The next stage of work – making the top of the boat. It should be noted that its size and shape largely depend upon components of the finished product will be able to choose the cabin design. In particular, the size of the glass used. Of course, the use of organic glass will build a salon of any size and shapes, however, it is more rational to base the road – for example, the rear window of cars (they are cheaper) for suitable brands. That is why the construction of the upper part of the body should begin with the manufacture of the frames under the front and rear glass. The easiest way to applied to the wall them from 3 mm plywood. To do this, cut strips of the required width and of them directly on the glass and laid out the frame. Strips primatyvajutsja to glass clamps, resembling clothespins or small clamps. The total thickness of veclachi about 20 mm.

Installation upper part of the body is made from plywood and foam. To start, set the frame front and rear Windows, two inclined frame forming a box liftgate (12 mm plywood), and two roof rail (rail with a thickness of 20 mm). All these elements are assembled with epoxy adhesive and screws. Frame front and rear side Windows are also laminated plywood.

Doors are assembled from plywood and foam. Each frame consists of two frames of 12 mm plywood and three cross-beams – pine slats with a thickness of 20 – 25 mm. At the top of each frame which are stuck to the rigidity of the diagonal elements. The space between the elements is filled with foam, the surface inside and outside is aligned and glued with fiberglass.

The surface of the upper housing part is formed exactly in the same way as the bottom: space between the frames is filled with foam blocks, processed and glued fabric.

In the back of the case is glued to the box the sub niches. You can do it by a molding of fiberglass on the boob, but easier to cut out elements of hardboard or plywood “stitch” them with safety wire and the junction to seal the strips of fiberglass. It is glued and subsequently the inner surface of the box.

Before you attach the top and bottom of the case, they should be treated from the inside and to hang two layers of glass. Connection is made with glue and screws, followed by the gasket outside and inside with strips of fibreglass.

The theoretical drawing of the hull of the boat

![The frame of the upper part of the body of the boat]()

The frame of the upper part of the body of the boat:

1,9, 10 – elements of base frame; 2 – tappet; 3 – frame front glass (plywood plywood); 4 – the instrument panel; 5,7 – frames door frame (plywood s12); 6 – roof rail; 8 – rear window frame; 11 – rear cross member; 12 – kerchief; 13 – longitudinal forming box lid; 14 – reinforcing solitaire

Front cover trunk and doors hung with conventional hinges used for hanging frames. For fixing the door in the open position is used a spring-lock-stopper. And doors, and trunk lid have a rubber seal that prevents the penetration of water into the housing.

Cabin boats – two semi soft sofa, designed for the driver and three passengers. The front sofa has a split backrest, pivotally mounted so that both can be tipped forward allowing the exit of the cabin passengers, located on the back of the couch. Back seat single, she also leans forward, opening access to the rear trunk.

Frames seat and back – wooden slats, covered the 4-mm plywood. Cushion – foam and artificial leather.

Remote control – standard, one of those that can be purchased in sporting goods stores. It consists of “wheel”, rope drive and engine control.

Inside, the cabin is trimmed with faux leather, equipped with a ceiling canopy. Body outside painted with automotive enamel air drying.

On the deck – front and rear – four fixed cleats for securing mooring. If you intend to use the boat for sailing at night, you need to install the running lights. Not be amiss and is fixed to the roof of the searchlight.

I. MNEVNIKI

Recommend to read

FUNNEL-DISPENSER

FUNNEL-DISPENSER

Any funnel, in addition to its direct purpose, can be given additional functions, for example, dosing for pour liquid. This will require a small improvement in funnels, available to... THE ROCKET PLANE “RADIO OPERATOR” FROM ENGLAND

THE ROCKET PLANE “RADIO OPERATOR” FROM ENGLAND

A large variety of schemes and designs of radio controlled raketoplana can be divided into three groups. The first is a classic, airborne with the Elevator control and ailerons. The...

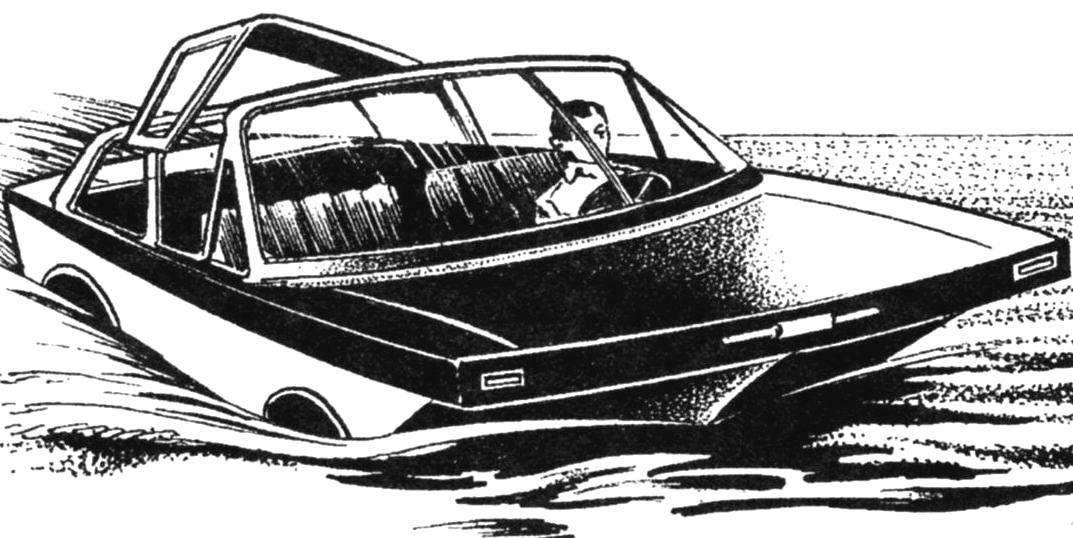

This boat has always caused the attention of vodnomotornikov. Some were attracted to him emphasized the car appearance, painted on the sides of the wheels. Other interior comfort, decent speed, maneuverability and controllability. Well, hobbyists and tinkerers, in addition, was interested in the construction and manufacturing technology of the body, could not be better focused on work in the home workshop.

This boat has always caused the attention of vodnomotornikov. Some were attracted to him emphasized the car appearance, painted on the sides of the wheels. Other interior comfort, decent speed, maneuverability and controllability. Well, hobbyists and tinkerers, in addition, was interested in the construction and manufacturing technology of the body, could not be better focused on work in the home workshop.