The FOX roadster project was born in 2004 from a youthful idea to build an open sports car with an original appearance to satisfy personal design ambitions.

Back in my school years, I was involved in car racing and was a multiple winner of Russian championships. He studied at the Yaroslavl Polytechnic University at the department of internal combustion engines. He also completed his graduate studies there. Now I work as a chief design engineer in a company whose activities are related to composite materials. (I worked with fiberglass and carbon fiber while still at school, as a model maker). I design various non-standard equipment.

FOX carried out the engineering work using books on car chassis design by the German auto designer J. Rampeil and other authors.

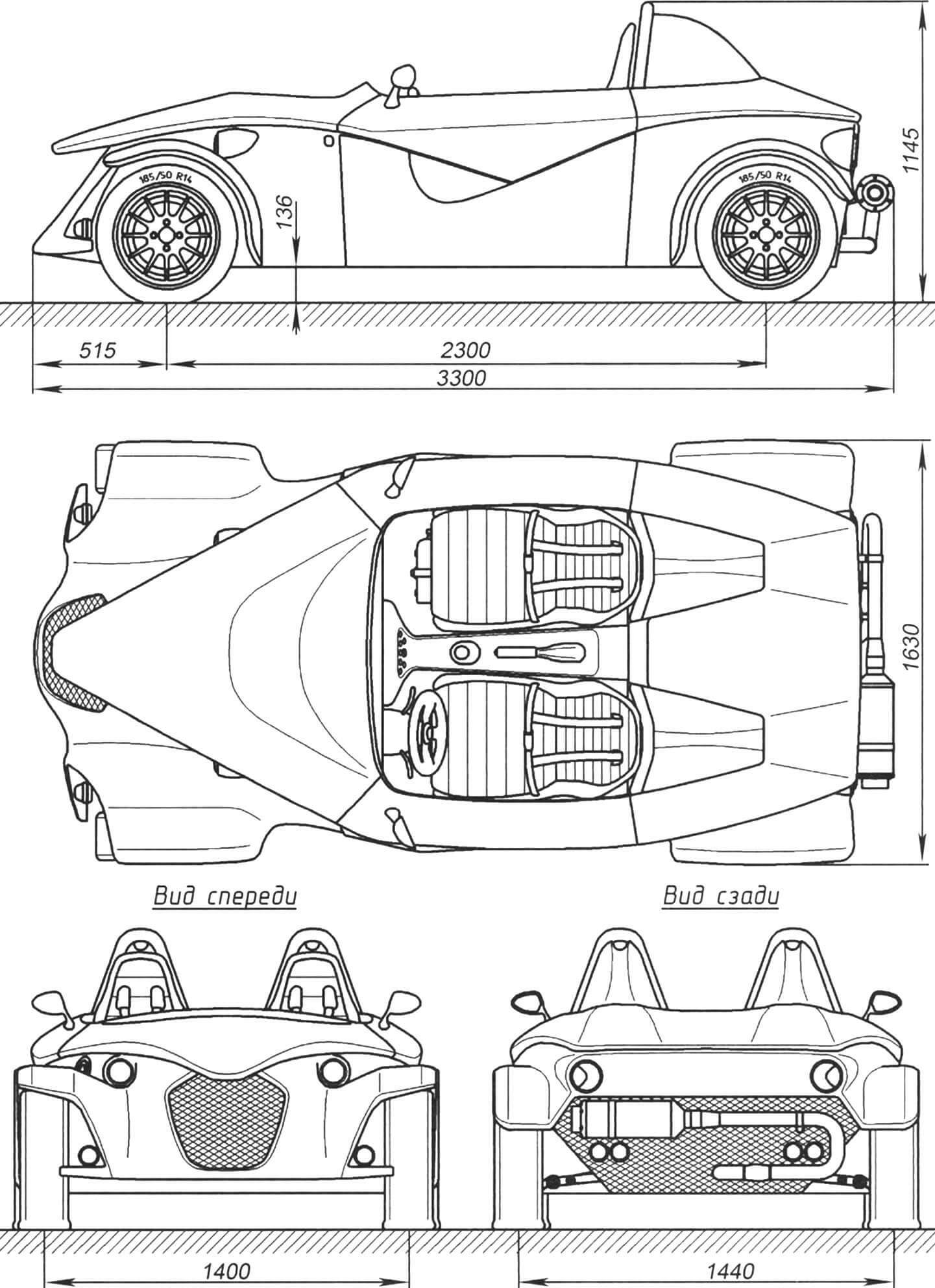

After working out the layout of the car, I received the main dimensions of the chassis (track, base, ground clearance, height), which were given to the designer for development.

Due to a modest budget, I decided to make a small car using components from domestic cars. I planned to take the power unit from the front-wheel drive cars of the Volga Automobile Plant and make a two-seater roadster with a transversely mounted engine in front of the rear axle.

As we worked on the project, the idea was born to build not a single car, but a small series and even implement a business project with the creation of a company producing original roadsters using kitcar technology. This technology involves the delivery of a kit to the client for assembling a car, and the readiness of the kit can vary, from the delivery of a bare frame and unpainted body to a turnkey finished car. The kitcar system is used in many Western countries, but in Russia this market niche is free. It was assumed that most customers would order the chassis and body, and purchase other components as needed directly from the company or from third-party manufacturers. With such an organization, the client has, on the one hand, the opportunity to reduce the cost of purchasing a car, and on the other hand, he gets pleasure from assembling and customizing a particular car to his requirements.

The concept of using components from domestic cars in the basic version allows you to take advantage of a wide selection of spare parts for tuning or use parts from a donor car. However, the client can use the necessary components from foreign cars instead of domestic parts or order special parts. In any case, the frame and body of the car remained completely original, which made it possible to patent them and protect the company from plagiarism, as well as give the car a recognizable appearance.

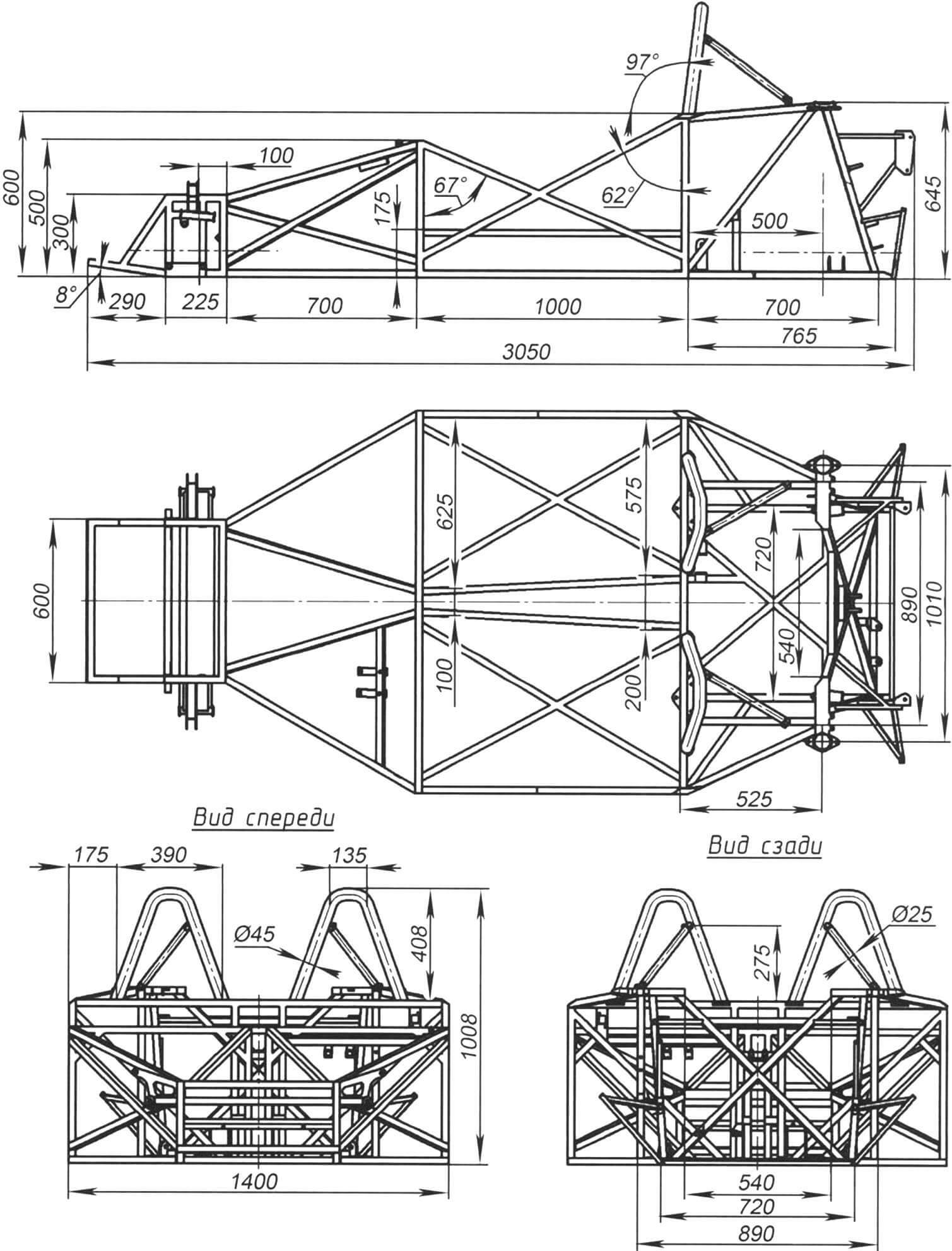

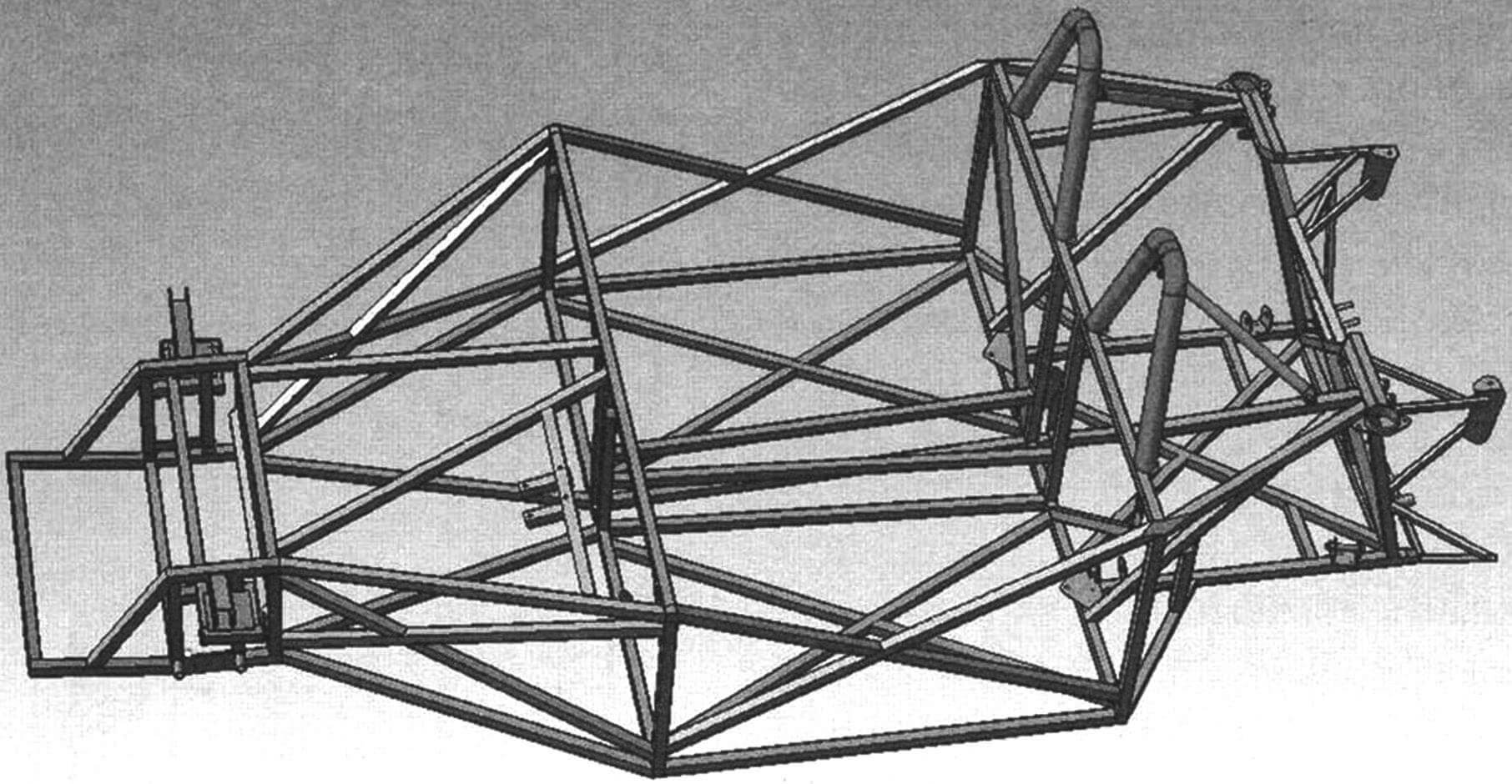

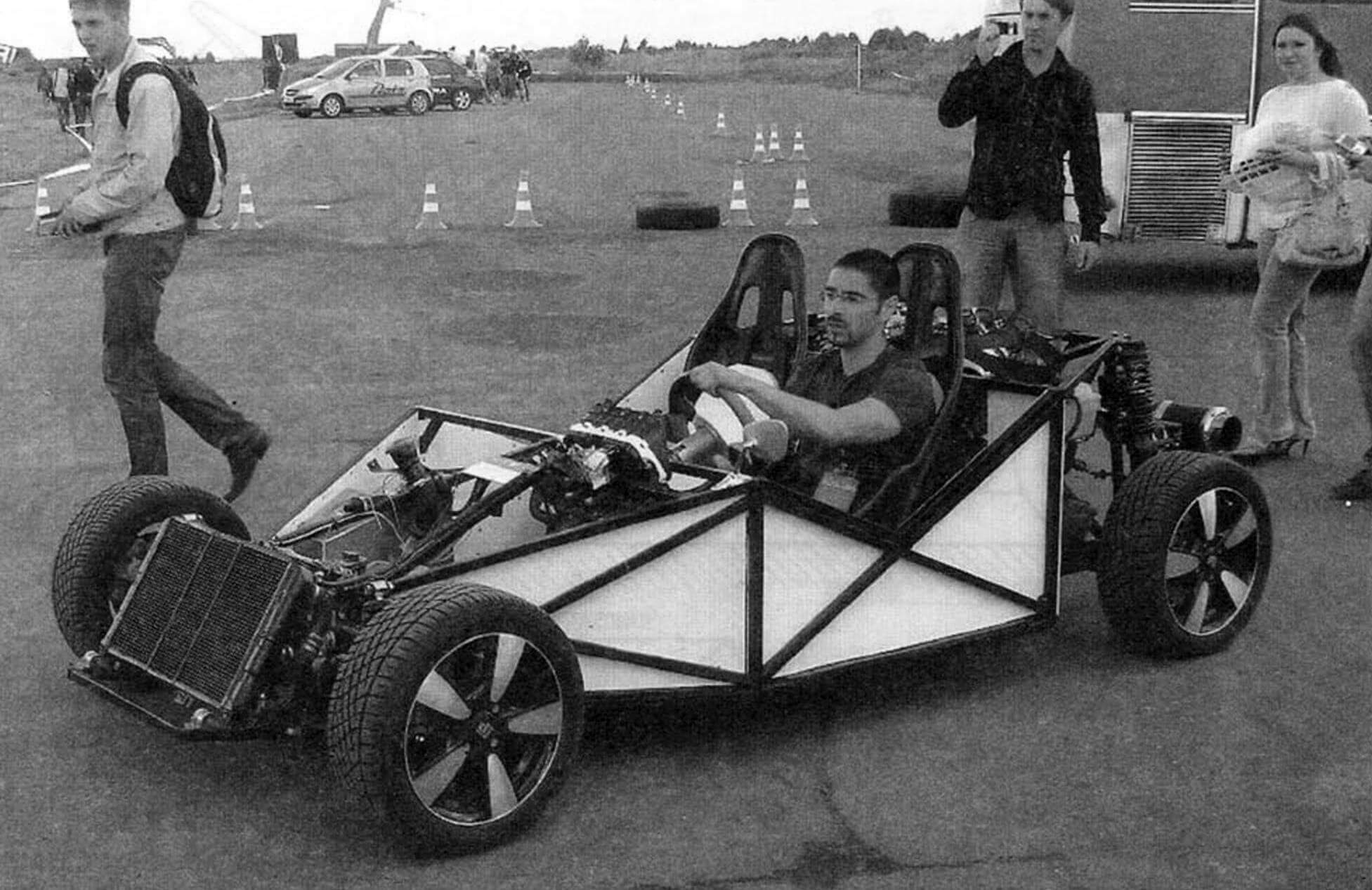

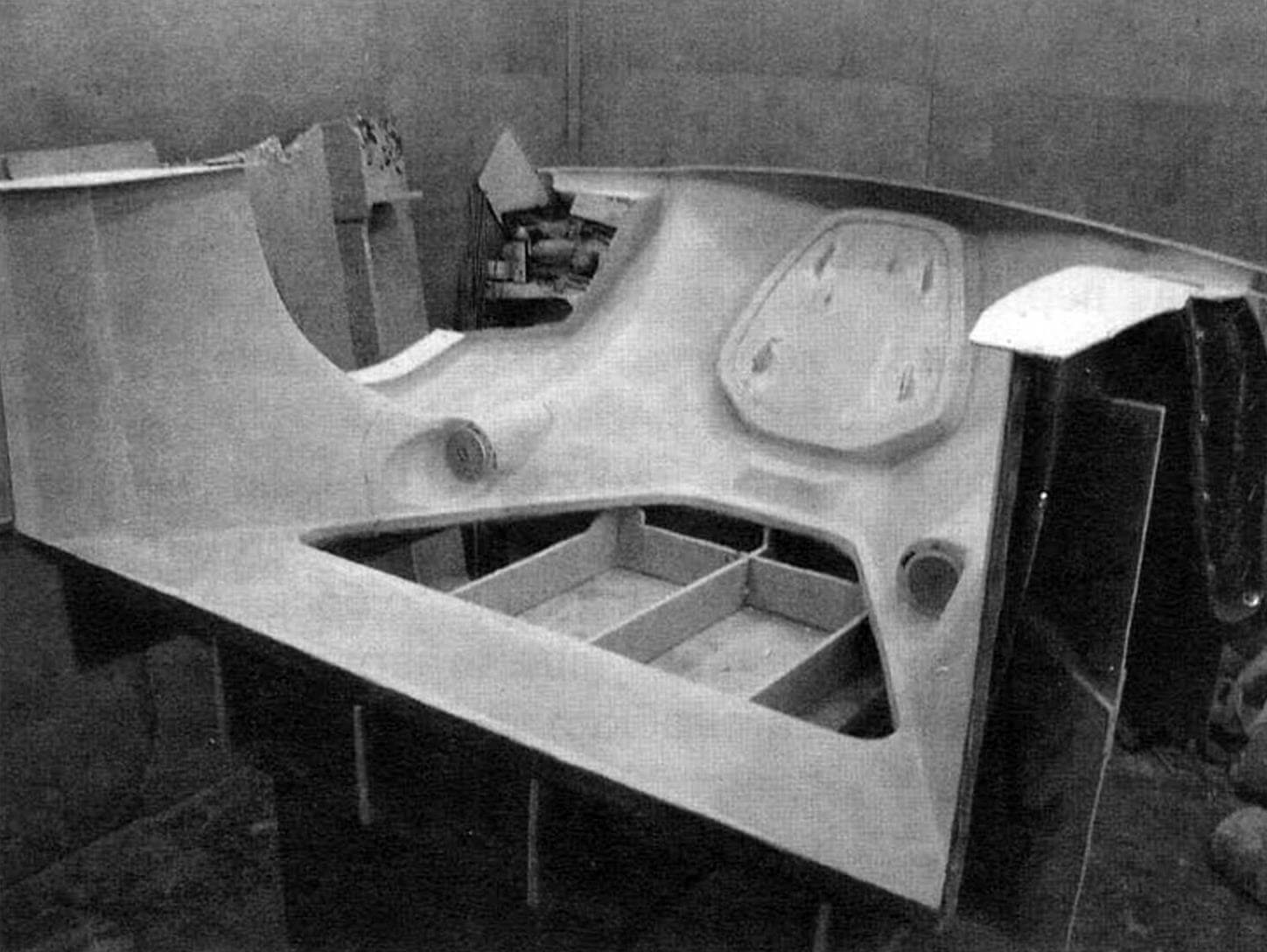

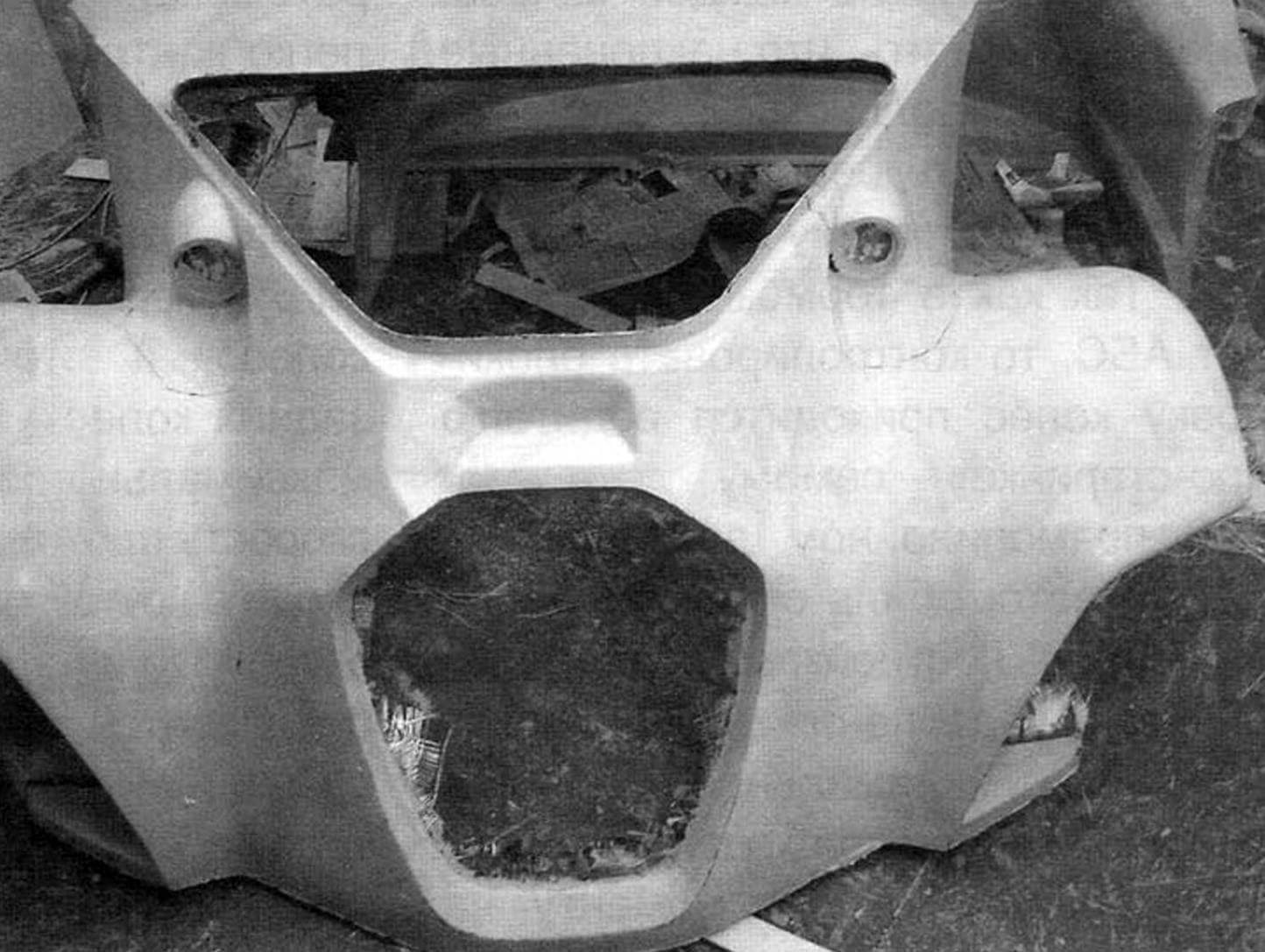

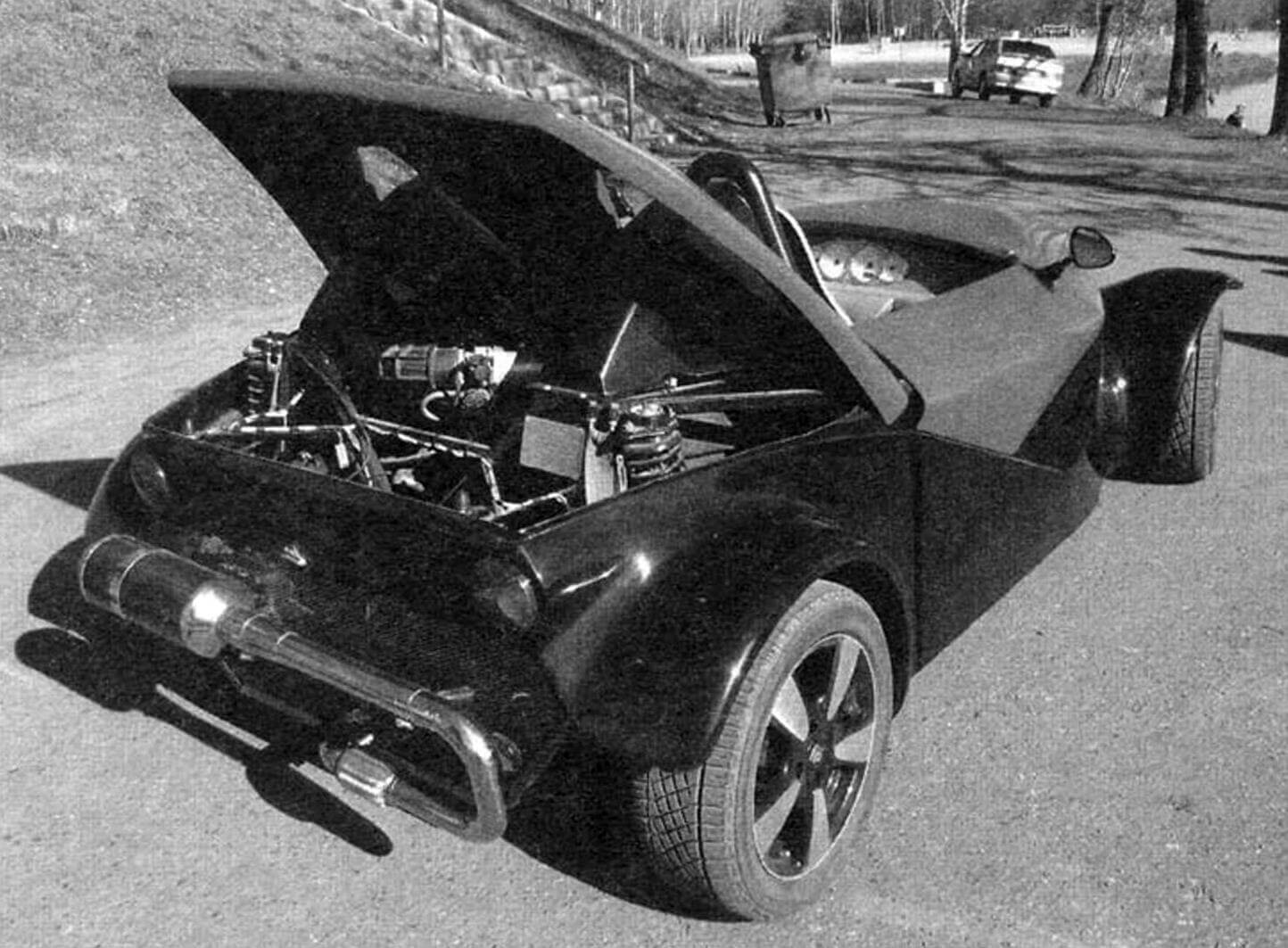

Now let’s move directly to the design of the FOX Roadster. The drawings show the existing basic version of the car. The chassis is based on a spatial tubular frame weighing 100 kg made of steel pipes with a square section of 25x25x2 mm. Almost all parts of the frame are made of triangles, which gives it very high torsional rigidity, exceeding that even in production cars, which has a positive effect on handling. The car body is fiberglass 4 mm thick: it has 12 external skin panels, 9 interior panels and weighs 70 kg.

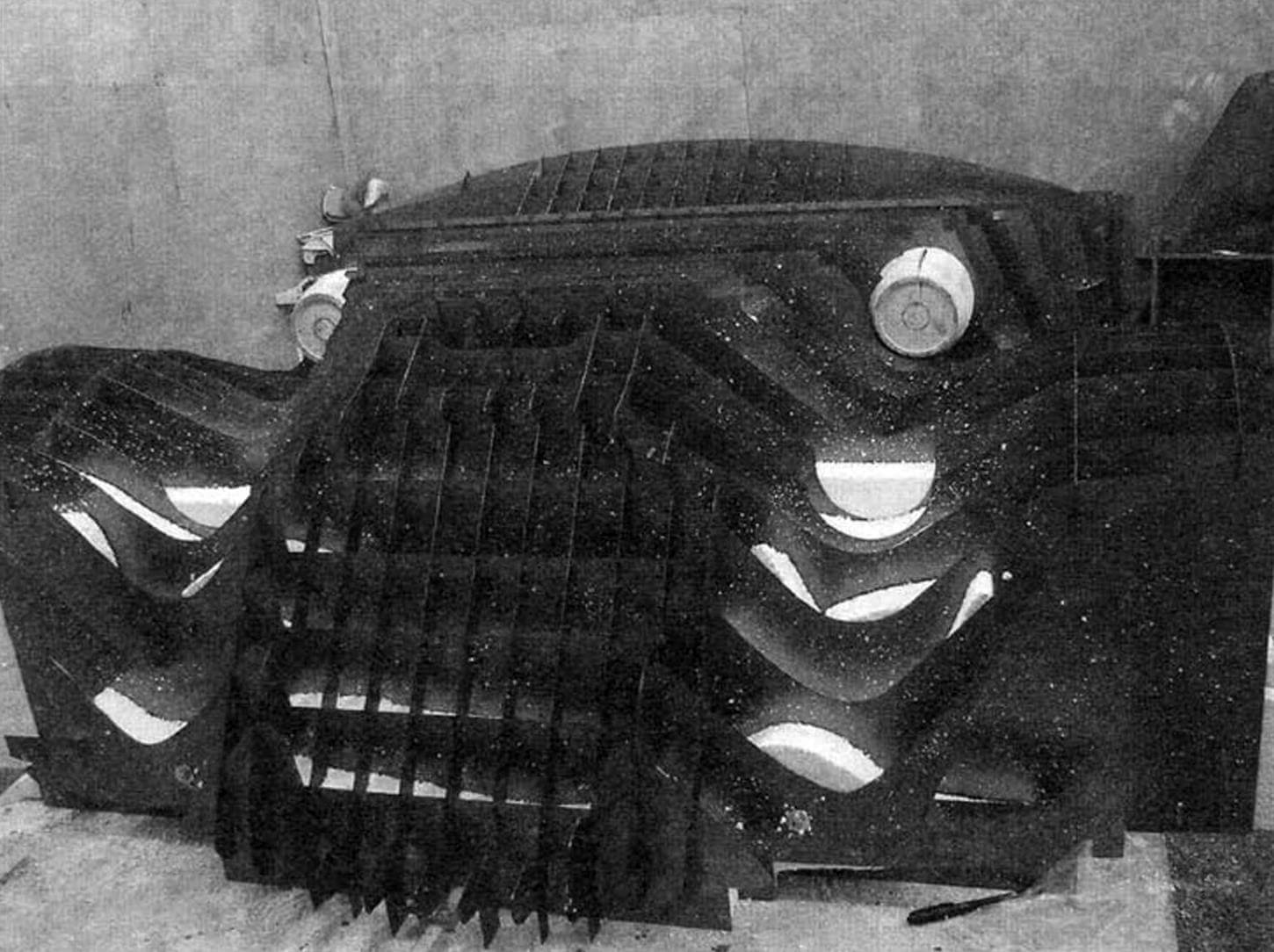

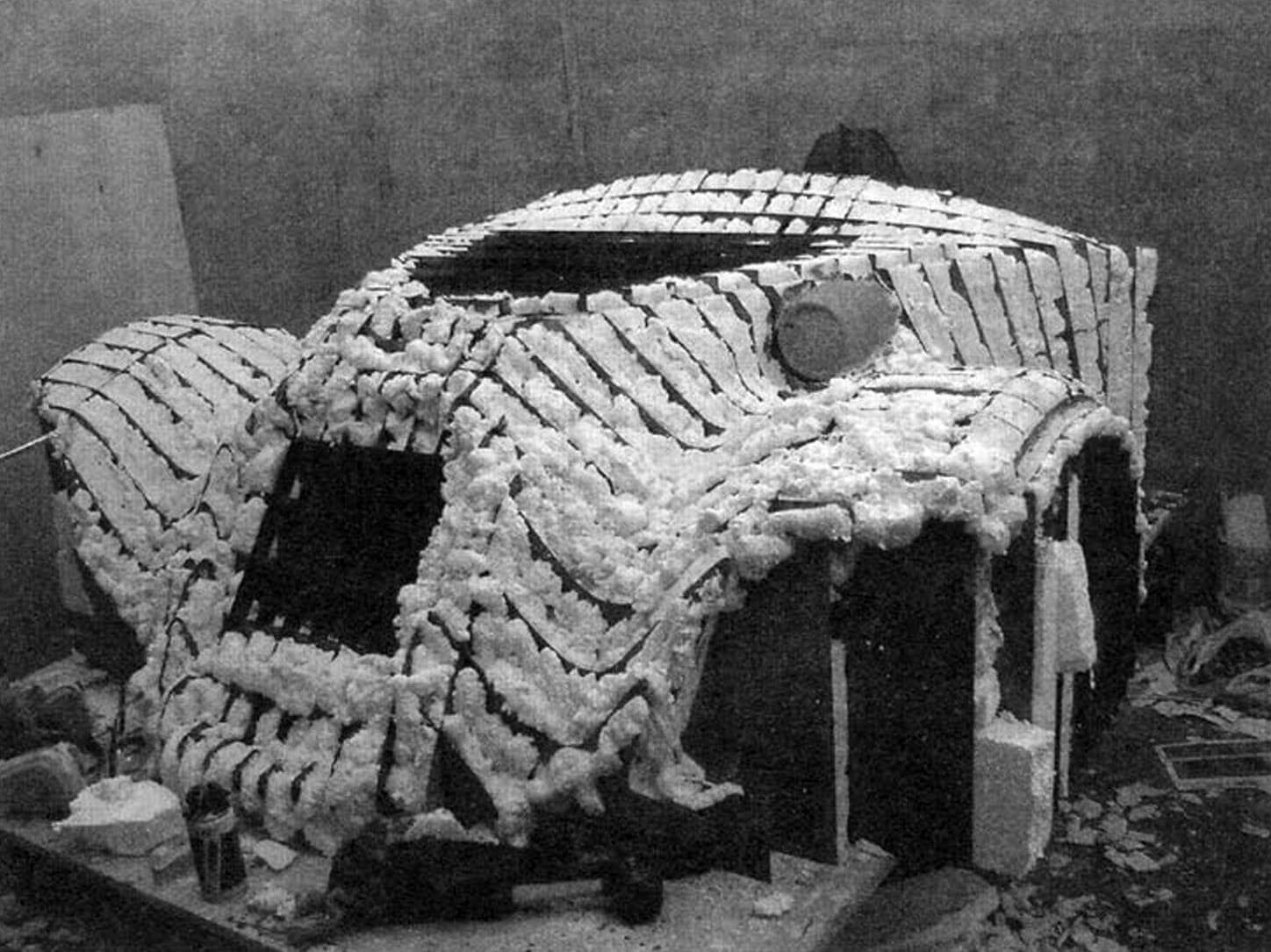

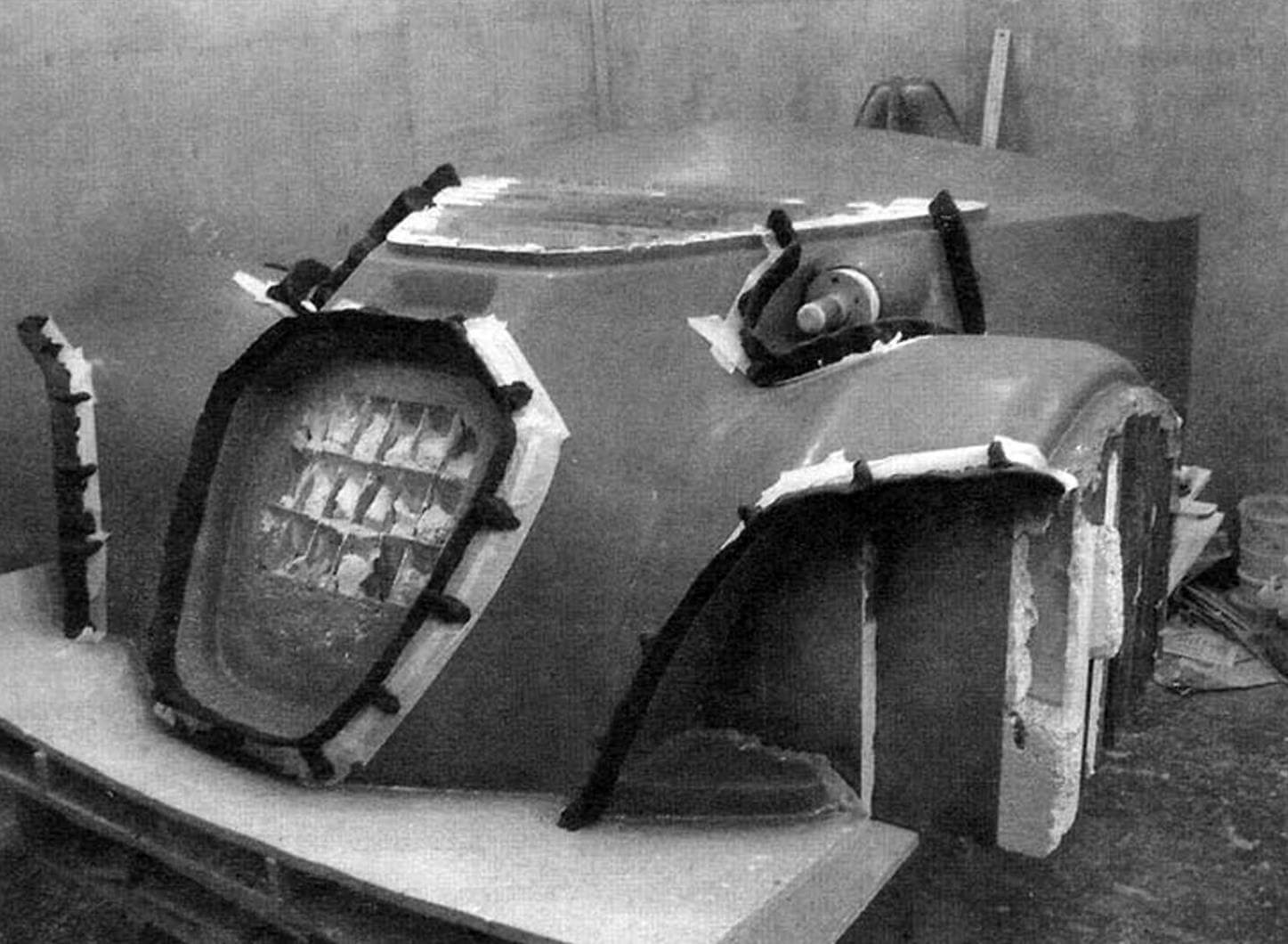

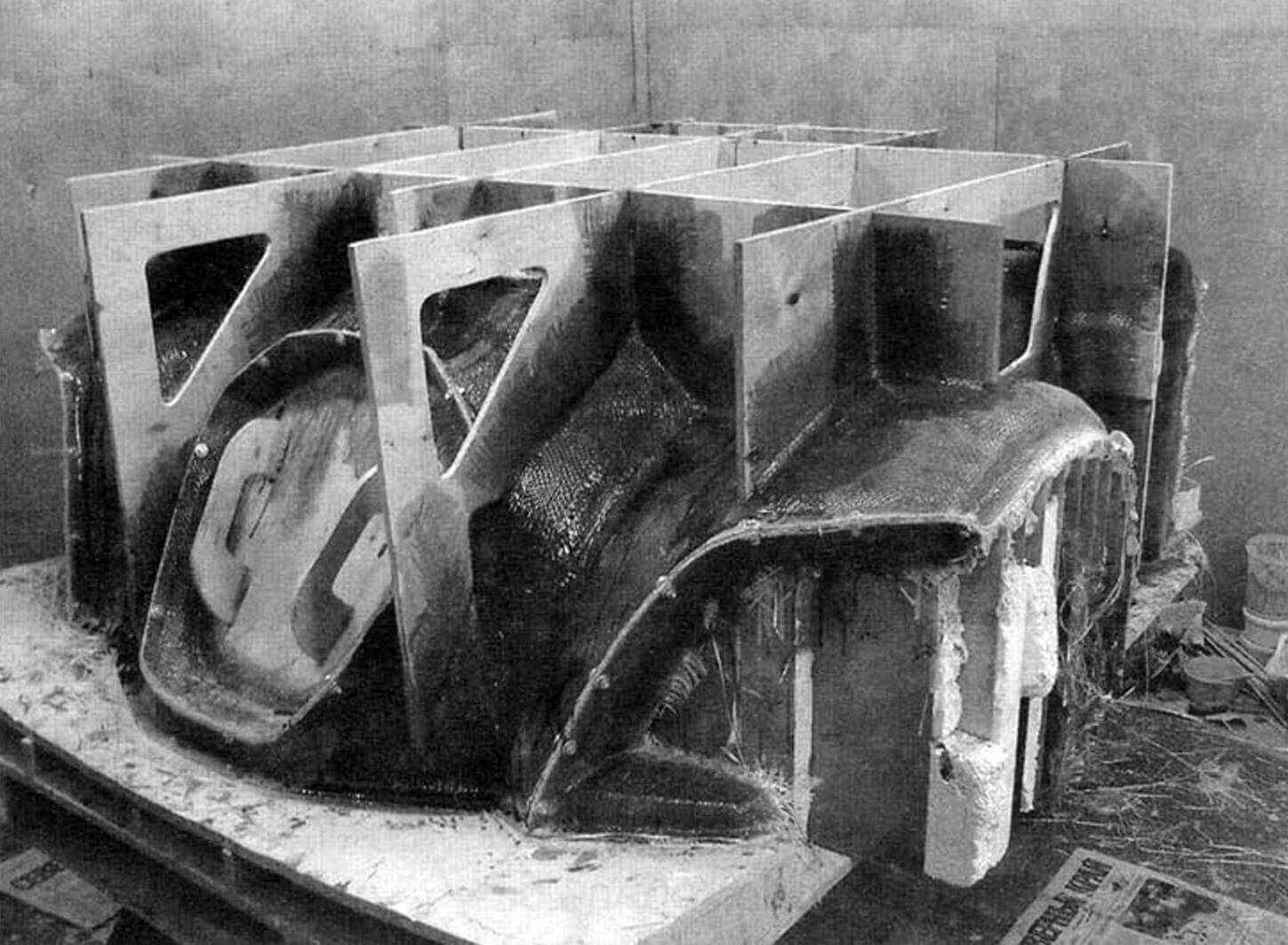

The master model was made from a set of spacing, tied in 3D, then frames were made from a steel sheet 1 mm thick, assembled on a sub-model plate with technological overlaps, then an almost finished matrix was removed from it, and the part was glued into it.

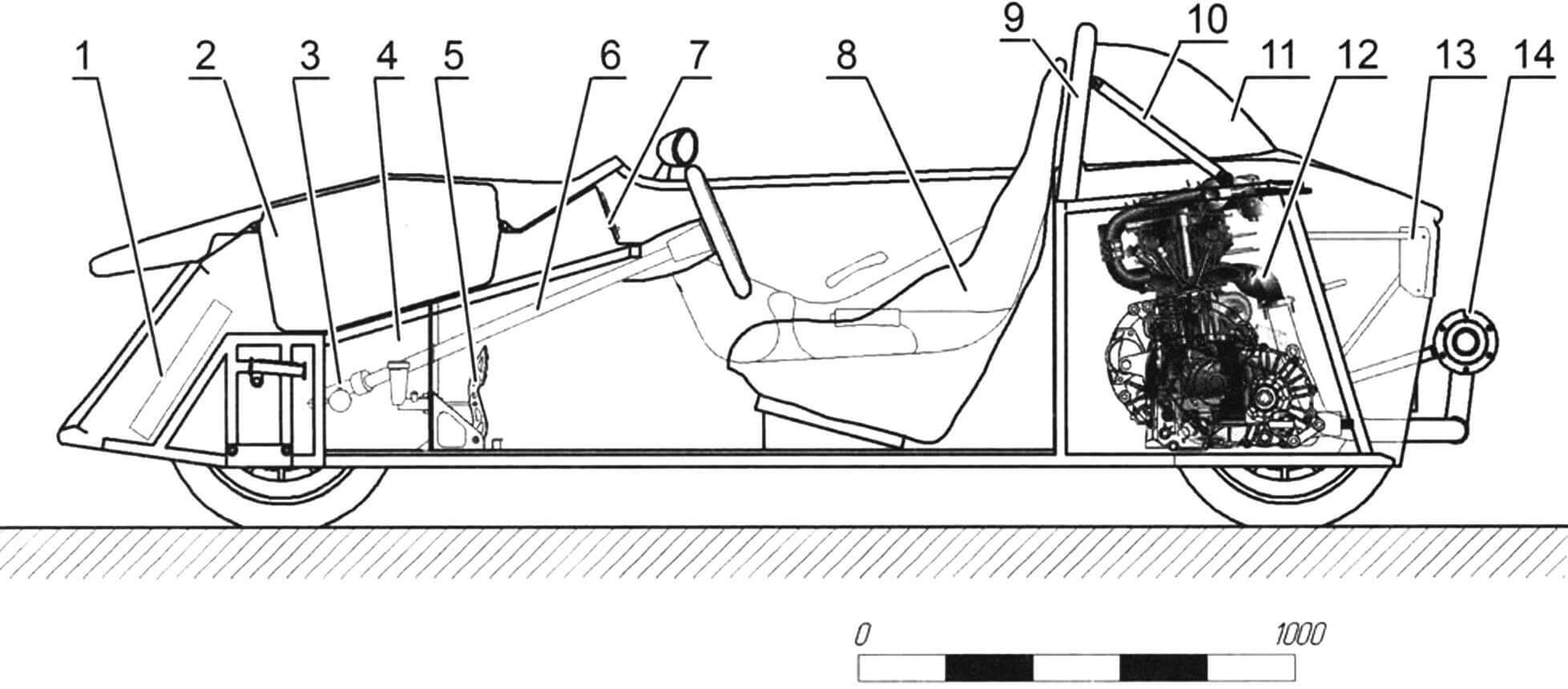

1 – radiator; 2 — luggage compartment; 3 — steering rack; 4 — partition between the luggage compartment and the cockpit; 5 — pedal assembly; 6 — steering rack; 7 — dashboard; 8 — sports bucket seats; 9 — safety arc; 10 — roll bar strut; 11 — fairing; 12 — power unit; 13 — brackets for supporting body panels; 14 — exhaust system

For the manufacture of the panels, a non-shrinking, fairly fluid, not very toxic epoxy composition “Etal-370” from the Moscow company “Epital” was used. The outer layer of the panels consists of a gelcoat 0.5 mm thick on the same resin, but with the addition of pigment (titanium dioxide) and a thixotropic additive – aerosil. Then there are two reinforcing layers of thin fiberglass with a density of 220 g/ m2 , then three layers of fiberglass mat with a density of 300 g/ m2 . The layers of fabric are impregnated with a brush, the ratio of resin to fiberglass is approximately 50/50. The parts turn out to be durable – I stood on the front cantilever fender of the car and it didn’t even bend.

The bottom of the car is covered with a smooth composite plastic-aluminum sheet. The floor is a flat part of a spatial frame made of square pipes measuring 25×25; on top of it, in the places where passengers sit, there is a tank, battery, electrics and pedals, 8 mm thick plywood is laid. Similar technology is used in buses. A sheet of composite sandwich 3 mm thick is placed below the same tubes, but over the entire surface of the bottom. This sheet is used for the manufacture of advertising and ventilated facades and is a PVC sandwich covered on both sides with 0.7 mm thick aluminum sheet, which is lighter and stronger than a solid aluminum sheet. The bottom turns out completely flat. Between the passenger seats there is a central tunnel, limited from below by a bottom sheet, and from above by a fiberglass part, which I actually call the “central tunnel”. Inside the tunnel are pipes of the cooling system, throttle cable, brake pipes, fuel pipes, gearbox shift rod, handbrake cables and wiring.

The plywood floor and bottom sheet are additionally secured from below using self-tapping screws with a press washer, simultaneously strengthening the frame. Fiberglass trim parts and parts that need to be removed are secured with hexagon socket screws through press washers to special threaded rivets pressed into the frame.

I’ll also note that the trunk lid and doors are hollow parts glued together from two halves. On the rear wings and on the massive “muzzle”, mudguards are glued from the inside. The remaining parts are crusts.

The engine compartment is located at the rear of the body. 16-valve engine with 150 hp. With. (a forced engine from a VAZ-2112) is located transversely in front of the rear axle. The exhaust system is welded from polished stainless steel pipes and moved back outside the body. The gearbox is also based on the VAZ front-wheel drive gearbox, but all gear ratios have been changed, the shafts have been strengthened and a limited slip differential has been installed. Gear shifting is carried out by a shortened lever with a rod going backwards inside the central tunnel and passing under the power unit. The gear arrangement is similar to front-wheel drive VAZ models, but the shifting has become clearer.

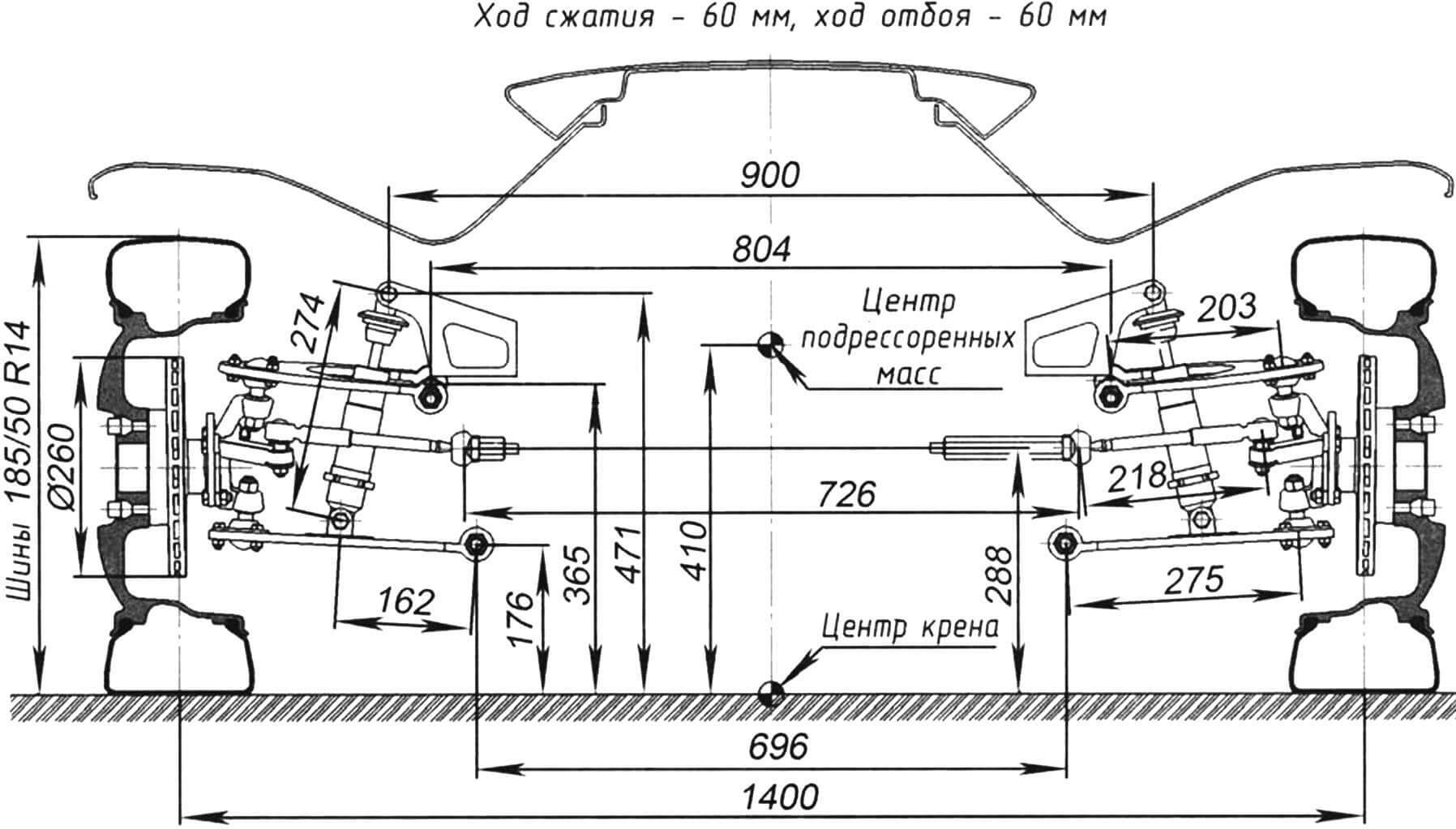

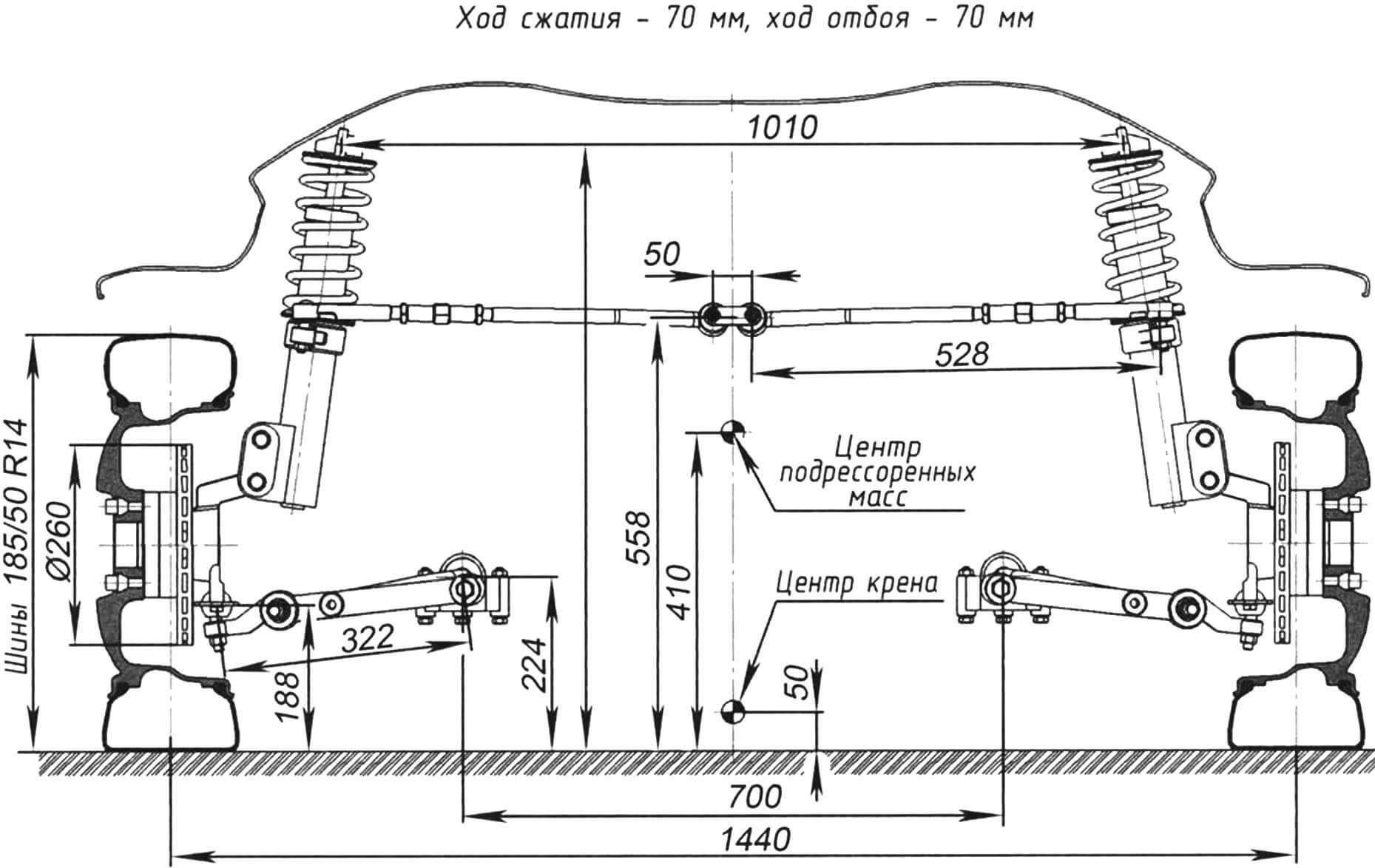

Although the car’s suspension uses parts from production cars, it was designed anew (the kinematics and dynamic characteristics of the springs and shock absorbers were changed). Forged alloy wheels are used on all four wheels, with low-profile tires of rare size 185/50R14. The front suspension is independent transverse double wishbone, made using levers, steering knuckles and hubs from rear-wheel drive VAZ cars. Adjustable shock absorbers, springs made in England, anti-roll bar of original design. The rear suspension is independent, MacPherson type, based on the levers and hubs of the VAZ 2108, the shock absorber struts and springs are original. The steering is rack and pinion, has 2.5 turns from lock to lock, with an imported steering rack and original steering bipods. The braking system uses ventilated disc brakes from the VAZ 2112 on all wheels. There is no pneumatic booster, but the light car brakes very intensively while maintaining sensitivity on the brake pedal. Pedal assembly of original (floor) design. The pedal travel is short, although the effort is higher than in production cars. The hand brake acts through cables on the pistons of the hydraulic rear brake machines. The clutch drive is hydraulic.

The car is very tightly packed. In the front part there is a radiator, tubes from it, which stretch under the central tunnel to the engine. The two-seater cockpit is separated from the engine compartment and the niche in the front of the frame by partitions. Inside the trunk, or rather the front part of the frame truss, directly on the floor, there is a 25-liter fuel tank, a battery, clutch and brake hydraulic cylinders, and a fuse box. A little higher there is a trunk that is quite spacious for a car of this class with a volume of about 70 liters.

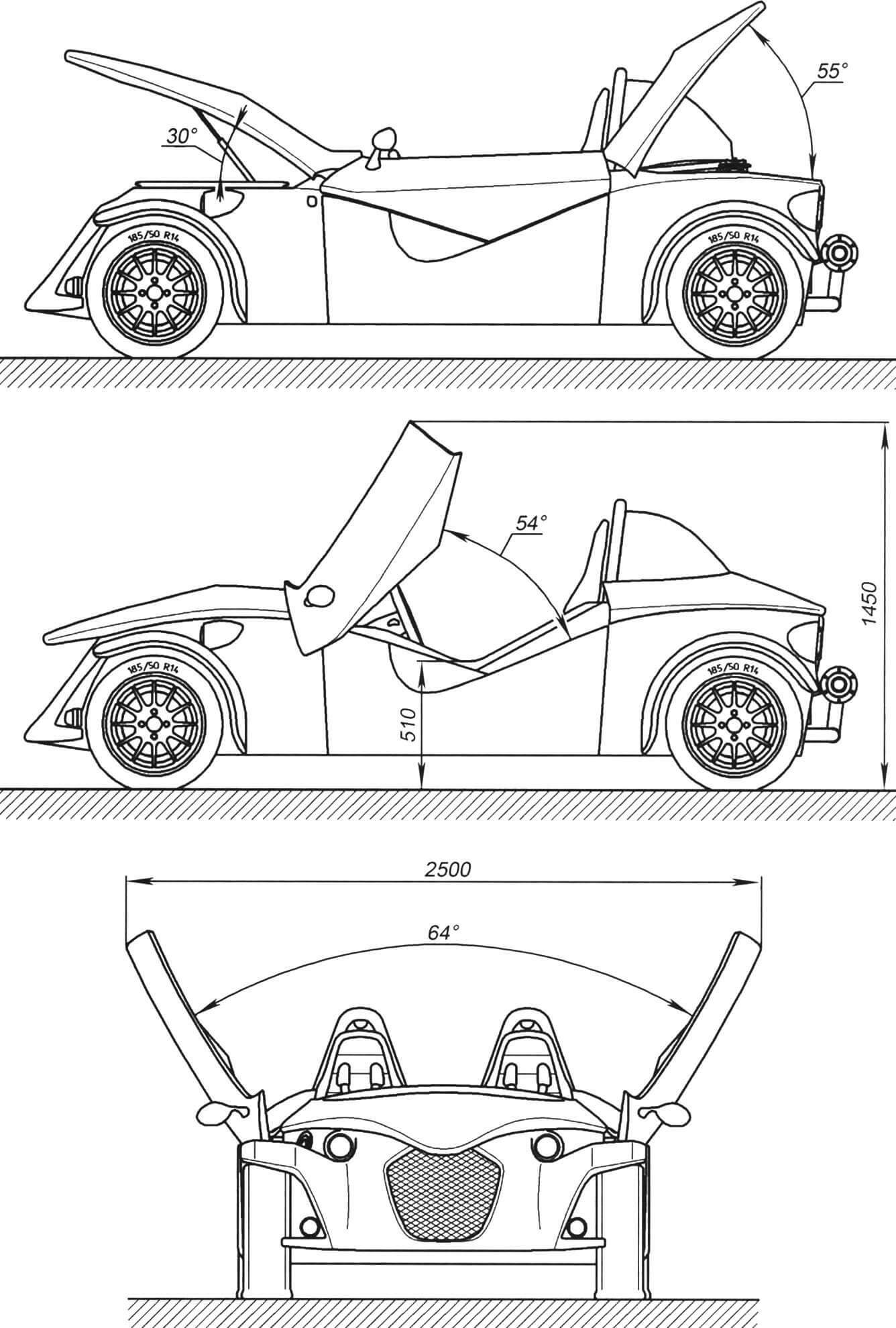

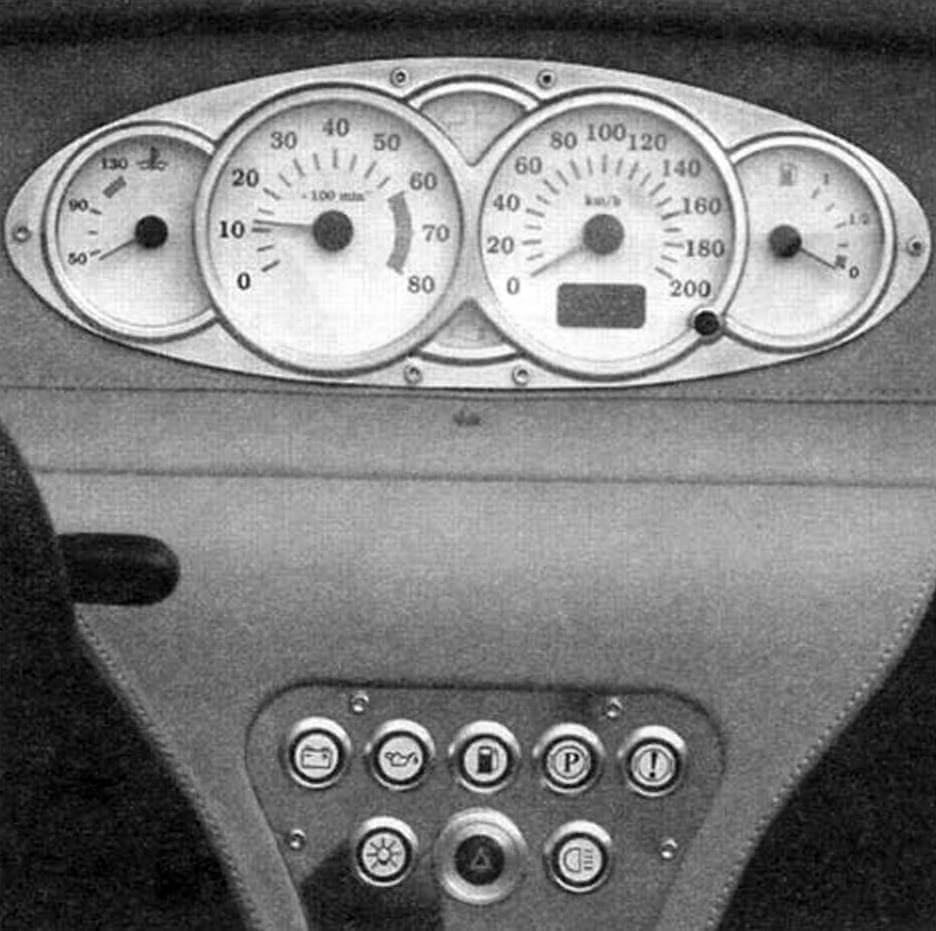

The cockpit floor is made of bakelite plywood 8 mm thick, the walls are covered with panels made of a composite plastic-aluminum sandwich, sheet plastic and fiberglass. The interior of the cockpit is trimmed with black carpet, the interior elements and seat buckets are covered in light beige leather, the steering wheel and gear lever are black. The driver and passenger seats are equipped with four-point seat belts. The original instrument cluster and warning lights are located in the middle of the “dashboard” and are framed by contours of milled aluminum in the style of Spyker instruments. On the floor, in the niches under the seats, there are mounts for a first aid kit and a fire extinguisher. Entry into the cockpit is carried out through two small doors that fold forward and to the sides on gas struts (like the wings of a beetle). There are massive roll bars behind the seats and air fairings behind them. The trunk located at the front is accessed through a massive alligator-type lid, and the engine compartment (at the rear) is accessed through the hood. When raised, the lid and hood are supported by gas struts.

The car’s optics are made from Hella components. Halogen headlights with a diameter of 90 mm have lenses and curtains inside, as a result, a side lamp, as well as low and high beam lamps are located in one compact module. The rear lights are combined, combining dimensions, brake lights and turn indicators. The rear lights are fog and reverse; the reflectors are made in separate housings and are located inside the engine compartment grille. The main front turn signals – orange, domestically produced and for general purpose – are used on trucks, buses, UAZs and other transport equipment. Side turn signal repeaters are from a Skoda Fabia.

The upper part of the car body is painted bright red, the lower part is black. For the coating, acrylic paint without effect (metallic) was used, but a layer of varnish was applied on top of it. After painting, the body panels were polished, which gave the color greater depth and expressiveness to the shades.

The car’s dynamics match its extravagant appearance. The transmission is tuned not so much for maximum speed as for intense acceleration. Rear-wheel drive, 40/60 weight distribution and a limited-slip differential prevent the drive wheels from slipping during a sharp start. The car reacts to the gas pedal with intense acceleration (the driver’s body is pressed against the back of the seat with force), the tachometer needle goes into the “red zone” and requires switching to the next gear. During intense acceleration, the gears have to be changed very quickly.

When braking, the car settles very intensely, but at the same time the weight of the car is distributed evenly to each wheel. It should be noted that the upper arms of the front suspension, tilted back in the longitudinal direction, prevent dive when braking. Since the braking system does not have ABS, the driver has to control wheel locking the “old-fashioned way” – himself.

In straight-line motion on the road, the car is very stable, thanks to the suspension and steering settings, which allowed for minimal lateral movement of the wheels during suspension strokes, and a stabilizing moment on the steering wheel, which is facilitated by a significant caster angle of the steered wheels. The suspension “swallows” bumps and cracks in the road very well. When turning, the car barely rolls, thanks to the low center of mass. At the same time, at moderate cornering speeds, the car behaves confidently and is easily controlled by the sharp steering. This is helped by low-profile tires, an anti-roll bar that loads the outer front wheel, and negative camber on the rear wheels. These measures maximize the permissible cornering speed. When entering a sharp turn at excessive speed, the car even skids: the effect is non-optimal weight distribution (the center of mass is shifted back), requiring a reduction in speed and adjustment of the turning trajectory by the steering wheel. To prevent skidding into a turn, you should enter the turn by first reducing the speed, then, as you pass, straighten the trajectory a little and add “gas” already when passing the turn. Porsche 911 cars demonstrate similar behavior.

Since the car does not have a roof or windshield, the riding sensation is close to that of a motorcycle. Therefore, when driving fast, you need to use an integral helmet, a thick jacket with a “closed” collar and even a woolen scarf.

At speeds less than 100 km/h in the summer, driving without an integral helmet is much more enjoyable: you feel the dynamics of the car better, there is a feeling of merging with the environment, and the rumble of the sports exhaust replaces the music.

Basic technical data of the FOX car

The layout is a two-seat rear-wheel drive roadster.

Vehicle curb weight 550 kg

Weight with two passengers and cargo 720 kg

Weight distribution along the axles with two passengers front/rear in % 40/60

Dimensions:

length 3300 mm

width 1630 mm

height 1145 mm

Engine power 150 hp (110 kW)

Maximum speed 160 km/h (limited by transmission)

Acceleration time to 100 km/h 4 s

Fuel tank volume 25 l

A. ZILIN, Yaroslavl