“Shoemaker without shoes” — this old Russian proverb current to this day. All of Europe has long been use Russian gas, and in the houses of the population, even gas producing regions of Russia natural gas came recently, and even then, not at all. Many people have not enough money even to bring gas from a street gas pipeline to your home. And still have to buy gas and equipment: pipe, plate, boiler, counter, etc.

“Shoemaker without shoes” — this old Russian proverb current to this day. All of Europe has long been use Russian gas, and in the houses of the population, even gas producing regions of Russia natural gas came recently, and even then, not at all. Many people have not enough money even to bring gas from a street gas pipeline to your home. And still have to buy gas and equipment: pipe, plate, boiler, counter, etc. Here I am with his family, indulging at times in the necessary, yet amassed the funds and we have gas in his house (or rather, paid services to the organizations authorized to produce such works). The same work, which rules don’t reglamentary to be executed only by means of specialized firms, in order to save himself performed, including and installed the chimney. But if the trench is dug with my son without any problems, with the construction of the pipe there was an unexpected difficulty.

As always, starting a new business, wanted to get information and to use the experience of others. But the literature on “gas pipe” was not found — there were only about furnace but the stone. Then I began to interview those who already have installed and a gas boiler, and a pipe on him. Revealed the problem: the boiler from the chimney when the furnace in cold weather, drain water condensate. And the lower the temperature of the outside air, the more.

As you know, from the combustion of natural gas when properly adjusted furnace smoke is almost there, but produced only carbon dioxide and water in vapor form. And if the carbon dioxide freely leaves through the chimney into the atmosphere, vapor condenseries on the walls of the pipe, and again flows into the boiler or on its cover, which is quite undesirable.

The head has matured the design of the pipe for the gas boiler, and to avoid claims from “the gasman” — made her drawings and agreed on a device with them. Of course, the design of the chimney had a little difficult (compared to traditional), but significantly reduced the formation of condensation, and one that is still settled on the pipe wall and ran down, seized and took away from the boiler.

Now, after starting the pipe work and several years of operation dare to recommend the design to the readers of the magazine “modelist-Konstruktor” and cite the article, its description and the drawings.

Traditionally, the chimney is mounted vertically directly onto the boiler and is excreted through the holes in the ceiling and the roof outside. Usually mounted over the pipe even an umbrella to avoid direct contact with precipitation — rain and snow.

My pipe is a bit more complicated, but more efficient to operate — at least it does not deliver the above-indicated trouble. Description of the design will start from the pipes and boiler. It is set in a small but separate room (boiler room, or as I call it — the boiler room) To the door of the boiler is arranged a sufficiently large ventilation hole to provide the required flow of air, without which complete combustion of fuel the blue is simply impossible.

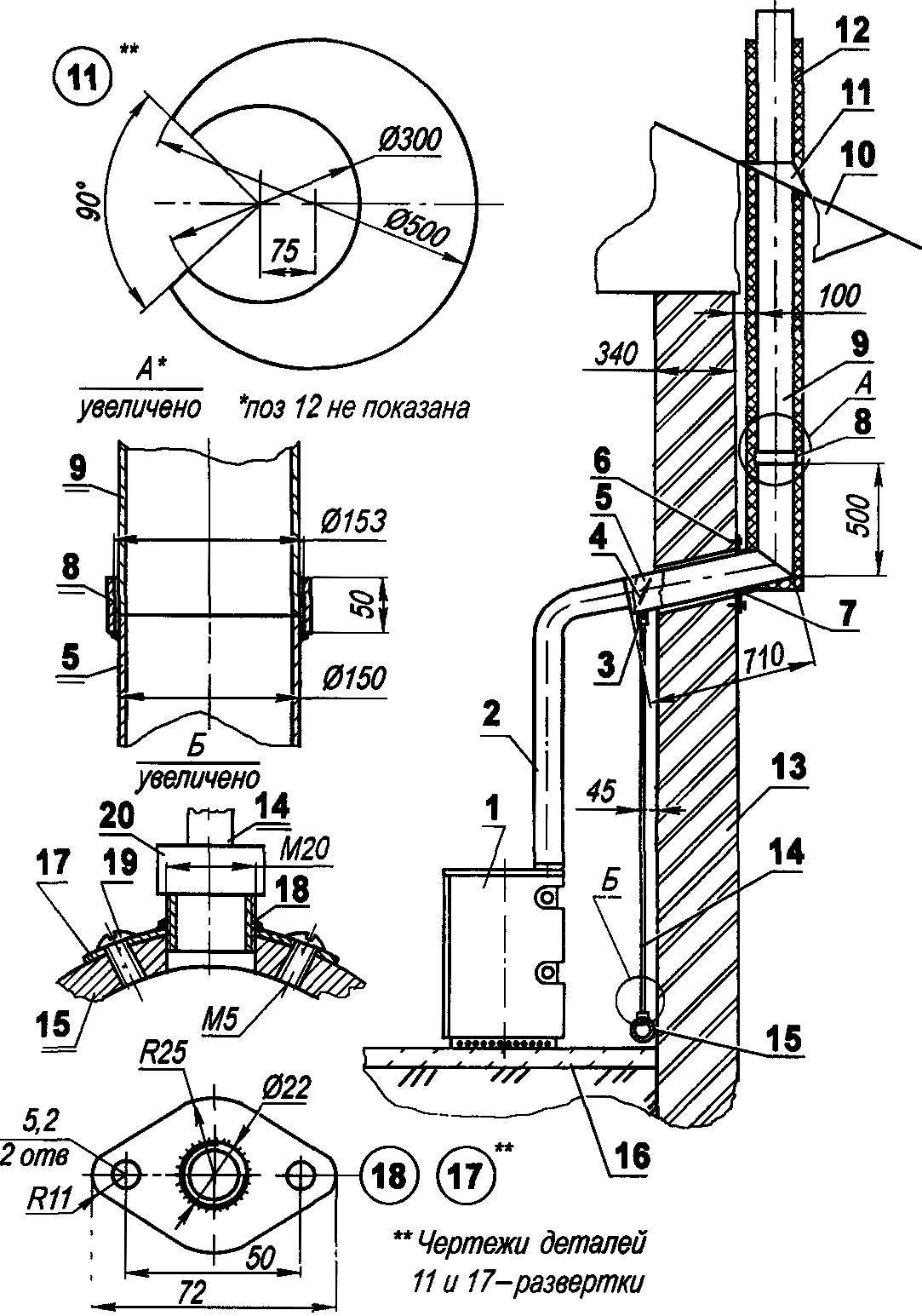

Insulated chimney with damper and steam trap set:

1 gas boiler, 2 — burs (steel tube Ø 120×3); 3 a drain—threaded pipe-nipple (1 /2″); 4—gate device; 5—inclined knee chimney (steel pipe Ø130х1); 6—anchor (dowel, 2 pieces), 7—bracket-clip (galvanized steel sheet s1), 8—ring (sheet s1); 9—chimney (from aluminum reclamation installation “Volzhanka”), 10—roof overhang, 11—skirt (galvanized steel sheet s1), 12—insulation (glass wool); 13—wall of the boiler house (silica brick); 14—hose; 15 — sewage pipe; 16—the bottom of the boiler (the boiler room floor); 17—flange; 18—threaded fitting M20 -, 19—flange mount (screw 2 pieces); 20—coupling nut flexible hose (2 PCs.)

In the boiler room wall, almost under the ceiling, a small window — pane — for “emergency” gas outlet. In the same wall Pradollano and another hole directly for the transaction of the knee of the chimney.

The boiler is installed on a concrete floor. The boiler is worn hog — bent in the upper part of steel pipe with outer diameter of 120 mm and a wall thickness of 3 mm. Pig is docked with the pipe the lower part of the chimney — the-knee made of steel thin-walled tubes. The joint was sealed with the clamp For a tight fit in the nozzle are made three longitudinal groove. Knee, like forests, also has bending only “reverse”. Its lower end is passed into the hole in the wall from the street to the boiler room and fixed bracket-clip, and the upper end is docked with the chimney. The gaps in the hole between the knee and the wall filled with clay pebbles on bbalabanova solution.

The chimney can be withdrawn through the hole in the eaves of the roof to the height of the ridge, and the gap between the roof and the pipe is covered with a skirt made of galvanized sheet metal To the chimney used dural tube from reclamation installation “Volzhanka” the Outer part of the knee and inclined the whole chimney “wrapped” in insulation of glass wool covered with glass tissue.

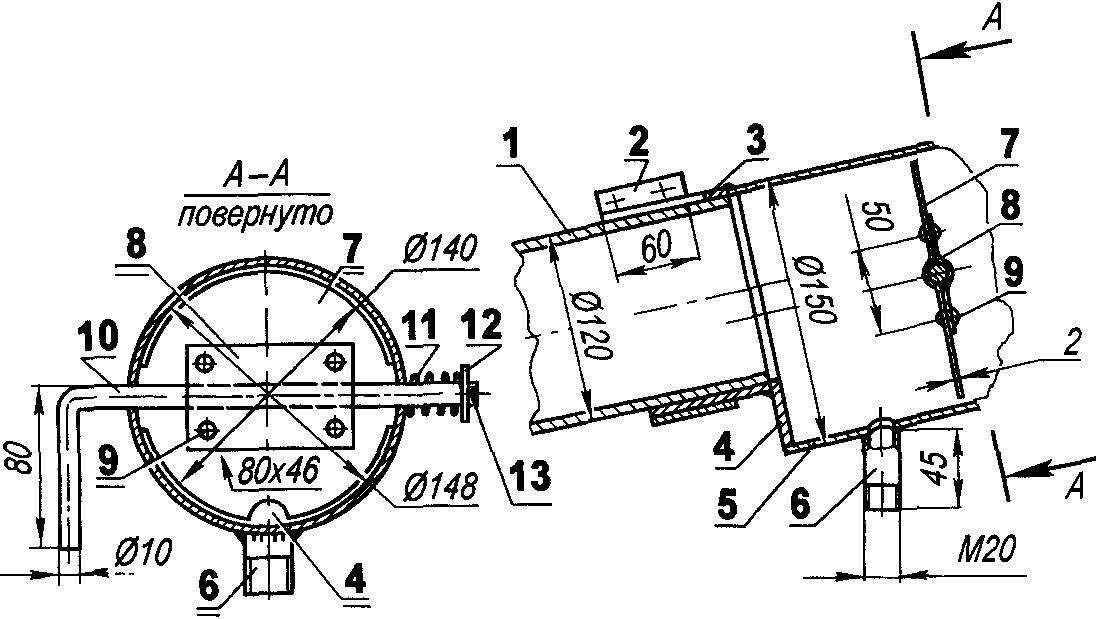

Gate device:

1—coniferous forests; 2—clamp (steel, sheet s1), 3 — pipe, 4—plug (steel, sheet s1), 5—knee; 6 drain — threaded pipe-fitting, 7 — vane damper (galvanized steel sheet s2); 8—plate (galvanized steel sheet s2); 9 — rivet (steel, 3 Ø, 4 pieces) 10—stick (steel rod Ø 10), 11 — spring (normally uncompressed), 12 — washer; 13 — pin.

But perhaps the main feature of my fume collection system is that it has a gate device installed at the bottom of the knee, almost at the junction with the hog During the furnace gate is used to control thrust, and at the usual time — valve. The design of the device simple and quite understandable from the drawing.

Here is a slide valve in the bottom wall of the tribe made a small hole (diameter 15 mm) and welded outside threaded inlet is for connection to a hose for discharging the condensed water. The water I drained into the sewer. Those who have sewage in the vicinity, suggest to bury the pipe below frost penetration of the soil and divert water into it.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.