Having once decided to build an airplane, the home-made man is faced with a number of questions, and the outcome of the whole matter depends on the answer to them. It seems to me that every competent person can make an airplane if he fulfills three conditions.

Firstly, you need to enlist the support and understanding of your idea from your family and friends. Creating an airplane takes up all your free time, and it is very important that the family does not mind. It’s even better to make it a common cause, to ignite the people closest to you with your idea. According to the American Experimental Aviation Association, about 70% of unfinished aircraft are caused by wives. Problems in the family associated with a lack of mutual attention during construction, in most cases, lead to the fact that the project is not completed.

Secondly, you need to develop willpower. This will ensure the superiority of reason over feelings. Creating your own aircraft is a very labor-intensive process. A huge amount of work can make you doubt the correctness of the chosen path, get upset because of mistakes or difficulties. Prepare for there to be ups and downs. You need to learn to fight with yourself: “I don’t want to, but I have to!” And every day, no matter what, go towards your goal!

Thirdly, it is important to find a suitable project. Nowadays, many ready-made aircraft designs have appeared for self-construction, and from all this variety you need to choose the one that is most suitable for yourself in accordance with the available financial, technological and operational capabilities.

To correctly assess all this, you need experience, of course, and in the material offered I would like to share my own thoughts on this matter.

PATH TO SKY

As a child, I dreamed of becoming a pilot. This desire even became the subject of a kind of parental “blackmail”: “If you want to be a pilot, you must study well.” My father then subscribed to the magazine “Modeler-Constructor”, in which I read with admiration reports from SLA rallies in the 1980s, and thought: “Is it really possible to build an airplane yourself?” My father was a military man, so, moving around different garrisons, I did not have the opportunity to go to clubs or SUT. And in middle school, vision problems arose, and I had to give up my dream.

After school, unexpectedly for everyone, I entered the College of Arts and became… a saxophonist. Then I graduated from the Institute of Arts, which was facilitated by work in the artistic ceramics workshop I created. Everything was going well and smoothly until I accidentally saw a model airplane in a toy store. This is where it all started! Unfulfilled dreams and memories overwhelmed me with terrible force.

I started by assembling plastic scale models of airplanes, and along the way I studied the history of aviation. I started “flying” in various computer simulators, which gave me an idea of how to fly an airplane. Then he moved on to independently building radio-controlled flying models, and these are the basics of aerodynamics and design. At this time, I met a local home-made man who owned a KhAI 29 “Korshun” aircraft. I took to the skies for the first time on this plane. It’s interesting that my first flight in my life was also my first solo flight! Well, then: “the wings have grown”, but still there is no plane…

After some thought, I came to the conclusion that the most accessible way for me to fly is to master a hang glider. The Delta Club that I liked ended up in the city of Zhukovsky. It is about 500 km from Smolensk, where I live. But as they say, whoever wants to, can. What a flight, what a delight! Among all the flying machines invented by man, the hang glider most fully conveys the flight of a bird! However, first you need a take-off run from the mountain or towing the device if it happens in flat terrain. Organizing flights is the most difficult thing in hang gliding.

While I continued hang gliding in Smolensk, I began to think about making my own plane. In the beginning there was a “wooden” project. But it turned out that aircraft plywood has not been produced in our country for a long time, and what is still available is incredibly expensive. I also considered a fiberglass device. Here, too, an insoluble problem arose – unidirectional fiberglass. But I didn’t even dream of an all-metal version because of the price of materials and equipment. And I didn’t want to get overgrown with devices and machines just because of one plane. As a result, I made a number of conclusions for myself. There are three most important of them: 1 – simple, accessible and reliable technology is needed: 2 – the most available materials should be used; 3 – a common and reliable motor is required.

Thus, I decided for myself that my homemade aircraft should only be single-seat for economic and moral reasons. It is much cheaper than a double. In addition, I am fundamentally against home-made two-seater aircraft, because I think this way: if you build it yourself, fly it yourself. And if you want to “share your emotions,” buy a factory model; you don’t have to make people hostage to your ambitions.

The most important parameter of an ultralight aircraft is the wing load. It should lie in the range of 20 – 27 kg. With a lower value, the plane will be “a fragile toy in the hands of the wind.” With more, you will have to use a more powerful motor. And this is what will necessitate strengthening the structure, which, in turn, will lead to an increase in weight and will entail the use of special technologies and materials – as a result, the aircraft will be heavy and very expensive.

It is also important to determine operational objectives. Basically, home-made airplanes are built “for the soul”, just to fly and that’s it. However, there should always be perspective! When I asked people who wanted to make an airplane what they needed it for, most often the answer was: “Fly in a circle and that’s it.” Former pilots added: “Well, take your breath away, remember…”. But such flights will get boring very quickly! There must be some more significant task.

For example, make your own plane for travel. After all, to “fly in a circle” a paramotor is enough (and you don’t need to invent anything!). Or an aircraft suitable for operation in different climatic conditions. For winter and summer, capable of taking off from the ground, asphalt or water (and landing there). Or maybe create an airplane to improve your piloting skills?

Typically, enthusiasts build aircraft with low wing loading to ensure low takeoff and landing speeds and good handling. It is relatively easy to learn to fly with such machines. However, choosing the right weather becomes extremely important! All the capabilities of the aircraft are used practically in the very first flights; the pilot does not develop. Or there is another extreme: the Argo aircraft, which is very popular among amateur aircraft designers. It is quite strict on the pilot, has a decent take-off and landing speed and a pronounced screen effect. It can be operated by a person with experience. And so, a home-made aircraft builds and builds such an airplane for several years, and then, in the very first runs (sometimes they end with random takeoffs) – bam, and the fruit of all the long labor turns into a pile of “firewood.” Therefore, an amateur needs an aircraft that, without serious training, would allow him to make his first flight, and then grow as a pilot: land on unprepared or limited areas, learn how to perform 2G turns, “combat turns” and “lazy eights”. Therefore, the prospect, in my understanding, is travel, and operation in winter and summer, both from the ground and from the water, and the development of one’s skills. All this can be achieved in SLA, choosing the right weather and having the right car.

Looking ahead, I will say that our aircraft meets all these requirements. You can learn to fly on it (but I still recommend taking your first steps with an experienced instructor), travel – in the summer, using wheels or floats, in the winter – skis, participate in holidays, festivals (flying with smoke, with ribbons, “racing” with a car ). I’m even considering using our plane to tow a hang glider. This is, in my understanding, flying “for the soul”, and not around the “sandbox” (in aviator slang, a “sandbox” is a runway).

Aircraft classified as SLAs are mainly operated outside of airfields. There is also always the possibility of engine failure, which will lead to the need to land outside the prepared area. Therefore, it is logical to choose a high-wing design with a fairly low landing speed, which is determined by the load on the wing. The choice of a landing gear design with a tail support, despite its shortcomings, is also logical: light weight, low aerodynamic drag, simplicity of design. All champion aerobatic machines are tail-mounted, and bush pilots in Alaska also prefer this design.

On the eve of the First World War, there was no dedicated aviation industry in the world. When creating aircraft, designers used developments from related fields of mechanical engineering. The rapid development of aviation during the war discarded all dubious and unpromising technologies, methods and aerodynamic designs. By 1918, the most compromise design had been formed, which became classic. And by the end of the 1920s, aircraft with a steel welded truss fuselage frame and a wooden wing with fabric covering reached their perfection. The desire to fly higher, faster and carry more cargo required new materials and technologies. But it is obvious that they will only increase the cost of a homemade aircraft. As I noted above, in order to build a reliable, well-flying aircraft, you can and should use the most accessible materials and simple technologies developed at the beginning of the last century.

TIMELESS CLASSICS

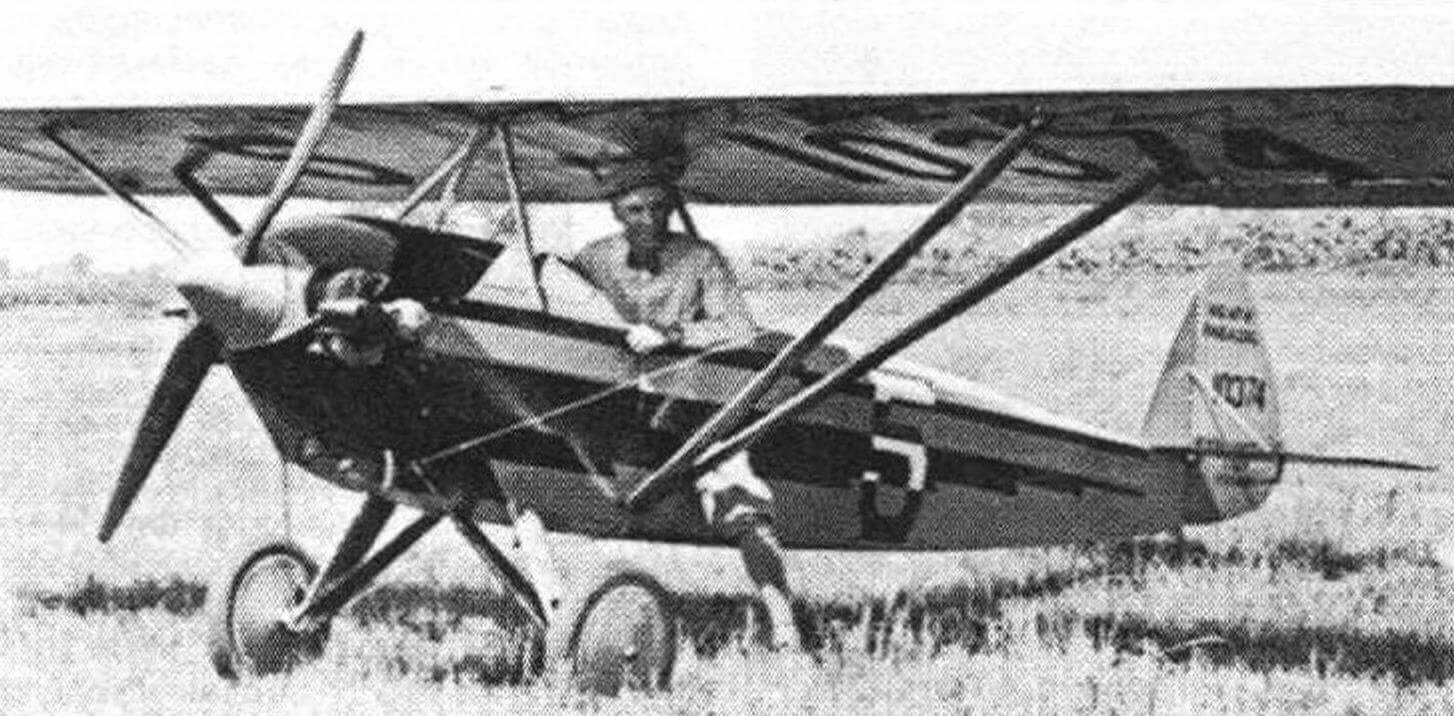

After reviewing all the available projects for self-construction, I discovered the work of Edward Heath and his legendary “Hit Super Parasol”. As you would expect, everything has already been invented before us! It was this aircraft that fully satisfied all my requirements and objectives.

The Heath Super Parasol is a very famous aircraft in the United States by ultralight aviation pioneer, pilot, designer and businessman Edward Heath. The peak of his technical creativity occurred in the mid-to-late 1920s. Aviation has always been a business for wealthy people, but Edd Heath dreamed all his life of creating an aircraft that was accessible to the average American. In 1918, the first project of such an aircraft was ready. It was a biplane with a wingspan of 6 meters, with a 15 hp motorcycle engine. The empty weight of the car, which Edd named “Feather”, was 122 kg. However, the end of the war made the project unprofitable: military aircraft flooded onto the market at a price below cost. Then Heath founded a company selling spare parts and materials, where any enthusiast could buy “everything in one place!” But the idea of an affordable aircraft did not leave him. Heath began designing and building aircraft to compete in the then popular air races. In 1926, he won the National Air Races in Philadelphia in a Tomboy model. Using the $2,500 they received as a prize, that same year, Heath and engineer Claire Linstead created the first version of the later famous “Hit Parasol.”

A year later, the next Parasol appeared, and at a competition in Spokane in the light sport aircraft class, Heath won a $1,000 prize with it. From that moment came recognition! Edd began to promote the slogan “Build your own plane.” It was he who first came up with the idea of selling the aircraft in the form of a “whale” (set). You could buy a ready-made device for $695 (a Ford-T, by the way, cost about $400 at that time), or buy it in parts for self-assembly, or order only the drawings for $5. It should be noted that this was a licensed aircraft, and after flying it for 200 hours, anyone could obtain a commercial pilot’s license. Hundreds of sets of drawings were sold. dozens of kits and about 80 finished aircraft. Many ordinary people became pilots thanks to Edward Heath and his “Super Parasol”!

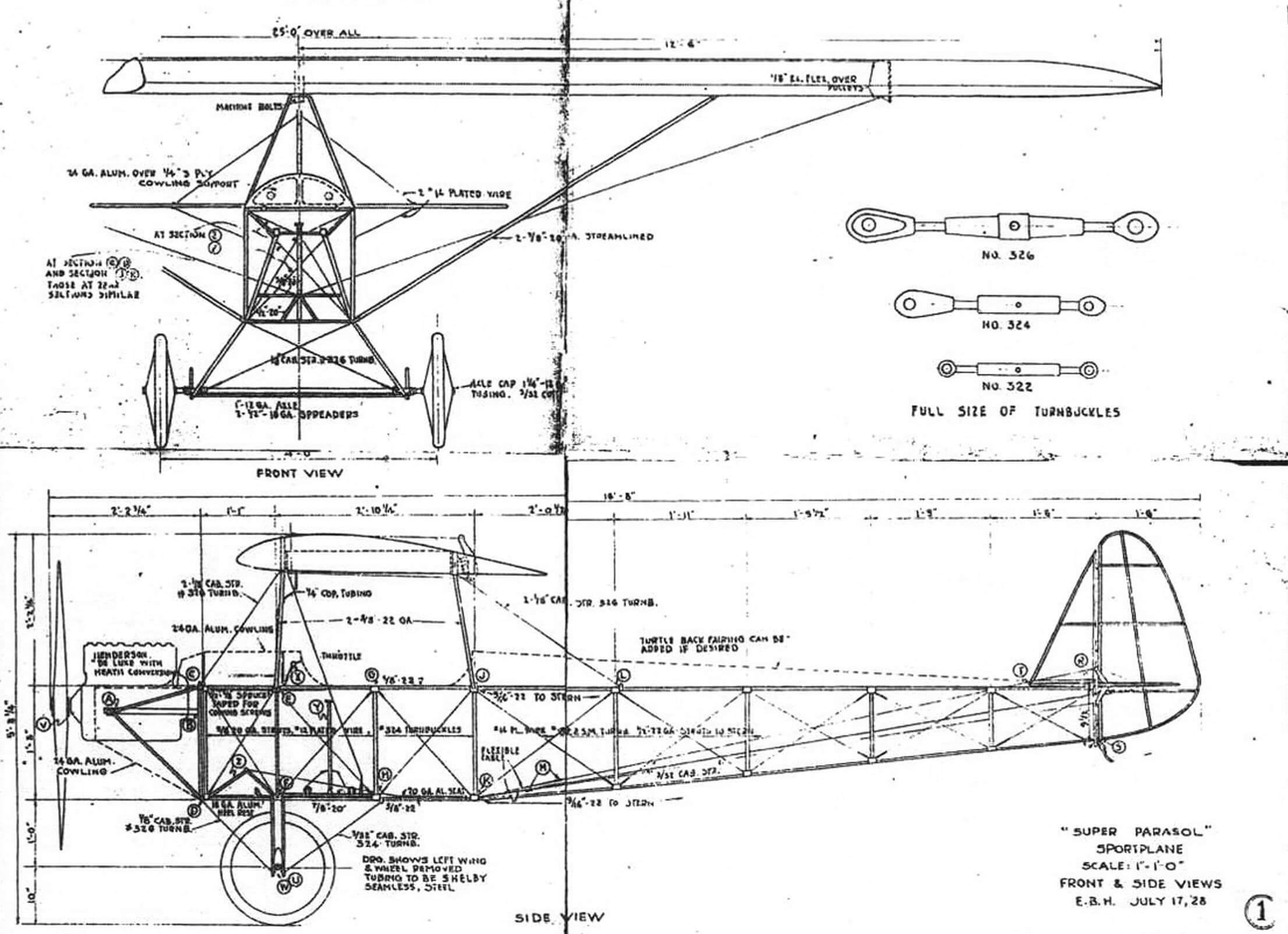

Edward Heath was the first to propose the option of a braced steel fuselage without the use of welding, which greatly facilitated the construction of the aircraft at home and did not affect the strength. However, in late 1929, Heath switched to a fully welded frame. The engine hoods were modified and a cooker appeared. The chassis received a split axle instead of a solid wheel axle. The parallel wing struts were replaced with V-shaped ones. A door appeared and the position of the fuel tank was changed. The upgraded version of the aircraft became known as the Hit Super Parasol, Model V.

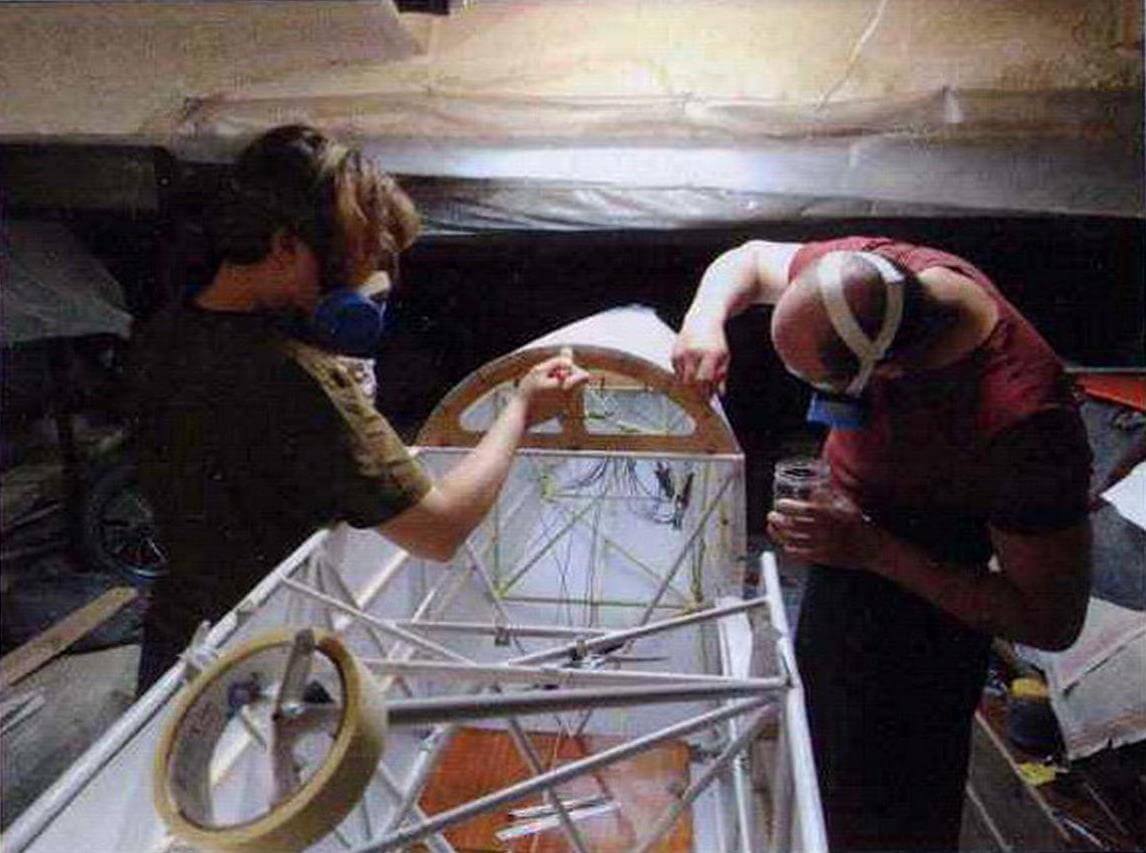

This is what our small team of like-minded people built in 2018. At the SPA meeting in Orlovka the same year (see “M-K” No. 8-2018), this work was awarded a prize. It should be noted that “Hit Super Parasol” was built for the first time in Russia. It was created by us in Smolensk over two and a half years. We wanted to make a small, light aircraft that was as affordable as possible in terms of materials (budget up to 200,000 rubles) and technology, so that anyone could replicate it, because the Heath Super Parasol is an aircraft that anyone can build!

FROM THE M-K DOSSIER

The experimental A-8 tandem aircraft is an example of a lightweight homemade fiberglass aircraft, created based on Burt Rutan’s “Quicky” at the Kuibyshev Aviation Institute in 1984. First demonstrated to the aviation public in Koktebel on the SLA-85 (see “M-K” No. 3-1986). The author of the design is Yuri Yakovlev (in those years a student at KuAI).

Technical characteristics: wingspan – 5.08 m; aircraft length – 5.2 m; wing area – 4.92 m2; take-off weight – 223 kg; engine power – 30 hp; screw diameter – 1.1 m; propeller pitch – 0.7 m; propeller speed – 5000 rpm; static propeller thrust – 65 kgf; specific wing load – 45 kgf/m2; specific load on power – 7.5 kgf/hp; maximum speed – 200 km/h; stall speed – 75 km/h; rate of climb at the ground – 5 m/s; maximum operational overload – 6

FROM THE M-K DOSSIER

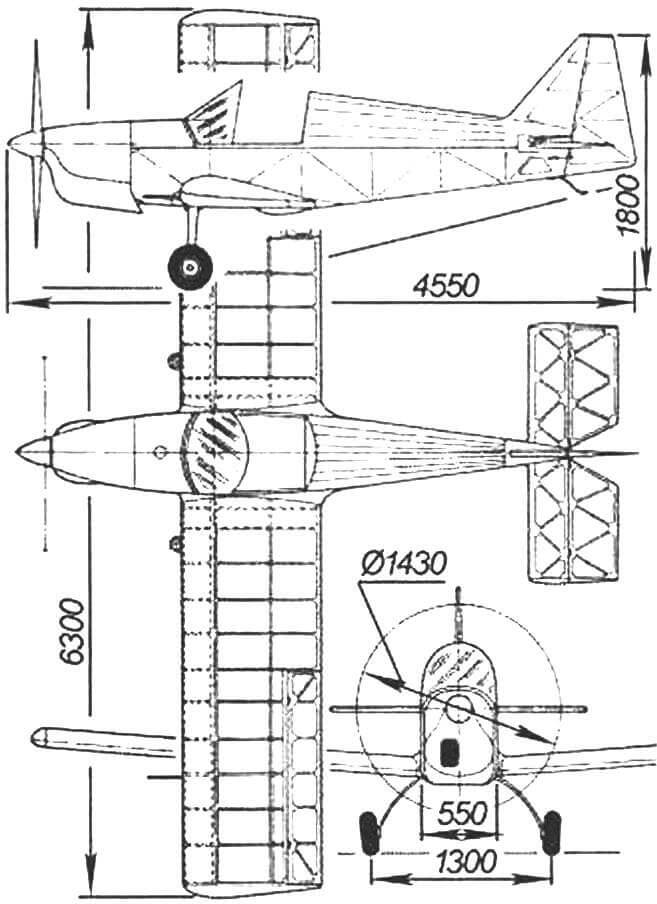

The ultra-light single-seat training aircraft “Argo-02” is a home-made aircraft with a wooden frame and fabric wing covering. Built by Tver amateur aviators Evgeny Ignatiev. Yuri Gulakov and Alexander Abramov in 1987. He successfully flew the SLA-87, SLA-89, and received first prize at the regional competition in Yaroslavl (see “M-K” No. 3-1990).

Technical characteristics: wingspan – 6.3 m; aircraft length – 4.55 m; wing area – 6.3 m2; take-off weight – 225 kg; engine power – 28 hp; screw diameter – 1.48 m; propeller pitch – 0.95 m; propeller speed – 2750 rpm; static propeller thrust – 95 kgf; specific wing load – 37.3 kg/m2; specific load on power – 8.39 kgf/hp; maximum speed -130 km/h; stall speed – 72 km/h; rate of climb at the ground – 2 m/s; maximum operational overloads – n.a.

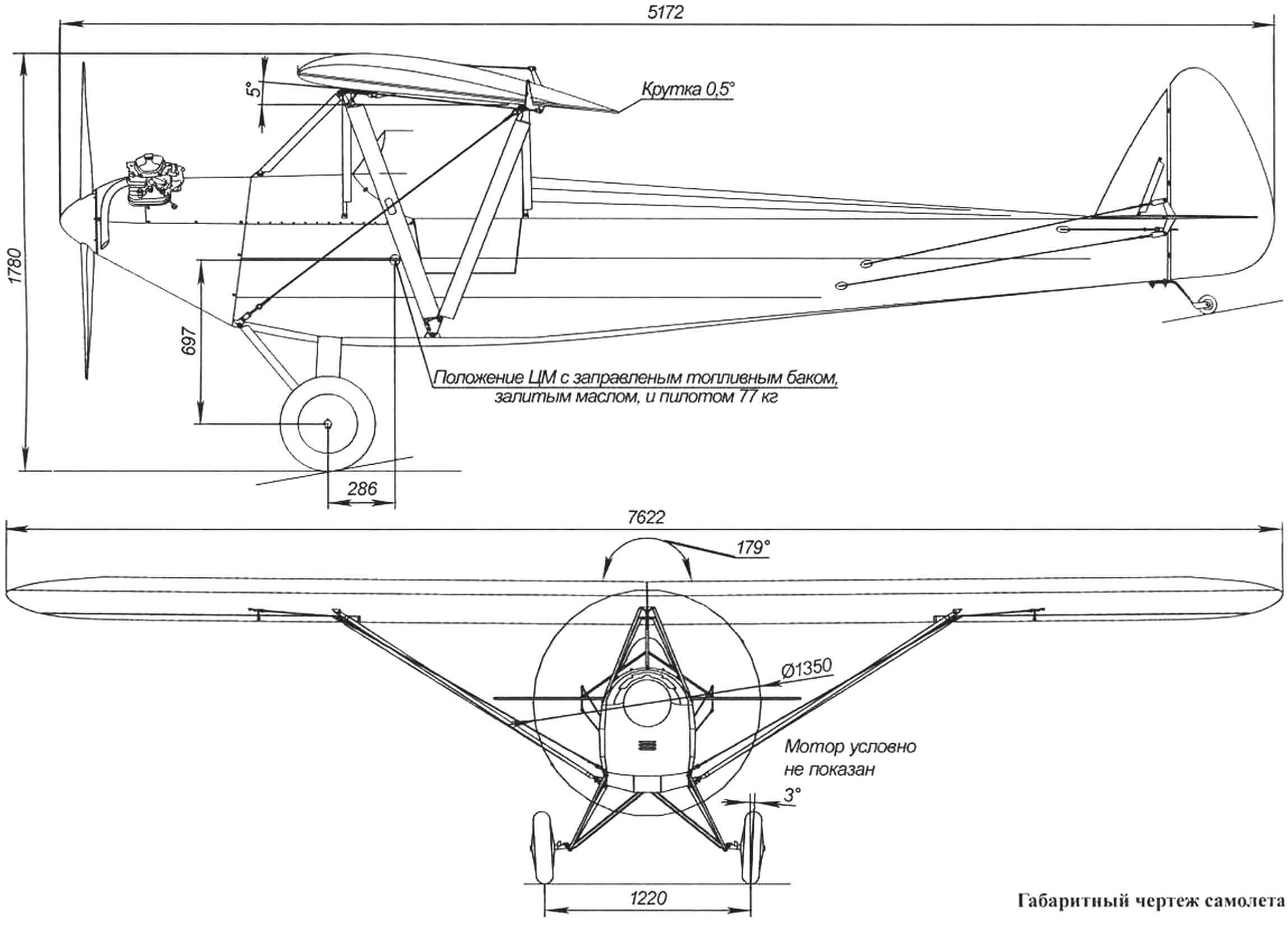

Main performance characteristics of the Hit Super Parasol aircraft, created in Smolensk

Wingspan, m 7.62

Length, m 5

Height, m 1.73

Wing area, m2 10

Max, speed, km/h 90

Landing speed, km/h 45

Gasoline engine,

four-stroke, carburetor.

air cooling Lifan 2V78-F2A. 24 hp at 3600 rpm.

Fuel consumption (Ai-92), l/h 5

Flight range, km ~ 270

Maximum take-off weight. kg 230

Maximum load, kg 105

Design overload 10

Number of places 1

Construction budget ~ $3000

Construction time, person/hour ~ 1500

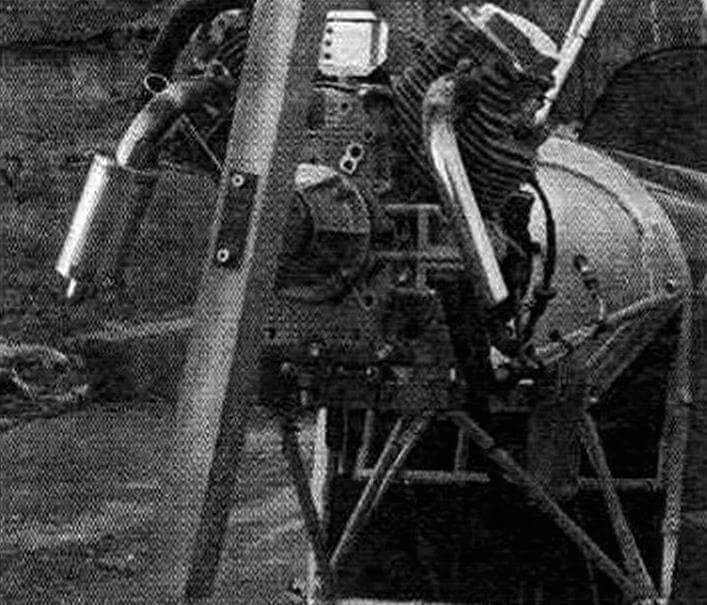

The heart of any aircraft is the engine, and here I am very conservative, saying that the main thing for an aircraft engine is reliability. Everything else – power, weight, noise, efficiency – is also important, but secondary.

In aviation, almost from its very birth, the four-stroke engine with a propeller on the crankshaft has been firmly established. Moreover, I refused the gearbox, for a number of reasons. Firstly, I am sure that it is in principle impossible to produce a reliable gearbox using the help of a homemade person. In addition, in aviation engine building it is believed that a gearbox with a long service life can only be obtained on an engine with at least six cylinders. Secondly, the gearbox means additional weight, and the issue of layout and bonneting is also not the least important. Thirdly, a gearbox is usually used to obtain maximum engine power by increasing the speed. However, this negatively affects both the resource and reliability. And a motor without a gearbox is easier to maintain and operate.

After analyzing many different options from motorcycles, snowmobiles and other equipment, I came to the conclusion that the industrial two-cylinder V-twin engine, which is used in power plants, lawn mowers, etc., was ideal for me. Chinese four-stroke Lifan 2V78F-2A with a power of 24 hp. at 3600 rpm it is a copy of the Honda and is quite affordable. It has a fairly large torque, lubrication is carried out under pressure, there is an oil cooler, each cylinder is ignited by its own magneto, and without a flywheel its specific gravity is almost like that of a “two-stroke”. The engine is sold as a ready-made unit, which makes its installation a simple task, requiring almost no modification. Before installing it on an aircraft, it is necessary to perform standard operations, such as: removing the speed controller, grinding and polishing the channels, selecting the diameter of the hole in the main jet of the carburetor, since initially the engine is artificially “strangled”. The thrust bearing bell was also cast and the exhaust pipes were fabricated. In my opinion, this engine is closest in its design to the concept of “aviation”. A four-stroke engine, unlike a two-stroke engine, has a wider power range, less thermal load and sensitivity to the quality of the air-fuel mixture, it is more economical and less noisy. All this generally adds to reliability. And what a sound!

I don’t really like amateur developments that use components and parts from rare, less common equipment. This significantly narrows the circle of people capable of repeating such a project. But this problem is especially acute in amateur aviation technical creativity. The use of components and assemblies from “large” aircraft makes the work almost exclusive. The same can be said about rare or expensive materials and complex technologies that are difficult to apply in normal practice. For example, to build a metal airplane you need expensive materials, special devices and mastery of technology, but all this is unlikely to be useful later in everyday life. On the contrary, creating a wooden wing requires skills and tools that will not be superfluous in life. The same situation applies to welding or soldering.

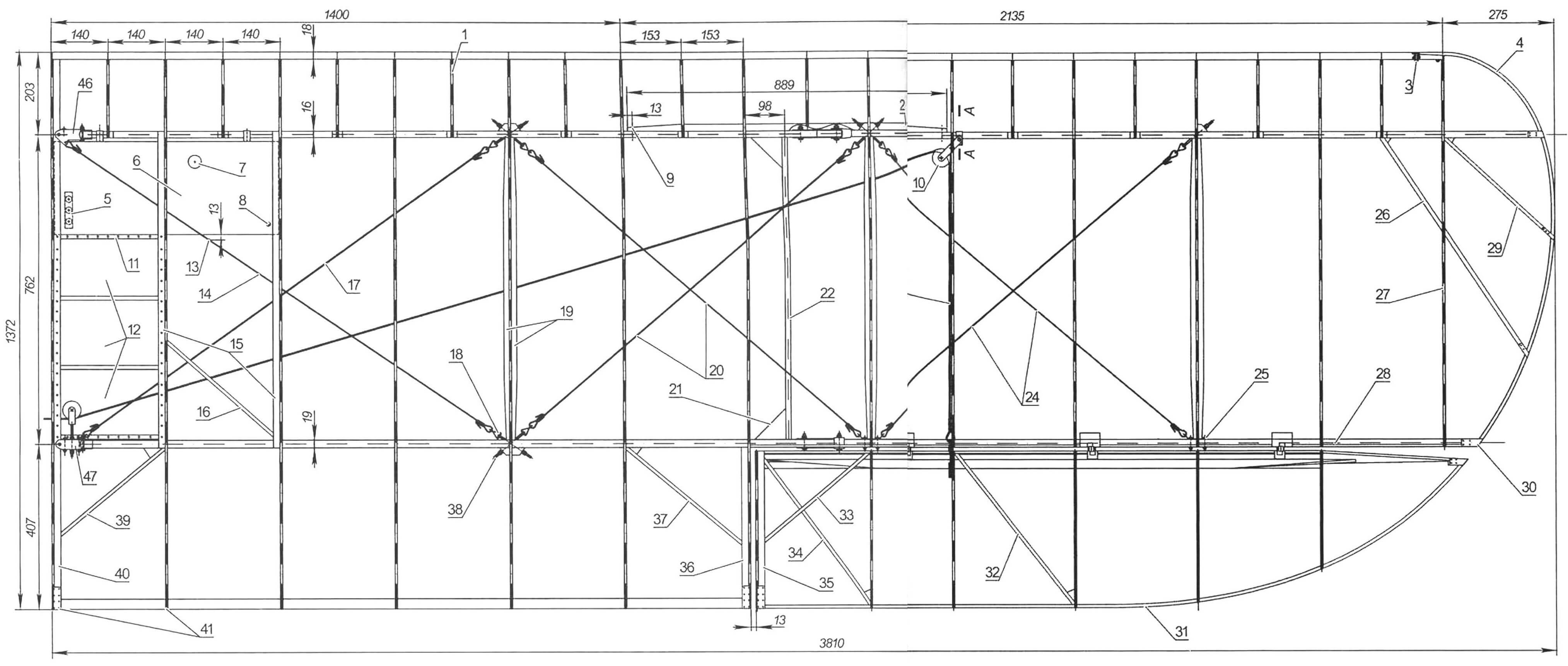

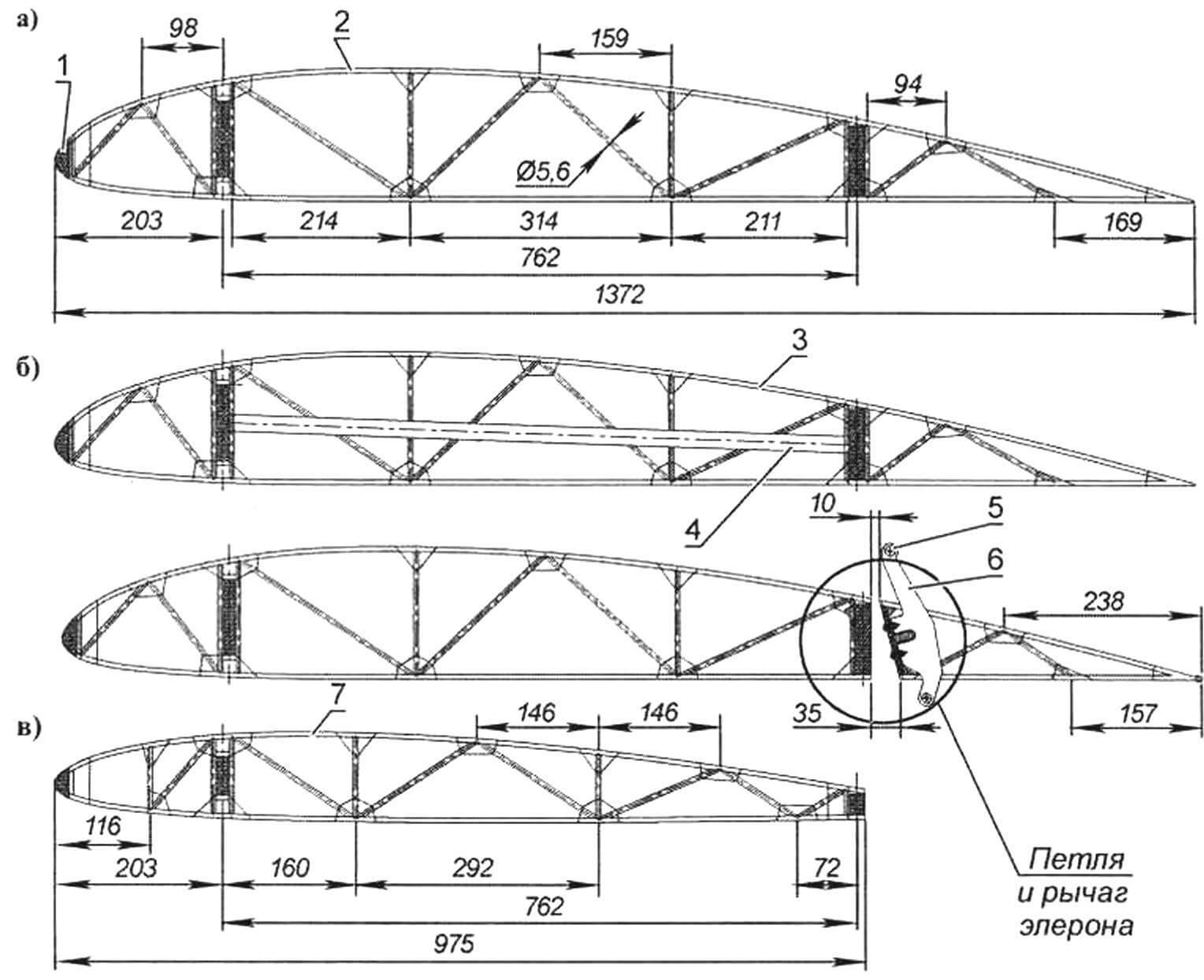

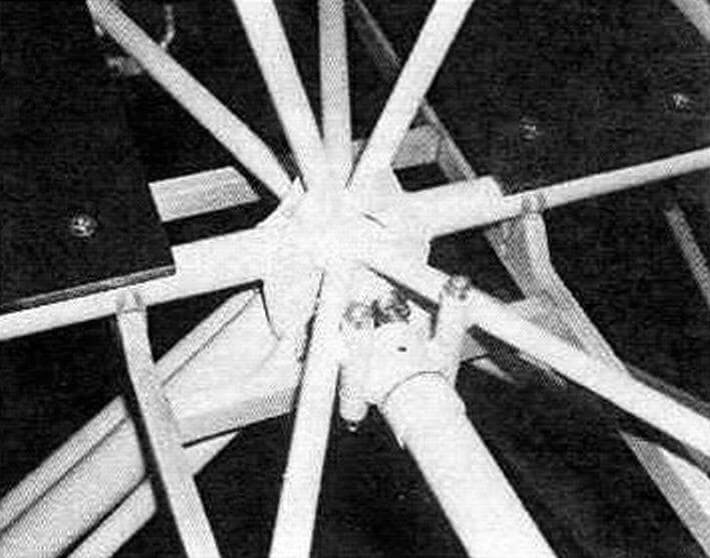

“Hit Super Parasol” is such a classic aircraft in aerodynamic and technological terms that students can be taught by its example! The wing is wooden, two-spar. The spars are essentially a board mounted on an edge. The box of spars is braced with OVS wire. The wing tip arc and the trailing edge of the aileron are a galvanized steel tube (a brake tube from KAMAZ, sold in any spare parts store for trucks of this brand, is suitable). The ribs are truss, with plywood brackets. I still have plywood from aircraft modeling days. In the absence of it (and, as I noted earlier, it is now in great short supply), I would confidently recommend brackets made of PCB with a thickness of 0.8 mm. Thin aircraft grade plywood is not used anywhere else on our aircraft.

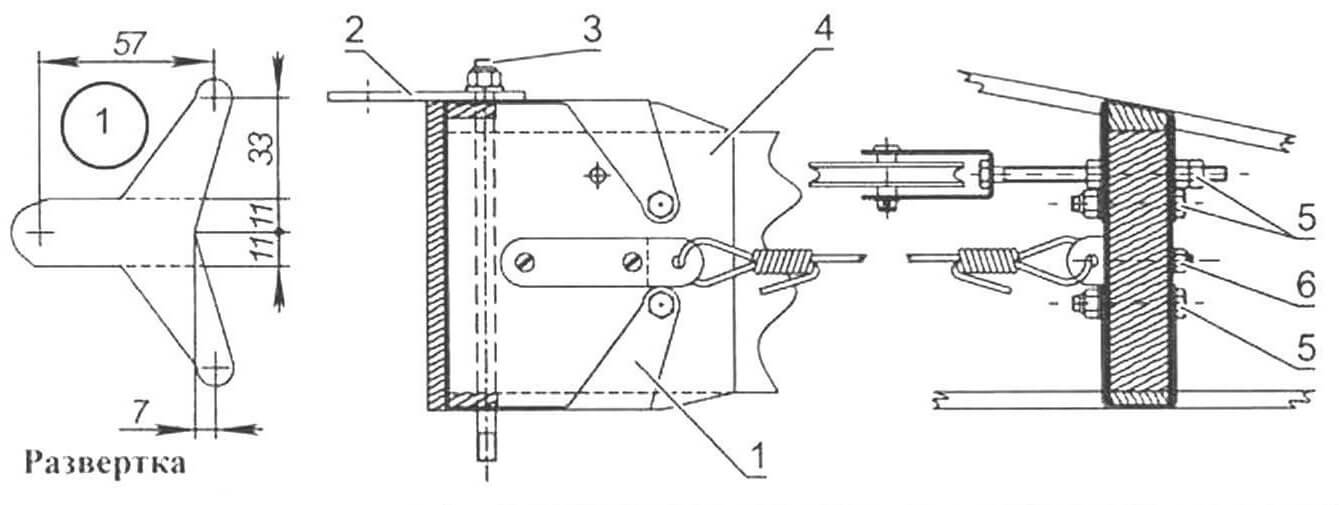

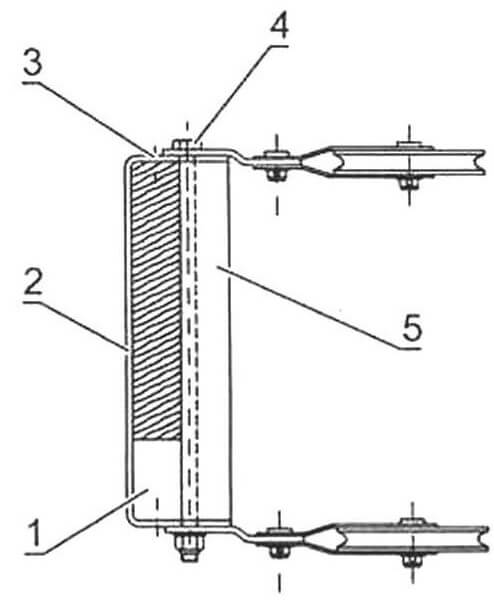

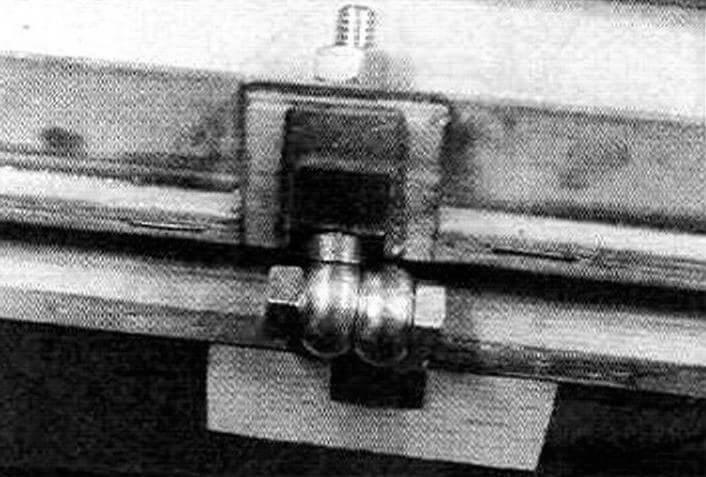

1 — clip (steel 1 mm); 2 — connecting plate 25x65x3 mm; 3 — M6 pin; 4 – plywood 1.5 mm; 5 — bolt and stud M5; 6 — M4 stud

1 — connecting plate 25x65x3 mm: 2 — M6 pin; 3 – filler; 4 – plywood 3 mm; 5.6 – M5 bolt; 7 — clip (steel 1 mm)

1 – filler; 2 — bracket (steel 2 mm); 3 – screw Ø3 mm: 4 – bolt M5x140; 5 – block (pine 16×16 mm)

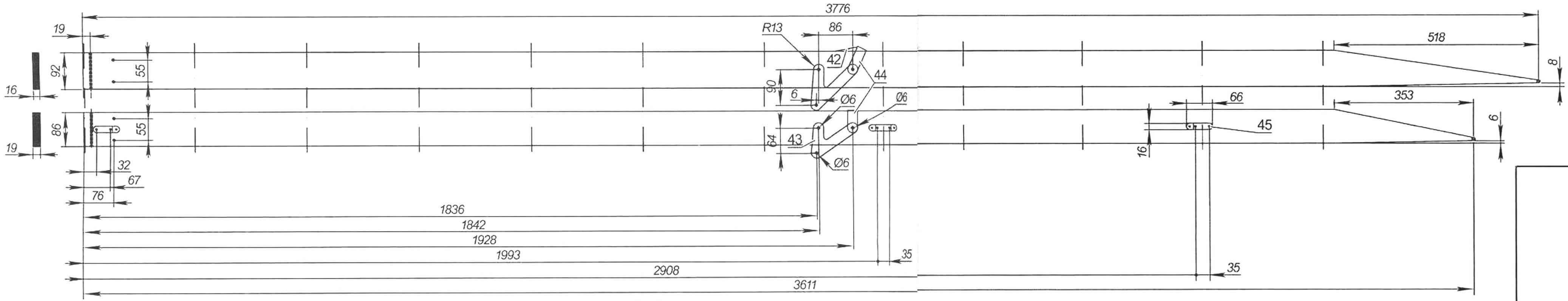

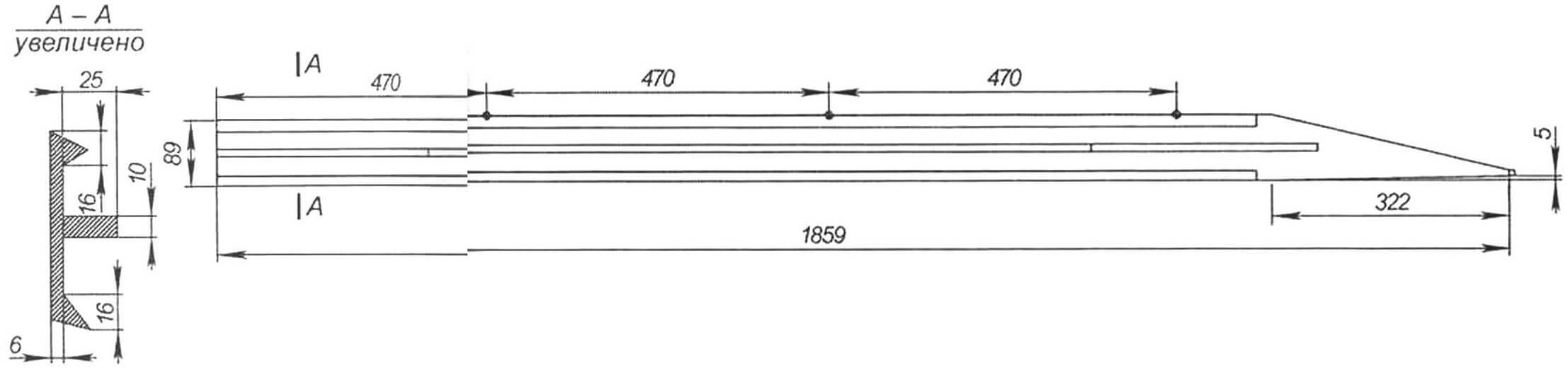

Wing frame and spars:

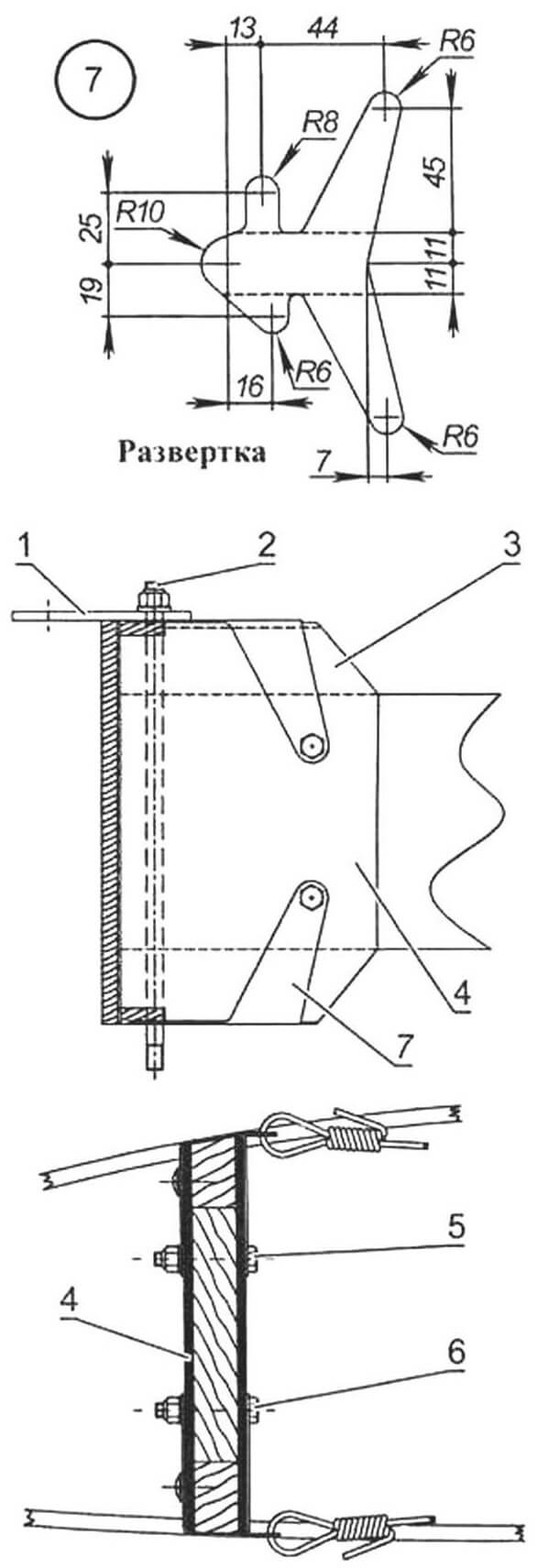

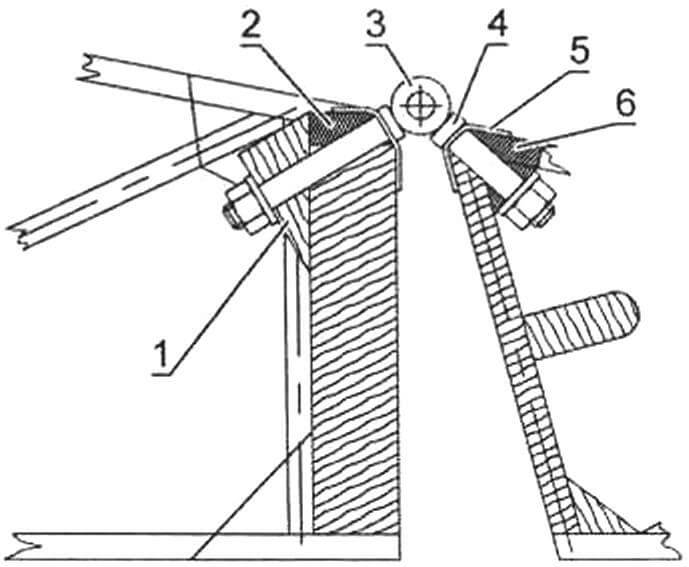

1 — false beacon; 2 — amplifier of side members 18×18 mm (2 pcs); 3 — M4 bolt; 4 — rim (pipe 08 mm, steel); 5 — tank crankcase; 6-fuel tank (only on the right wing, galvanized steel 0.6 mm); 7 – filler neck; 8 – drain valve; 9 — screw Ø3.5 mm; 10 — roller 050 mm (dural, 2 pcs); 11 — strip 10×10 mm; 12 — light window (acrylic 0.8 mm); 13 — spacer sleeve 05 mm (steel, solder to braces); 14 — brace (OVS wire Ø1.6 mm, 2 pcs. above and below the tank); 15 — amplifier 16×5.6 mm (2 pcs each); 17-jib 8×8 mm (2 pcs); 17 — brace (OVS wire Ø2.0 mm); 18 — earring (steel 1 mm); 19 — frame racks of side members 16×13 mm; 20 — brace (OBC wire Ø1.5 mm); 21 — gusset (3 mm plywood); 22 — spacer 16×16 mm; 23 — control cable (KSAN Ø3.2 mm); 24 — brace (OBC wire Ø1.5 mm); 25 — M4 bolt; 26 — rail 10×10 mm; 27 — wing tip rib; 28 — filler 5.6×5.6 mm; 29 — rail 8×8 mm; 30 — rim fastening clip (brass); 31 — trailing edge of the aileron (pipe 08 mm, steel); 32—rail 8×8 mm; 33 — 8×8 rail (2 pcs); 34 — rail 8×8 mm; 35-amplifier 16×5.6 mm (2 pcs); 36-amplifier 16×5.6 mm (2 pcs); 37 — rail 8×8 mm (2 pcs); 38 — bolt M5x80; 39 — rail 8×8 mm (2 pcs); 40 — reinforcing rail 16×5.6 mm along the contour of the rib; 41 — clips for fastening the trailing edge; 42 – filler; 43 — cable brackets (steel 2 mm); 44 — clips (steel 2 mm); 45 — earring (steel 1.5 mm); 46 — root part of the front spar: 47 — root part of the rear spar

1 — frontal stringer (pine 50×18 mm); 2,3,7 — rib flange (pine 5.6×5.6 mm; brackets — plywood 1 mm); 4 — frame racks of side members (pine 16×13 mm); 5 — washer 5x12x1 mm (solder with brass); 6 — aileron lever (1.5 mm steel, reinforced with 3 mm plywood overlays on both sides)

1 — cracker (pine 19×50 mm); 2 — filler (plywood 6×50 mm); 3 — “folding” bolt M6; 4 — spacer (tube 8×1 mm); 5 — support plate 13x25x1 mm; 6 – filler (plywood 6×25 mm)

The fuel tank is located in the wing. This allows for backup power to the engine by gravity in the event of a fuel pump failure. The tank is one of the big problems for the DIYer. I decided to make it from ordinary thin galvanized steel. I built a small sheet bender, bent the tank parts and soldered them with POS60 solder. The filler neck is a brass plug from a plumbing store, selected according to the diameter. The engine power supply pipe fitting is again from the KAMAZ store. The result was a very simple, inexpensive and fairly light tank. By the way, on the Po-2 planes the tanks were also made of galvanized steel. There was a slight problem with the fuel tap: all the suitable ones from auto parts stores were leaking. As a result, I found the right part among the plumbing products. I modified it to connect it to copper pipes, and the result was a reliable and very “aviation-style” faucet.

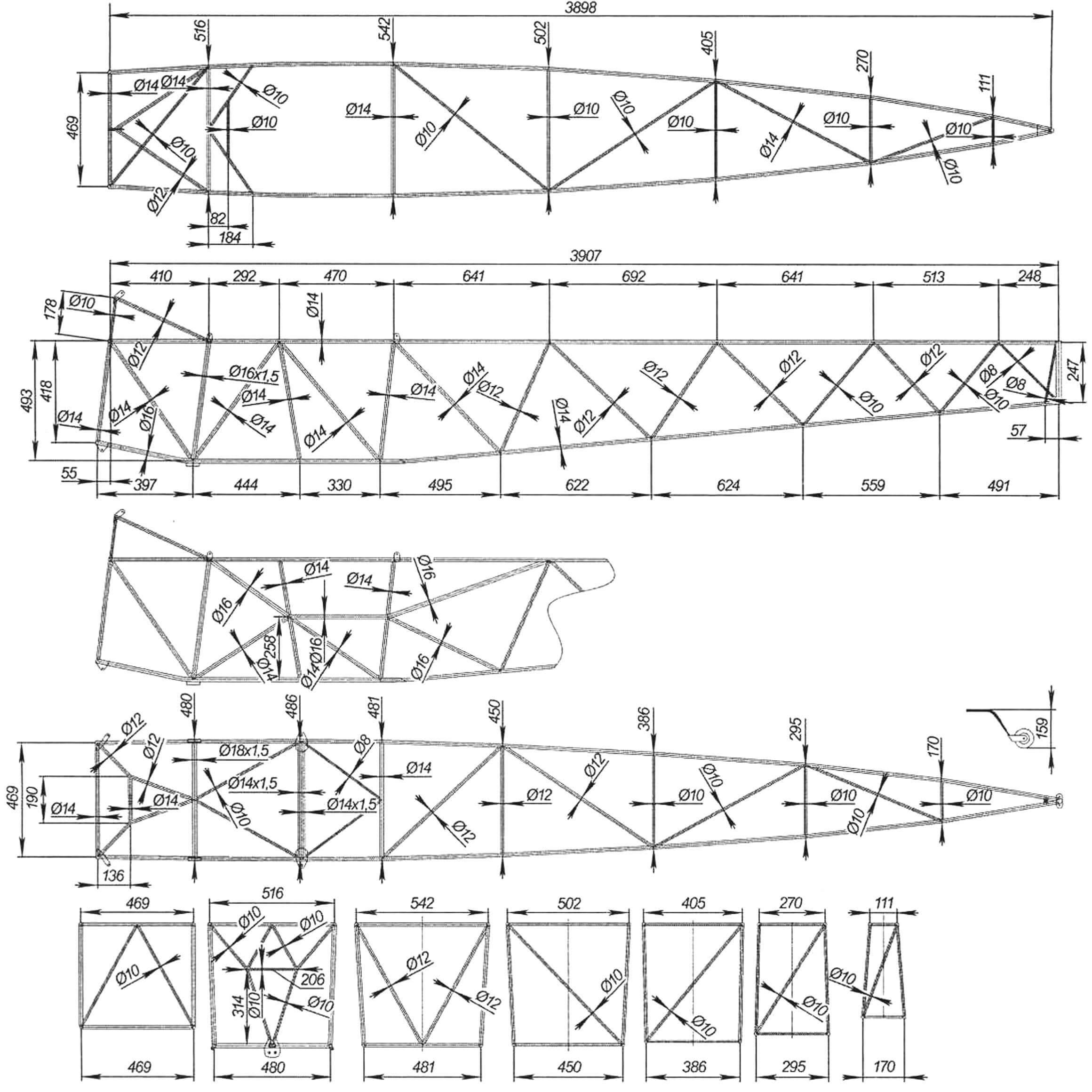

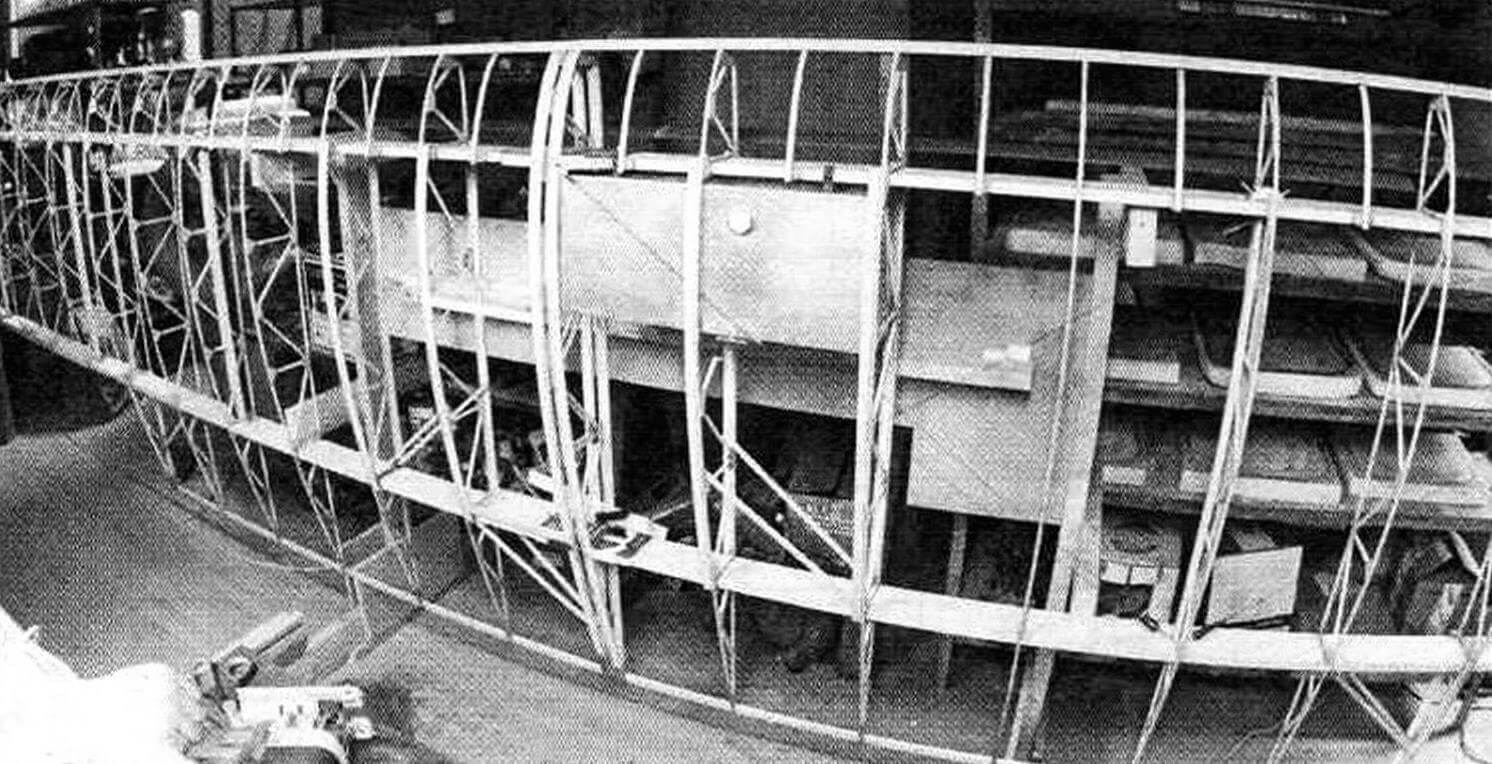

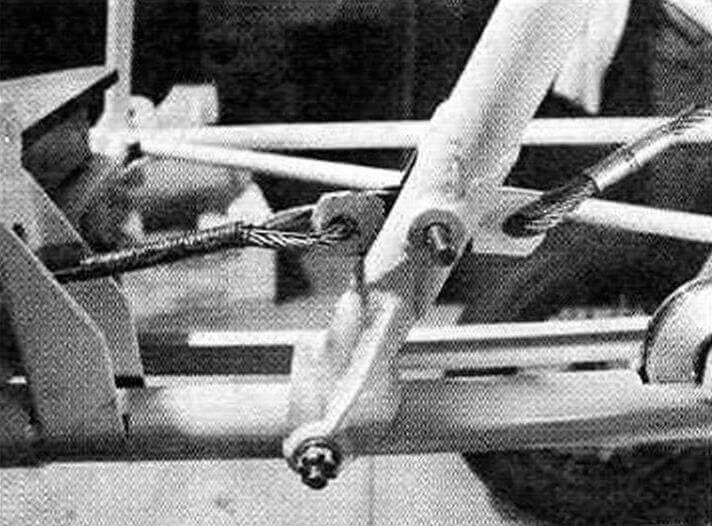

The fuselage and tail are welded, from thin-walled seamless pipes St-20. The fuselage is truss, with diagonal braces. It was easier for me this way. Edward Heath proposed making the fuselage without welding, making its production accessible to most people. However, the original design uses a large number of tanders (turnbuckles) to tension the wire braces. Suitable ones these days are either practically impossible to get, or their purchase (and even more so their production) makes the cost of the fuselage so expensive that the use of this essentially simple technology loses all meaning. Thunderers are a challenge for the DIYer. They are used in control wiring and wing braces. I made them from an eye bolt (referred to as a “flap bolt” in hardware stores) and a steel strip, connected to each other by a machined nipple nut. I used the same bolt for the hinges of the ailerons and tail rudders, which solved the hinge issue very simply.

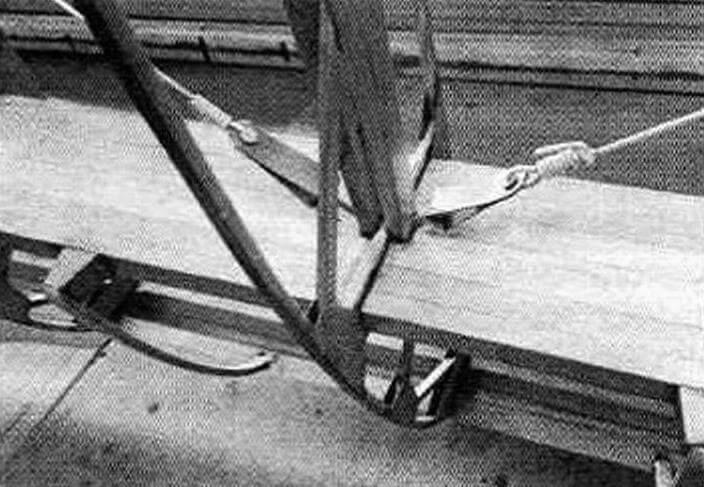

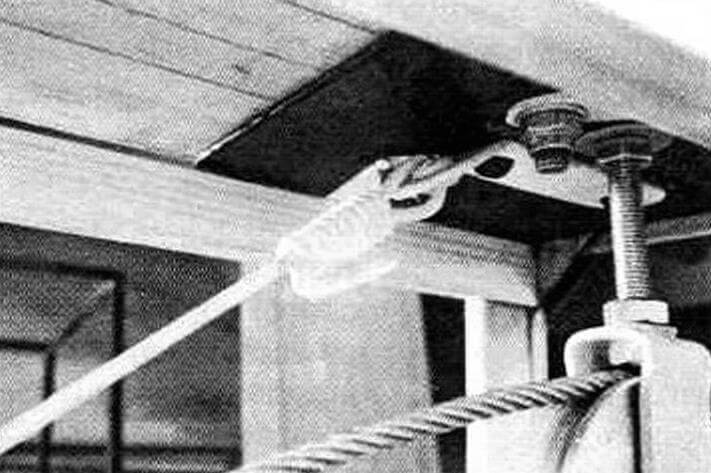

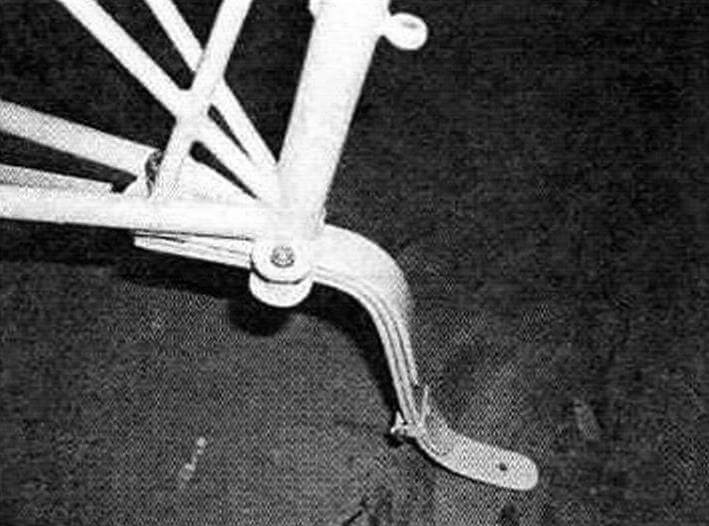

The chassis is pyramidal, made of thin-walled steel pipes St-20, assembled without welding with bolts. The tail spring is made from KAMAZ cab springs.

Two chassis axles are made of thick-walled steel pipes 25×3 mm (also St-20). These pipes are calibrated, so they do not need to be machined to install the wheels. Chassis shock absorption is rubber cord. I purchased the cords at a sporting goods store.

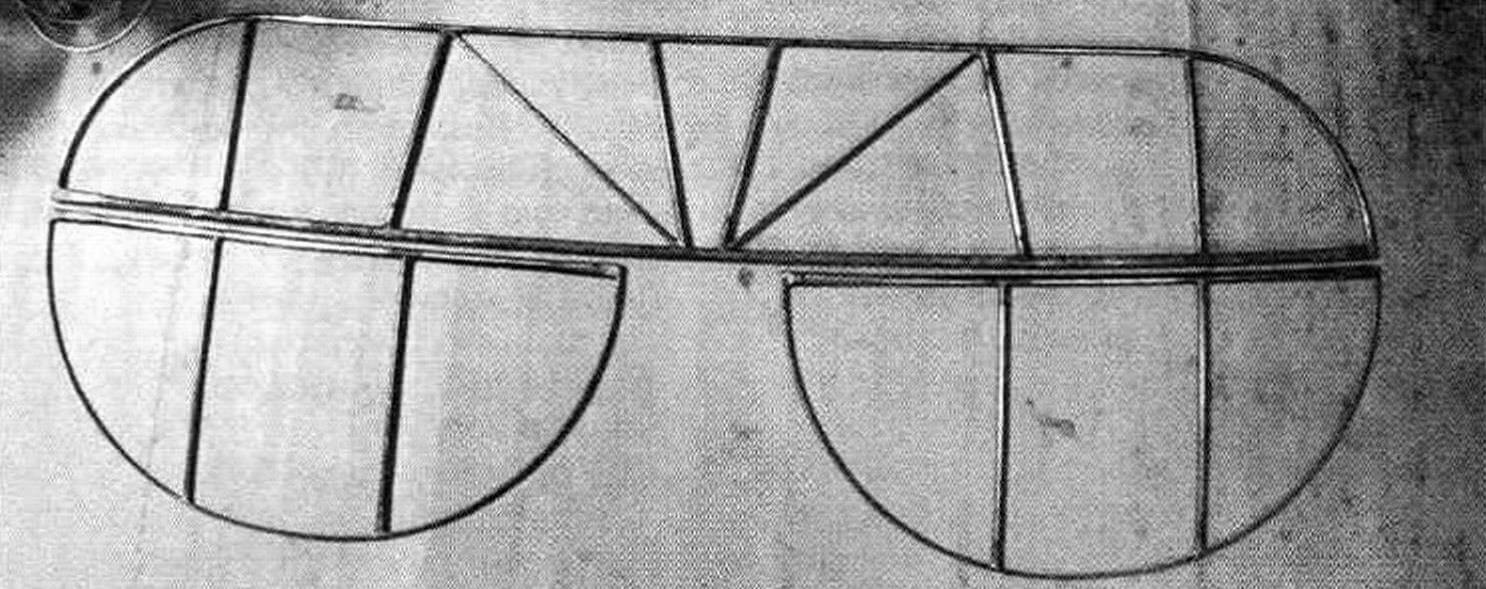

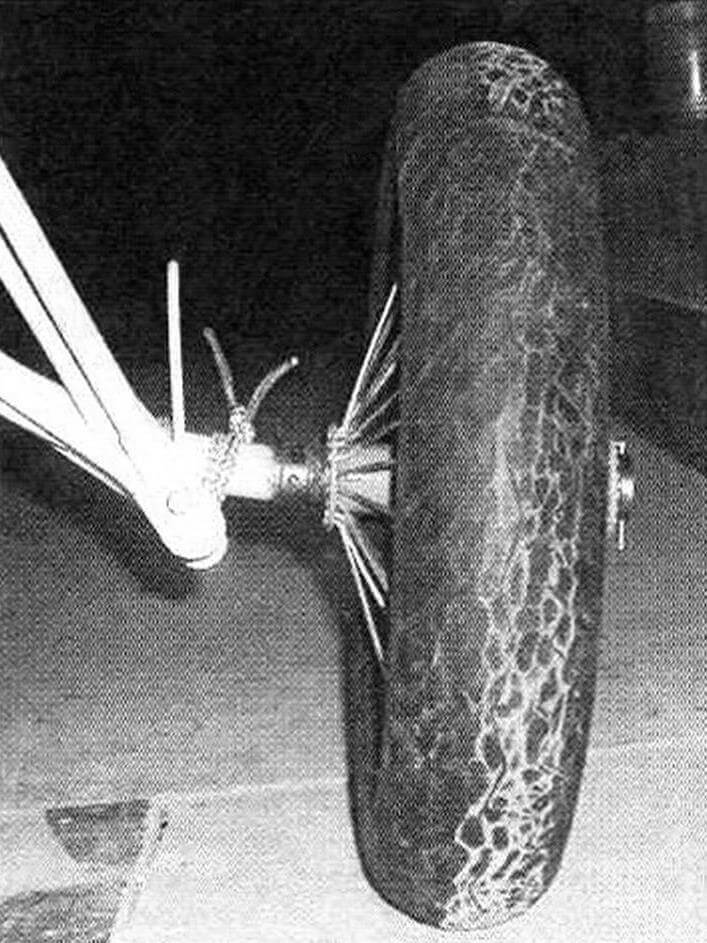

Wheels are another highlight of ours – they are also homemade! The fact is that wheels are another headache for the homemade aircraft builder. It is very difficult to find suitable ready-made ones. I didn’t succeed. The ones on sale are heavy or expensive, or I have doubts about their durability. I thought for a long time and came to the conclusion that, again, “everything has already been invented before us.” Indeed, at the beginning of its existence, aviation was quite successfully content with spoked wheels. That’s what I decided to do. I ordered bushings from a turner, bought steel wheels from a scooter at a motor disassembly for 300 rubles apiece, and reinforced spokes with a diameter of 3 mm from a bike shop. Calculated and started manufacturing. I removed the rims with a grinder and got two excellent rims. Since I didn’t have a machine for rolling threads on the spokes, I had to shorten them on the head side and make a small press from a jack to form new heads. Using the same press, I pressed out the holes for the nipples in the rims. As bearings I used suitable bronze bushings from the GAZ store. Overall, the resulting wheels were light and very durable, ideal for our aircraft.

The aircraft is covered with fabric stretched and impregnated with “enamel” (varnish NTs-551) in two layers. Two more layers – “enamel” with aluminum powder, serve to protect the fabric from exposure to ultraviolet radiation. And then it was painted with automotive acrylic. Such a small number of layers of “enamel” and a limited area scheme made it possible to reduce the “harmful” weight. The fabric is ordinary lavsan with a density of about 60 g/m2, also for lightness, sold in any fabric store and called differently: polyester, polyester. We conducted tensile tests and decided that this would suit us. The fabric is sewn to the frame of the wings and tail unit with lavsan threads, and glued to the fuselage frame. All seams are sealed with tapes cut from the same fabric with special scissors that give a serrated edge (scissors were bought at the Ikea store). Sewing to the wing requires long needles with which you can pierce the entire thickness of the wing. I couldn’t find any of these, so I had to make them myself from OBC wire with a diameter of 2 mm. Varnish NTs-551 is sold in 50-liter barrels. At first it seemed that this amount would be more than enough, but in the end we only had about five liters left. So a barrel on a small plane is normal.

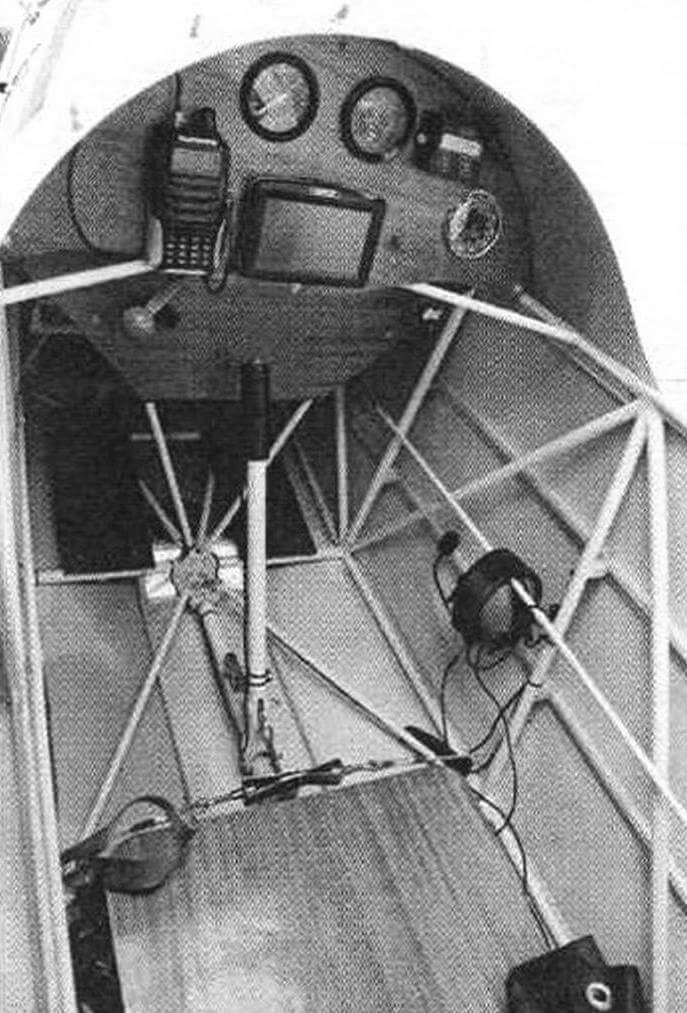

Separately, I would like to dwell on the devices. This is a very expensive item in the budget for building any aircraft. Plus, real devices are also quite heavy. All this prompted us to look for alternative solutions. The main difficulty is the speed indicator. However, I made it in an hour from a piece of OBC wire with a diameter of 2 mm and two duralumin plates. The result was a flag-type speed indicator, which was widely used in the 20s of the last century.

A tourist aneroid barometer with an altitude indicator scale served as an altimeter. Mechanical oil pressure indicator – from a PAZ bus. I purchased the UT-200 oil temperature indicator (it is also mechanical!) at the Agrozapchasti store. The tachometer is a very common, electronic, induction type. The fuel gauge is a transparent tube on the fuel tank. And they gave me a slip indicator, although I could have made it myself.

The plane flies great! The run is about 50 meters. In the air the car is stable and obedient. In a turbulent atmosphere, the efficiency of the rudders is sufficient. Sits down, with the handle fully pulled towards you, exactly on three points. During landing there is no tendency to stall on the wing. During takeoff and run on the ground it is even more stable than on asphalt, but this is a feature of all vehicles with a tail support. In general, according to my subjective assessments, the plane is friendly and pleasant to fly, fully satisfies my needs for the “joy of flying,” but requires preliminary training from the pilot. Among the disadvantages, I can note restrictions on the pilot’s weight (up to 90 kg) and his height (up to 190 cm), as well as dependence on weather conditions, but this is typical for all UAVs. Perhaps someone will say that a rate of climb of 1.5 m/s is not enough, but this is enough for me, especially considering the task at hand. After all, we wanted to get the most affordable homemade aircraft that anyone can build, and I think we succeeded.

In conclusion, I would like to quote the words of V.P. Kondratiev from the book “Airplane – with your own hands.” Here is what he writes: “The activities of the media have turned an airplane, in general a simple and understandable machine, in the eyes of non-specialists into an incredibly complex apparatus, the calculation of which is being worked on by tens and hundreds of scientists and engineers, relying on the help of scientific institutions and modern computer technology. Where are the home-made people with their home-grown techniques and semi-handicraft aircraft? This media activity caused considerable damage to amateur aircraft construction in our country. As a result, all this had a negative impact on aviation sports, gliding, and even aircraft modeling. The influx of enthusiasts into the aviation industry has sharply decreased. As a result, completely correct machines are born, built “without soul”, “without zest”. Such equipment is successfully used, but, of course, it cannot compete with the best foreign models.

The experience accumulated to date shows that any competent person can build an airplane in our time. However, in order for flying to bring joy and not grief, many rules and conditions must be observed in the work. These rules have been developed over many years of aviation development.”

The result of building a homemade aircraft depends on compliance with these rules, and our example demonstrated this perfectly.

This aircraft is widely known in the USA. It was invented by ultralight aviation enthusiast, pilot, designer and businessman Edward Heath in the 20s of the last century. Andrei Yakovlev from Smolensk with a group of like -minded people for the first time in our country decided to build this successful model. The plane was created for two and a half years. There was a task to make a small light plane that is most accessible in materials and technologies so that anyone can repeat it. After all, Edd Hit said: “Heath Super Parasol, which everyone can build!”

Andrey Yakovlev, Smolensk