Somehow caught us a description of the six-wheeled Rover “Giger”. The main nodes it was very simple. Absent transmission, driveshaft, rear axle — these, in General, quite complex and heavy assemblies. Small engines — separately for the left and right sides through a V-belt CVT transmit torque with its series of wheels connected by a chain. The supports of the axes of pneumococcal rigidly attached to the body and turns was carried out by adding the engine speed on one side and reduce the speed of the other.

Somehow caught us a description of the six-wheeled Rover “Giger”. The main nodes it was very simple. Absent transmission, driveshaft, rear axle — these, in General, quite complex and heavy assemblies. Small engines — separately for the left and right sides through a V-belt CVT transmit torque with its series of wheels connected by a chain. The supports of the axes of pneumococcal rigidly attached to the body and turns was carried out by adding the engine speed on one side and reduce the speed of the other.

We wanted to create your six-wheeled all-terrain vehicle that would be as easy to manufacture and manage.

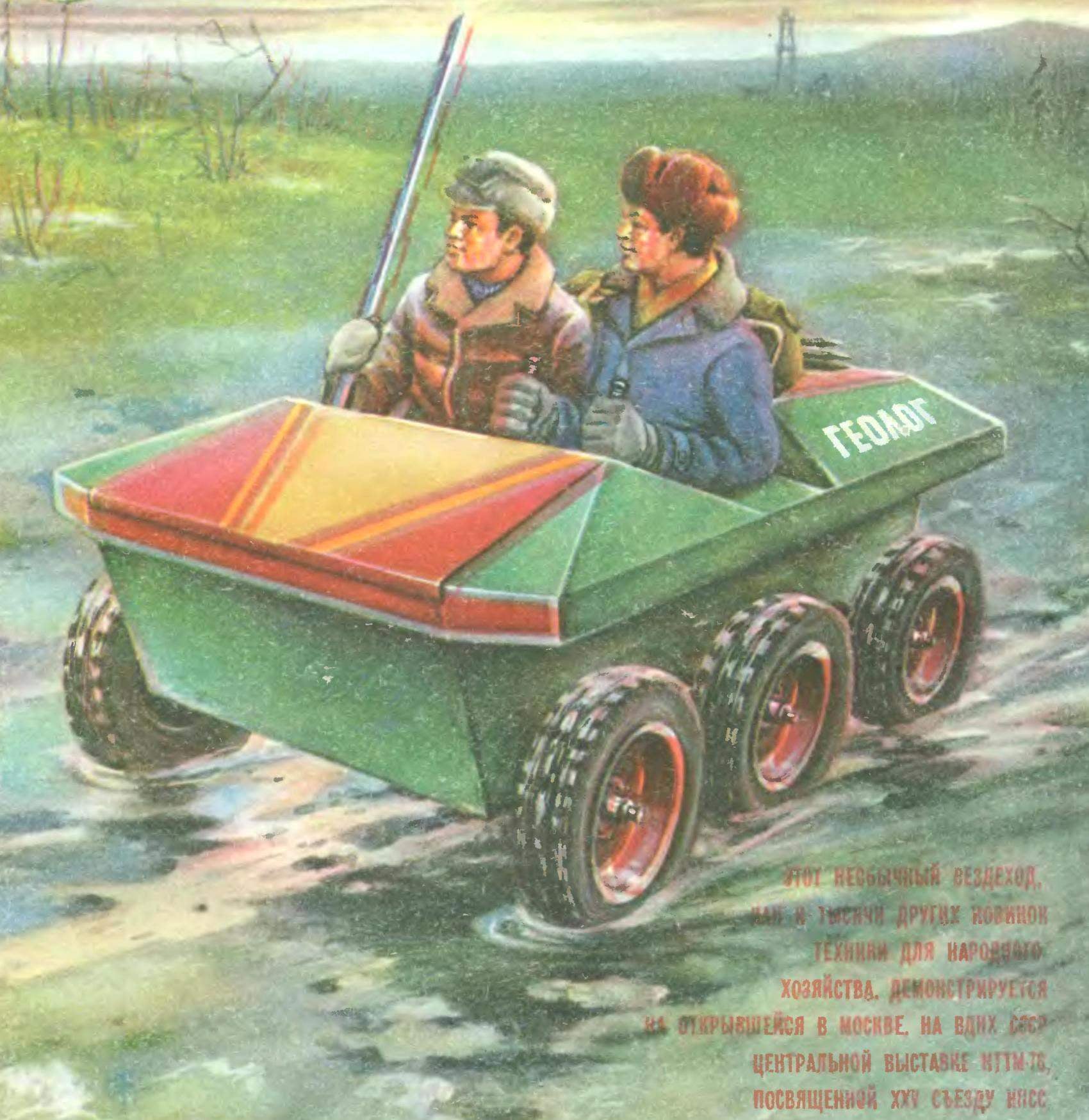

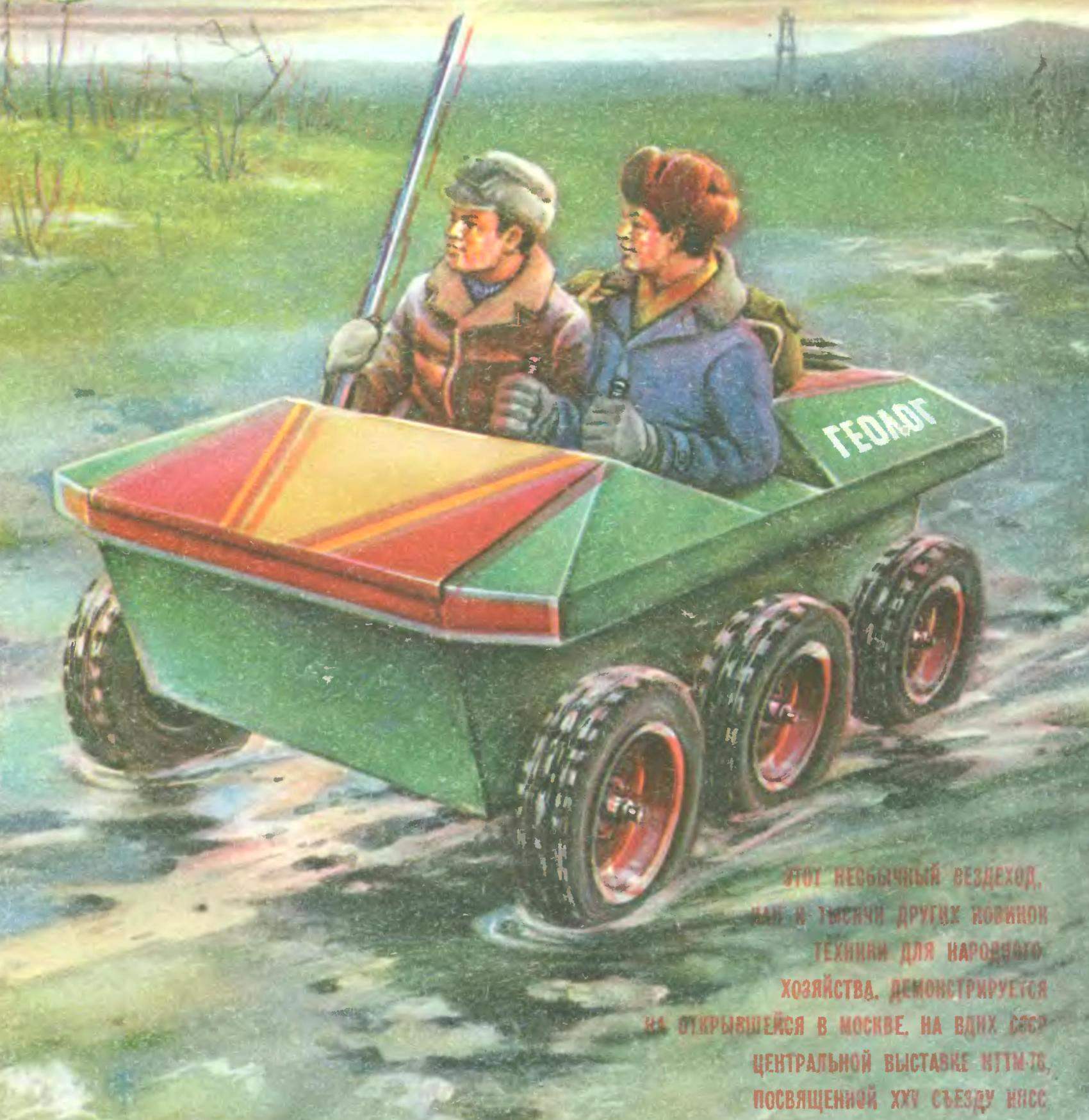

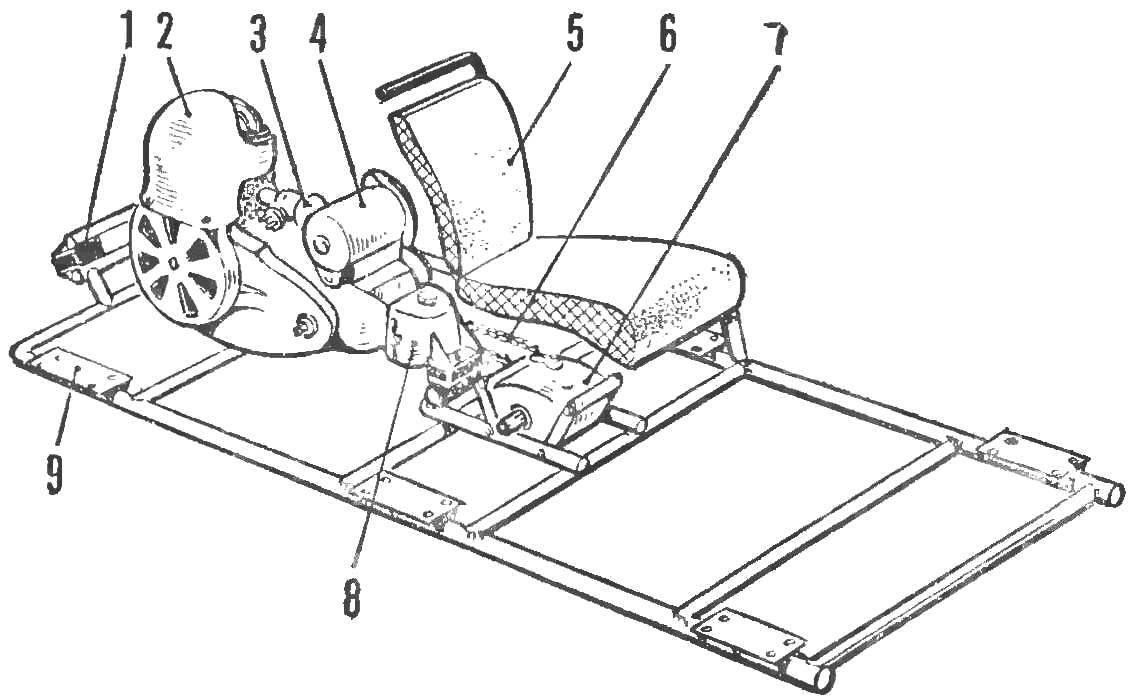

In the laboratory design of compact machines Cut Novosibirsk Akademgorodok we have built such a machine (Fig. 1), which, when some external similarity is very different from the “Giger”.

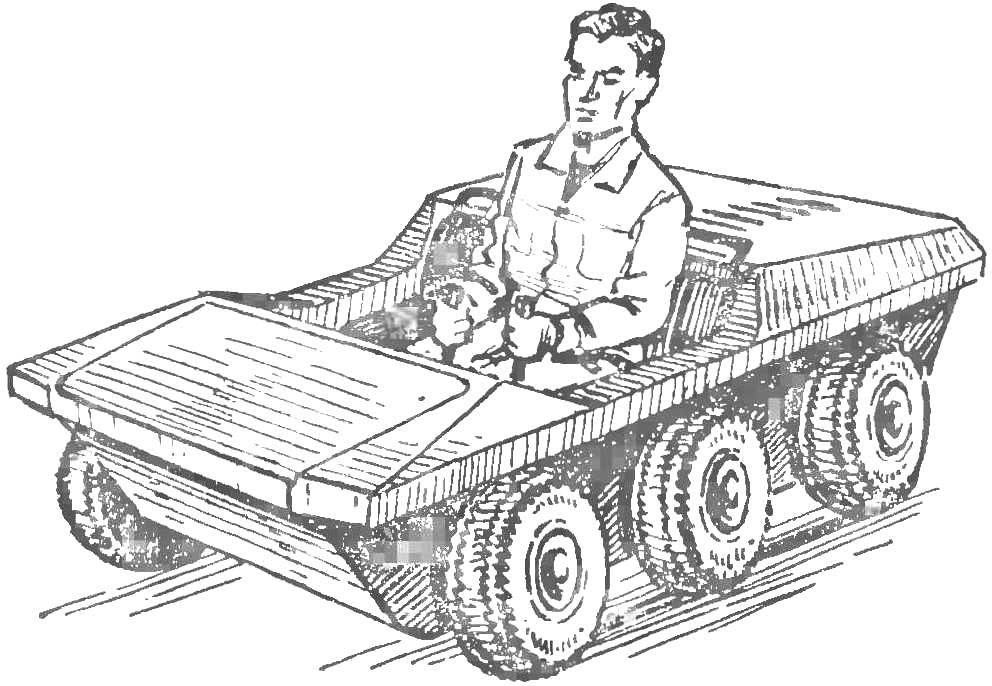

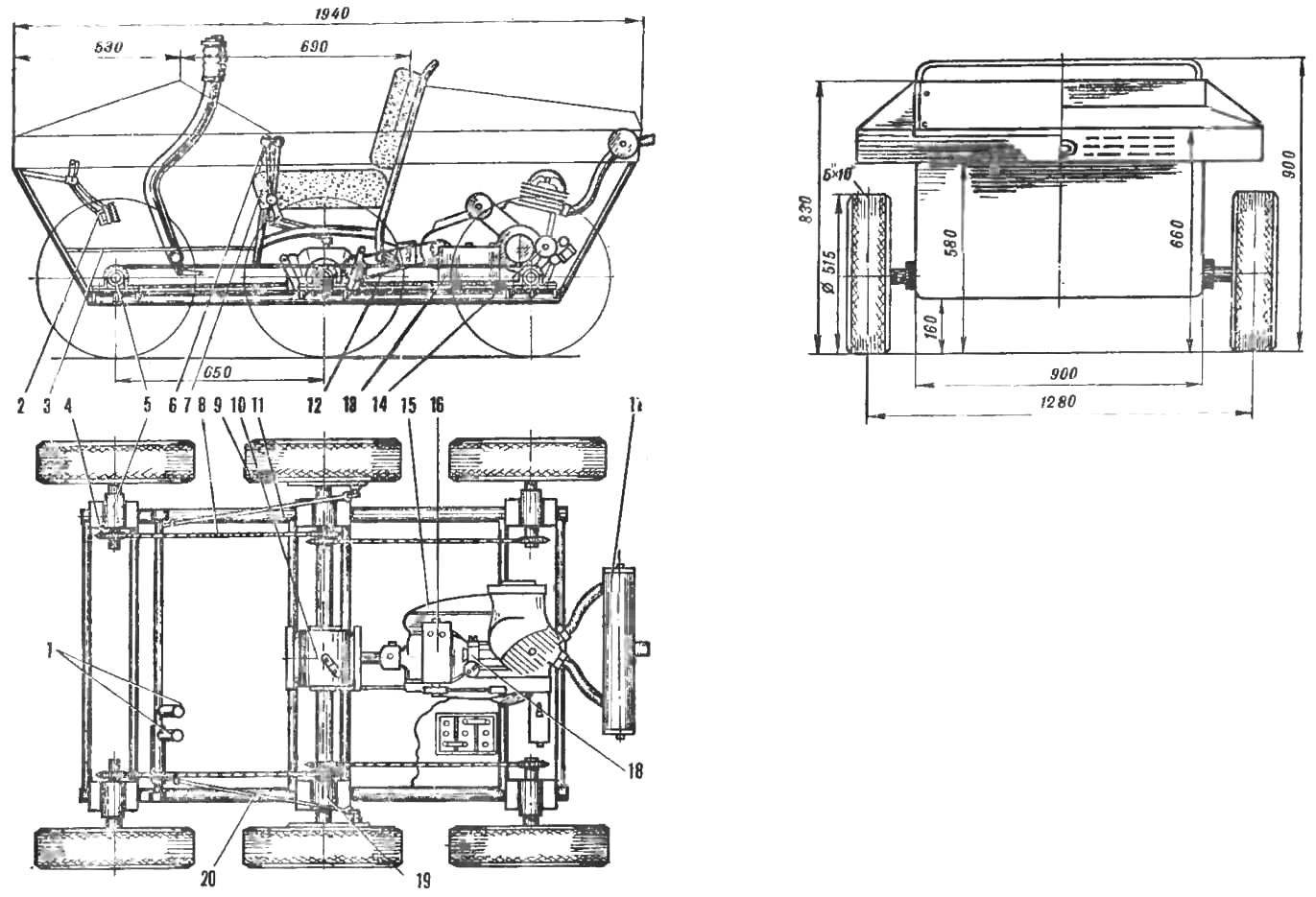

On our all-terrain vehicle (Fig. 2) used only one engine — a motorcycle IZH-56 (motorized С3А, with generator and starter). It is located in the rear part of the car body. Start the engine from the handle in the cabin on the left side of the driver. The control system includes: levers turns the clutch pedal, gas pedal, gear shift knob, handle starter, ignition switch.

Engine torque through the differential (also from motorized С3А) is transmitted to secondary wheels of the right and left sides. Each such wheel is connected by a chain drive with the other wheels on your side.

Fig. 1. The six-wheeled Rover.

Fig. 2. The layout of components on the frame:

1 — airbag, 2 — engine, 3 — carburetor, 4 — generator, 5 — seat, 6 — circuit main gear, 7 — gear, 8 — tensioner circuit 9 platform attachment hub

Fig. 3. Diagram of the Rover:

1 — arm turns, 2 — pedal clutch, gas, 3 — cabin floor, 4 — star front wheel 5. front wheel hub, 6 — shift lever, 7 — seat, 8 — chain transmission, 9 — wheel, 10 — main gear with the differential, 11 — frame, 12 — circuit main gear, 13 — battery 14 — starter motor 15 — engine 16 — generator, 17 — exhaust pipe and muffler, 18 — carb, 19 — middle hub of the wheel, 20 — pull clutch.

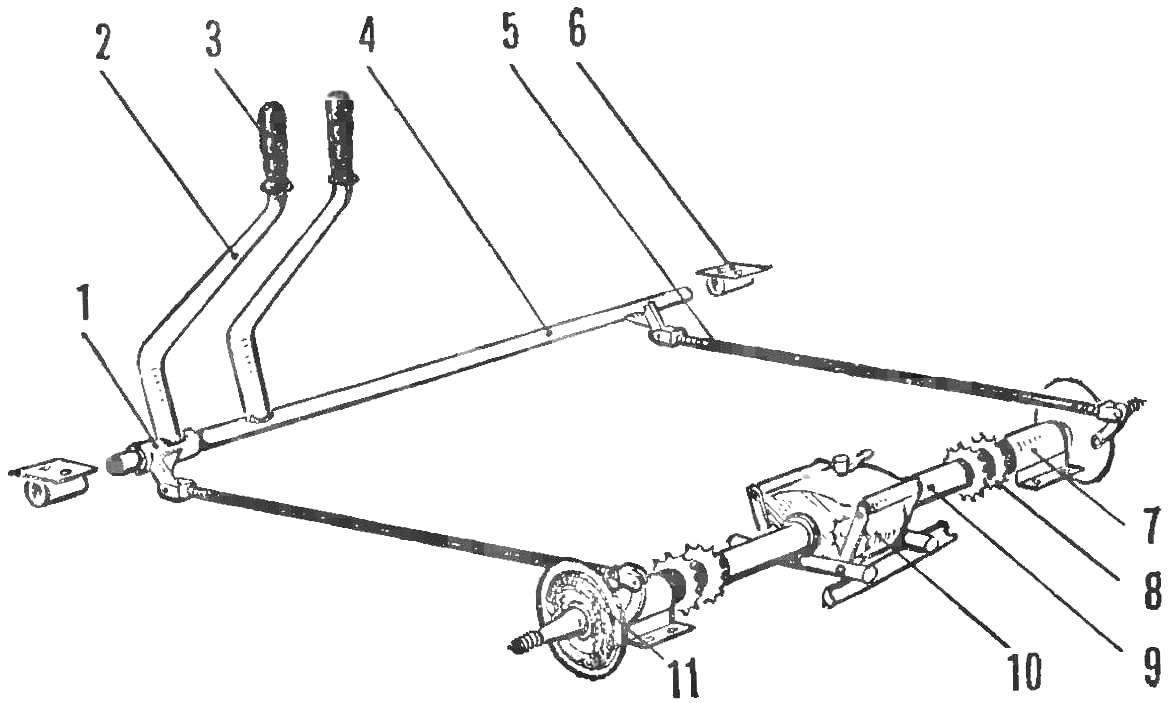

On average, the same wheels installed brake pads from the sidecar С3А. They are used for… of rotation of the machine, which is not a steering wheel, an independent clutch levers located in the cockpit (see Fig. 3 and 7). Pulling the left lever on itself, slowing down the three-wheel port side. The motor continues to rotate the wheel starboard and the vehicle turns left. Turn right the same.

Under this system, control is completely absent skid, even on tight bends up to 180° at a speed of 20-30 km/h the brake Pedal to stop the vehicle, so as to brake enough to pre-squeeze the clutch, pull the right lever of the friction. The transmission control of the engine is made by one knob, which is located on the seat between driver and passenger.

The basis of our all-terrain vehicle — supporting rectangular frame, welded from tubes Ø 40 mm. is welded To the frame of the six grounds of size 120X140 mm, each with four holes for M10 bolts for fastening the hub axle (Fig. 4).

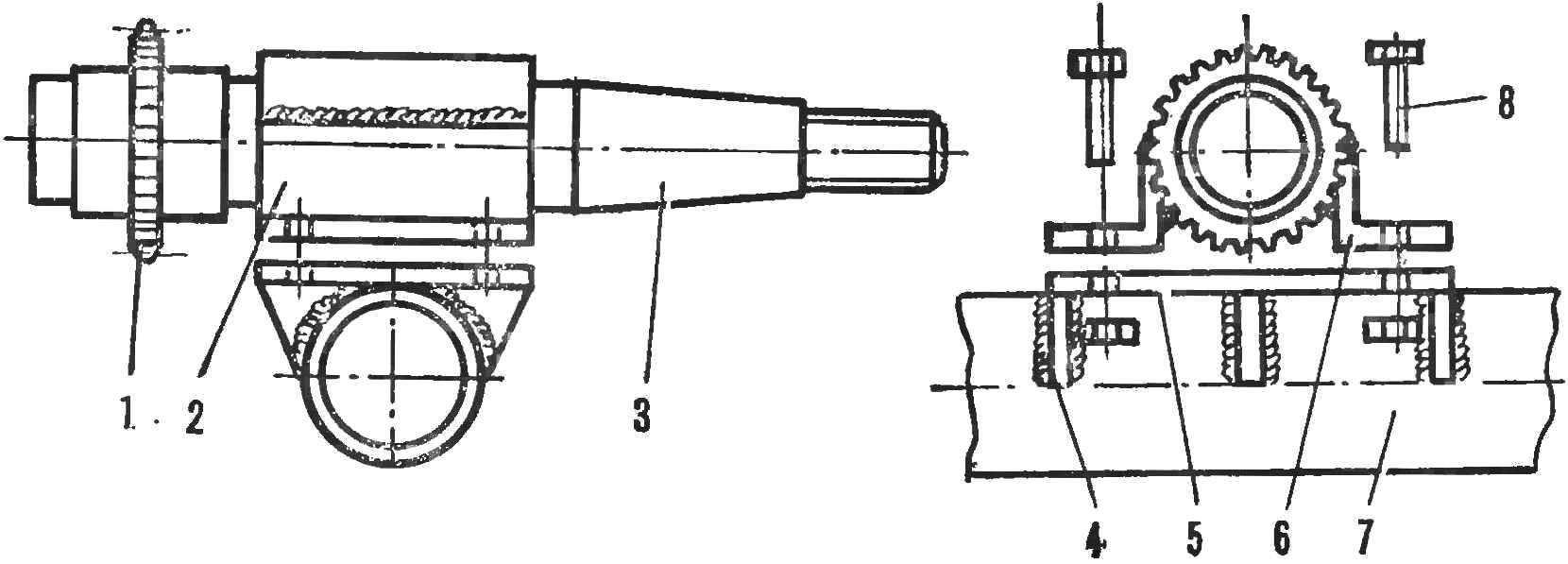

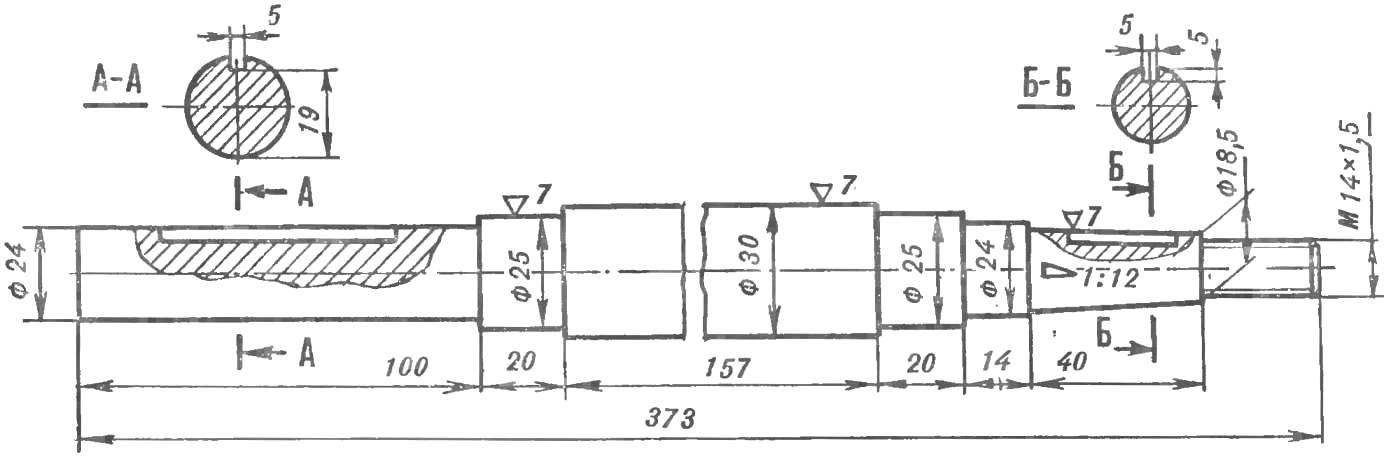

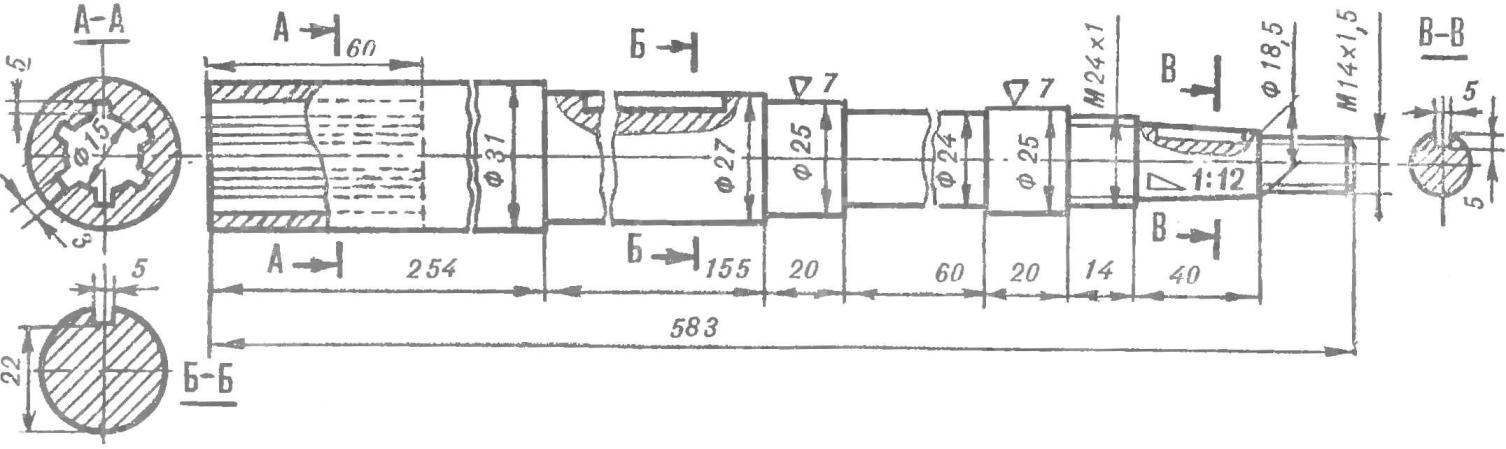

Hub front and rear wheels are home-made, from pipes Ø57 mm, machined on both ends for attachment bearings # 205. They rotate, cropped, turned from steel St. 45 the axle shaft (Fig. 5) which is mounted and fixed by dowels wheels. At the other end of each axle, also on the dowels, attach the sprocket Z-19 from the machinery, “Izhevsk” chain. On the sides of the hubs welded angles 35X35 mm with drilled holes for mounting to the platforms of bolts M10.

Average used hub from the rear axle of the sidecar С3А. They on a conical bearing rotating axle of the middle wheels (Fig. 6), carved from a steel St. 45 and connected to the ends of the bevel gears differential with splines. On the half-worn and fixed on the splines dual sprocket Z-19 under “Izhevsk” chain from agricultural machinery.

For the engine mounts used the sub frame from the sidecar С3А, pre-cropped the lower part for mounting the differential. Cropped subframe is welded to the support frame, the lower part of it with the mount for the differential is also welded to the base frame (see Fig. 2).

The engine is mounted on rubber pads to reduce transmission of vibration to the body. The cushions are tilted at an angle of 45°, which softens the longitudinal jerks of the engine, the change of the load during movement.

Fig. 4. Mount the hub to the frame:

1 — star, 2 — hub body, 3 — axis, 4 — Klondike 5 — area 6 — area 7 — frame, 8 — bolt M10.

Fig. 5. Driveshafts front and rear wheels.

Fig. 6. The drive axle of the middle wheels.

Fig. 7. General view of the control system:

1 — sleeve, 2 — lever left clutch, 3 — rubber handle, 4 — shaft, 5 — thrust, 6 — bearing, 7 — hub body, 8 — sprocket, double, 9 — axis, 10 — main gear, 11 — brake pads.

Torque from the engine through a chain transmission is transmitted to the differential with him on the middle axle and the chain transmission to the front and rear axles. Six wheels of our Rover are leading. They are taken from the sidecar С3А. The pressure in them it is desirable to maintain no more than 0.8—1 kg/cm2: to improve patency and mitigating the impact when driving on rough.

Body frame is welded of tubes Ø15 mm, made of sheet-steel thickness 1 mm. the Body and frame together constitute a single rigid structure.

The six-wheeled Rover was easy to control, maneuverability, and stability on the turns, showed high permeability.

Technical characteristics

Engine IZH-56, power, HP…….12

Cooling…………………………………..air, forced

Carb…………………………………..K-28E

Battery…………………………………..6 V, 80 A/h

Weight dry, kg………………………………….890

Useful load, kg…………………….200

Dimensions, mm:

width…………………………………………1440

height…………………………………………..900

Ground clearance, mm…………………………………..160

The number of wheels (all wheel drive)………………6

Wheel drive—pitch chain, mm……15,88

The maximum speed, km/h ………….50

A. KIZHEVATOV,

member of the roundabout design

compact vehicles

CUT Novosibirsk Akademgorodok