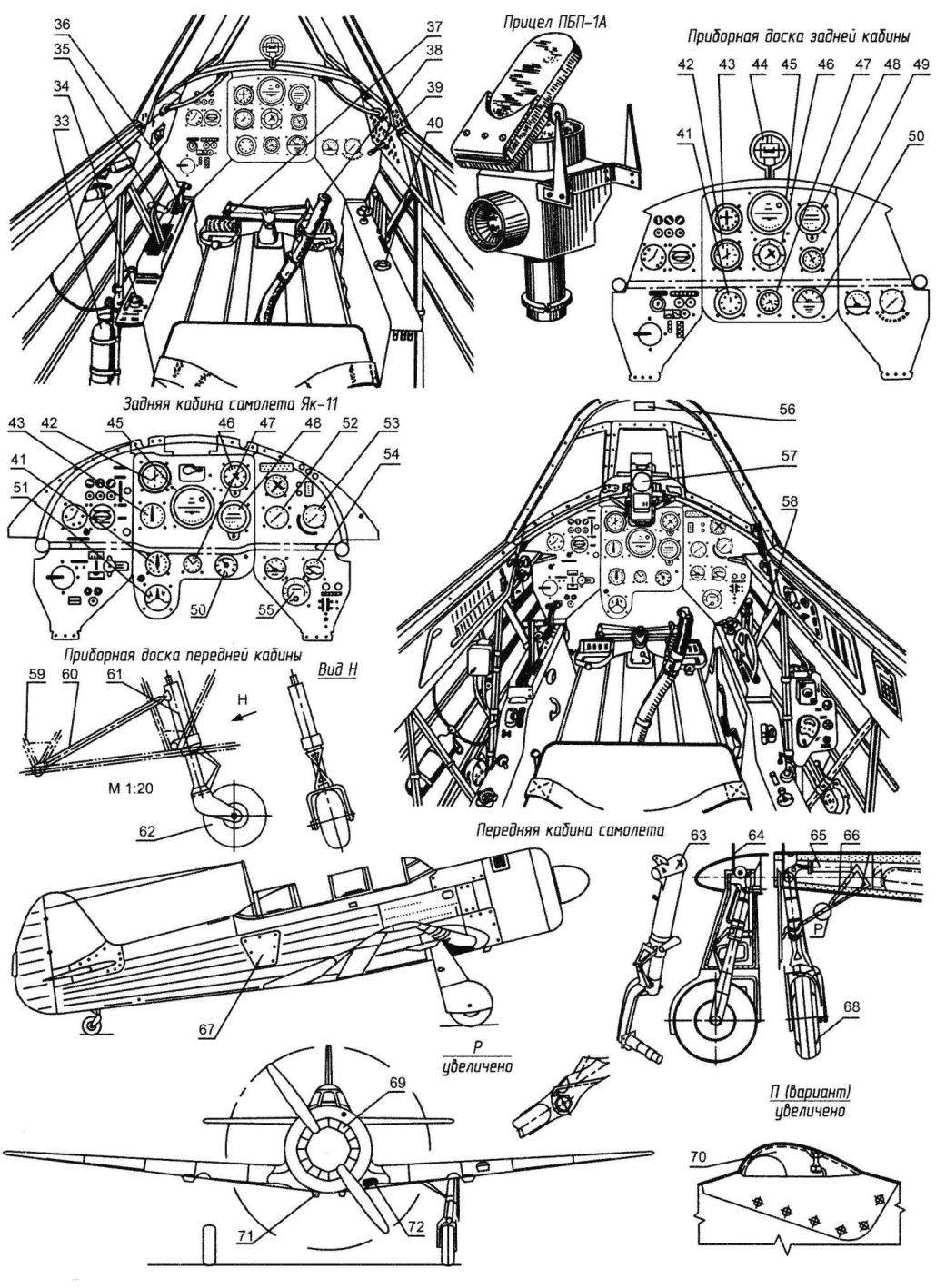

Training fighter Yak-11:

1 — cylindrical cowl; 2 — the bottom cover of the hood motor; 3 — antenna HF radio RCI-ZM or RSI-6K; 4 — cover flap of the filling of the pneumatic system; 5 — shot-method C-13; 6 — footrest (only on the Yak-11T and x 1); 7 — propeller VISH-1 P-b-20; 8 — antenna VHF-station (only s-11); 9 — Aileron; 10 — cover of the shot-method PAH-22; 11 —flap; 12—Luke the filler neck of the fuel tank; 13 — fold adjustable hood; 14 — step; 15 — hole transport tubes of the fuselage; 16 — rear hatch of the fuselage; 17 — mesh air filter; 18 — Luke benzinger; 19 — antenna radiolucency, RPKO-10M; 20 — extreme wing Luke; 21 — average hatch wing; 22 — root hatch of the tank; 23 – the lower center of the hatch; 24 — rear lower hatch wing; 25 — wing holder DB2-45; 26 — plamegasiteli pipe machine-gun UBS (A-12,7 C-11); 27 — the top cover of the hood motor; 28 — landing light; 29 — rod LDPE; 30 — mount landing lights; 31 — design wing BANO on the Yak-11 to 24 series; 32 — rear lower hatch wing; 33 — oxygen tank; 34 — valve emergency oxygen supply; 35 — lever step screw; 36 — the lever of a fire hydrant; 37 — pedal foot control; 38 — aircraft control stick; 39 — control knob sash ventilation; 40 — rheostat lamp UFO; 41 — pressure-vacuum gage MV-16; 42 — altimeters VD-12; 43 pointer speed DC-800; 44 — compass KI-11; 45 artificial horizon AGK-47B; 46 — compasses MPC-45; 47 — tachometer TE-45; 48 — variometers BP-30; 49 watch AMR; 50 – trehstranichnye indicators; 51 — course indicator; 52 — pressure gauge compressed air main network; 53 — pressure gauge compressed air emergency network; 54 — voltammeter VA-140; 55 — ratiometer of benzenamine BES-46; 56 – rear view mirror; the sight ПБГ1 57-1A, 58 — steering wheel controls doors hood motor; 59 — farm fuselage; 60 — rod; 61 — absorber tail wheel; 62 — the tail wheel (295×110 mm); 63— strut main landing gear; 64 — mechanical position indicator chassis; 65 — pneumatic cylinder; 66 — breaking brace; 67 — Luke service of radio equipment; 68 — brake wheel (600h180 mm); 69 — louvered hood; 70 — constructive design of the wing BANO-45 aircraft with 24-series; 71 — exhaust pipes of the engine; 72 — the air intake of the engine oil cooler.

The scale of the cross-sections M1:36

The need in the Yak-11 was so great that, starting next year, it has mastered the production of the Leningrad plant N3 272. In the process of serial production of Yak-11 in its structure, equipment and armament were constantly altered. They, in particular, replaced the wooden formwork of the fuselage and the lantern of the cockpit of metal and changed the location of the individual rods of the farm mounting a machine gun. In 1950 the pilot G. T. Beregovoy experienced sight ASP-ZN, subsequently replacing the collimator PBP-1A in the machine, released in Leningrad, where it was carried out a control test. The equipment of the aircraft also included radiolucent, RPCO-UP fighter radio RSI-6K installed on a new combat machines, intercom SPU-GP. These and previous improvements executed on the machines, starting with the 24th of the series in 1951, Then the Yak-11 set combo electric artificial horizon AGK-47B scale roll instead of a dive the artificial horizon AGP-2 and turn up with a vacuum pump AK-4C (stopped set machine No. 01209). On the visor of the cadet flashlight mounted shot-method s-13 is the wing POW-22. With the cockpit placed the aerial camera AFA-IM. Aircraft No. 58201 changed the fuel system, now it is possible to completely produce the fuel. The use of on-Board navigation lights BANO-45 and new navigation equipment on the Yak-11 were given the opportunity to perform training flights in both day and night. Installation of stabilizer angle of +1° increased the longitudinal stability margin of the machine. There were other changes aimed at simplifying the maintenance of the aircraft and improving the quality of training of future pilots.

In 1950, the pilot of Boltonosov under the leadership of chief engineer Vershinin conducted the production tests of the Yak-11 with a winch for hauling of cones, designed for training of firing at air targets. The tests confirmed flight performance and handling characteristics. In particular, the release of the aircraft from a spin without delay after giving the rudders on the conclusion that it is important for the learning machine. Serial planes 292 on plant weight by almost 30 kg, and the tests showed that the Yak-11 of the Leningrad plant was lighter by about 20 kg, and fully meet specifications. At the same time he was slightly smaller horizontal and vertical speed, which, however, was within the technical requirements of a customer. Yak-11 with the removed arms and was operated by DOSAAF.

It should be noted that the combination of sight and shot-method allowed to work out the elements of aerial combat without the use of small arms, which simplified the learning process and increased safety. The assets of the Yak-11 listed five world records registered by the FAI class C-1, C! (flight mass of 1750 to 3000 kg). The first of these was established by the pilot J. D. Forostenko, showing August 28, 1950, at a distance of 500 km average speed 441,176 km/h. a Year later, he has brought this figure up to 471,348 km/h In 1951 and 1953. pilots N.M.Golovanov and P. I. Zagudalin set speed records 442,289 km/h and 360,032 km/h at distances of 1000 km and 2000 km Last record achievement was in September 1954 when the pilot I. S. Chernov flew straight 1990,183 km.

The Yak-11 had the opportunity to participate in “combat” operations. In the GDR it was used to combat the propaganda balloons, launched from the territory of “friendly” countries. According to some, during the Korean war, the Yak-11 was used as a night attack aircraft, armed with both bombs and rockets.

When he created the Yak-11, the fleet of the Soviet Union were aircraft with tail wheel. However, since the early 1950s. the situation began to change dramatically. Planes of times of war were gone, their place was occupied with the nose landing gear. This required changing the methodology of training of flight personnel. In accordance with the new requirements in 1951, OKB-115 was charged to the test two modified options: training Yak-11 training and Yak-11T with tricycle landing gear. The last of them was distinguished by the installation of the equipment of a fighter. As expected, the empty weight of the machine in comparison with the predecessor has increased by 166 kg, and flight, due to the smaller amount of fuel, only 60 kg. In the same year, leading engineer Vladimir Svetlov and pilot S. G. Frolov held the state tests Sparky, but it never got wide distribution, mainly due to the worst performance on soft ground. Moreover, in 1950 it needed a jet trainer. Built a small series Yak-11 From the factory in Czechoslovakia under the designation C-11U.

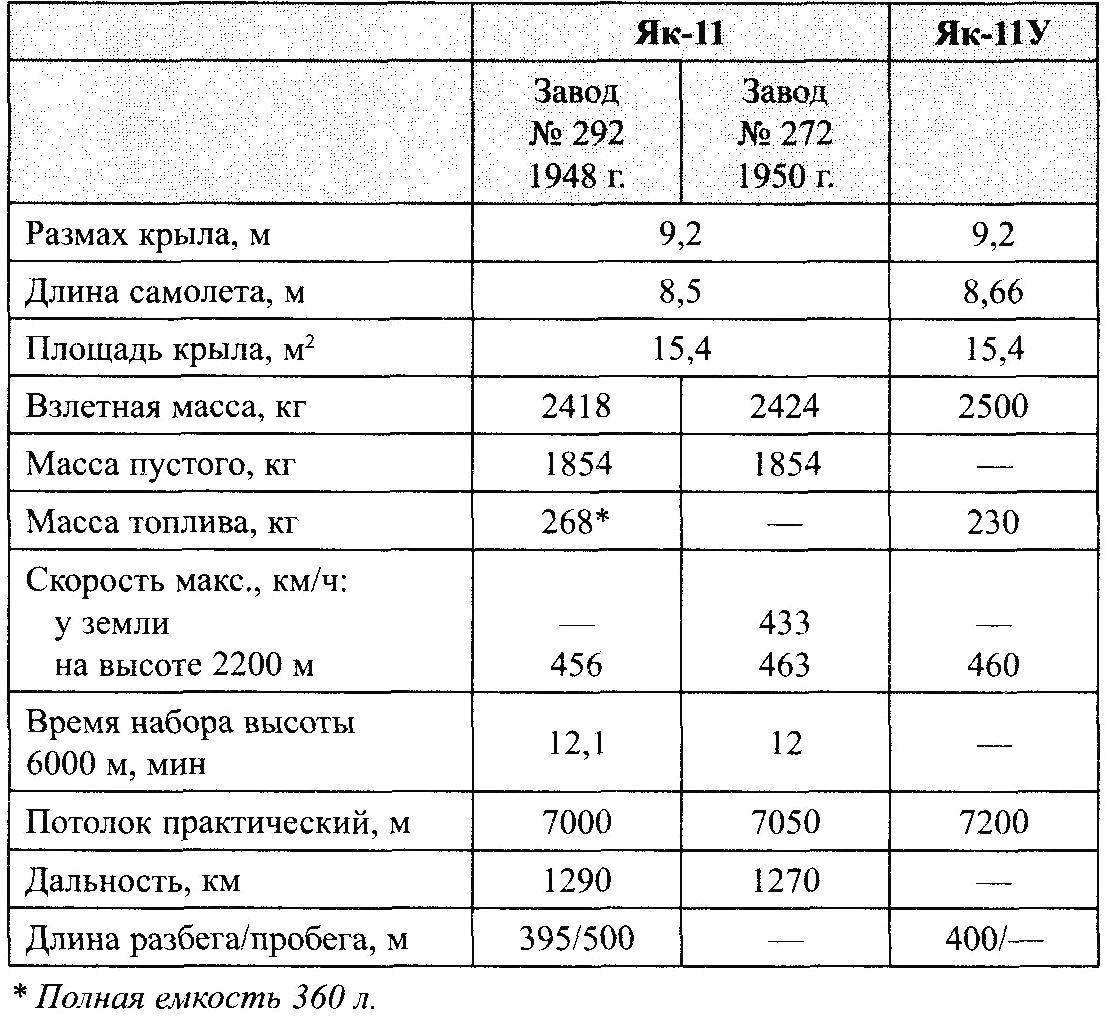

Main features the training of a fighter

Originally the Yak-11 was equipped with a machine gun Berezina, but in 1955 at the request of Czechoslovakia in OKB-115 developed a system under the synchronous machine gun A-12,7 design Afanasyev and at the end of the year gave her the necessary documentation. The modifications include a few Yak-11 converted to a single intended for filming Soviet feature film “Normandy — Neman”. The same path was followed by the French, but the goal they had the other part in an air show. The engines AL-21 was replaced with R-1830-94 of the company “Pratt & Whitney”, takeoff power 1350 HP, which is almost two times more than the AL-21.

During serial construction (from 1946 to 1950) plant No. 292 issued 1706 machines, and the maximum release occurred in 1948 — 871 plane. The plant № 272 from 1949 to 1955 has passed to the customer 1753 machine, and the maximum release occurred in 1953 — 400 aircraft. Participated in the construction of the Yak-11 and plant No. 151. In addition, from 1952 to 1956 in Czechoslovakia built the 707 C-11 (Yak-11). These machines are widespread not only in the USSR but also abroad. They can be seen on the airfields of Albania, Austria, Algeria, Bulgaria, Vietnam, Guinea, Germany, Egypt, Iraq, Yemen, Poland, Romania and Syria. One of the Egyptian cars was in 1986 in the United States in the aviation Museum. The aircraft was fitted with radial engine R-1830-94 and painted under the fighter La-7 I. Kozhedub stored in Monino air force Museum. The Yak-11, produced in large series in three factories, has left its mark in the world of aviation. The machine gave a ticket to the sky thousands of pilots, but it somehow “modest” bypass in the national press.

Painting the Yak-11 — mimicking fighters

Serial production of Yak-11, as already mentioned, began in the first postwar year at the famous Saratov aircraft factory No. 292, the war produced combat “yaki”. However, the color of this plane is strikingly different from his predecessors. However, everything in order.

1946 this year, the plant № 292 29 delivered the first Yak-11. Their release coincided with a great rush job for repair of wooden parts of the structure of the aircraft and updating the paintwork on the fighters of the air force. In January, 18 serial of airlines, among them such giants as plants No. 1, No. 18, and No. 153, seconded team of painters and carpenters to repair the aircraft in the flight parts. The fact is that when storing the aircraft outdoors after some time (about a year), due to sun exposure, rain, temperature fluctuations on the surface of the paint film began “chalking” — the formation of a thin layer of light powdery coating. This phenomenon increasingly was exposed to the surface, covered with bright and matte enamels containing a great amount of pigment and filler. During the war it paid no serious attention — not every fighter has lived up to these kind of “gray hair”. But in time of peace every year (and sometimes more often) to update the color on all fleet aircraft was a luxury.

By may 1947 in combat units were repaired 5688 planes! To avoid repetition of this history, the air force, in the face of their commander-in-chief air Marshal K. Vershinin, among other measures demanded to produce color planes “with the warranty service life of coatings of at least two years” (service life before repair of Yak-9, Yak-3 and La-7 still in service, was installed in two years (Approx. ed.). The coating had to remain without fading, omelene, cracks and peeling. Unexpectedly it has become a stumbling block. If other obstacles to a two-year term of service were overcome all-metal construction new piston, and especially jet aircraft, the paint did not want to endure this period.

To fulfill this condition matte colors was impossible; it seemed easier to do it with the help of glossy enamel. The air force has agreed on their use, despite the reduction (if not complete disappearance) the masking effect. Thus, in the first place was a function of corrosion protection. And fighters are painted with a nitrocellulose gloss green AGT-4 — top and blue AGT-7 — bottom. As the primer layer used silver nitro an AP., which protected the fabric and plywood covering from the ravages of ultraviolet solar radiation penetrating through a layer of colored paint. In a range of colors and was produced in 1946 — 1947 serial Yak-11. During these two years the plant number 292 built 68 cars — 20% of the total number of Yak-11, produced in the USSR.

Looking two years ahead, it should be noted that, in 1948, to solve even a simple task — the creation of enamels that retains its quality under the open sky for one year — the Soviet industry failed. The IAP ensured the quality of coatings on the aircraft for 12 months only when you create normal conditions of storage and care of the aircraft. This implies a hangar storage of aircraft, care for them, such as: full Chechenia, ventilation, wipe down surfaces with a chamois or cloths, that is something that is not in the military units. And yet, at the end of may 1947, the patience of the air force command and Deputy chief engineer of the air force of the armed forces Lieutenant General IAS Ioffe demanded from 20 June to stop painting metal plating fighters (with the exception of the Yak-11) nitropaints and apply for this purpose only lamaslany glossy enamel according to the schemes provided for by order of 3 July 1946 letter of the chief of the air force of the armed forces from January 30, 1947 Metal hull of the Yak-11 had to be painted glossy nitrocellulose synchrometer on the ground ALG-1 hot drying. However, the aviation industry again failed to meet deadlines. The order of map No. 549с about switching to a new color was signed on August 11, 1947, as If in mockery, he began with the words: “In connection with the requirements of the air force of the armed forces about the immediate transition to the painting of metal fighter planes oil enamels…”. The first paragraph of the order concerned, of course, combat aircraft. Then talked about the Yak-11.

Here the task was a bit easier, and time more free: “the Director of the plant № 292 to move on to a monochromatic painting of the Yak-11 nitroenamels, AGT-16, ensuring the delivery of the aircraft on the Assembly, this painted enamel on 1 October”. At the end of the indicated measures that were supposed to ensure the implementation of the first two paragraphs: “the Chief of VIAM tov.Tumanov: a) in a two-day period to agree on MHP (Ministry of chemical industry. — Approx. ed.) specifications oil enamel A36-G and send them to all the factories together with the color standards of paint A36-G and AGT-16, ensuring the identity of their colour; b) till 13 August to send plants guidance for the application of new coatings in production. Zam. Minister comrade.For Sandler to provide within ten days the supply of these plants paint A36-G and AGT-16”.

Based on these unrealistically tight deadlines production of aircraft in the new colour has also been disrupted. But in 1948, the Yak-11 began to paint above and below glossy blue-gray enamel, AGT-16. Thus, the color of the Yak-11 was completely repeated coloring of the fighters.

In the same 1947 was approved specifications for oil matte enamel A-23m. Its nitrocellulose counterpart was called DK-23 (probably DK — for the cabin). Although the legal name of the color of these enamels was “gray-green”, some data associated with the more recent system of classification of shades of paints, suggest that it would be better to call it “greenish-gray”. A-23m was used for painting exterior surfaces, and since 1946 it nitroenamels DK-23 factory No. 292 stained the inner surface of the Yak-11. They have also covered the engine mounts, suspension struts and the flaps, gear, flaps, etc. the First years, the color of these enamels were rigidly standardized and controlled by the pattern of the chief designer. Probably because of this, he could be not only gray-green or zelenovato, but even dark gray. All outer surfaces, as noted above, with gray-blue AGT-16. The same pattern was stained and the Yak-11 Leningrad plant № 272, which took over the production of these cars from the Saratov plant in 1949 Since the second half of 1953 until the end of production in 1954 to paint the Yak-11 was used perchlorovinyl enamel, HVE-16 of the same colour AGT-16. This paint was more resistant. But the main difference from nitrocellulose enamels was incombustibility.

When heated, the enamel is allocated chlorine, which inhibited the reaction of combustion and, if you do not have time to ignite wood or fabric panelling, the flame is quenched in the Bud. The number of Yak-11, painted feathers-vinyl chloride enamel was approximately 240 instances (7% of total output). When shipped from the factory on planes attacked markings: red with a white star (50 mm) and red (10 mm) banding in six positions — on the sides of the rear fuselage, fin and on the lower surface of the wing. Stars and edging was applied red and white enamels on the same basis as the color of exterior surfaces. The diameter of the circumscribed around stars circles was equal to 600 mm (on the keel) and 900 mm (fuselage and wing). Tail number applied on the fuselage, in front of the star. Met and unusual color, for example, English Yak-11, painted the Yak-3 squadron “Normandy — Neman”. Several machines were used in the filming of “Baltic sky”, “Normandy — Neman”. The colour of these cars imitated the colouring of Soviet fighters of the Second world war. And in the series “the Last flight of the Albatross — a German bearing the number 24+E72.

ORLOV, N. YAKUBOVICH