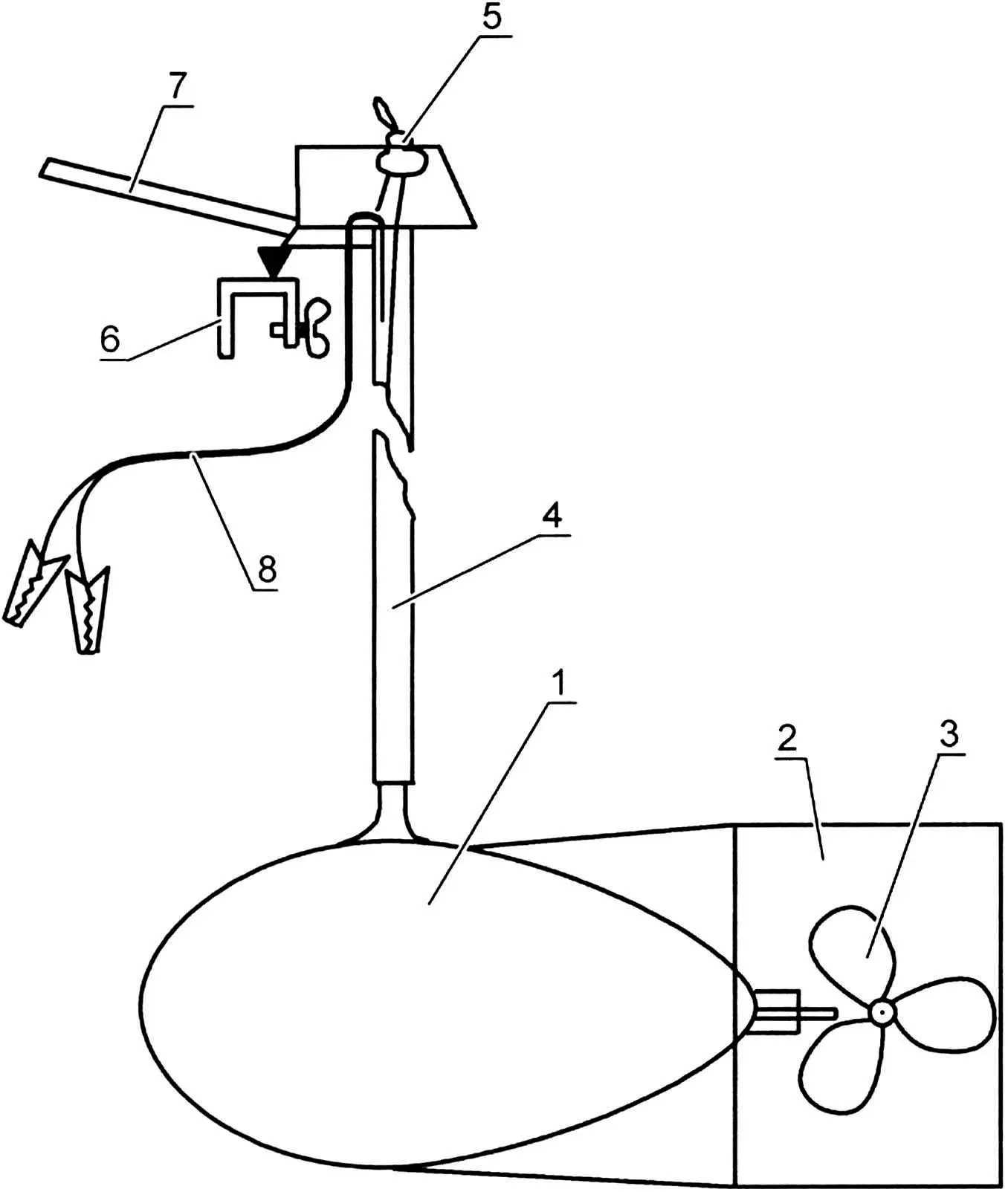

For some time, I was fond of fishing from a boat. That’s why I decided to make a portable electric motor for trolling (fishing from a moving watercraft powered by a motor, usually using a spinning rod with a lure).

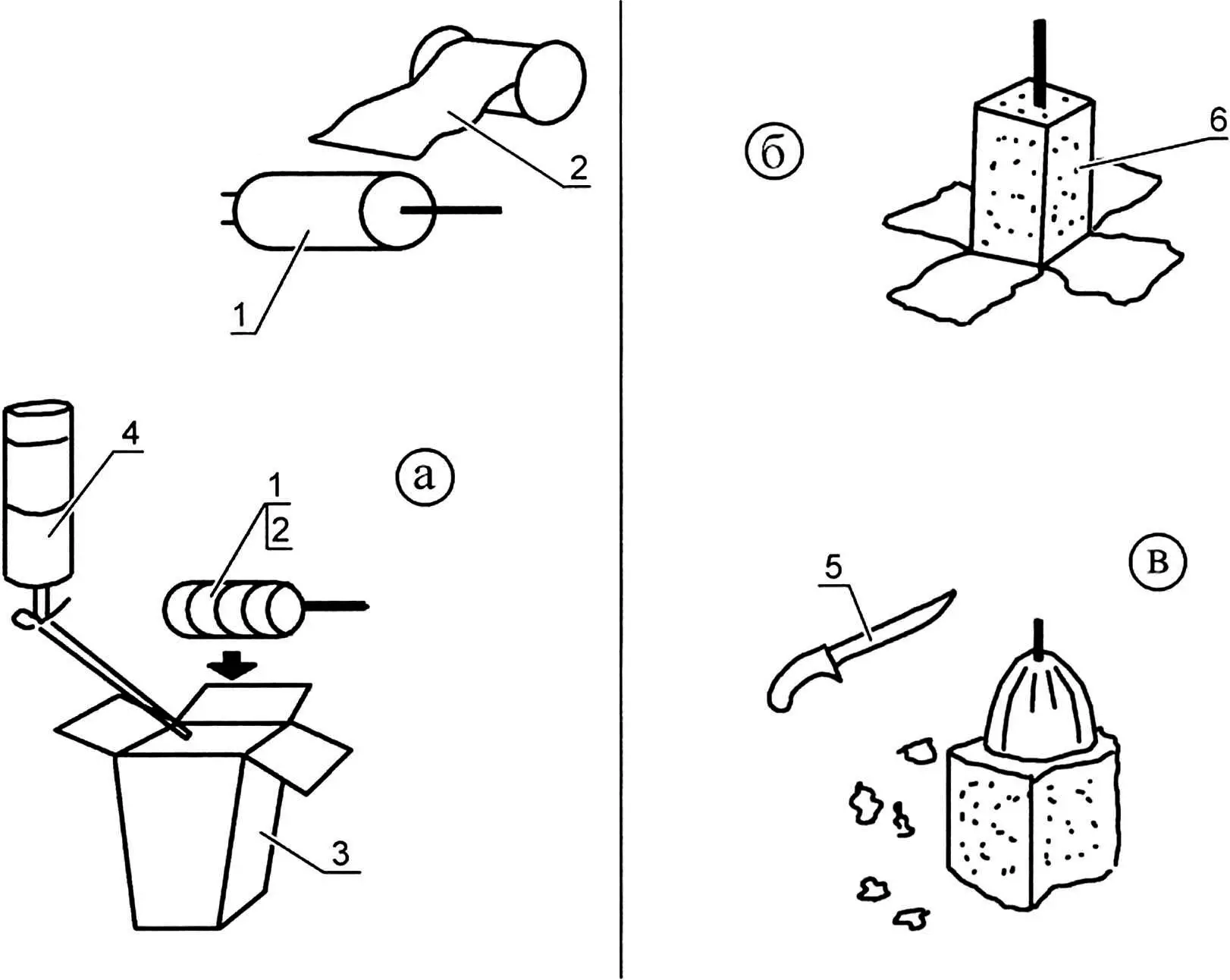

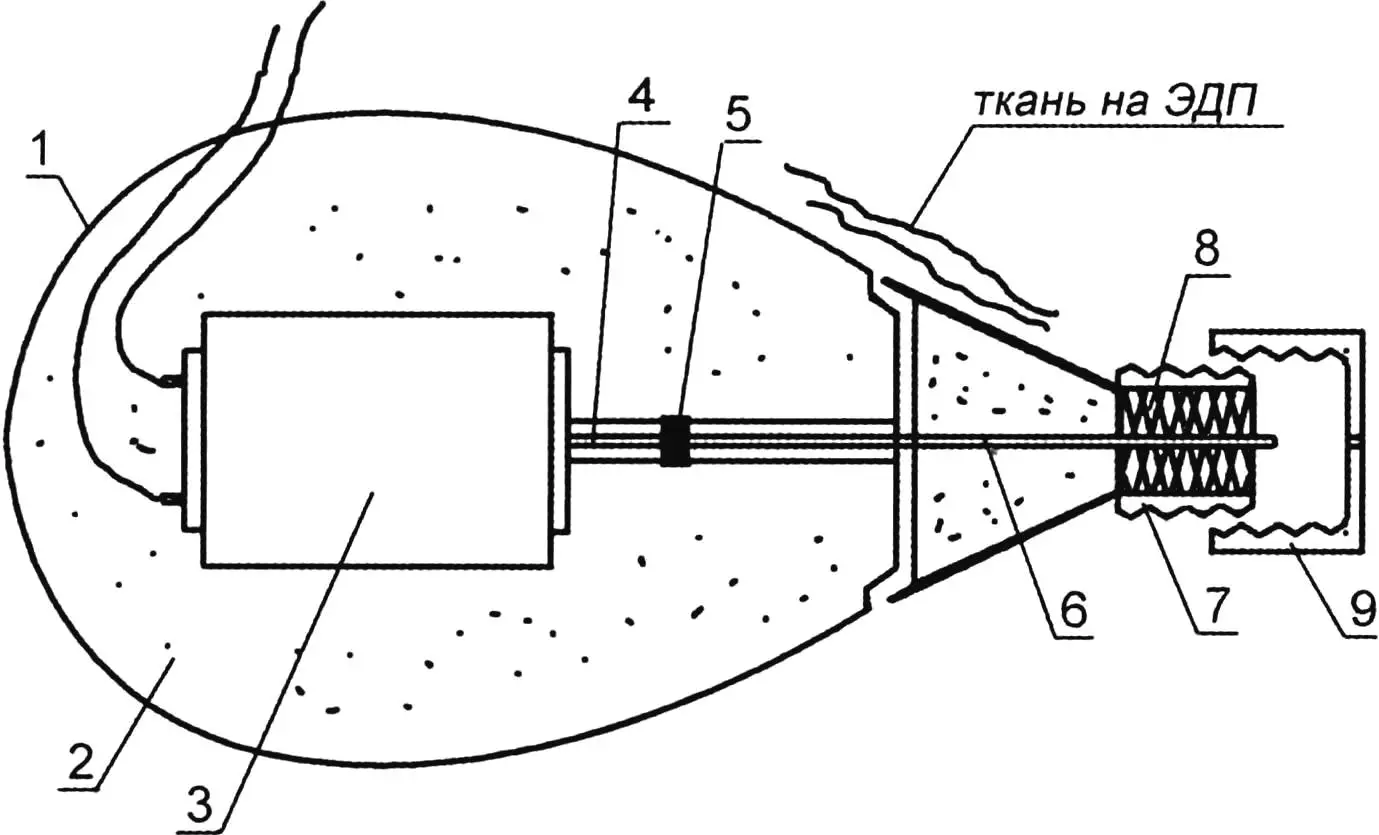

Here’s a design that resulted from this idea. Its core is a motor from a VAZ-2121 car interior heater. A standard 12V car battery is used to power the electric motor. The motor was placed inside a “cocoon” made of expanding foam, which was trimmed to form a streamlined shape. The entire assembly was then wrapped in gauze soaked in epoxy glue (EDP) in five to six layers. Only the power wires and motor shaft exit the cocoon.

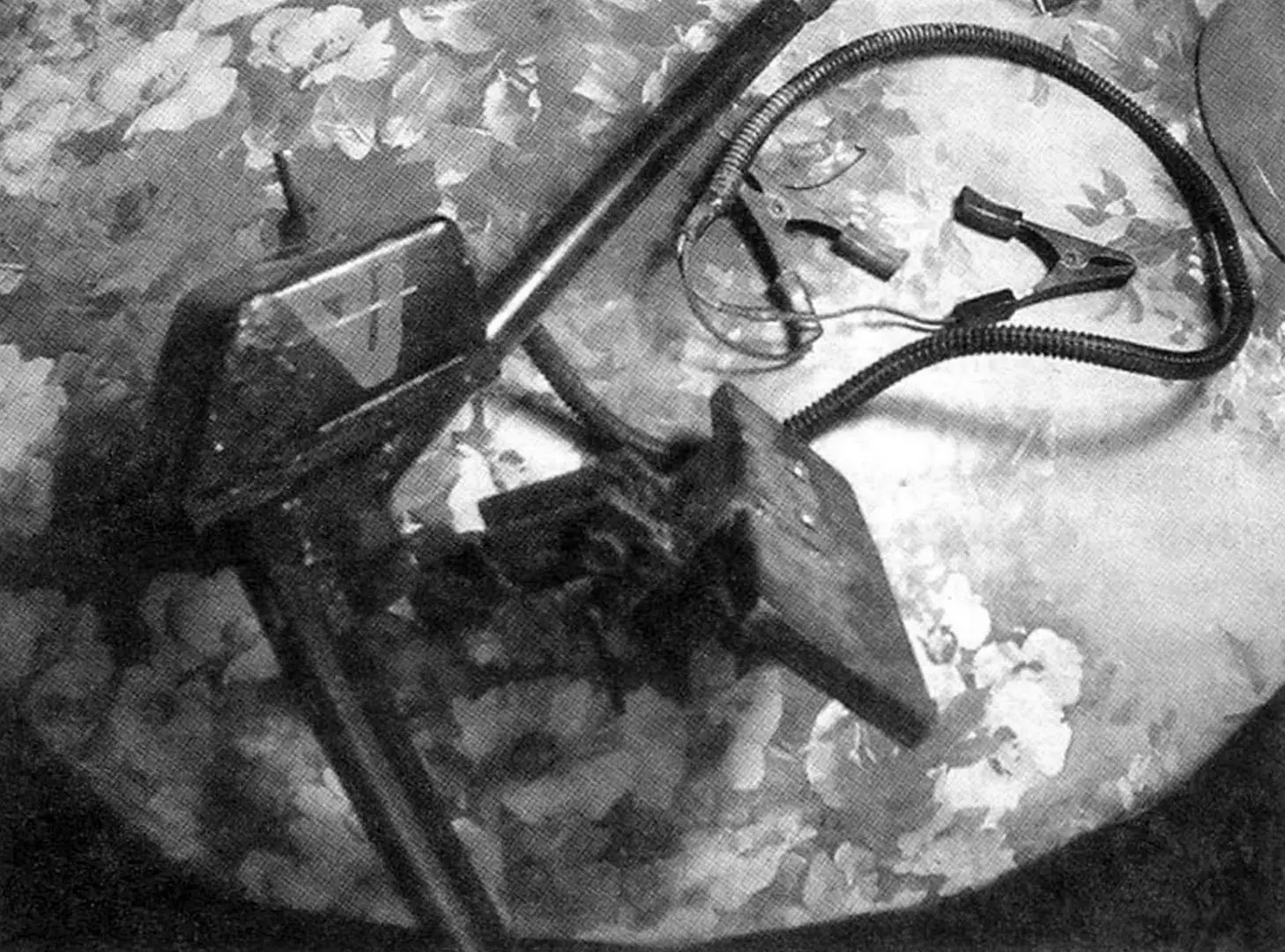

1 – drive shaft housing; 2 – ring; 3 – propeller (rotated); 4 – housing pipe; 5 – switch; 6 – clamping bracket; 7 – tiller; 8 – cables with crocodile clips

I didn’t find it necessary to make the motor unit detachable for repair or replacement, since the motor has a fairly long service life and isn’t used very intensively. So far, after five years of use, there has been no need for replacement. And even if needed, the whole unit can be rebuilt quickly.

1 – electric motor; 2 – food wrap; 3 – cardboard box; 4 – can of foam; 5 – knife; 6 – hardened foam

The propeller shaft is sealed as follows: the neck of a Coca-Cola PET bottle is cut off, a felt seal is glued inside, and the propeller shaft passes through it. The neck is glued securely into the motor housing, the felt is soaked with suitable lubricant (I used engine oil), and a bottle cap with a hole in the center is screwed on to clamp the felt and allow the shaft through. The motor shaft housing (shaft tube) is made from an aluminum pipe, with only the power wires running inside. At the top of the pipe, there’s a power switch, a clamp for attaching the motor to the boat’s transom, and a tiller handle.

1 – housing (fabric soaked with epoxy glue); 2 – filler (foam); 3 – electric motor (from a VAZ-2121 car heater); 4 – motor shaft; 5 – damper (spring); 6 – propeller shaft; 7 – tail housing (PET bottle neck); 8 – seal (felt soaked in oil); 9 – plug (PET bottle cap)

The power cables connect to the battery via quick-release crocodile clips. The propeller is homemade, four-bladed, made of ABS plastic with a diameter of 220 mm. It was balanced using the “two-blade method” (see specialized literature for details). The balance can tolerate a fair margin of error since the motor speed and propeller mass are low. A protective ring made from a metal strip was placed around the propeller to prevent aquatic plants from wrapping around it and to enable steering without a rudder.

During tests, the electric motor’s thrust reached about 3 kg, which is quite enough to move a small boat during fishing trips. In the future, I plan to install a variable resistor in the power circuit to control the propeller’s speed and thus regulate the boat’s movement.

I. PRONIN