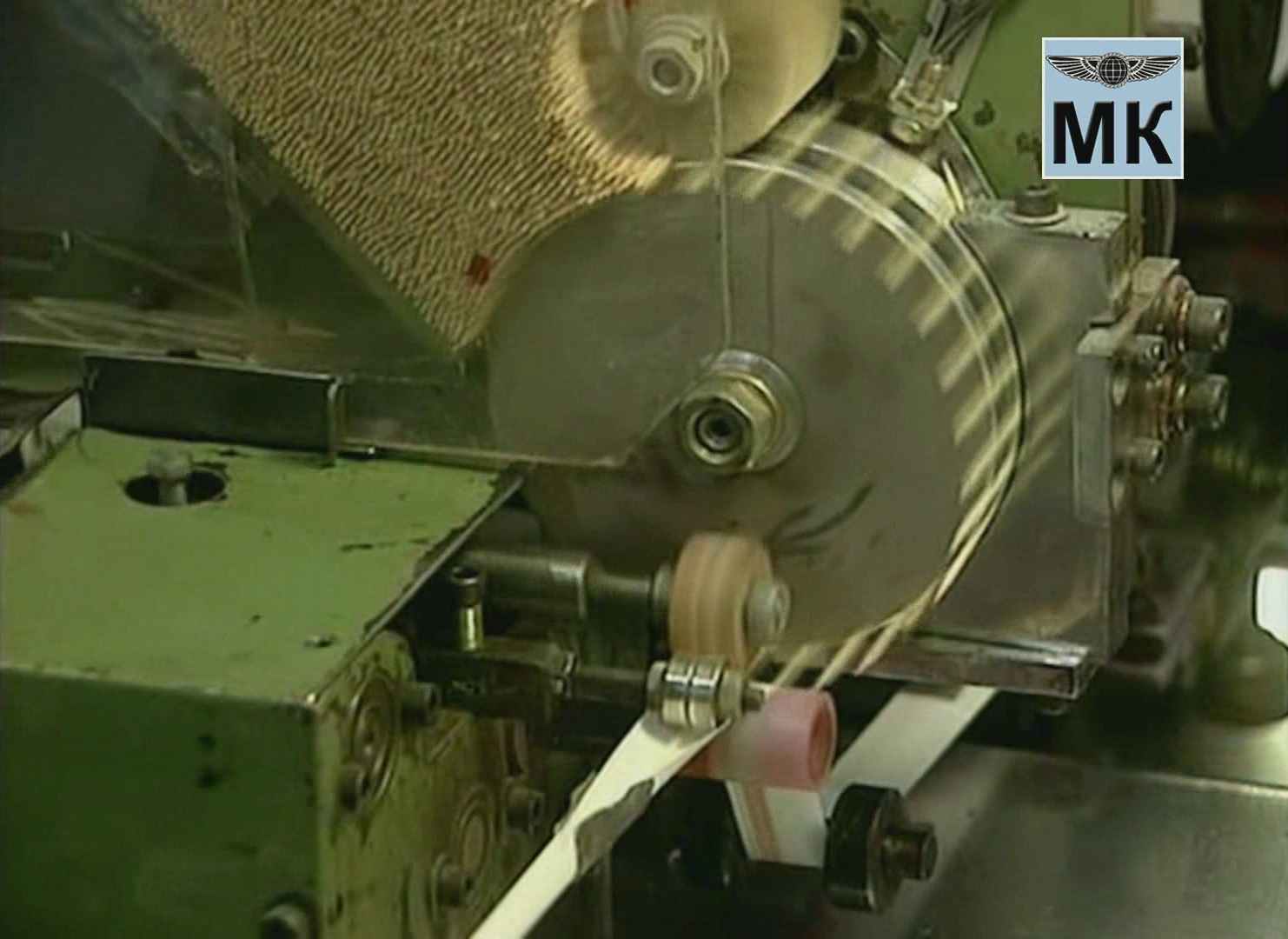

To cut with such ease, the blade must be razor sharp. In the future, the same blades are used for cutting these strips on toothpicks. Then begins the next stage of processing. The cut tape is rolled up, blank. Billet is rolled into rolls of strips manually charged into the machine. The machine automatically unwinds the coil, cut the strips into small sticks of the same size. Sticks pouring a continuous stream. The knives work with great speed, in a minute they fall of 2000 times, producing 8000 future toothpicks. Sticks on jolobu fall into the container, at this stage the wood is still soft, so she hardened her need to dry for 4 hours at a temperature of 121 degrees Celsius.

Further subcity served in polerowany drum, where for 4 hours under the action of friction of talc, and their surface is perfectly smooth. From the drum they are doing on the sorting sieve, which separates the broken toothpicks, and the rest served in the ductwork, which also separates marriage. Blower delivers the toothpicks into two conveyor drums at the ends of the conveyor distribute the flow for the automatic packers.

The machine puts a toothpick in the stack, and then puts them in boxes. Automatic packer designed to pack on 650 subcision in the box. For an hour he fills 1150 boxes. Per hour camera packages 747 500 toothpicks. Some toothpicks wrapped in paper, for shipment to restaurants or airlines. This machine wraps 1200 toothpicks per minute, Narita, turning and saleeva paper. The productivity of the plant for the production of toothpicks just astronomical 20 217 600 toothpicks a day.

Atideo: