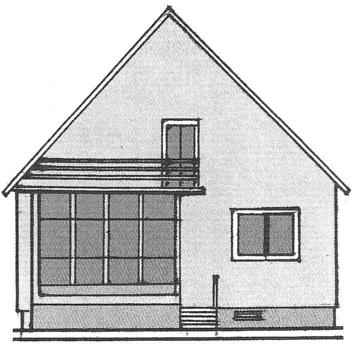

Bearing part perceives and transmits the load to the Foundation, maintains warmth in the house.

Exterior cladding protects against penetration of moisture from the outside design.

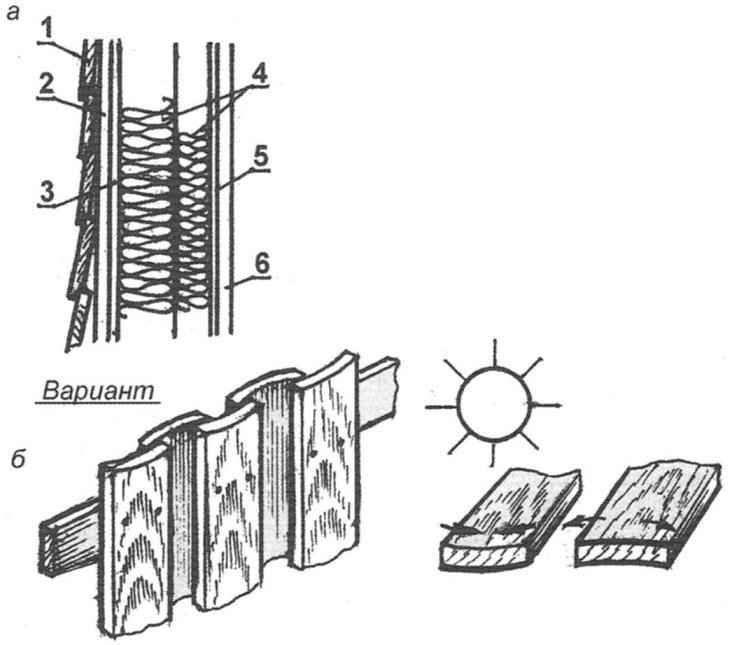

The figures show the types of structures exterior walls.

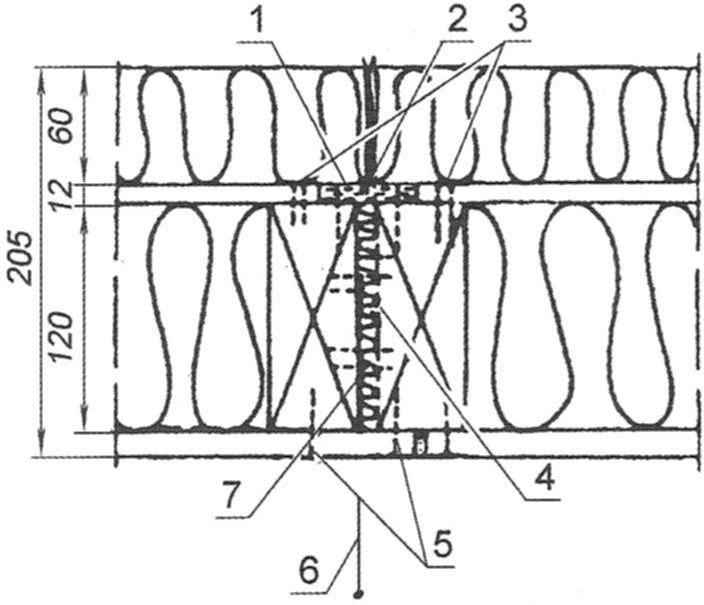

Frame walls are in place. If the insulation thickness is greater than the thickness of the wooden frame, used, or an additional frame including a plate, installed under the outer cladding, or plate on the outside of the frame consisting of mineral wool and having a coating that protects from blowing off (Fig. 1). All structural layers are bonded to the plastic liners that prevent compression of the insulation plate. The distance between the frame uprights not more than 600 mm.

Fig. 1. External wall cladding exposed to the greatest climatic influences

(a – the construction of the outer walls; b – embodiment of the trim panel):

1 – external facing; 2 – vertical wooden lath for fastening of a covering; 3 – film for protection from freezing; 4 – mineral wool; 5 – vapor barrier layer; 6 – inner lining

If the insulation thickness more than 200 mm, use double frame, parts of which connect the or metal mount, or use hardboard.

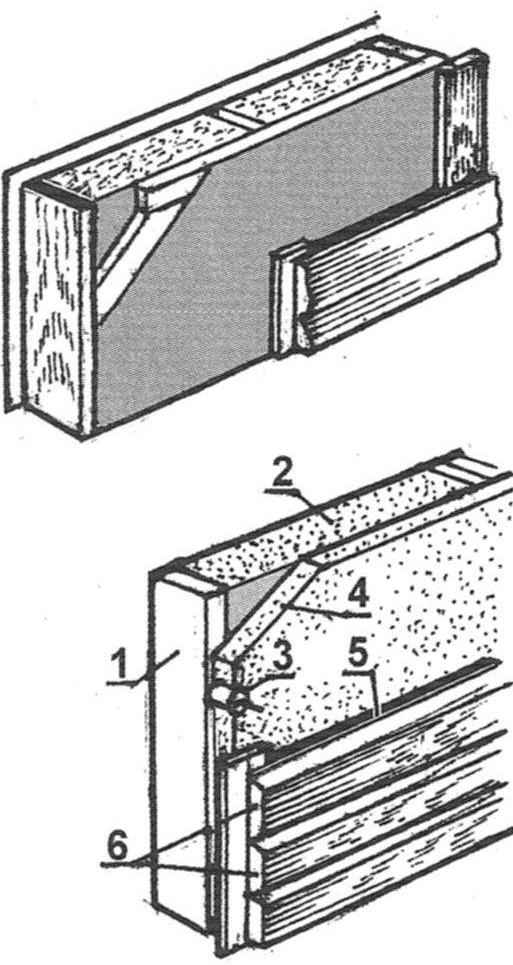

The modular wall panels (Fig. 2) as the insulation may be used sheets or plates of polyurethane foam, heat transfer which is approximately two times less than that of mineral wool. Hole in a wall cut out on the jobsite. The outer and inner facing surfaces of the walls as they do in the usual way. Hardwood mounting beams mounted on top, is calculated in such a way that the load-bearing beams are not located over the mounting holes.

Fig. 2. Types of panels of external walls, manufactured ia the place:

1 – the timber frame section 125×50 or 50x50mm; 2 – mineral wool (filling the frame); 3 – fixing element; 4 – the outer layer of insulation; 5 – ventilated air space; 6 – plank exterior siding

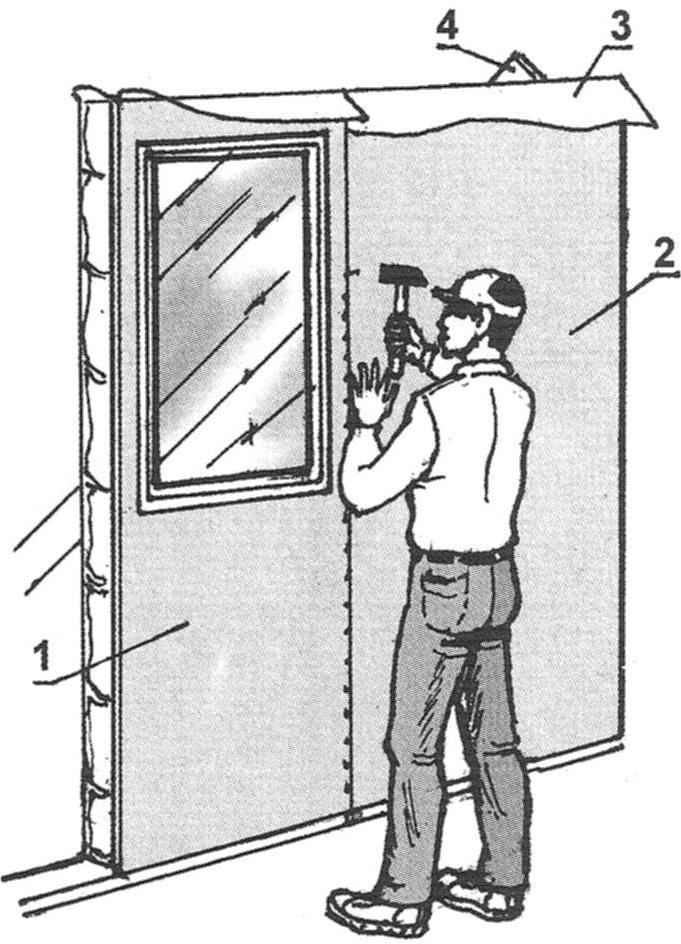

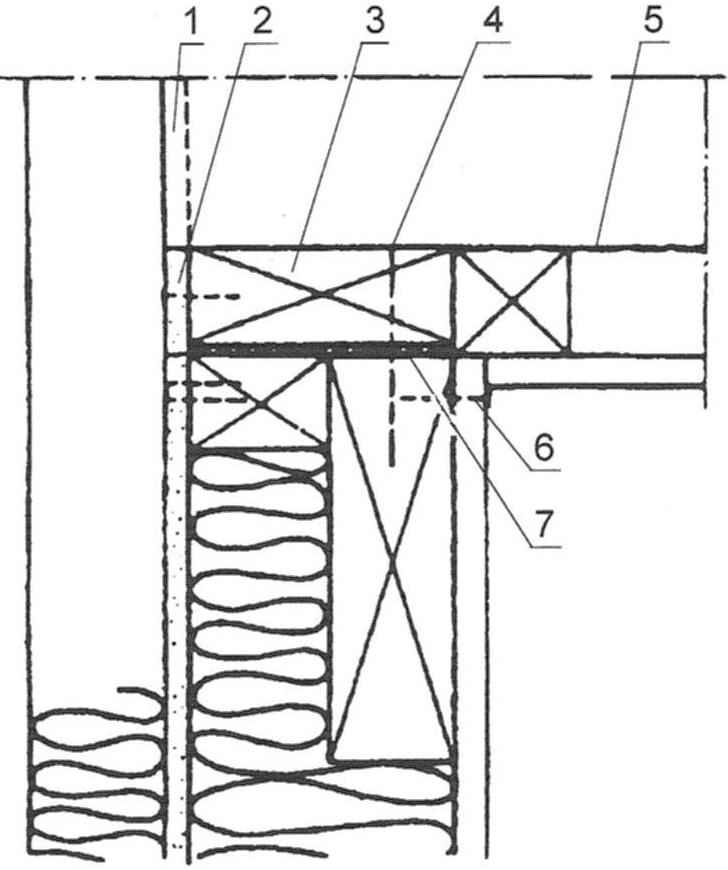

Fig. 3. Installation of exterior wall panels:

1 – window panel; 2 – wall; 3 – moisture proof film; 4 – mounting rail wall fastening

Figure 3 shows how the outer wall, consisting of small panels. Their design is the same as in the traditional outer walls (Fig. 4). Vapor barrier lay a single layer of connecting it in place of the silicone mastic seams (Fig. 5). Fastening the individual elements to the lower beams made at the seams and the inner surface of the collecting wall.

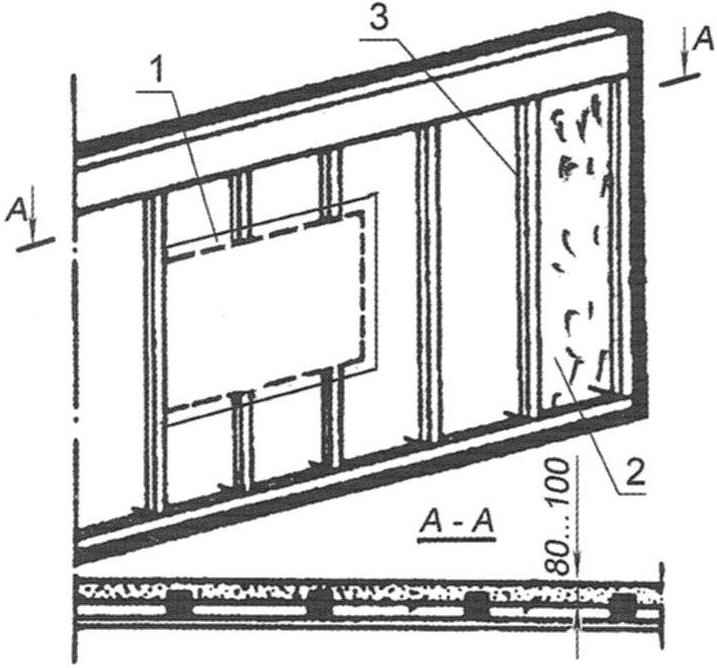

Fig. 4. Outer wall with a wooden frame:

1 – window opening; 2 – thermal insulation Board (filling the frame); 3 – front frame

Fig. 5. Knot the seam of the connection elements of the external walls:

1 – sheet of plywood at the joint; 2 – vapour barrier tape – sizing welds; 3 – sealing mounting pad of porous material; 4 – field joint; 5 – fastening the outer plate of the panel; 6 – axis (marking); 7 – silicone mastic

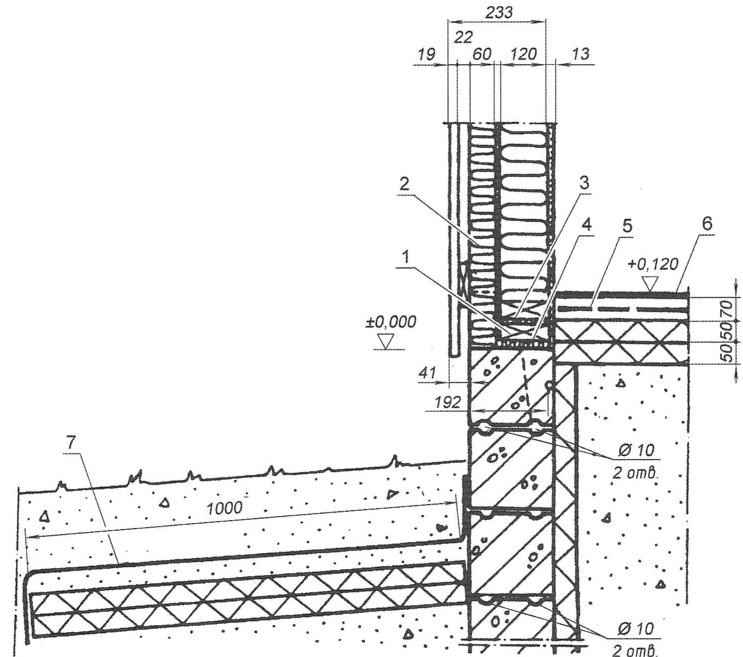

Fig. 6. Installation of elements of the panels of the exterior walls:

1 – a supporting structure made of impregnated wooden boards section 45×120 mm to ensure the mounting frame panels of external walls to the Foundation; 2 – strip; 3 – mounting the suture; 4 – gasket; 5 – reinforcing mesh from steel with a diameter of 4 mm with a cell size of 150 × 150 mm; 6-floor level (top floor); 7 – polyethylene film (waterproof layer)

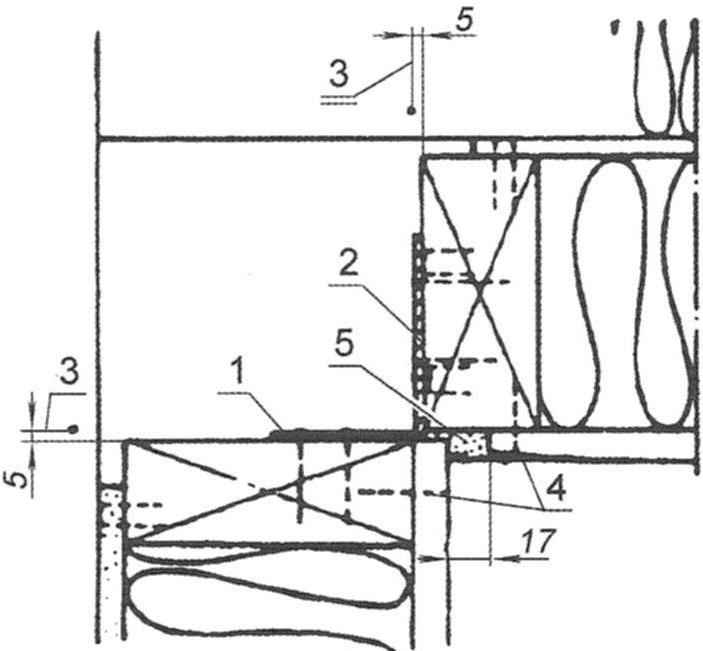

RIP. 7. The coupling of corner wall panels. The same solution is used in the normal skeleton, collected at the construction site:

1 – hardboard; 2 – liner of drevesno-fibrous plates (installed at job site); 3 – top bearing wood beam cross-section 45kh 120 mm; 4 – nail connection; 5 – vapor barrier film; 6 – mount the inner trim panel nails; 7 – mounting seam

Fig. 8. Node gusset outer panels when performing interior angles:

1 – steel mounting element; 2 – silicone mastic; 3 – axis (marking) line; 4 is the factory nail mounting; 5 – cutting of the inner lining plates on the job site

Compound wall and Foundation such as in a wall consisting of small panels. When connecting wall at the top horizontal I-beam connecting bar at the top of the building, calculated separately for each opening in the bearing wall panels. The construction of frame houses designs, self-Assembly, the beam count for the largest hole.

But how to connect the seams between the panels of the walls (see Fig. 7, 8). Vapor barrier is laid, as shown in figures 1 and 6.

Recommend to read

THE UNIT IN THE COUNTRY

THE UNIT IN THE COUNTRY

In the country, as shown by many years of experience gardeners for cooking predominantly uses electric. Industrial design of these heating devices, usually equipped with thermostats or... THREAD IN A THIN SHEET

THREAD IN A THIN SHEET

Usually designers avoid threaded joints if at the conventional "nut" less than two to three threads. Method shown in figure, allows you to make a threaded connection more reliable....

Wall

Wall