Rod is a pipe with a diameter of 26 mm and a length of 204 mm, which has a wheel axle with welded to it a bearing holder on the rear wing. The axle is pressed into the tubular rod and is additionally fixed by screw. Bush wheel mounted on the axis through the inner bearing No. 60203 (40x17x12 mm) and the glass on the outer bearing No. 60101 (28x12x8 mm).

End of the rod wheel is inserted in the hub of the pendulum and is fixed in this locking screw which is screwed into is welded to the nut casing and inserted simultaneously into the holes in the sleeve and the rod.

The seat is the most simple and at the same time is also quite original part of the recumbent. The arc of his back, the emphasis and the limiter stops form a triangle supported by the frame. One of the sides of this triangle (limiter focusing) always works only in tension, the designers have built it from lightweight, durable synthetic tape. This solution allows you to fold seat one hand!

The seat base is made of two pieces of 2-mm dural strips, bonded linings with rivets. It is mounted on the ridge of the rear articulated by curly braces and has the ability to move. Through holes with a diameter of 16 mm in the cheeks brackets omitted the axis connected to the seat base by two clamps. On the same axis are two pairs of spacer sleeves.

The node of the rear wheels :

1 — state (dural tube Ø26×5, L=204), 2 — axis (steel, circle 20); 3 — bracket; 4 — wing; 5 — bearing 60203; 6 —Bush of a wheel with spokes; 7 — bearing 60101; 8 — Cup (aluminium, circle 40); 9 — mount pressure washer; 10 — a stopper(rubber); 11 — pressure washer inner ring of the bearing (steel, s); 12 — lock axis (screw M5 flat head screws)

Swivel-swivel (connecting) node half-frames:

1 — front of frame; 2 — rear frame (ridge); 3 — strut hinge (front rear articulated); 4 — cone; 5 — balls (2 clips); 6 — cone bushings (2pcs); 7 — sleeve; 8 — nut-cone

Parts kit seat:

1 — arc of the backrest (dural tube Ø19×1,5); 2 — blank back (dural tube Ø19х1,5); 3 — rod (dural tube Ø22х 1,5); 4 — network; 5 — sticky tape; 6 — fastening of the arc rods and to the axis (M4 screw notched washer); 7 — bracket (2 pieces, steel, sheet s2); 8 — axis (tube Ø18×1); 9 — the base of the seat (made of anodized aluminum, the sheet s1,5); 10 — the short spacer (pipe Ø22х 1,5,2). the 11 — seat (foam); 12 — long spacer (tube Ø 22×1,5, 2); 13 — clip (steel, sheet s3); 14 — spacer (aluminum, sheet s4): 15 — stop stop; 16 — backrest (foam)

Behind torita recumbent folded

The attachment of the seat to the frame

At the ends of the axle with the bolts and curved washers fixed rods, inside which the ends of the arc of the seat back. The arc tight network of cross-linked synthetic belts. Axis of the backrest to the “twist” is sewn, and the seat base glued “Velcro” for mounting pads. The pillows themselves are made of sheet foam (for base) and “skin” – Mat for tourists (for the back). Both are Packed in cases made of artificial leather, which is also sewn tape”Velcro”. Their grip is enough to hold the pillows in a comfortable position

The seat is adjustable. It can be moved along the frame enough to loosen the locking screw, and with it the plate blank. Height of the backrest is changed too: the arc is fixed to the rods with screws in several positions. And the backrest is set by changing the length of the limiter stops.

The velomobile “Dandy” is very simple, good color combination: a rear part of the frame, including the suspension components, painted with powder enamel in black, and the drive and parts seats — silver “metallic”. The little bar — all open ends of the tubes of the frame and the drive inserted plastic decorative plugs.

For folding velomobile “Dandy” is sufficient to weaken the retaining bolts to the rods supporting the ear, to release from the outer rubber rings pendants pendulums fingers and drown rod pendulums. After this it is necessary to rotate the rear part of the frame 180 degrees and the velomobile can be removed in the backpack!

The new “Test rounds” of Amateur designers want to improve the patency of the “Dandy” through the use of increased wheel. That will only be possible to maintain in this case the unique compactness of the velomobile?

V. UL

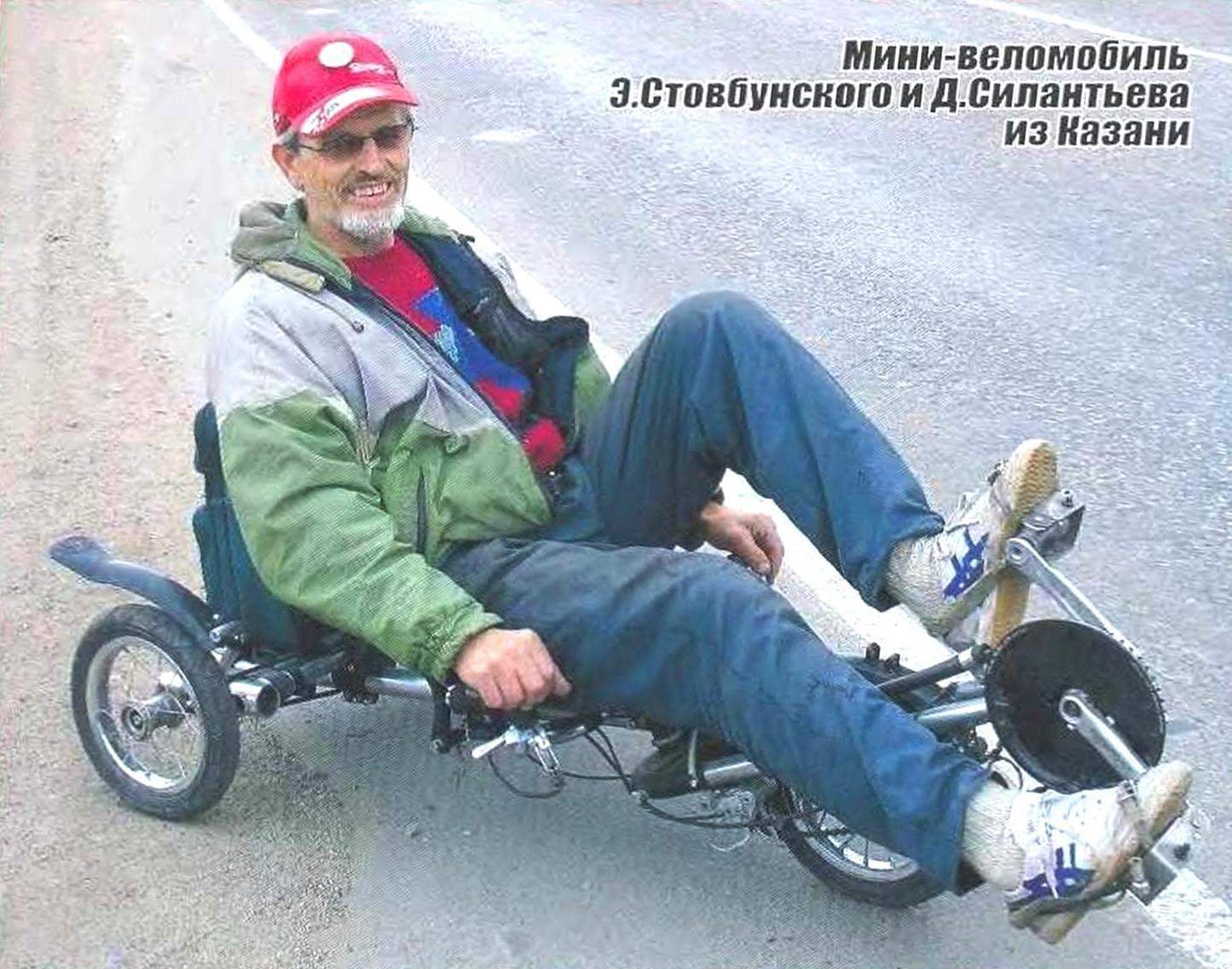

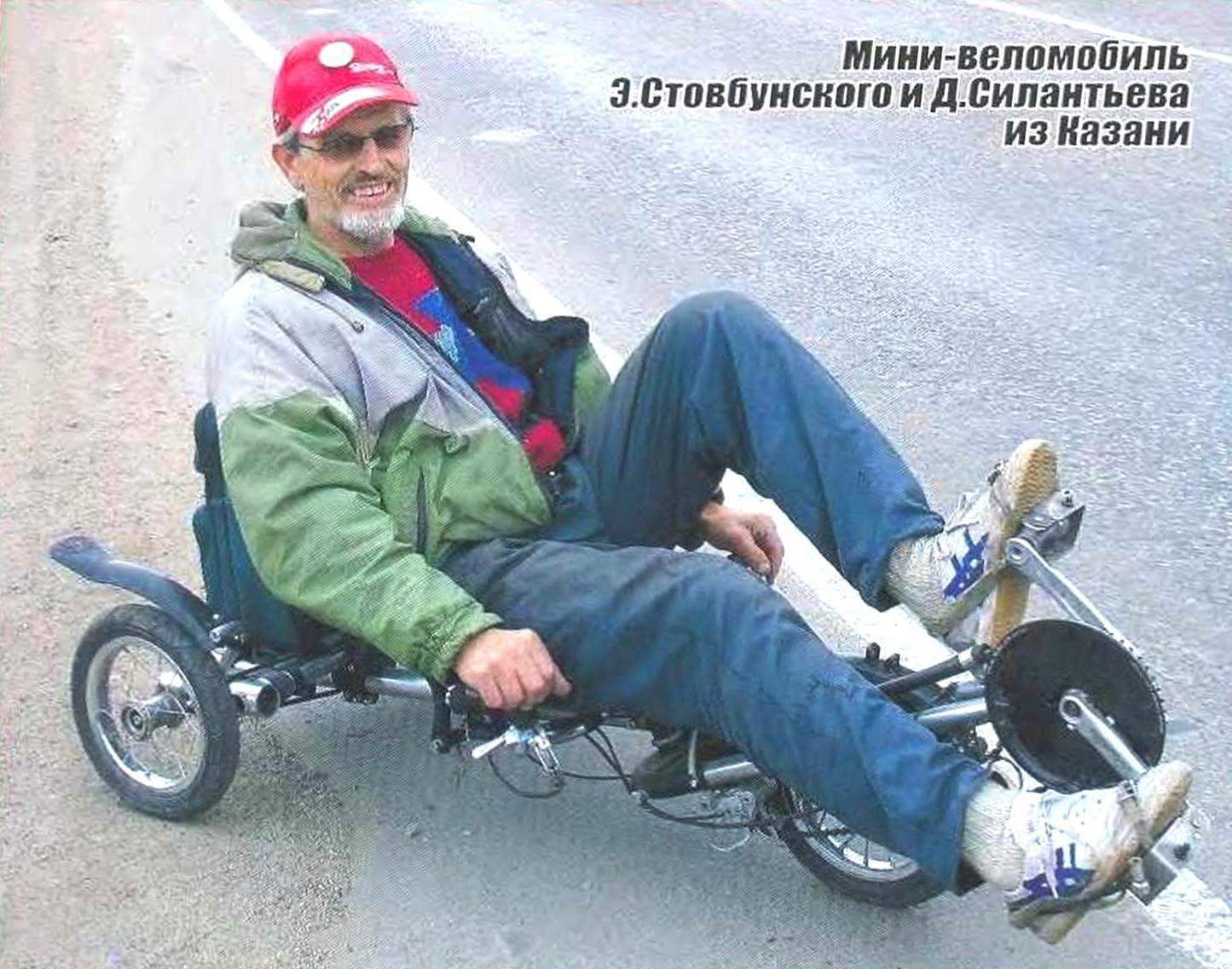

Mini-recumbent, about which speech will go, was born in the Kazan Studio of Edward Stovbunenko — designer of velomobiles and a lover of travel to them. Edward party festivals, parades velomobiles “Golden ring” organized by Moscow club of enthusiasts biotransport (CAB) twenty years ago. Since then, he’s on different models with a muscular drive of his own, passed under the Russian and foreign roads the way, almost equal to the equator of the Earth.

Mini-recumbent, about which speech will go, was born in the Kazan Studio of Edward Stovbunenko — designer of velomobiles and a lover of travel to them. Edward party festivals, parades velomobiles “Golden ring” organized by Moscow club of enthusiasts biotransport (CAB) twenty years ago. Since then, he’s on different models with a muscular drive of his own, passed under the Russian and foreign roads the way, almost equal to the equator of the Earth.