This car was designed (if one can call the process of thinking about design and estimates of size) and made for several hours after my brother and I received a message from his father from the village with a request to help him make his entrance to the house. It was clear that a stretcher we cannot do the work expected is significant, and any mechanized commercial vehicles was not expected.

This car was designed (if one can call the process of thinking about design and estimates of size) and made for several hours after my brother and I received a message from his father from the village with a request to help him make his entrance to the house. It was clear that a stretcher we cannot do the work expected is significant, and any mechanized commercial vehicles was not expected.

As often happens with homebrew, design cars identified available in the shed materials and tools. Very useful two wheels of the motorcycle M-103 “Minsk”, long lying idle — the engine-it was already used on a snowmobile “Thought” (an Article about this snowmobile was published in No. 11 for the year 1991 of the journal “modelist-Konstruktor”). Of the other details that were used in the manufacture of, is the arms and legs from the backs of old metal beds; useful and cutting sheet metal thickness of 1.0 mm.

Production technology is simple, as the design of the car.

First of the two temples and cropped to the desired size of the pair of legs of the bed welded piping bucket body. Then carved out with small margins, a bottom wall, grabbed all the joints welded and put “bucket” in the piping Aligning the parts relative to each other and fit in the place of the region of the body, said allowances and cut off the excess.

Then, tucked the edge of the “bucket” to the pipes edging, provari intermittent seam (welding) around the perimeter and all edges and joints of the sides — solid seam.

Further from the pipe bed leg sawed off period — axle wheelsets. In accordance with the size of the pipe (its inner and outer diameters) and the wheel hub (its length and seed diameter of the inner ring of the bearing) machined two-axis and insert them at both ends of the pipe welded. Turning the body upside down, set it strictly across the bridge and welded, and then welded reinforced mounting pads in the form of staples. Thus the car came with a monocoque body.

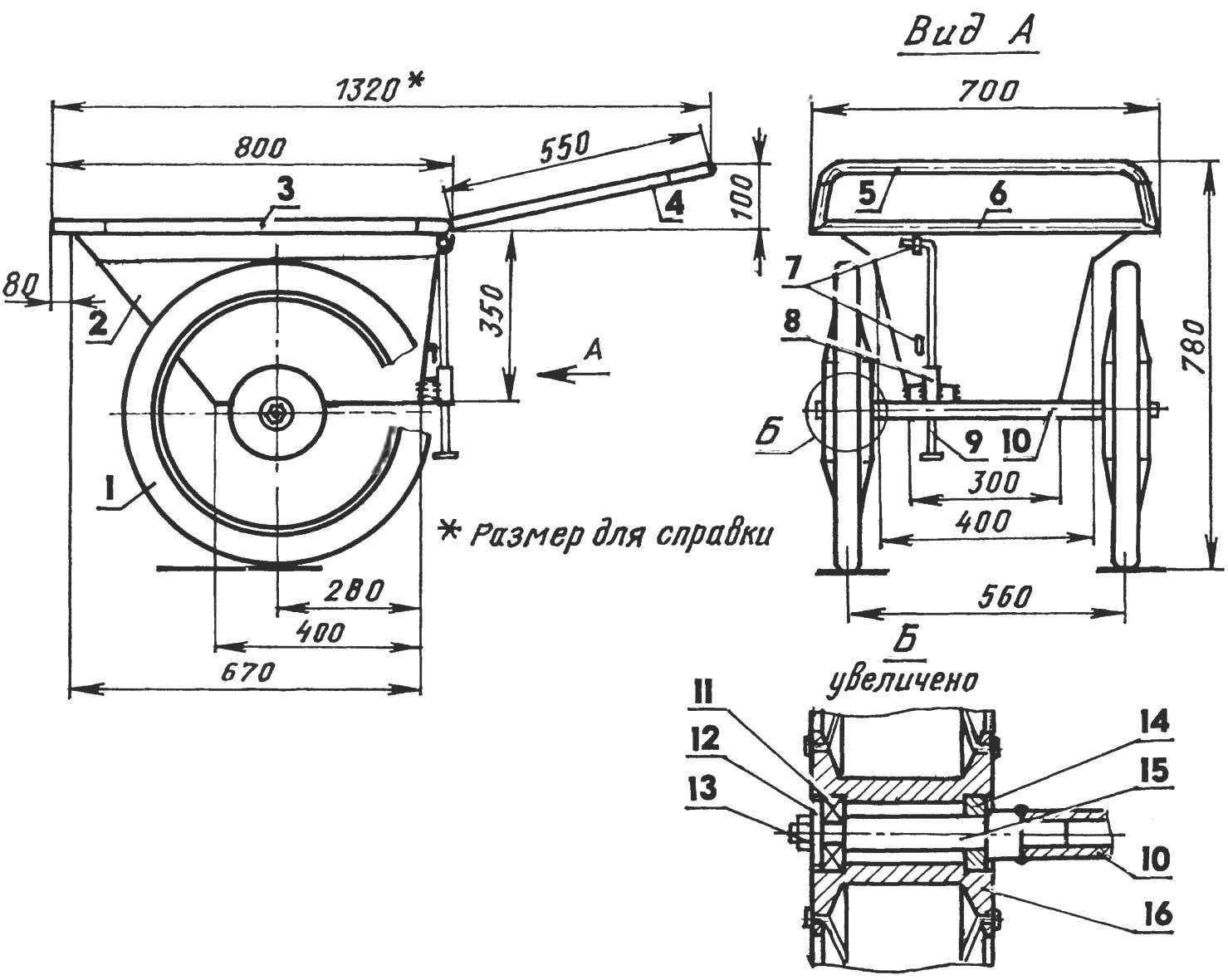

Wheelbarrow-weight:

1 — wheel (motorcycle M-103 “Minsk”, 2); 2 — body (steel sheet s1,0); 3 — lateral border of the body (bed leg, 2 pieces); 4 — the feathers of the arms (bed leg, 2 pieces); 5 — arm (wishbone headboards); 6 end bezel (ear headboards, 2); 7 — hooks transport and static standing feet (ft3, sheet s2); 8—remote plate and the guide bushing support leg (steel sheet s2 and the pipe is 1″); 9 — support leg (steel pipe 1/2″); 10 — bridge (tube 1″); 11 – standard bearing (2); 12 — thrust washer (2); 13—a nut of fastening of a wheel (2); 14 — bearing (bronze, 2); 15 — axle 16 — wheel hub

Now secured on the axes of the wheel again and turned the body to its original position. The handle was also made of the arc and back legs of the old bed. Its angle of installation picked up on his height and welded the ends to the back of the arc the outline of the body.

The support foot made the journey up to not hurt when moving. Because the track and ground clearance of the car allow it to move through a fairly large obstacles.

And finally painted the wheelbarrow and quick-dry primer to look decent.

The next morning, ready car hitched to a double four-wheeled velomobile and went to my dad’s village…

Since then, it took about 15 years, a lot has changed (deteriorated recumbent, his dad died), but the car continues to serve as a helper and always at work. During this time it moved tens of tons of various cargoes (breakbulk, bulk and even liquid): soil, gravel, manure, firewood, bricks, mortar and other things.

Large diameter wheels allow to transport the car and bumpy and shaky ground and mud. To unload the truck (if you load) you can “dump” method, threw the body forward.

Car fully demonstrated its positive qualities: simplicity of design, reliability, versatility in use and environmental friendliness. The last quality was manifested not only in its operation, and creating. Because it is made almost from scrap metal, which had rusted many years under the open sky. And because the motto of “Use of metal a useful piece of metal” have long become for me a principle of life.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.