Just so you can say about worn parts restored by the method developed at the Chelyabinsk Institute of mechanization and electrification of agriculture.

Just so you can say about worn parts restored by the method developed at the Chelyabinsk Institute of mechanization and electrification of agriculture.

With the larger axles, fingers and other parts of agricultural machines, most suffer from the abrasive effects of, restored using a simple setup for zapekanija to the surface of the metal powder. Such a setup can be assembled in any workshop. Its basis may be, for example, a lathe with gear drive to lower the rpm of the spindle and a few converted welding transformer type TC-500. They will need to make only fixture with a copper roller for electric napisania powder hopper with a screw device for feeding powder into the working area under the roller.

Napakahusay device has a housing cylinder, which is fixed in the tool post of the machine. In case the inserted hollow rod with a spring inside. At its fork end bushings of insulating material planted axle and freely rotating copper roller.

The hopper is mounted on the caliper of the machine. The hopper is fixed to the gear motor to drive the vertical auger, forcibly feeding a metal powder to the pressing point of the roller to the workpiece.

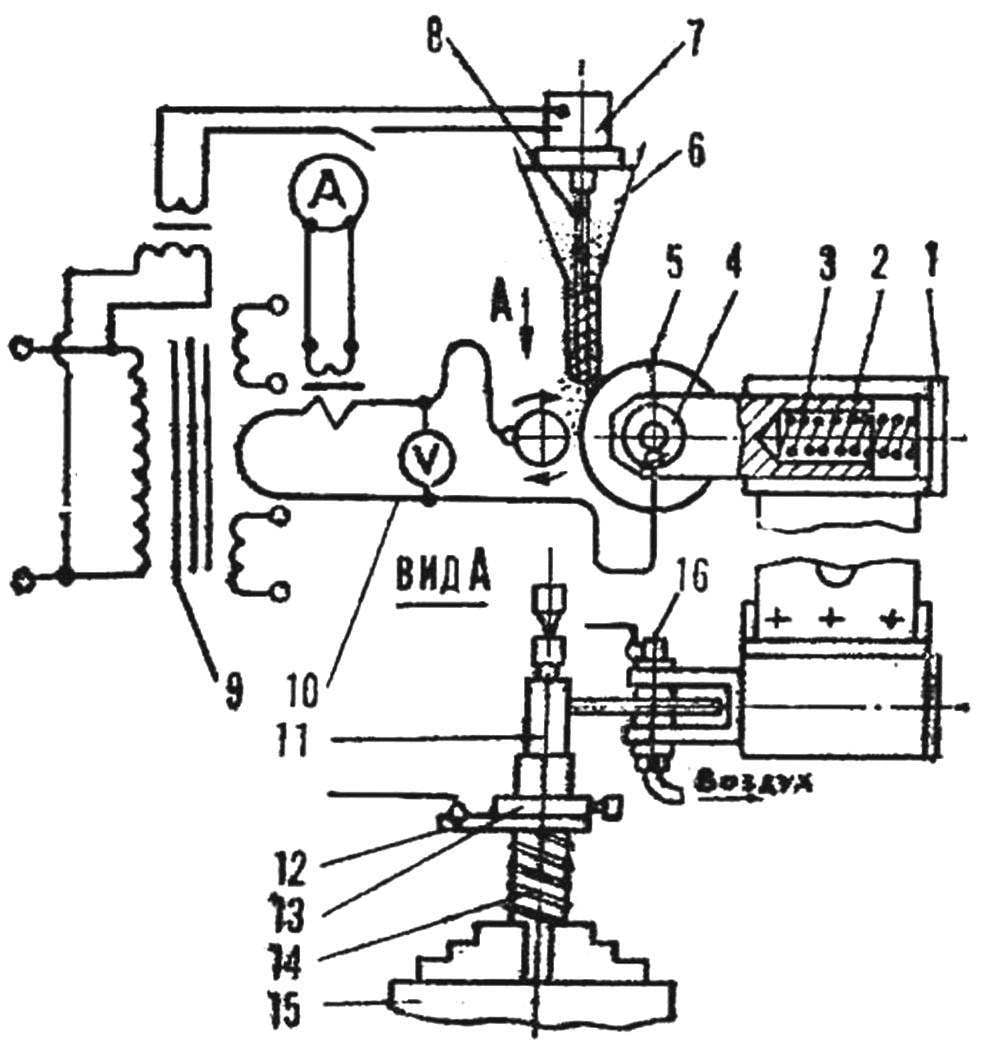

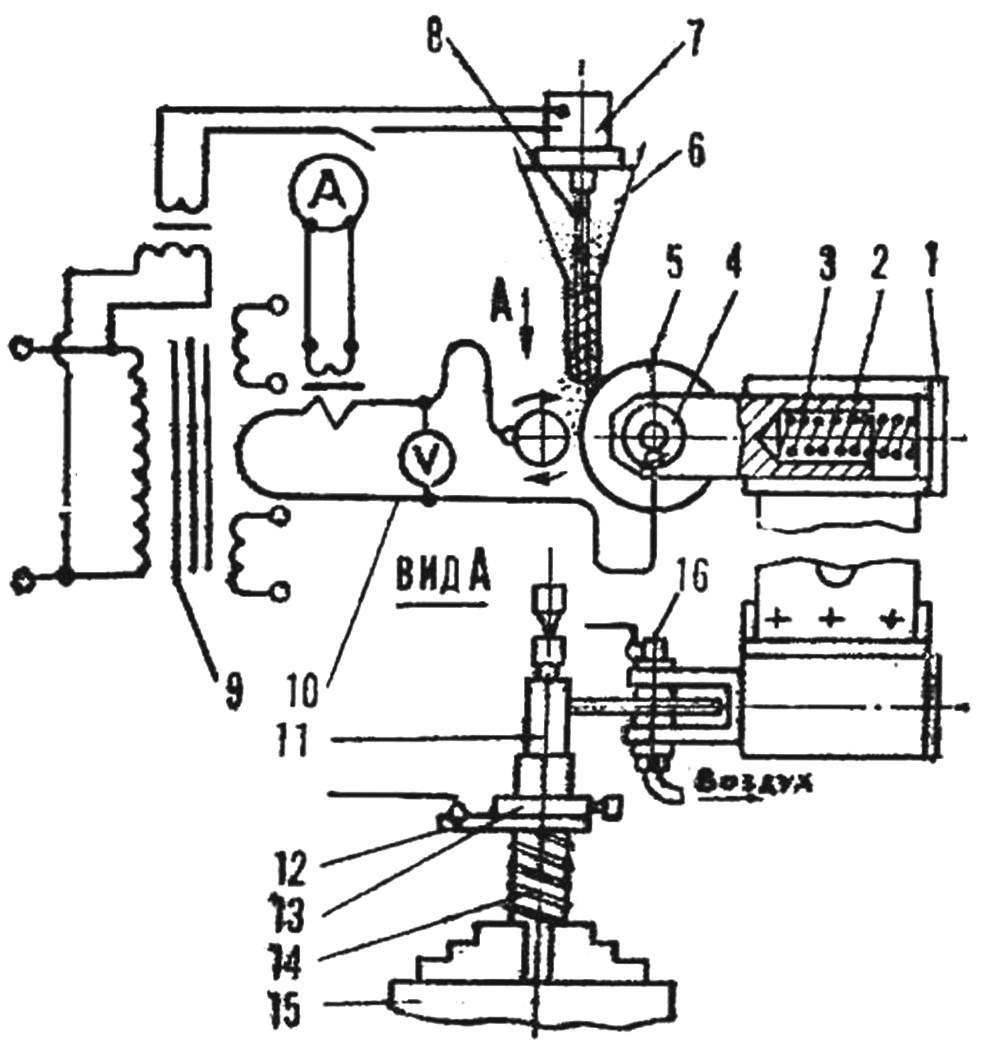

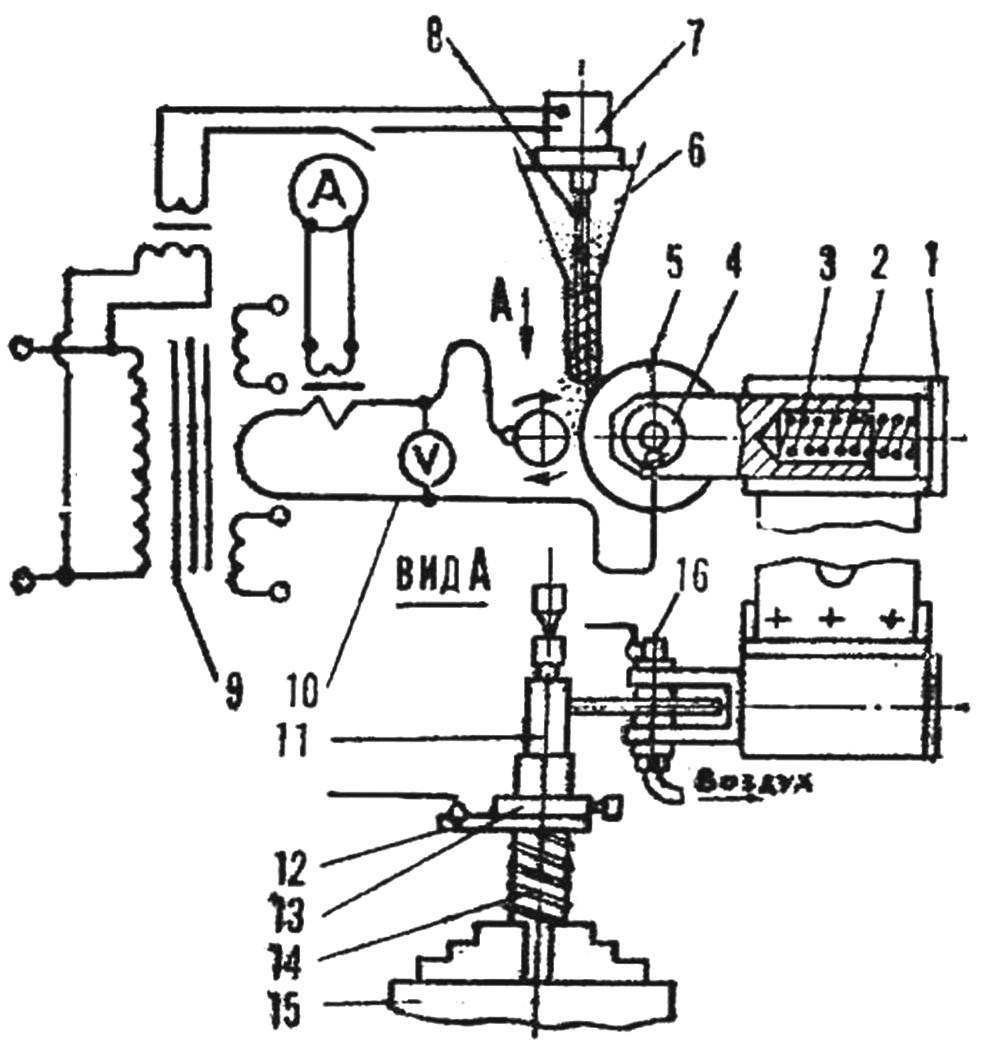

Installation diagram for welding:

1 — housing fixture, 2 — hollow shaft, 3 — spring, 4 — insulating sleeve 5 — copper roller, 6 — bunker with a metal powder, 7 — motor screw, 8 — screw, 9 — transformer 10 — additional round, 11 — restoring item, 12 — movable ring with the current-carrying wires, 13 — stationary ring-tocolumn screw 14 — spring 15 — cartridge machine.

In the welding transformer used as a current source of low voltage, introduced additional third winding in the form of one loop of the four welding wires cross section of 120 mm2 each. One ends of the wires displayed on a movable slip ring freely put on the item, others connected to the axis of the copper roller.

Worn the item is fixed in the Chuck of the machine. She put on a spring, a movable ring with the current-carrying wires and copper ring-collector, fixed in place with screws. Then to a part with a cross feed of the caliper is pressed against the roller device, synchronously

included longitudinal feed, motor screw, transformer and engine torque cartridge. In the contact zone of the roller is zapekanie new layer of metal. And it can grow in various schemes of mutual motion of the part and the movie, including the helix.

When using iron powder brand RV-5M new surfaces have high wear resistance, similar to the hardened steel St 45.