In this issue of “M-K”, we want to introduce our readers to one of the most efficient soil cultivation mechanisms, which has recently been gaining more popularity among DIY builders. This is a motorized winch, whose main advantage lies in the fact that, unlike self-propelled tillage units, it uses all of its engine power for traction.

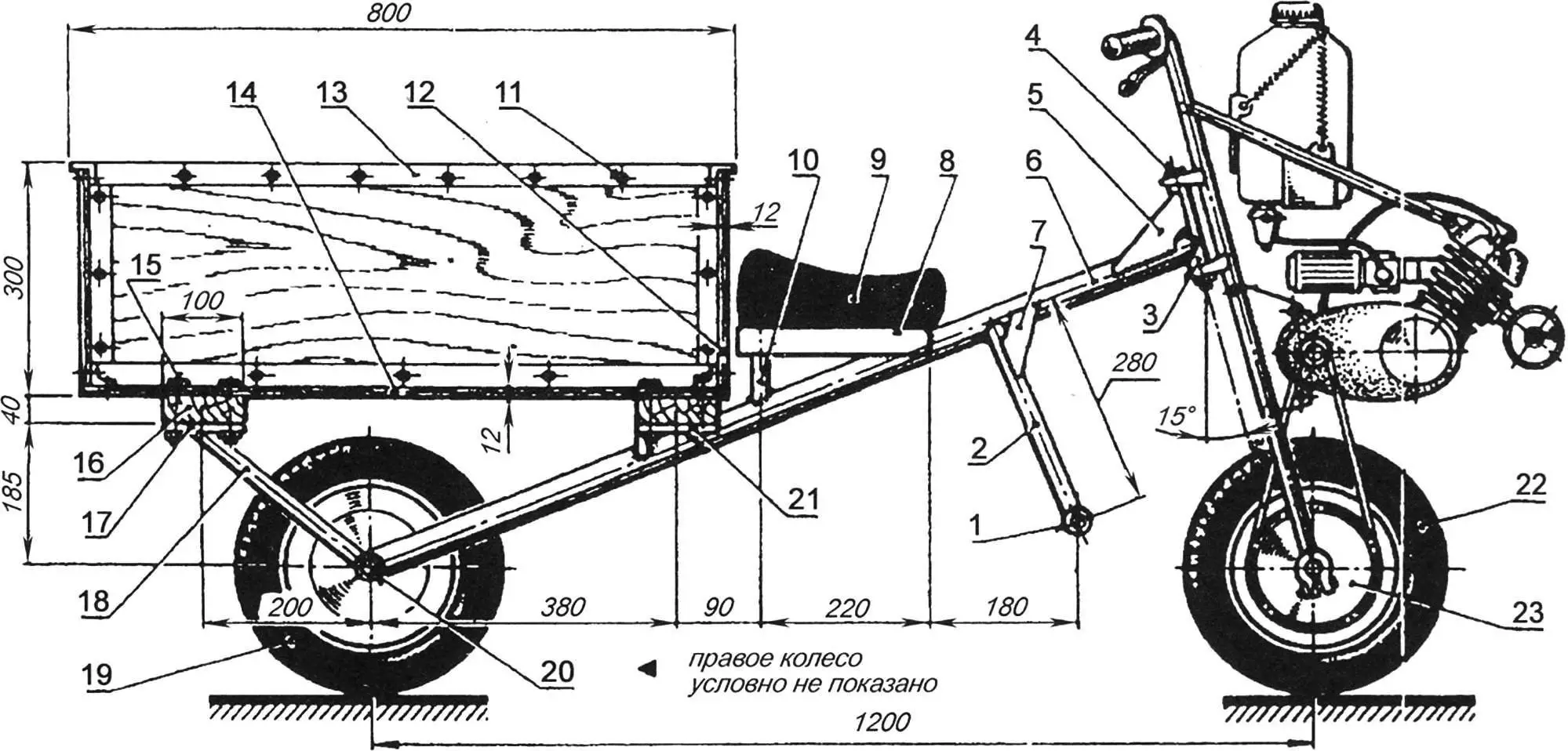

The basis of the winch, developed by Moscow resident I. Sorokin, is a V-50 engine — once used in “heavy” mopeds like “Riga” or “Karpaty”, with a power output of about 2 hp (many such mopeds still sit in garages and sheds). The engine is mounted on a frame welded from 30×2.5 mm steel pipes and sheet metal parts about 3 mm thick. A moped handlebar is mounted on top of the frame, while at the bottom, a support platform with a drum and drive sprocket is attached. A spring-loaded U-shaped frame with two sharpened steel plate anchors (resembling sapper shovel blades) is attached at the rear of the platform as an anchoring device.

1 — fuel tank; 2 — braces of the front engine mount; 3 — V-50 engine; 4 — muffler; 5 — clutch lever; 6 — gear shift lever; 7 — throttle grip; 8 — hand brake lever; 9 — engine frame stands; 10 — rear engine mount cheeks; 11 — winch drum; 12 — frame crossbars; 13 — fork bridges; 14 — steel cable Ø5; 15 — guide bracket (steel rod Ø8); 16 — support platform (tube 22×2.5); 17 — anchor; 18 — anchor leg; 19 — drive sprocket

The winch drum is made from a moped wheel hub (a hub from any light motorcycle will do), to which a duralumin flange and driven sprocket are attached — for example, a large sprocket from a road bicycle.

If the gear ratio of the chain reducer is insufficient, a sprocket with more teeth will be needed. A 4–5 mm thick duralumin sheet is ideal for this. Calculating such a sprocket is simple. For instance, if z = 80, then 80 × 12.7 mm = 1016 mm (pitch circle length). Divide by 3.14 (π), and you get the pitch diameter (Dd = 323.6 mm).

Mark the sprocket center on the blank, draw the pitch circle using calipers, divide it into 80 equal parts (each 12.7 mm), mark the hole centers, drill all 80 holes (ideally using a drill press), and then use a rod matching the chain bushing diameter to trace each tooth profile with a bicycle sprocket as a template. Finally, cut out the sprocket using a hacksaw and files.

The fuel tank is a 3-liter plastic canister from motor oil, with a standard motorcycle fuel tap installed at the bottom.

The winch controls are typical of any moped: on the right handlebar — throttle grip and hand brake lever (its function will be discussed later), and on the left — clutch lever and gear shifter.

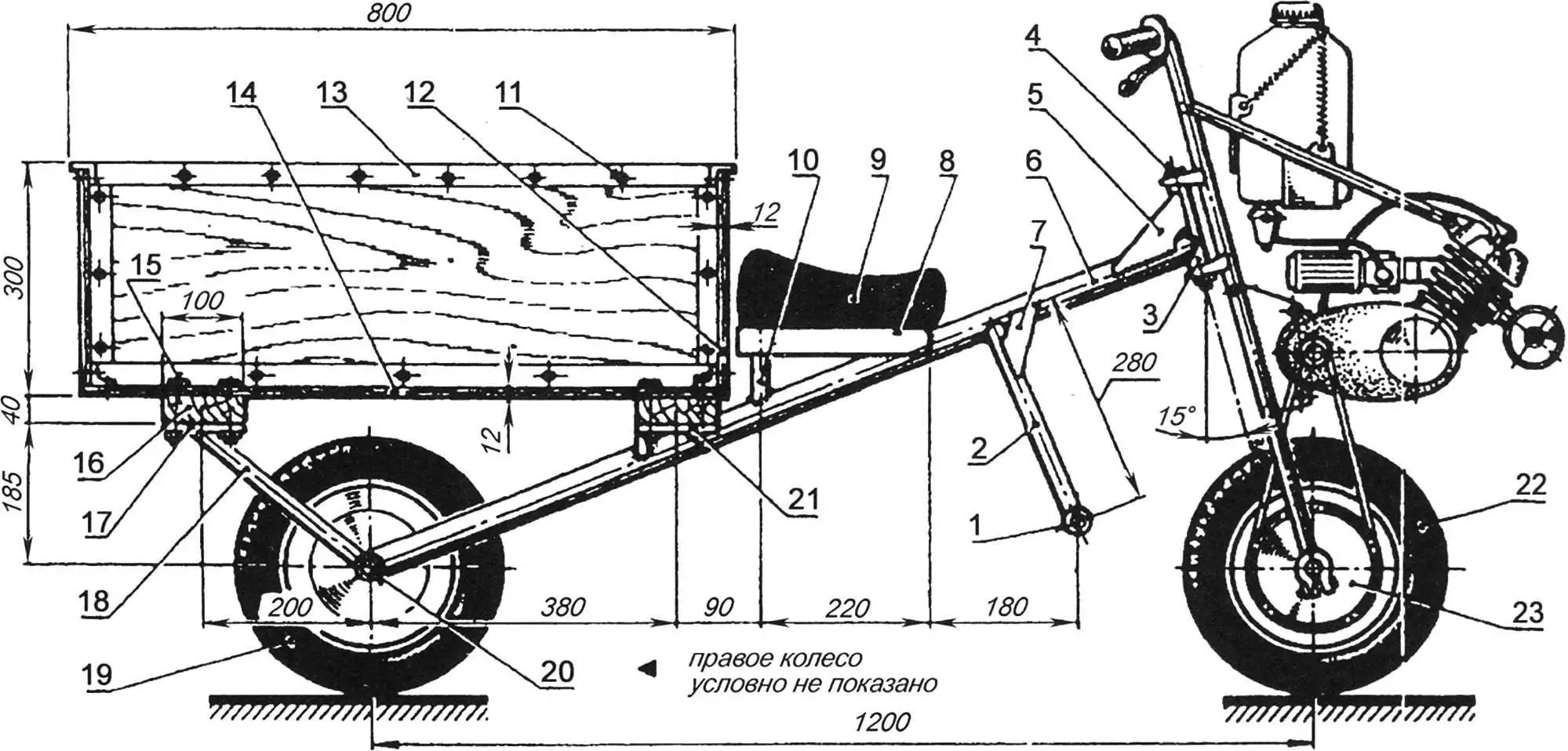

1 — footrest (tube 22×2.5); 2 — footrest bracket; 3 — steering column (tube 30×2.5); 4 — steering column axle (M12 bolt with nut and washer); 5, 7 — gussets (steel, s2.5 sheet); 6 — drawbar (tube 40×2.5); 8 — seat bracket (channel 50x50x3); 9 — seat; 10 — seat post (tube 22×2.5); 11 — M6 bolt with nut; 12, 14 — body wall and floor (plywood s12); 13 — edging (angle 40x40x2.5); 15 — M8 bolt with nut and washer; 16 — body support (wooden bar 40×100 mm); 17, 21 — body support platforms (steel, s3 sheet); 18 — brace (tube 22×2.5 mm); 19, 22 — wheels; 20 — cart axle; 23 — front drive wheel sprocket

The engine is equipped with a homemade muffler, welded from thin-walled tubes (20 mm and 80 mm in diameter) and two 2 mm thick steel caps. Inside is tangled wire or metal shavings. The design is simple but effective.

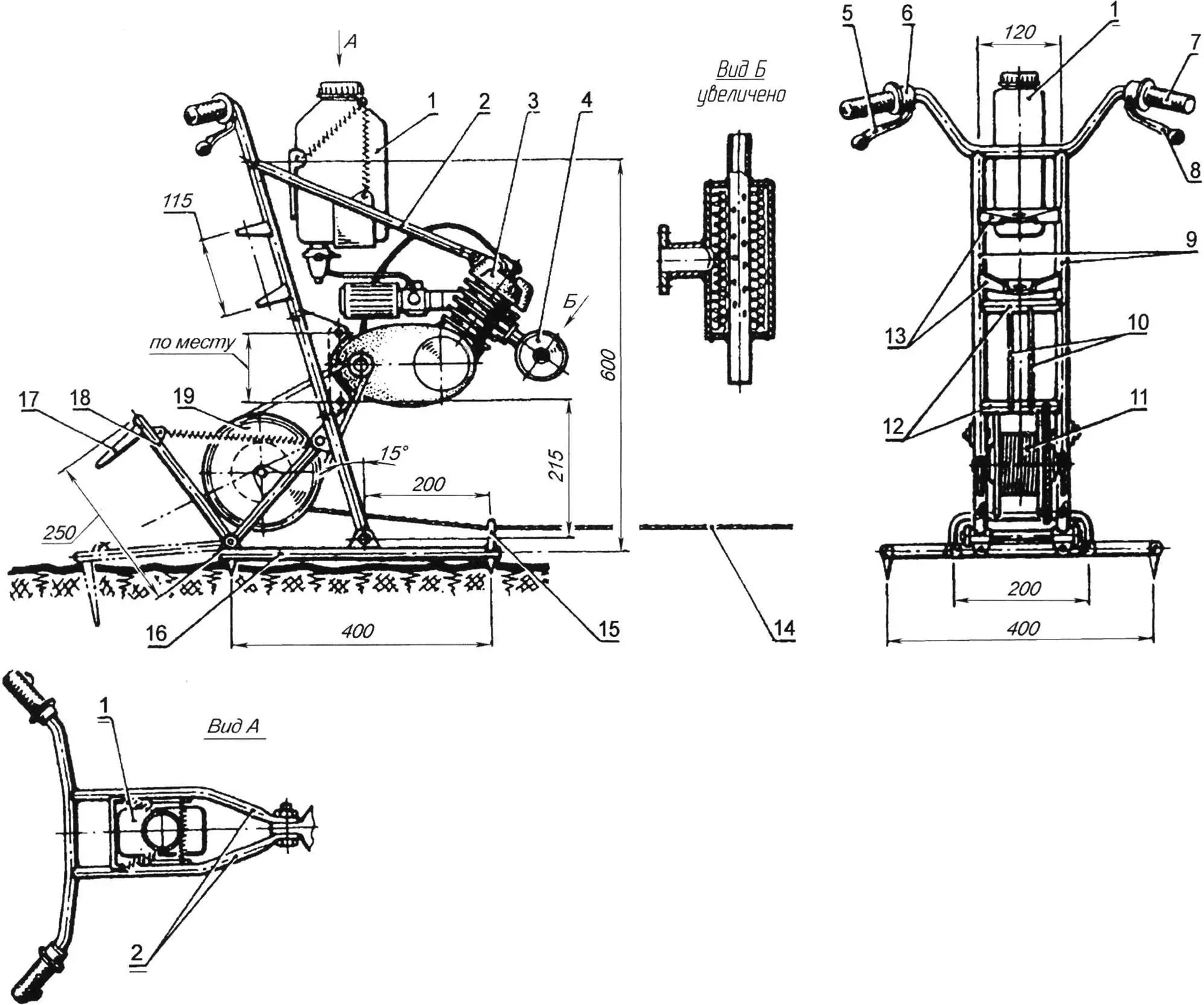

Engines of this type can generally run for a long time without forced cooling — especially if exposed to wind. However, adding a forced air cooling system is a good idea. A pulley is mounted on the flywheel rotor, and a bracket with a bearing unit is fixed on the cylinder head. Inside, a shaft with a pulley and fan impeller is installed.

Here’s how to use the winch. Place it at the edge of a field and secure it with the anchor device. Put the gear lever in neutral, and take the working tool (plow, hiller, or cultivator) to the opposite end of the field. Ideally, two people should operate it: one handles the winch, the other the tool.

Let’s begin. Start and warm up the engine using the kick-starter, squeeze the clutch lever, engage first gear, and gradually release the clutch. The cable winds onto the drum and the tool moves forward. That’s it.

Of course, using a compact and powerful unit like this solely for tilling would be impractical. Fortunately, it can also be used to power a cargo trailer. With such a hybrid setup, the winch can be transported to the worksite under its own power, carrying a plow or cultivator, tools, and planting material. On-site, the cart transforms into a winch in about 30 minutes, performs its task, and then reverts back to a cart to bring back the harvested crops.

To convert the winch into a motor cart power unit, some modifications are required. Replace the support platform with a wheel and driven sprocket. Connect the right-hand brake lever cable to the hub’s brake mechanism.

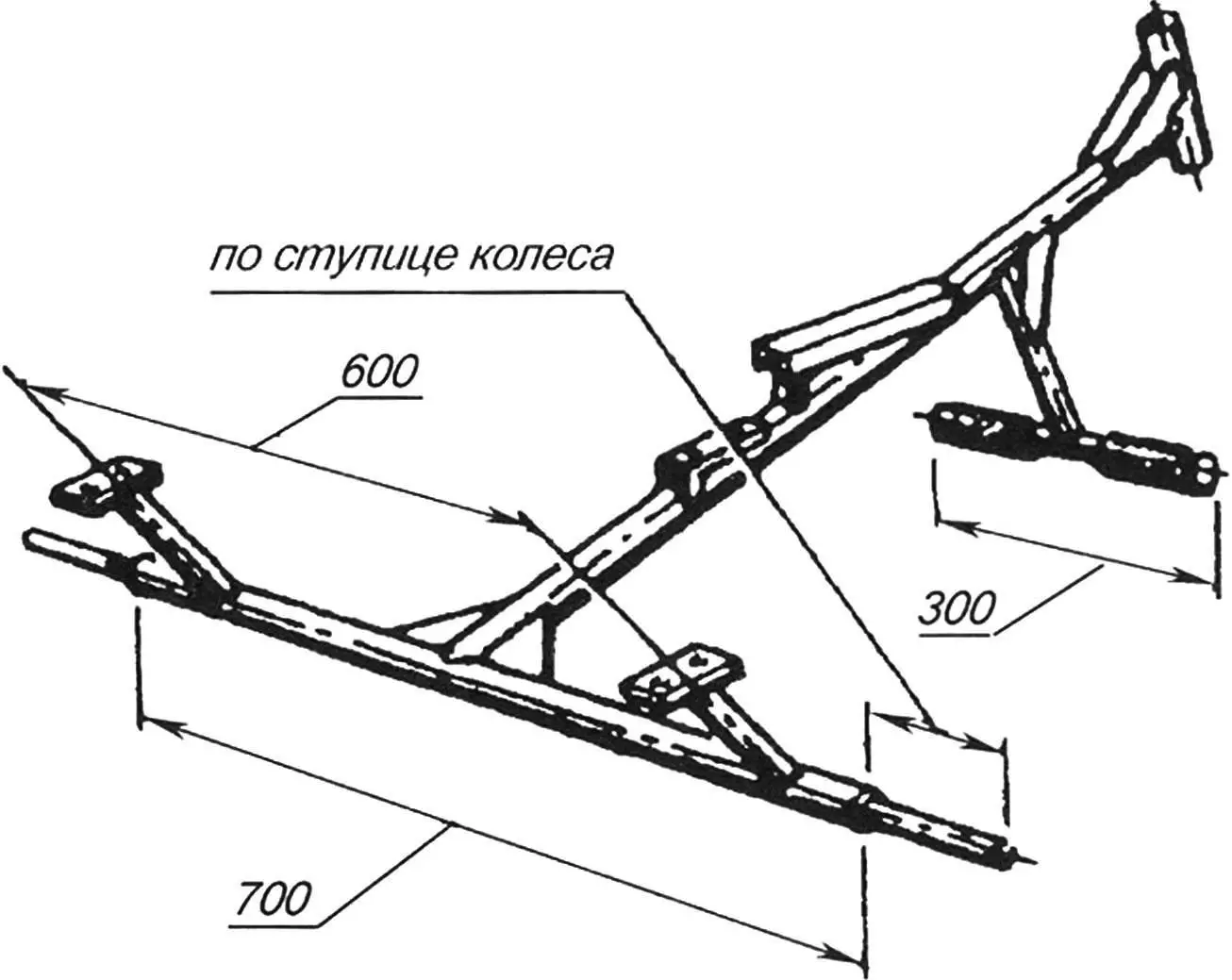

The core of the cargo trailer is a welded frame made from steel pipes of various diameters, onto which a plywood body is mounted. The frame connects to the engine unit via a drawbar with a steering column at the front end — a piece of 30×2.5 mm pipe with two bronze or textolite bushings. The other end of the drawbar is welded to the cart axle — a pipe of the same diameter, into which two half-axles are welded. These are stepped shafts with threads on the outer ends, matching the hub bearing diameter.

Two braces with support platforms (cut from 40×100 mm wooden bars) are welded to the axle. The body is assembled from 12 mm thick plywood sheets and metal (steel or duralumin) angles, fastened with M6 bolts and nuts.

Ahead of the body is a seat and T-shaped footrest for the driver. The steering angle is about 90° left and right, allowing the cart to turn on the spot.

If the motor cart is used at night, it makes sense to install a headlight and tail lights powered by the generator’s low-voltage winding.