«Dear editorial board! While reviewing back issues of ‘Modelist-Konstruktor’ from previous years, I became interested in materials about biogas published in issues No. 1’87, 5’88, 4’96 of the magazine. However, I didn’t dare to implement any of the proposed ideas on my farm. But I recently heard from neighbors that in Lithuania, some farmer got their own, more original biogas plant working. I would like to learn the details».

S. IVANCHENKO

In October 1997, the first rural biogas station in the republic was built on the farm of I.Gradyatskas in the Prenai district. Liquid manure from a breeding pig farm, designed to house up to 30 sows and 120—130 head of breeding young stock of different age groups, began to be subjected to anaerobic processing there.

The animals are fed dry feed there. Sawdust is poured as bedding for pigs at a rate of 100 kg/day for the entire herd. Manure from the pens is manually pushed into the channel of the scraper conveyor TSN-160, which moves it into a buried container with a capacity of 12 m3. From the container, manure enters the bioreactor.

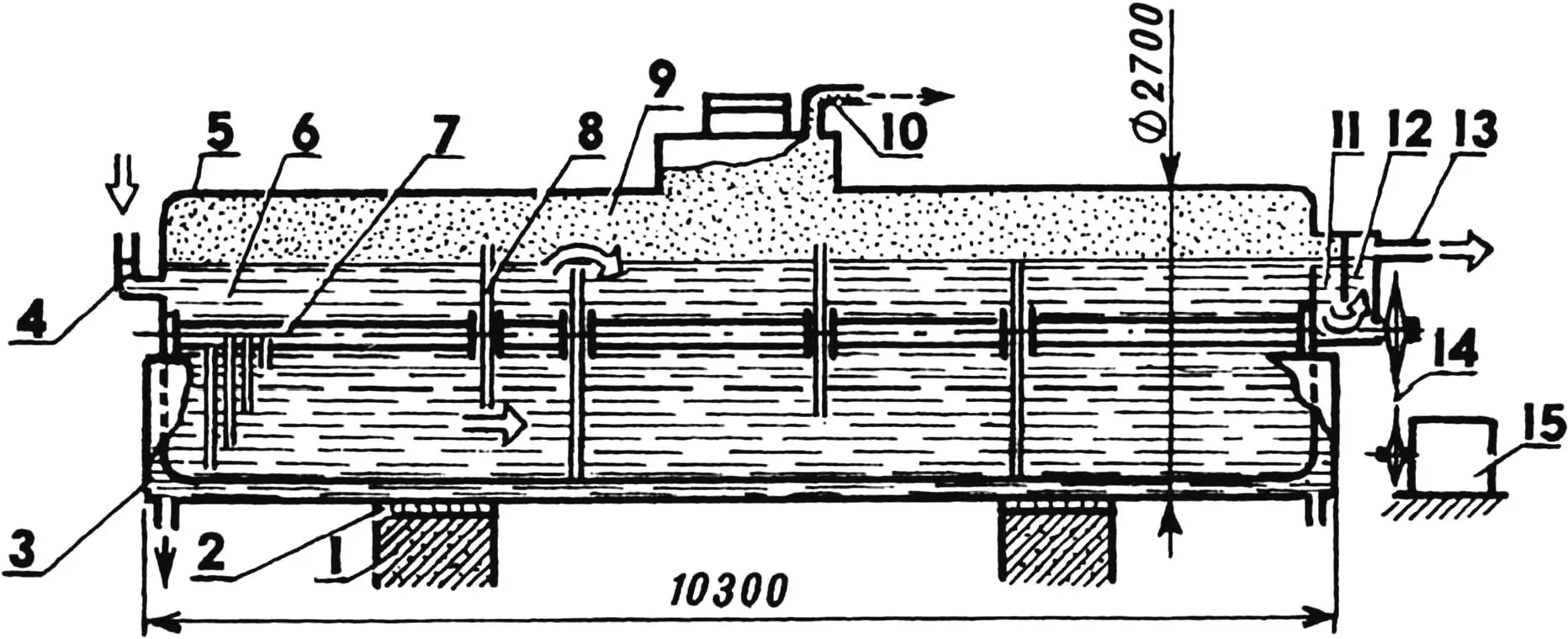

1 — concrete base (2 pcs.); 2 — thermal insulation “cushion” (2 pcs.); 3 — heater with thermofication water (“thermal jacket” of the base railway oil tank car); 4 — raw material intake pipe; 5 — bioreactor body (tank car); 6 — raw material (liquid manure); 7 — mixer shaft with blades; 8 — sluice partition (4 pcs.); 9 — biogas; 10 — gas pipeline pipe; 11 — processed biomass; 12 — siphon lock; 13 — processed biomass pipeline pipe; 14 — chain drive; 15 — motor-reducer (220 V, 3 kW)

The bioreactor is made from a railway tank car. It has a double bottom — this is a “thermal jacket” for circulating hot water that heats the contents of the tank car.

According to the phases of the biochemical processes of anaerobic treatment — hydrolytic (ion exchange between various substances and water), acidophilic (fermentation by special bacteria) and methanogenic (methane is formed during the decomposition of organic substances without access to air) — the bioreactor cavity is divided by sluice partitions into three sections. A mechanical mixer shaft with blades made of steel angles, arranged in a helical line, is mounted along the longitudinal axis.

The tank car capacity is 60 m3, useful capacity — 50 m3. The anaerobic treatment temperature is 35—37 °C. Thermoregulation, i.e., the supply of heat carrier (water), is automated. The design daily manure loading dose is 2.5 m3, the design biogas output is 50—60 m3/day. The mixer rotation frequency is 4 rpm, drive from a motor-reducer with a power of 3 kW. The mixing mode is cyclic: operation — 1 min, break — 4 min. The bioreactor is installed under a roof and insulated with upholstery with wood sawdust.

Manure from the storage is fed into the bioreactor by pump NZHN-200. At the same time, its processed contents are removed. Overflowing through sluice partitions and a gas-separating siphon, it goes through a pipeline to an organic fertilizer accumulator — a container located in the manure sector of the pig farm.

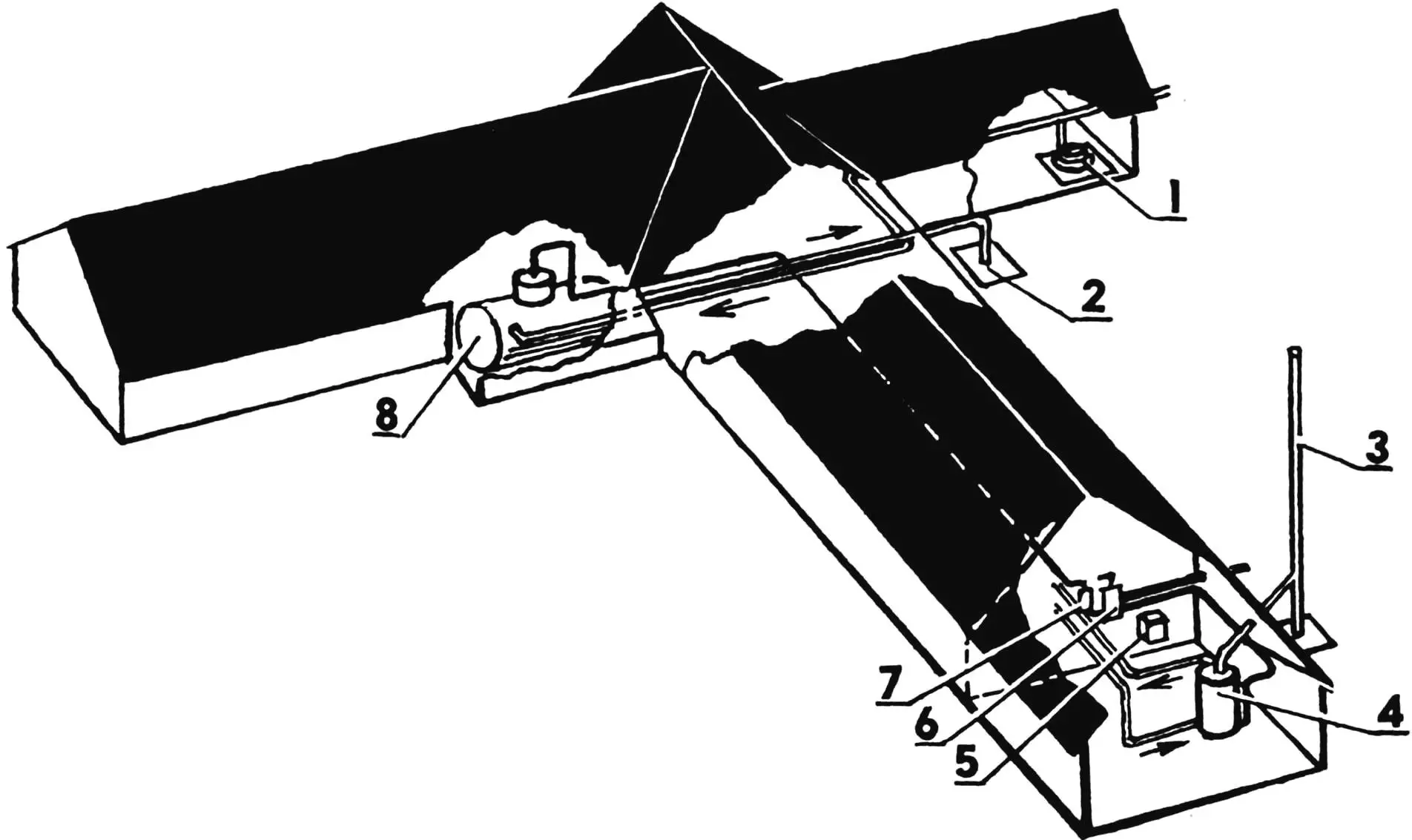

The gas produced in the bioreactor is directed to the boiler room. And the thermofication water (heat carrier) goes to heat the bioreactor and production facilities.

1 — pump NZHN-200; 2 — processed biomass accumulator (organic fertilizers); 3 — chimney; 4 — gas boiler (other biogas consumers are conditionally not shown); 5 — control panel; 6 — pressure regulator; 7 — biogas meter; 8 — bioreactor

The experimental biogas station was tested from October 1997 to April 1998. Over seven months, about 400 m3 of liquid manure was processed, from which 3800 m3 of biogas was obtained. The average production of “blue fuel” is 19 m3 per day — this is 38 percent of the bioreactor’s design capacity. The low biogas output is due to the small number of animals on the farm. More precisely, the insufficient amount of manure obtained from pigs and the deficiency of dry organic substances in it.

Studies, performed in parallel under laboratory conditions and on the farm, have established that when feeding pigs dry concentrates, 0.3 m3 of biogas is produced per kilogram eaten. Therefore, to ensure the design capacity of the bioreactor, the pig farm herd should be increased by 2—3 times.

Inspired by the experiments, I.Gradyatskas plans to expand his farm, bringing the number of animals kept there to 400 head. So, there are prerequisites for obtaining higher indicators in biogas output as well.

«Modelist-Konstruktor» No. 1’2001, A. ANTSYUNAS, R. YANUSHAUSKAS, Lithuania