In the design of the transmission of a snowmobile “Buran” has a centrifugal accelerator, the CVT. During intensive operation of the snowmobile this node will wear out within two seasons. First fail the movable cone of the variator and Cams-weights. The reason for such a rapid wear of the mentioned parts is quite simple: the Cams abut in the troughs of the movable cone, thus squeezing out deep dents. When starting the snowmobile from the place when the engine begins to develop momentum, the Cams are unable to smoothly get out of these depressions, there is a sharp jerk of the belt variator, which leads, among other things, and rapid wear of the belt. In short, almost every season you have to change the movable cone, centrifugal accelerator and a belt.

In the design of the transmission of a snowmobile “Buran” has a centrifugal accelerator, the CVT. During intensive operation of the snowmobile this node will wear out within two seasons. First fail the movable cone of the variator and Cams-weights. The reason for such a rapid wear of the mentioned parts is quite simple: the Cams abut in the troughs of the movable cone, thus squeezing out deep dents. When starting the snowmobile from the place when the engine begins to develop momentum, the Cams are unable to smoothly get out of these depressions, there is a sharp jerk of the belt variator, which leads, among other things, and rapid wear of the belt. In short, almost every season you have to change the movable cone, centrifugal accelerator and a belt.

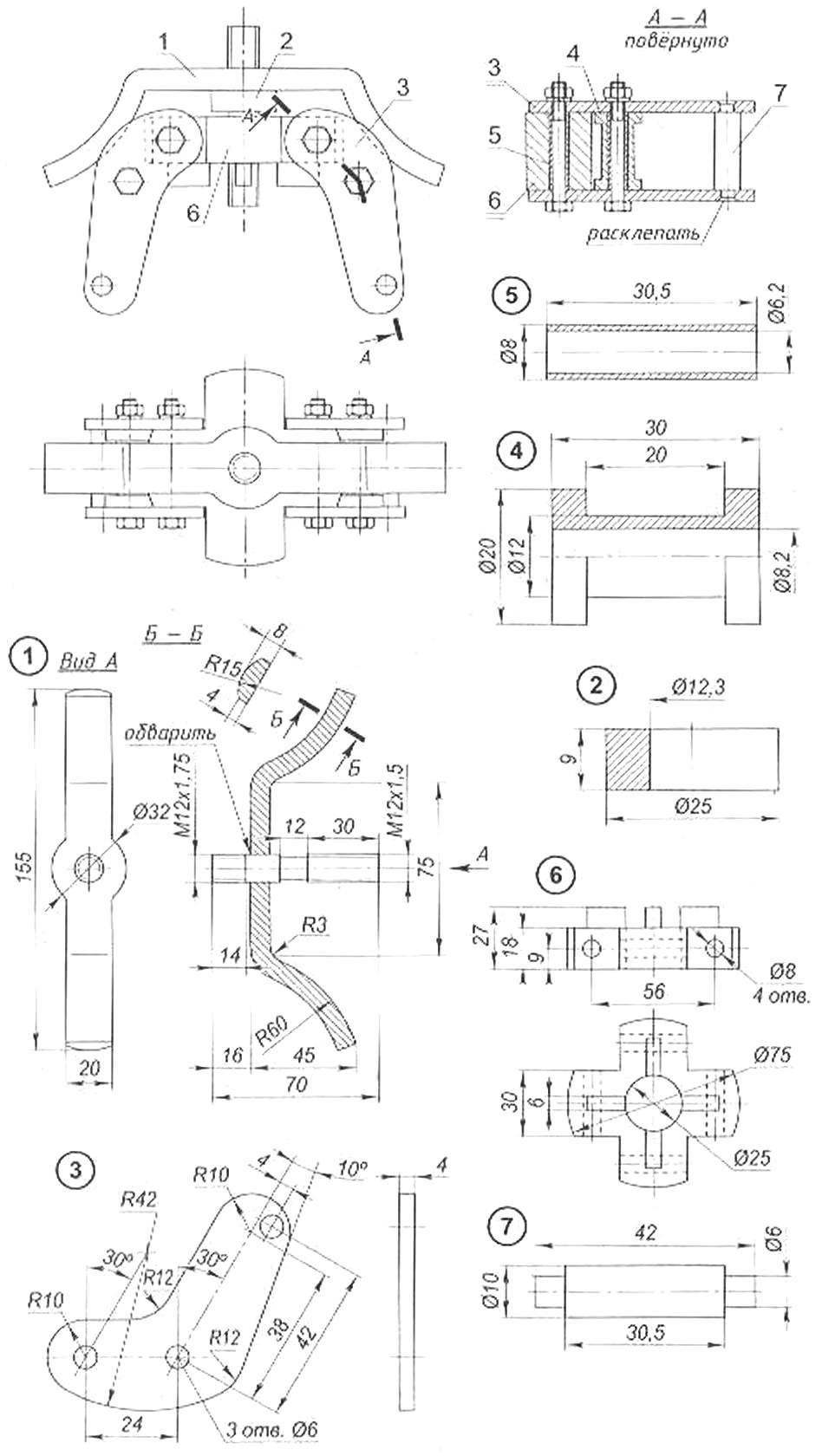

I managed to eliminate all of these shortcomings only after the manufacture of the centrifugal accelerator of his own design, represented in the drawing. Rod cross, rollers, bushings and fingers are machined on a lathe. Cheeks can be cut from 4mm sheet steel with a simple hacksaw, and then processed with a file and drill the holes. Bushings, rollers and crossbar must be tempered. From the old, the factory accelerator I have only used a protective cover.

Centrifugal accelerator:

1 — guide; 2 — washer; 3 — cheek; 4 — roller; 5 — bushing; 6 — cross; 7 — finger

The proposed alteration increases the service life of cone CVT and reduces slippage of the belt, thus improving traction properties, and hence increasing the speed. Have the opportunity to use a strap without replacement to run 200 km.

B. PAVLOV. dyad’kovo the city of Bryansk.