It is not easy to surprise residents of the city of Tolyatti with a new car. On their streets they are the first to meet promising models from the Volzhsky Automobile Plant and new products from foreign companies. But wherever the miniature yellow car with the cheerful name “Kolobok” appears, it invariably attracts the attention of passers-by and, of course, car enthusiasts. And after the program “You Can Do It,” where the design was presented to a multimillion-dollar audience, interest in it increased even more.

Responding to numerous requests from TV viewers and readers of our magazine, we publish a description and drawings of this interesting car, prepared by its author, VAZ design engineer Viktor Timofeevich Gorbunov, and our correspondent S. Nadzharov.

The passenger car has firmly entered the everyday life of modern people. The models offered by the industry are distinguished by their reliability, ease of operation and maintenance, and versatility. However, amateur car builders, even using the maximum number of standard units, rarely copy them, but, as a rule, create original designs that best suit the specific purpose of the car. Lovers of outdoor recreation are attracted to all-wheel drive vehicles with increased ground clearance; autotourists – on the contrary, low, squat cars with a streamlined body; Those who prefer a holiday on wheels with the whole family are more satisfied with the layout of a minibus.

And what kind of car does a city dweller need for everyday trips to work, shopping, for household needs, and for short-distance country routes? The answers of specialists to date “come to a common denominator.” Such a car should have a minimum length of about 3 meters, a spacious body that is convenient for frequent entry and exit, with a capacious luggage compartment that can be transformed due to folding rear seats. It must have excellent maneuverability, and its engine must, first of all, be economical and have low exhaust emissions. And indeed, who among the car enthusiasts has not noticed: movement in the general traffic flow equalizes the advantages of the fast “Zhiguli”, and the powerful “Volga”, and the nimble “Zaporozhets”: they all move at the same speed. And on spacious highways, the maximum speed is limited to a value that is easily accessible to any modern car. But the driver of a small, short car feels much more confident in the city: it is easier for him to maneuver on the road, find a parking space or near the sidewalk, and quickly park the car. Despite the modest external dimensions, the body of the mini-car is no less comfortable. After all, as statistics show, on average, each car carries one or two people and a small load. Therefore, even a small car with a 4-5-seater cabin and a capacious trunk most of the time carries… air. While in a minicar, the rear of the cabin can be used, if necessary, as both a passenger and a cargo compartment. This layout solution makes it possible to significantly reduce the length of the body. Engine power is 30-40 hp. With. quite enough for a light car. And, driving around the city, you will not feel the difference in dynamics and speed compared to serial passenger cars. At the same time, fuel costs will be significantly lower: the best minicar models consume about 5 liters of gasoline per 100 km. And the toxicity of exhaust gases is less. Because the lower the engine power, the more often it operates in modes close to the nominal, where specific fuel consumption is lowest and the content of harmful components in the exhaust gases is minimal.

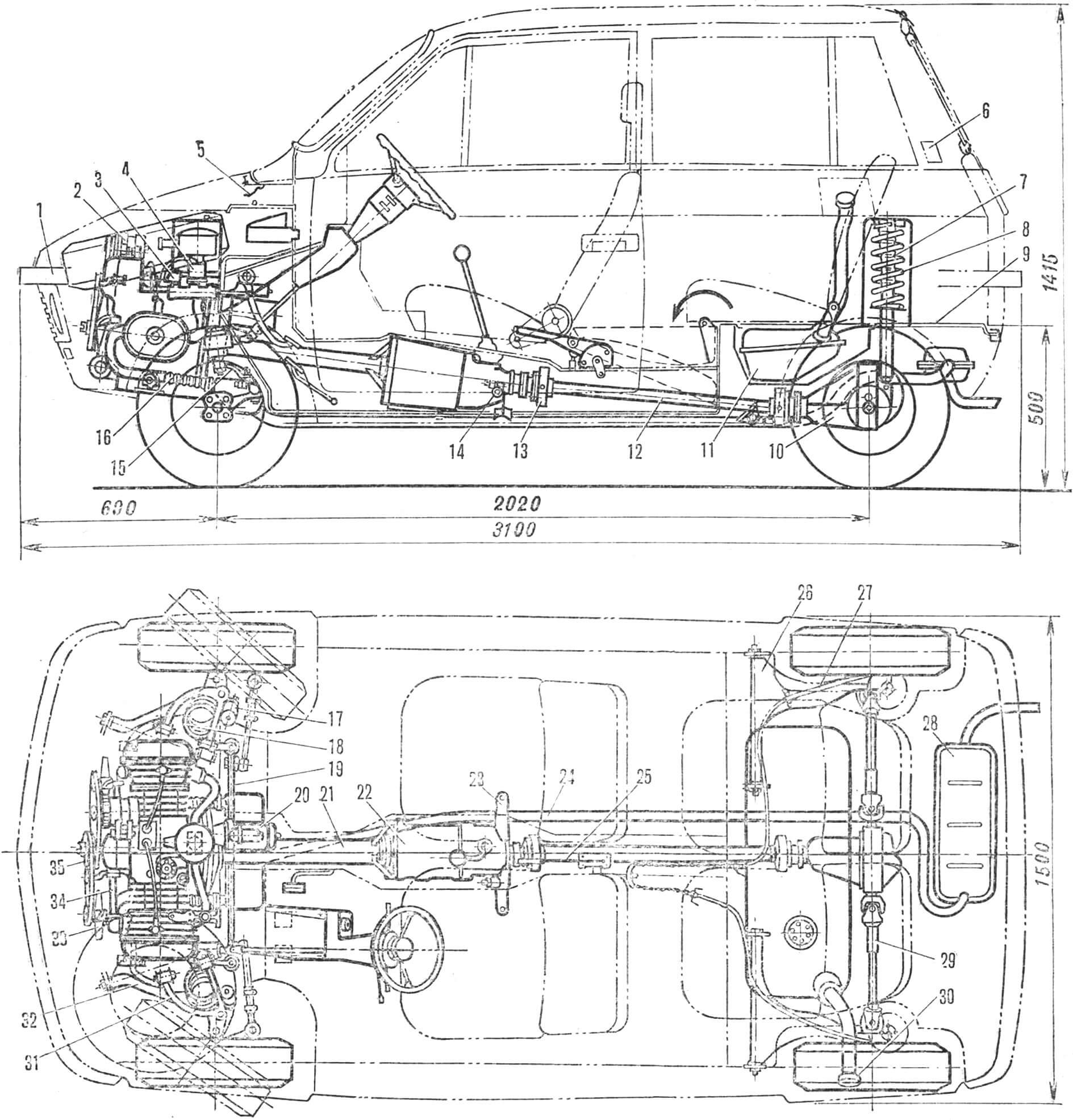

1 – safety lining (elastic bumper), 2 – generator, 3 – fuel pump, 4 – carburetor, 5 – air intake hatch for the body ventilation and heating system, 6 – outlet vent, 7 – shock absorber, 8 – rear suspension spring, 9 – cargo compartment floor, 10 — main gear, 11 — gas tank, 12 — transmission connecting shaft, 13 — elastic pin coupling, 14 — speedometer drive, 15 — steering bipod, 16 — exhaust pipe, 17 — shock absorber, 18 — front suspension spring, 19 — tie rod, 20 — starter, 21 — extension, 22 — gearbox, 23 — engine mounting crossbar, 24 — gearbox, 25 — hand brake lever, 26 — rear suspension lever, 27 — hand brake cable, 28 — muffler, 29 — wheel driveshaft, 30 — fuel tank filler neck, 31 — upper front suspension arm, 32 — lower front suspension arm, 33 — engine cooling system fan, 34 — fan bracket, 35 — drive pulley.

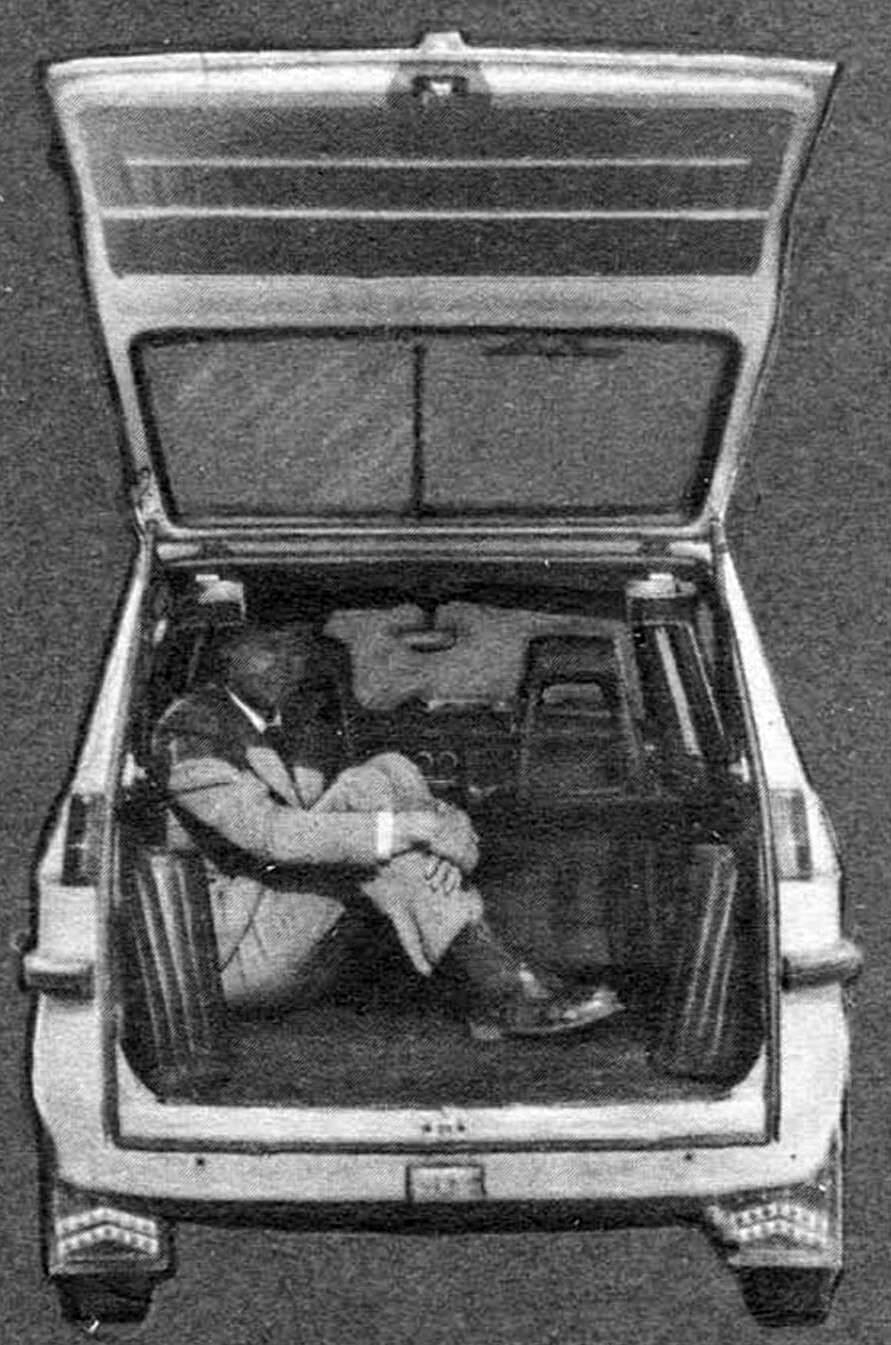

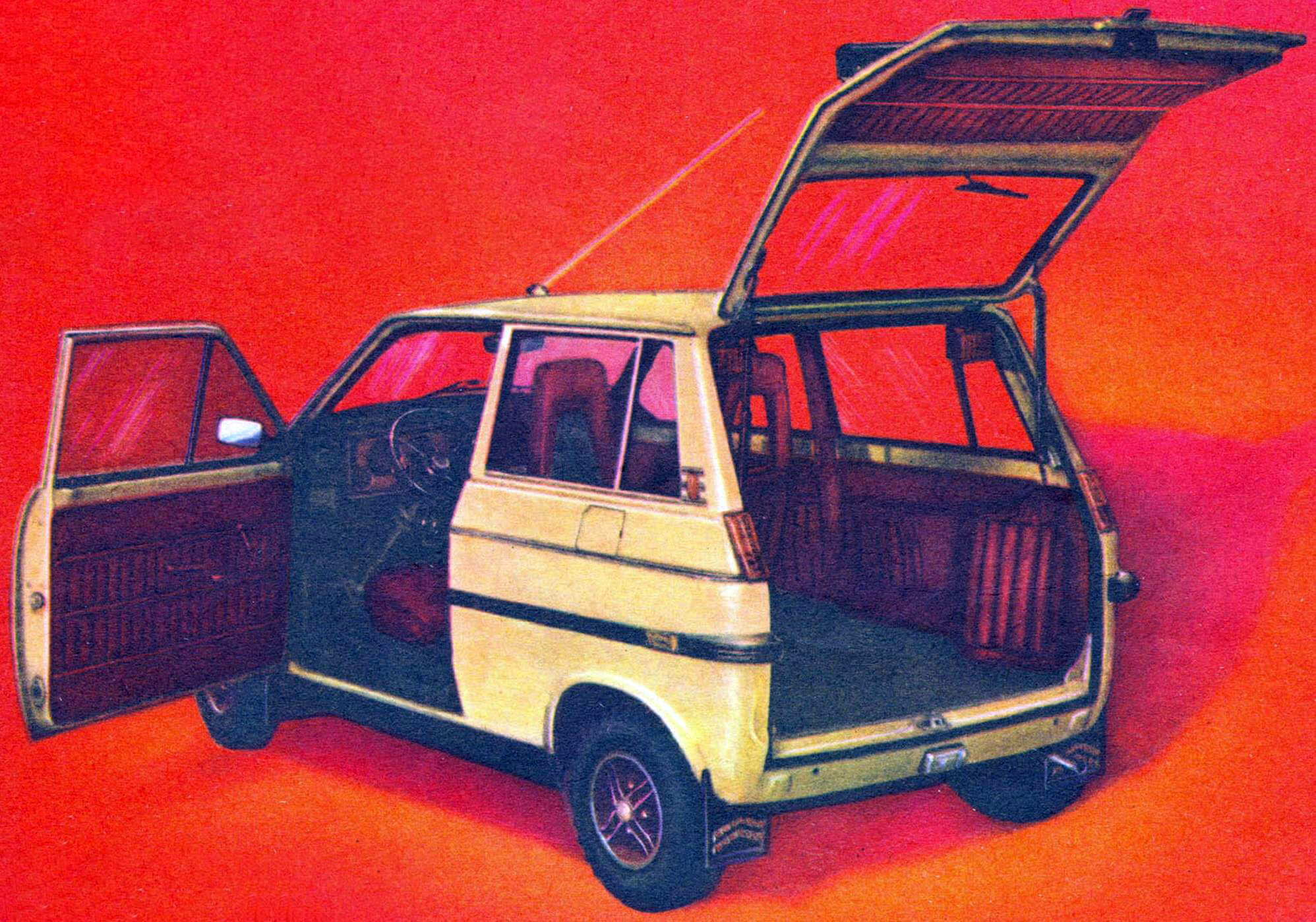

Based on these requirements, “Kolobok” was designed and manufactured. It is 3.1 m long and 1.5 m wide, but the cabin can comfortably accommodate four adults. When driving together, the rear of the body turns into a spacious luggage compartment with a flat bottom. Access to it is through the large rear door. The lower plane of its connector is located at a height of only 0.5 m from the ground, so loading even heavy objects into the machine is not difficult. The small dimensions of the body and large steering angles with a wheelbase of just over 2 m provide the vehicle with excellent maneuverability. The salop, even in the four-seater version, is comfortable for the driver and passengers. Comfort is achieved by increasing the height of the body: sitting on higher seats is more familiar and comfortable, especially with frequent stops and exits from the car. Of course, such a car is less streamlined for oncoming air flow, but for city speeds the increase in aerodynamic drag is not so significant.

Learn more about the structure of the car.

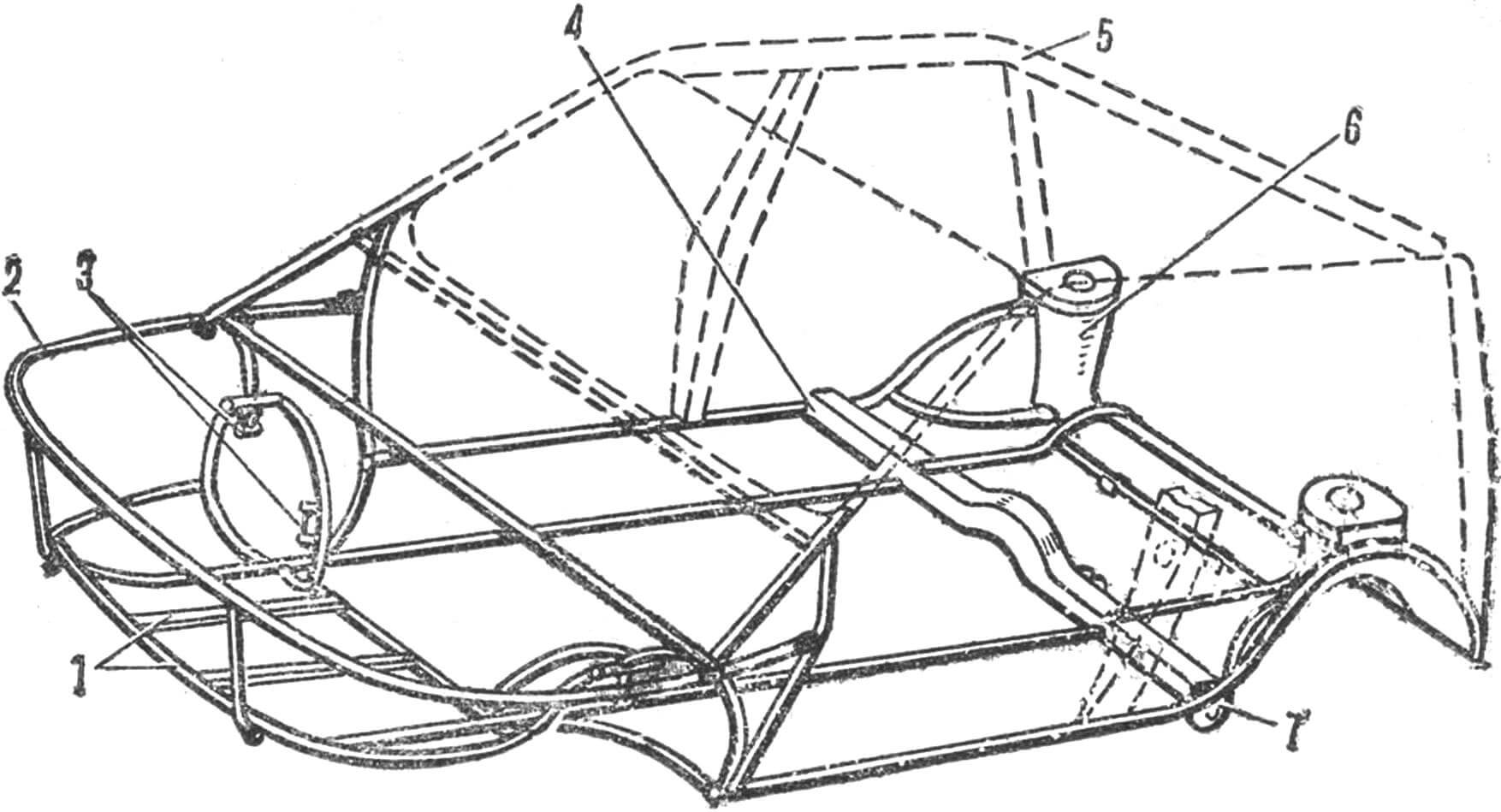

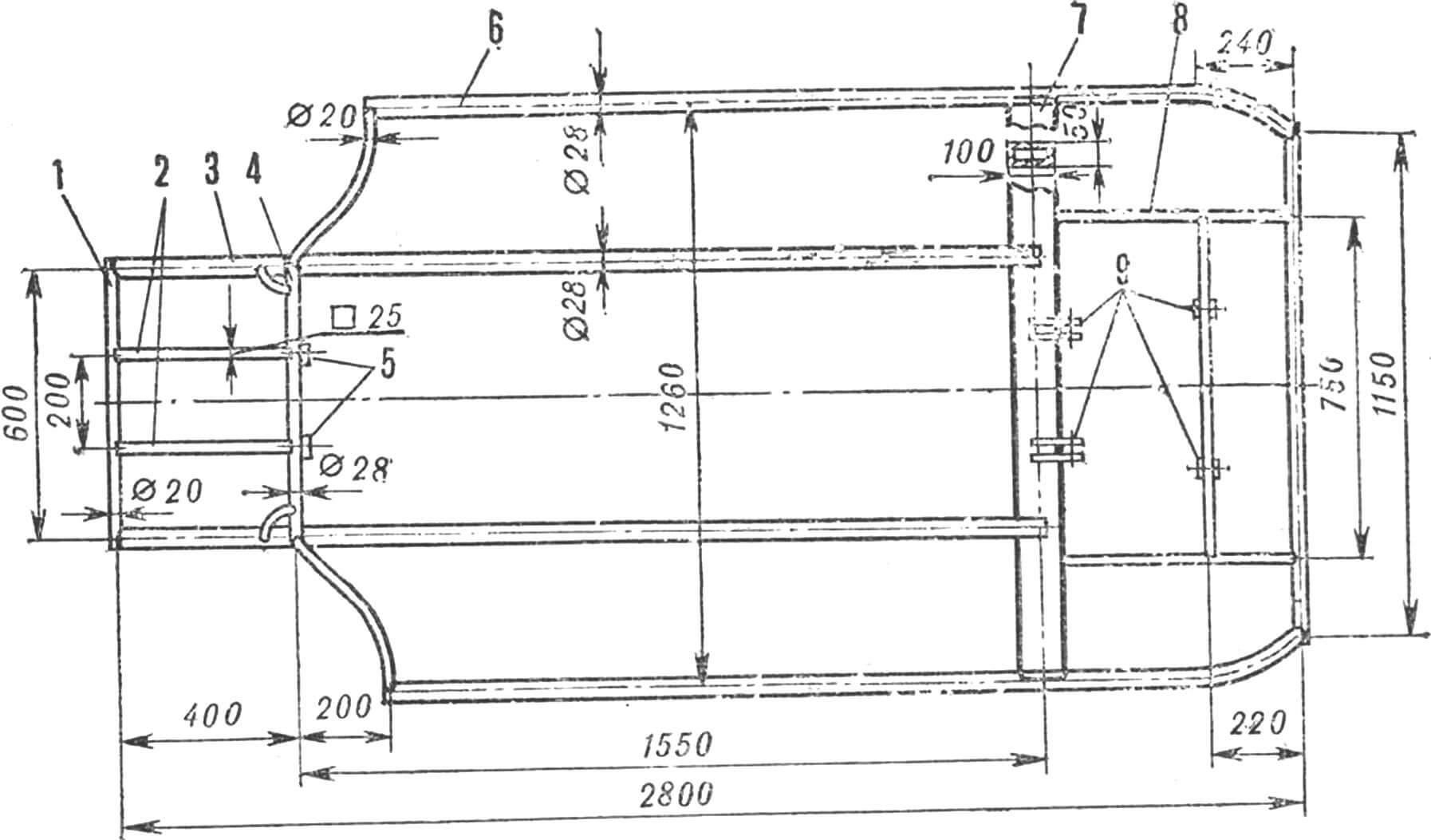

1 — subframe side members, 2 — tubular frame of the removable front end of the body, 3 — brackets for fastening the front suspension elements, 4 — rear transverse beam, 5 — upper part of the body, 6 — wheel niche with a well for installing the rear suspension spring, 7 — arm mounting bracket rear suspension.

The body is monocoque, three-door, with tubular reinforcement of the floor and engine compartment. In its manufacture, VAZ-2102 body parts were used: side and rear doors, roof, pillars and sills. To fit them to the selected dimensions, the doors were increased in length and height by 100 mm, and the roof was significantly shortened and narrowed by 100 mm.

The lower and upper parts of the body were manufactured separately. First, a tubular frame was welded with brackets for installing suspension arms, the engine and shock-absorbing elements. It was then sheathed in steel sheets forming the interior floor and four wheel wells. The shape of the latter is hemispherical, without pockets or niches where moisture could be retained. Such niches are available for control and thorough treatment with anti-corrosion compounds. The upper part of the body – the pillars assembled together, the roof and sides of the rear compartment were mounted on the lower part; after welding, they form a rigid supporting body. Tubular reinforcement of the bottom of the cabin made it possible to lighten the thresholds; each had one of its walls facing the salon cut out. In addition to reducing the width of the threshold, this helps to simplify the anti-corrosion care of the body: now the internal cavity of the threshold, through the wall perforated with large holes, has excellent access for applying “anti-corrosion”.

1 — front transverse pipe, 2 — subframe side members (under the engine mounting brackets), 3 — central side member, 4 — transverse pipe, 5 — mounting brackets for the body heating system heat exchanger, 6 — side spar, 7 — rear transverse beam, 8 — tubular reinforcement of the cargo compartment bottom, 9 final drive housing mounting brackets.

The front of the body, reinforced with a tubular frame, has a removable design: it is secured with bolts. This will make it easy to replace it in the event of an accident, as well as to maintain or repair the engine with the greatest convenience.

The hood is alligator type. It can be folded back almost to the windshield, completely opening the engine compartment.

Instead of bumpers that limit the maximum dimensions of the car, an elastic safety strip is installed along the perimeter of the body. It also serves as a decorative molding, giving the relatively high body greater speed.

For glazing the interior, standard side windows from Zhiguli cars were used: with lifting mechanisms in the doors and fixedly installed in the rear of the body. The windshield is from a ZAZ-968 car, the rear one is from a VAZ-2102. The “vents” at the A-pillars and rear pillars are home-made and fixedly installed, but the ventilation of the cabin through the outlet openings in the rear pillars is quite effective.

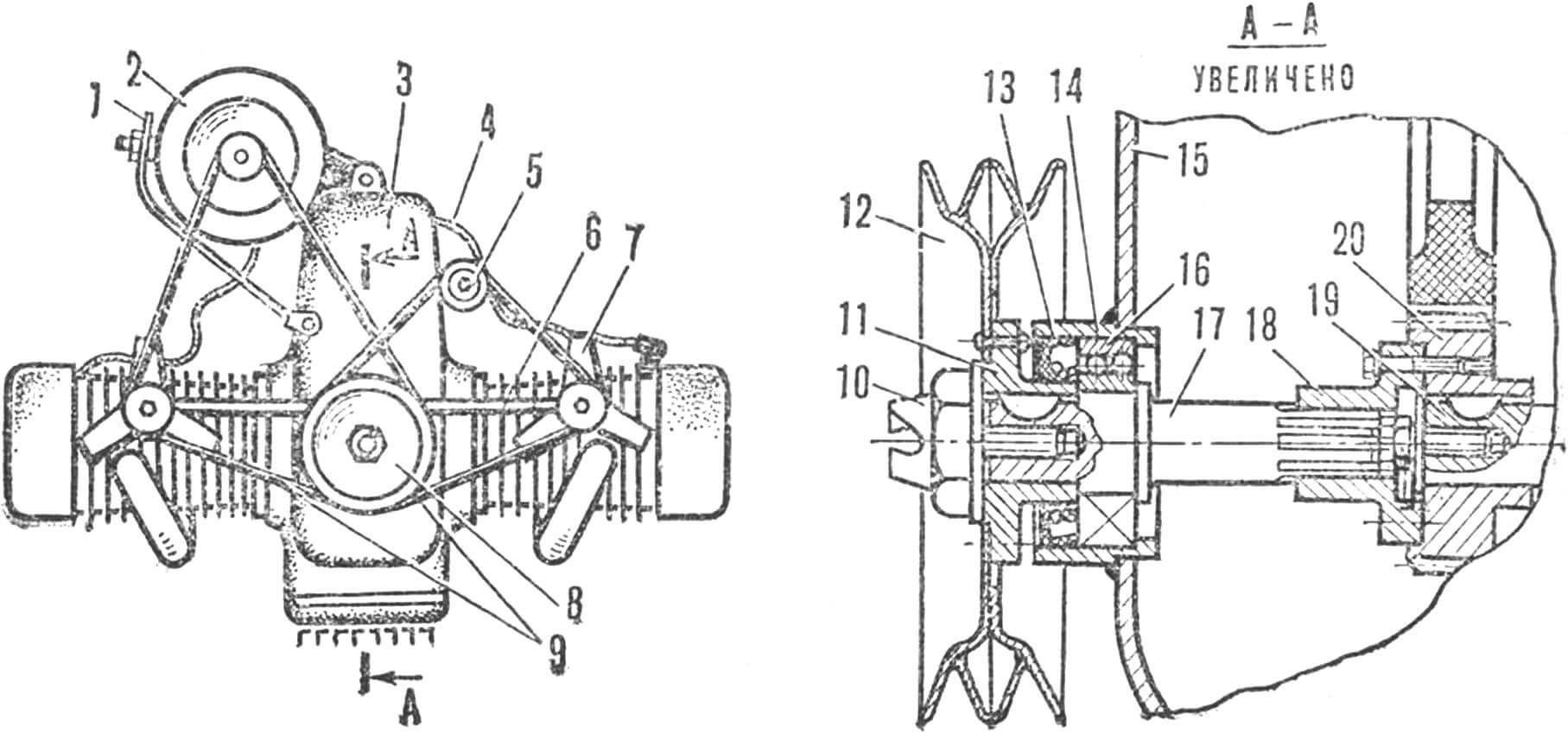

The Kolobok’s power unit is a two-cylinder, four-stroke air-cooled engine from a Ural motorcycle. Its power is 36 hp. With. at 5600 rpm – enough to move a car weighing 700 kg at speeds up to 100 km/h. The average consumption of A-76 gasoline per 100 km is 6 liters. Thanks to its opposed design, the engine fits perfectly into the tiny engine compartment, and air cooling, which does not require installing a radiator in the front of the car, made it possible to give the body a wedge shape. The advantages of the chosen engine made it possible to make the car so short.

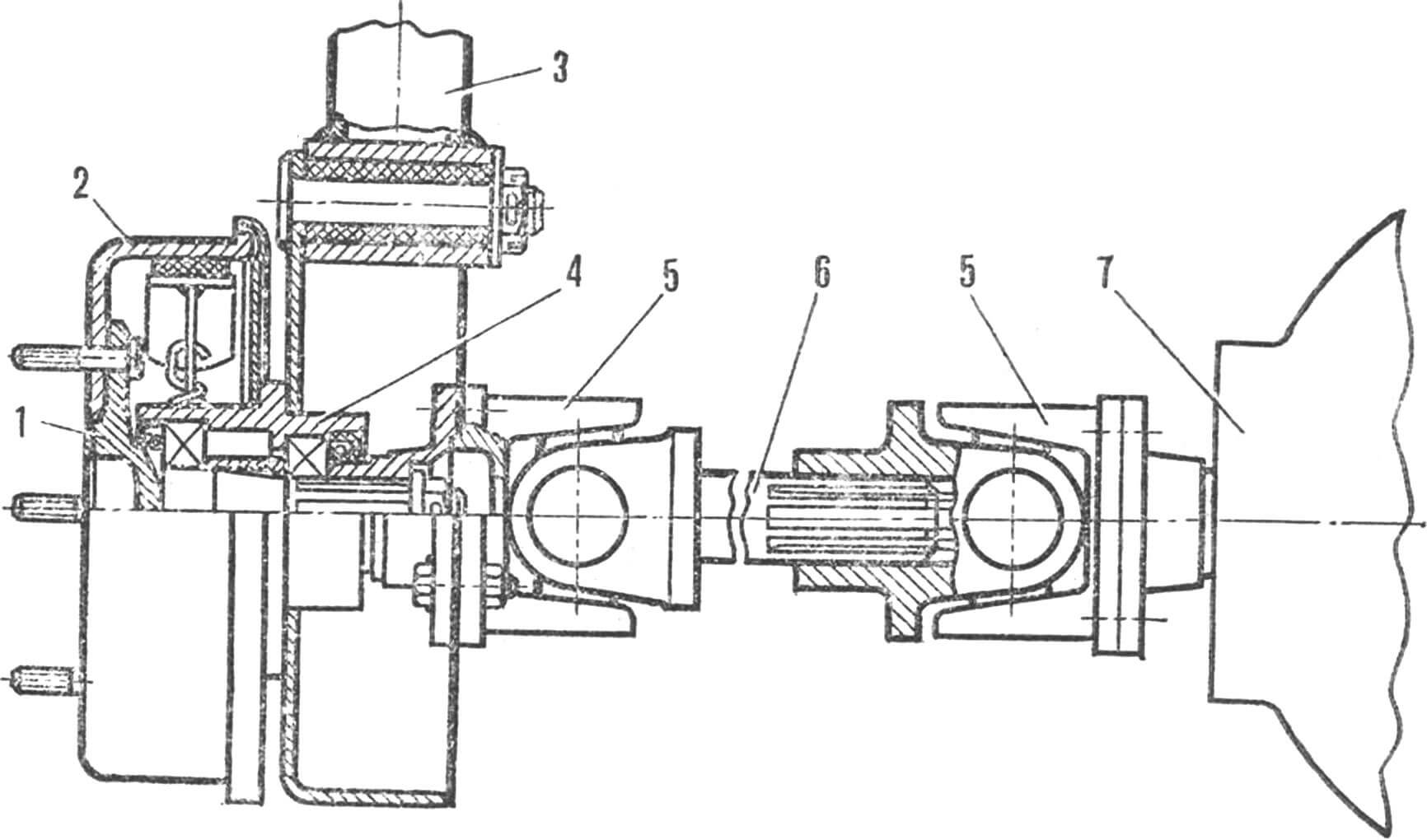

1 — generator bracket, 2 — generator, 3 — engine, 4 — high-voltage wire of the ignition system, 5 — tension roller, 6 — fan bracket, 7 — engine cooling fan, 8 — drive pulley, 9 — V-belts, 10 — bolt -ratchet. 11 — drive pulley hub, 12 — drive pulley, 13 — oil seal, 14 — drive unit housing, 15 — engine cover, 16 — spherical ball bearing, 17 — shaft, 18 — spline bushing, 19 — front crankshaft shank, 20 — gear crankshaft.

In the power system, instead of two carburetors installed on each cylinder, one is used – type K-127. It is attached to a common intake manifold welded from steel pipes above the engine – where it is convenient to adjust it. To improve performance in the cold season, the manifold is heated from below by the heat of the exhaust gases: an arc-shaped tube connecting the exhaust pipes of both cylinders is closely adjacent to its lower wall. During engine operation, part of the hot gases passes through it and heats the wall of the intake manifold with its heat.

The air filter is of the oil-inertial type. Due to its small diameter, there is enough space under the hood to the left to accommodate a spare wheel.

Fuel is supplied to the carburetor by a diaphragm-type fuel pump driven by an eccentric washer from the oil pump shaft.

1 – crankshaft, 2 – engine housing, 3 – flywheel, 4 – extension ring with ring gear, 5 – starter, 6 – clutch pressure plate, 7 – clutch housing, 8 – extension flange, 9 – extension pipe, 10 – shaft , 11 — catch washer, 12 — splined coupling, 13 — clamp clamp, 14 — gearbox input shaft, 15 — cup strut, 16 — gearbox flange cup, 17 — gearbox flange, 18 — front wall of the gearbox.

To ensure uniform cooling of the cylinders and avoid overheating when operating in the hot season, the engine is equipped with forced airflow: a metal three-bladed fan driven by a V-belt drive is installed in front of each cylinder. To install such a drive, the front part of the engine had to be modified. A hole was bored into the timing gear cover coaxially with the crankshaft for the housing of the drive pulley assembly. It is attached to the cover with bolts or using special welding. The pulley shaft is installed in the housing on a self-aligning ball bearing and is driven into rotation by a splined sleeve attached to the end of the crankshaft gear. A double pulley, assembled from two pulleys of a VAZ water pump, is mounted on the shaft shank with a key and secured with a ratchet bolt. V-belt transmission from the drive pulley to the fans is carried out by two belts. The right one drives the fan and generator, the left one drives only the fan. The tension of the first is regulated by the position of the generator, the second – by an additional roller.

The engine lubrication system as a whole remained unchanged. However, for layout reasons, the oil filter had to be installed horizontally: this required several steel bushings and rubber o-rings. And to improve oil cooling, several steel corners are welded to the underside of the pan.

1 — secondary shaft of the gearbox, 2 — pin disk, 3 — pin, 4 — steel cage, 5 — retaining wire ring, 6 — rubber disk, 7 — centering bearing, 8 — spherical pin of the shaft, 9 — connecting shaft.

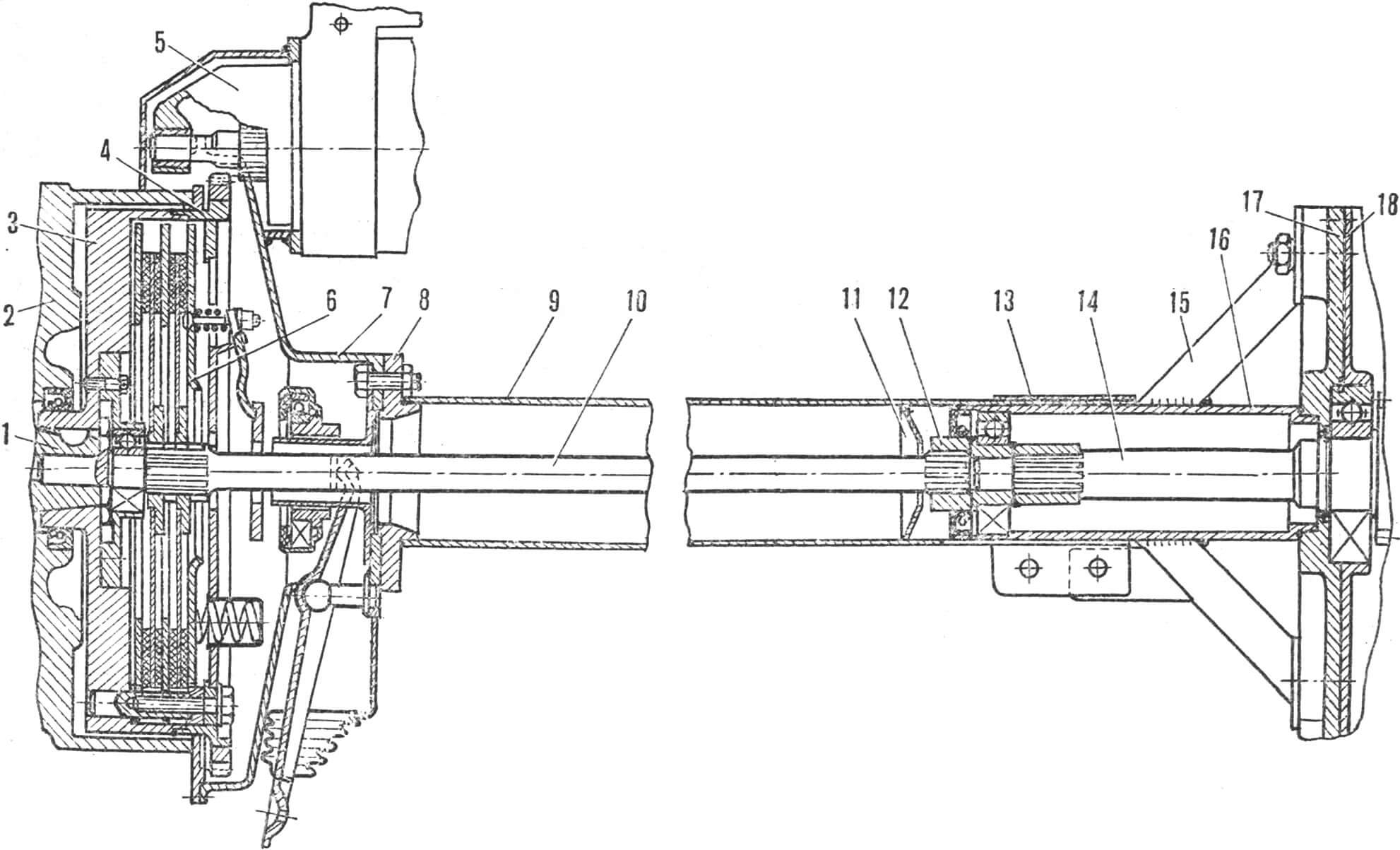

To start the engine with an electric starter, the flywheel has been modified. A standard ring gear from a ZAZ flywheel is pressed onto an extension ring concentrically welded to the end of the flywheel. The reverse rotation starter is mounted on a machined steel clutch housing.

The clutch is double-disc, dry. Its design is improved according to the automobile type. The release lever drive is cable.

The gearbox is standard, Zhiguli, but it is not attached to the clutch housing, as in most cars, but through an extension with an intermediate shaft, so that on the car it is located between the front seats. This arrangement, despite the slight complication of the transmission, provides better weight distribution of the car, and most importantly, allows for more free placement of the control pedals.

The extension is a piece of thin-walled steel pipe (the driveshaft from the Moskvich-408 car can be used as a blank). On one side it is welded into a round flange for connection to the engine clutch housing. On the other side, a longitudinal groove is cut into the pipe, and a wide clamp is put on top to connect it to the gearbox flange sleeve. This flange is made from the end wall of a standard VAZ engine clutch housing. In its central hole, a thick-walled steel cup is welded, in which a bearing and an intermediate shaft seal are installed. Four steel struts provide additional rigidity to the connection. The intermediate shaft rests with its front shank on a bearing pressed into the inner flange of the flywheel, and the rear shaft, through a splined coupling, rests on the bearing of the box flange cup. This shaft transmits rotation from the clutch driven discs to the transmission input shaft. When assembling the unit, the intermediate shaft housing parts combine the engine and gearbox into a single power unit, which is attached to the car body at three points: to two subframe brackets and to the crossbar, under the rear of the box.

The box is connected to the main gear by another shaft. Since the car uses independent rear wheel suspension, the main gear housing is attached to the body almost motionlessly – using rubber-metal bushings. Therefore, elastic pin couplings can be used on the connecting shaft instead of cardan joints.

The main gear reducer has a gear ratio of 4.1. Its short axle shafts are connected to the wheel axle shafts by two driveshafts.

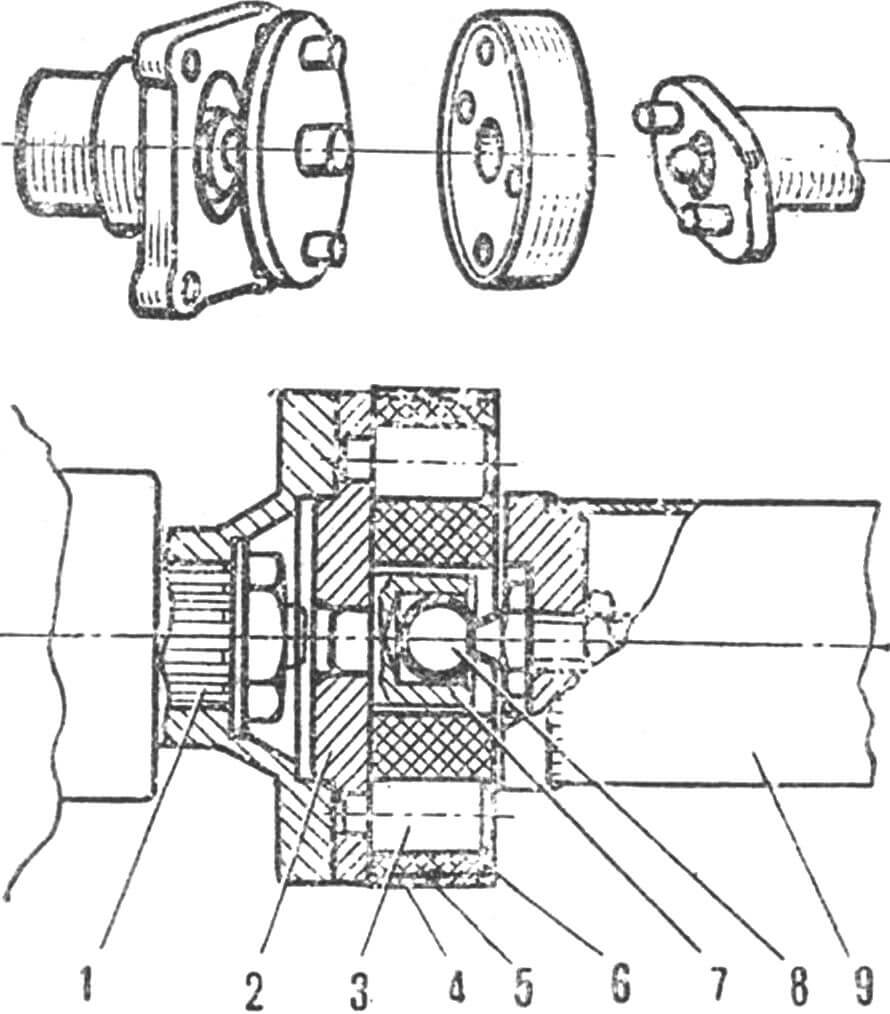

The hubs and bearing units of the rear wheels can be used from the SZA motorized stroller. To increase reliability and durability, instead of standard wheel axle shafts, home-made ones with an increased journal diameter for bearings No. 205 and No. 206 are installed.

1 — wheel axle shaft, 2 — brake drum, 3 — suspension strut, 4 — wheel hub, 5 — universal joint, 6 — propeller shaft, 7 — final drive.

When choosing the wheel size (5.0-10), not only the availability and low cost of tires were taken into account. Their size largely determined the entire layout of the body: the smaller the wheels, the smaller the size of the wheel niches, and therefore the more space in the cabin. The use of light, small wheels has a beneficial effect on comfort and driving dynamics: the lighter they are, the lower their moment of inertia and unsprung masses of the suspensions. And finally, the smaller outer diameter of the wheels also determines a smaller transmission ratio: a more compact final drive gearbox. The disadvantages of small wheels are slightly faster wear and poorer cross-country ability. However, the first is compensated by the cheapness of tires, and the second is of secondary importance in city conditions.

The suspension of all wheels is independent. The front ones are on the transverse, and the rear-the longitudinal levers, sub-dramas spiral springs and hydraulic shock absorbers of the VAZ.

The steering is a traditional scheme: the worm mechanism (from the “Cossack”) moves its bipod to cross the steering steering rod connected by spherical hinges with the levers of the steering trapezoid on the hubs of the front wheels.

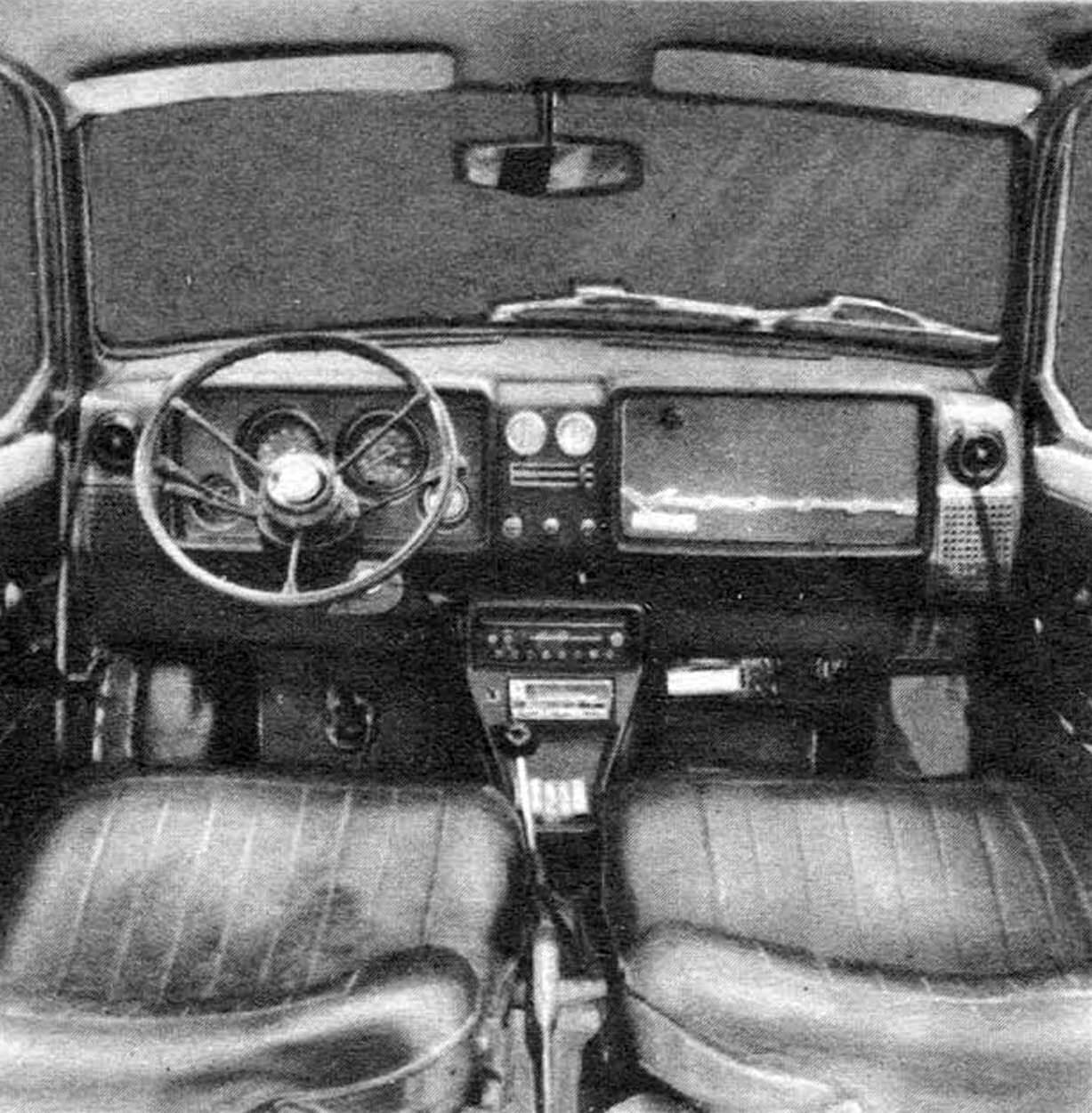

The electrical equipment of the car is 12-volt, with a generator and a relay regulator of the VAZ. The battery is 6-ST-45, but a successful layout of the engine compartment allows the installation of any battery from cars. There is all the necessary signaling and control equipment: headlights, turns indicators, stop signals, sound signal, instrument panel-from the VAZ-2103. It is not forgotten and additional: the lighting of the cabin, a spacious glove box, an electric heater of the rear window and its glass cleaner, as well as radio equipment – a receiver and a tape recorder.

The necessary comfort when operating the machine in the cold season provides an original interior heater.

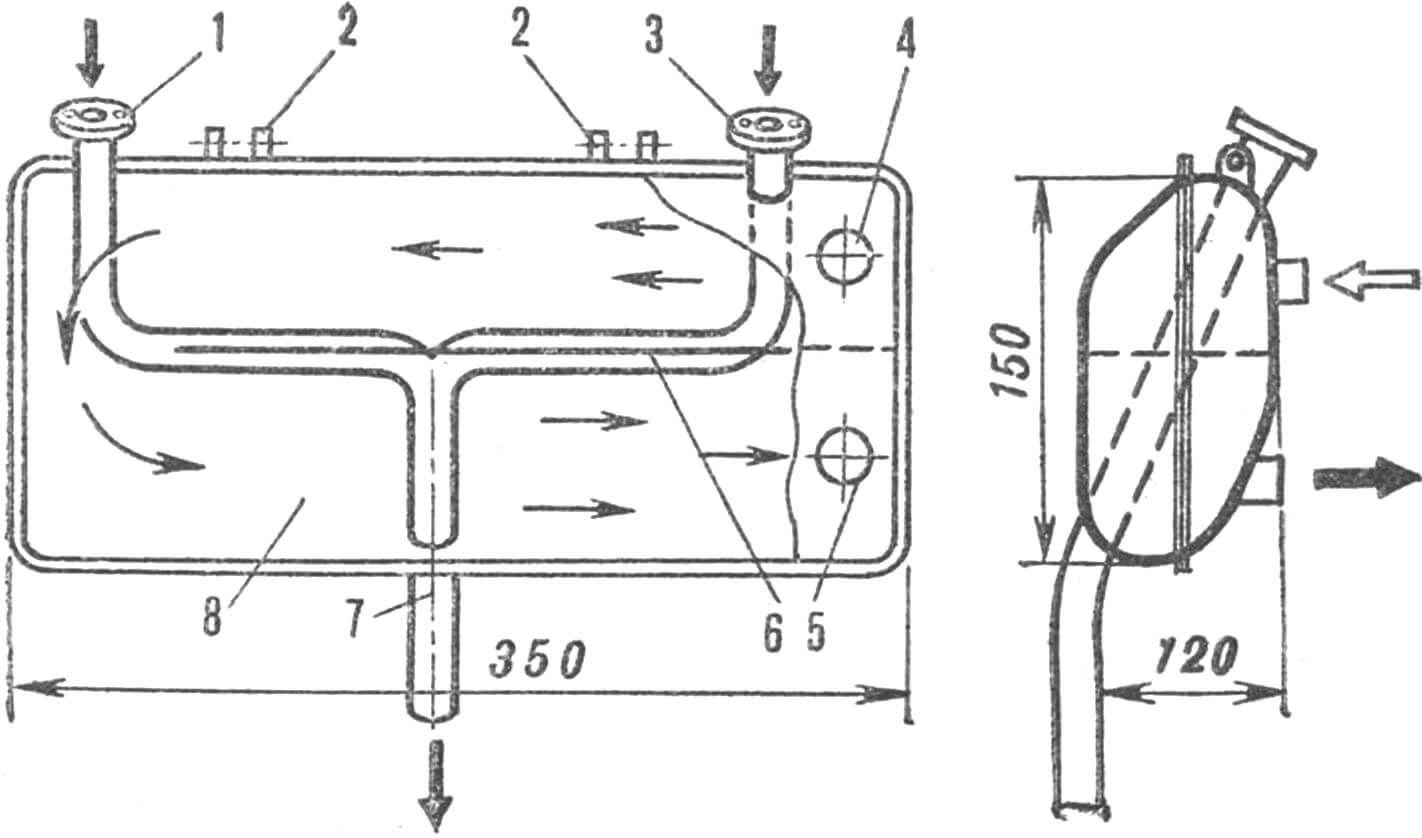

1 – flange of the final pipe of the left cylinder, 2 – mounting brackets to the body, 3 – flange for the final pipe of the right cylinder, 4 – a cold air supply pipe, 5 – a pipe of heated air, 6 – partition, 7 – graduation pipe, 8 – 8 – 8 – heat exchanger covered with asbestos.

The heater is arranged. The exhaust pipes of the right and left cylinders through corrugated heat -resistant pipes are connected to a heat exchanger – a container cooked from sheet stainless steel. There, the pipes converge into one, which is further displayed and connected to the jamming system. Two short pipe are welded to the top of the heat exchanger case for the supply and outlet air hoses, and a longitudinal steel partition is welded inside the container, directing the flow of air between them along the maximum path – along the heated exhaust gas pipes. To reduce heat exchange with an oncoming air flow that blows the unit during movement, the heat exchanger body is isolated by asbestos. The circulation of air through the heater provides a two -speed fan installed under the hood near the air intake hatch. The temperature of the air supplied to the salon can be adjusted in a hatch in a hatch that changes the ratio of cold and heated air. In the cabin, the output holes of the system are made along the windshield, on the sides of the front panel, with deflectors for supplying air of the side glass, and in the lower part of the cabin: at the feet of the driver and passenger in the front seat.

All seats in the car are separate. The front ones are adjusting the position in length and tilt of the back. The rear can fold forward. Moreover, in addition to passenger and cargo options, an intermediate is possible: having folded one of the rear seats, we get a triple salon with a cargo ward on the side of the rear passenger.