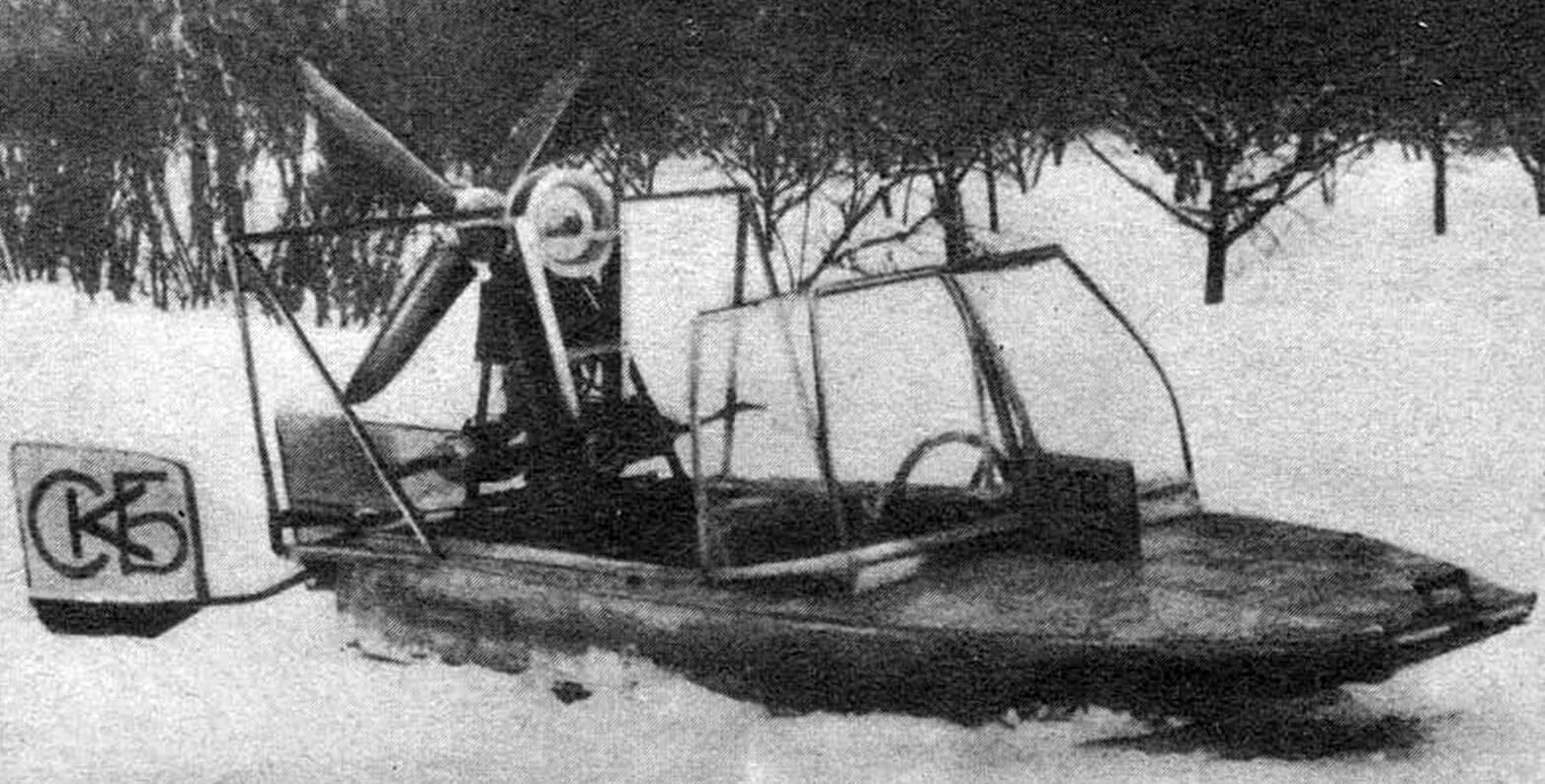

Any snowmobile, including amphibians, has a relatively low load-carrying capacity, and therefore their use is fully justified only under certain operating conditions, which will become clear from what is said below. Our amphibian is a combination of a pleasure boat and a ski. The shape of its bottom is designed for planing on water and snow, without any alterations or changes during operation. In planing mode, the amphibian provides the best driving performance.

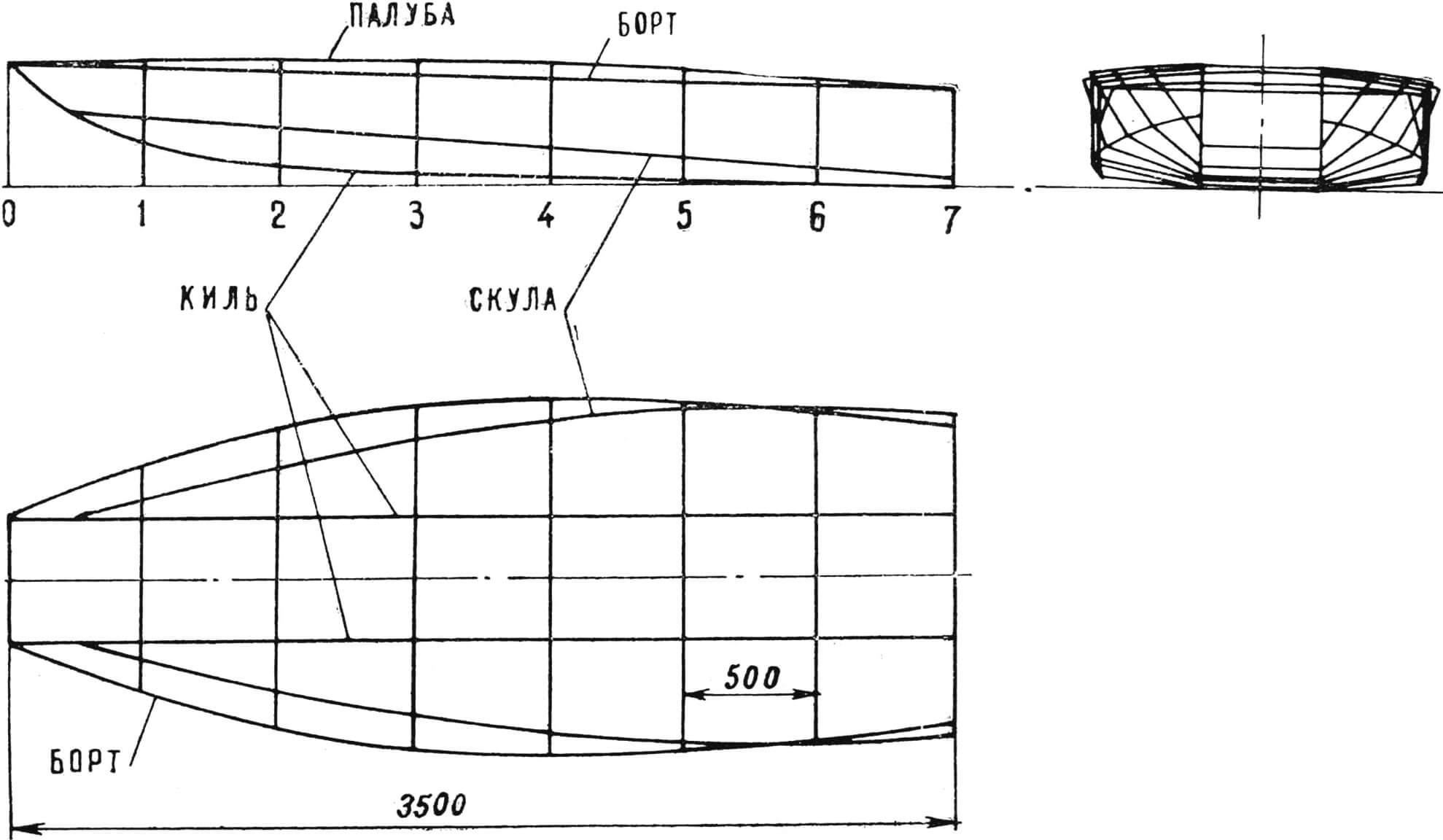

Boat hulls are specified by ordinate tables and theoretical drawings. We offer an amphibious hull option designed for a payload capacity of 200-250 kg (Fig. 1). Hulls with similar contours can also serve as good pleasure boats with outboard motors. Their appearance is shown on the tab.

The method of constructing the hull is practically no different from that described in shipbuilding literature. Work begins with the manufacture of frames, their installation on a rigid horizontal base – a slipway – by connecting the frames with slats along the keel, chine, sides and deck. Then six bottom and two side longitudinal rails – stringers – are attached. To improve shock absorption of the hull, the stringers should protrude 10-12 mm below the frames. After careful external processing, the frame is sheathed with duralumin. A polyethylene sheathing is attached to the bottom using K-153 glue, which is additionally pressed along the ski-shaped part by three runners – undercuts, and along the cheekbones – with a stainless steel corner. The first two bow frames are sewn up tightly and serve as a pressurized compartment. Inside the aft part along the sides it is necessary to install float tanks with a total volume of at least 80 liters. It is also necessary to provide for sealing seams, sockets for rowlocks of oars and other equipment.

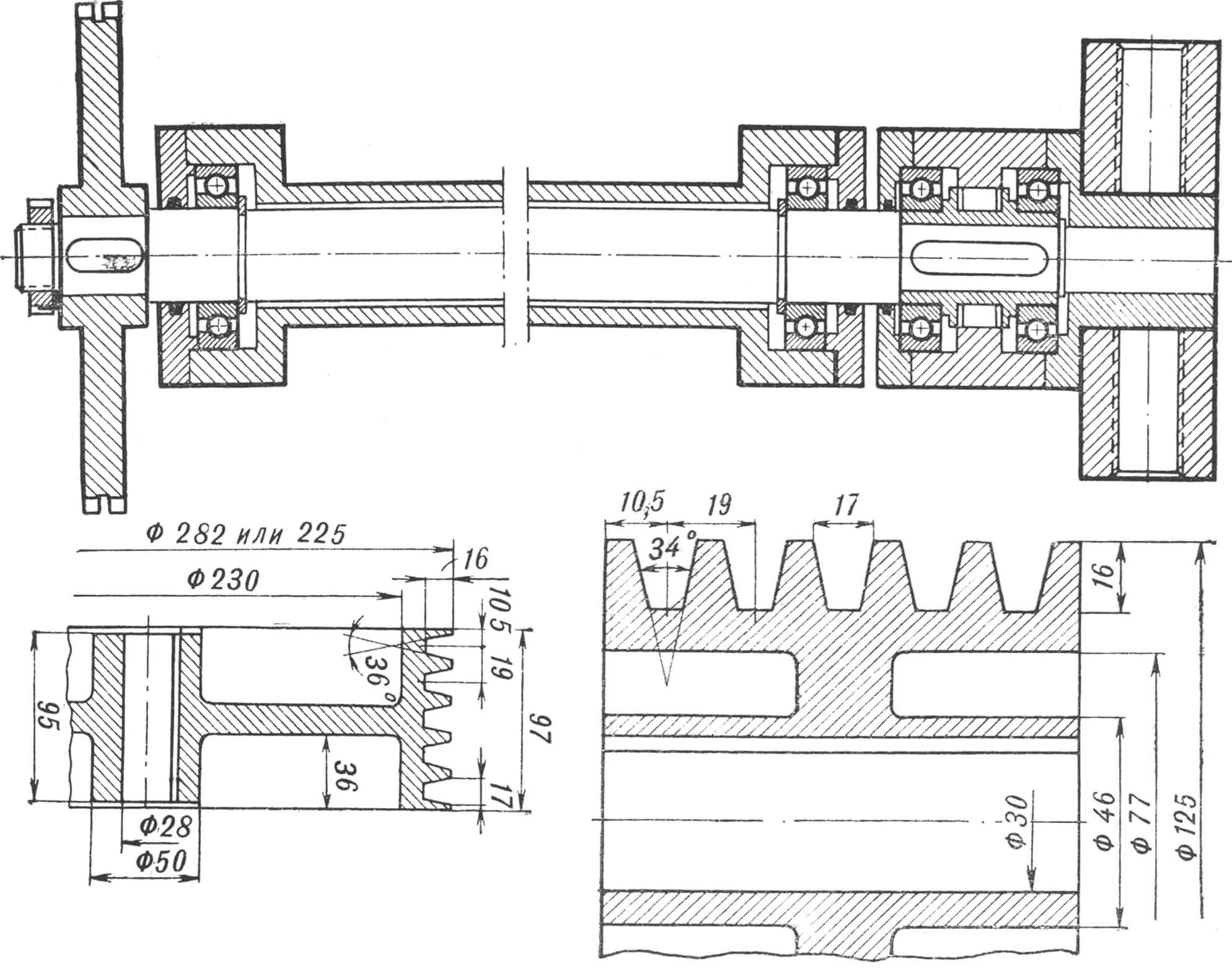

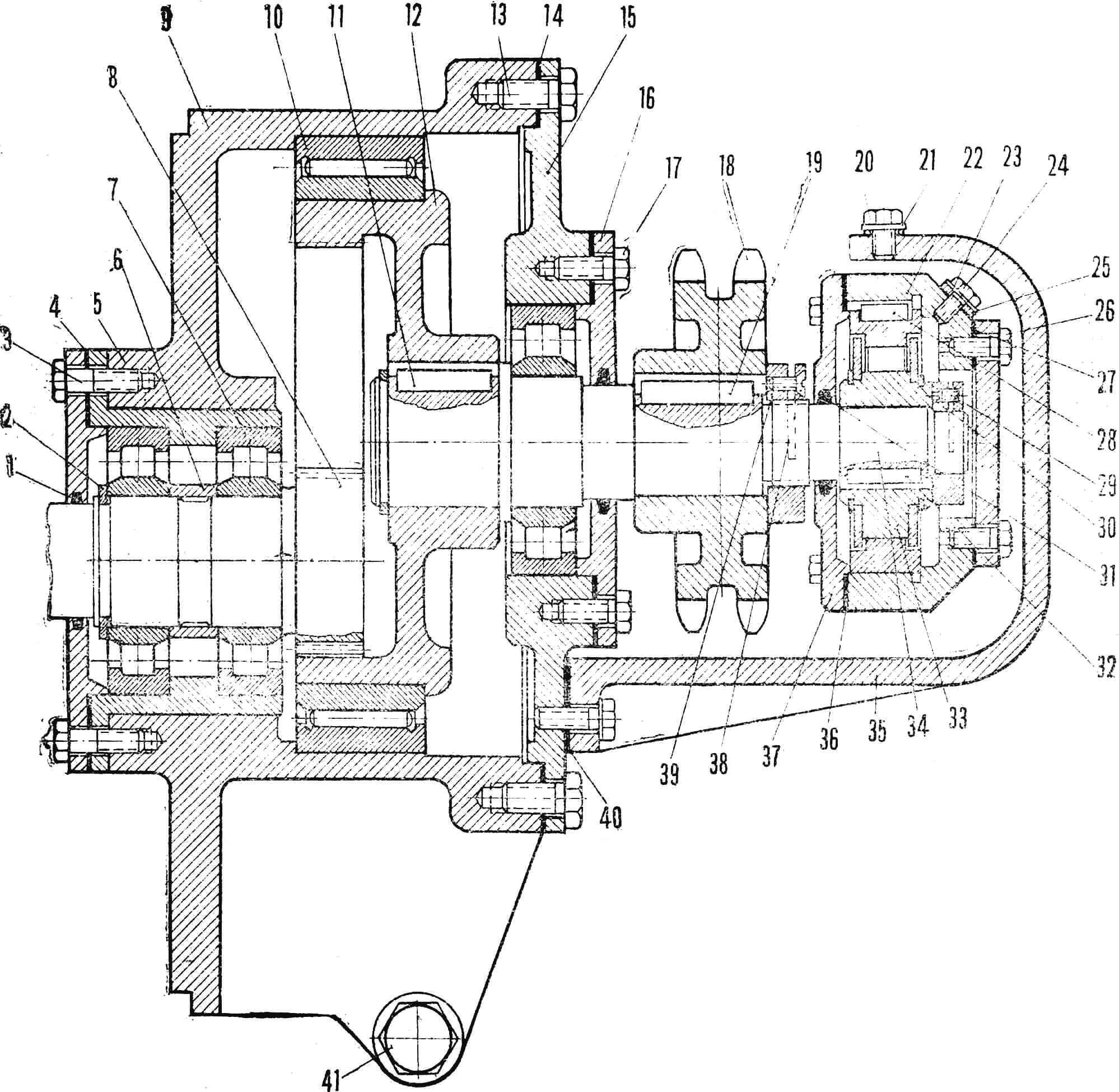

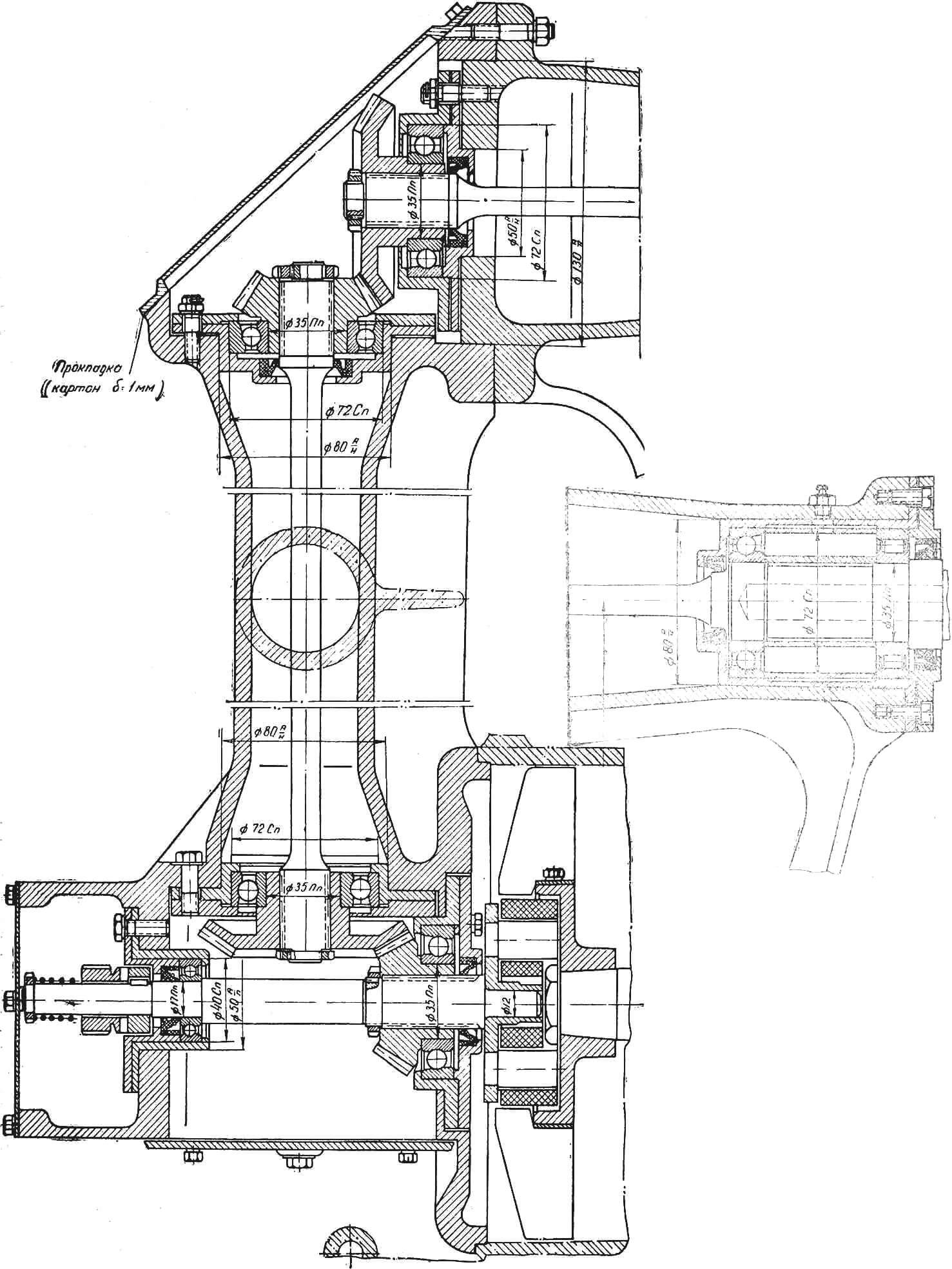

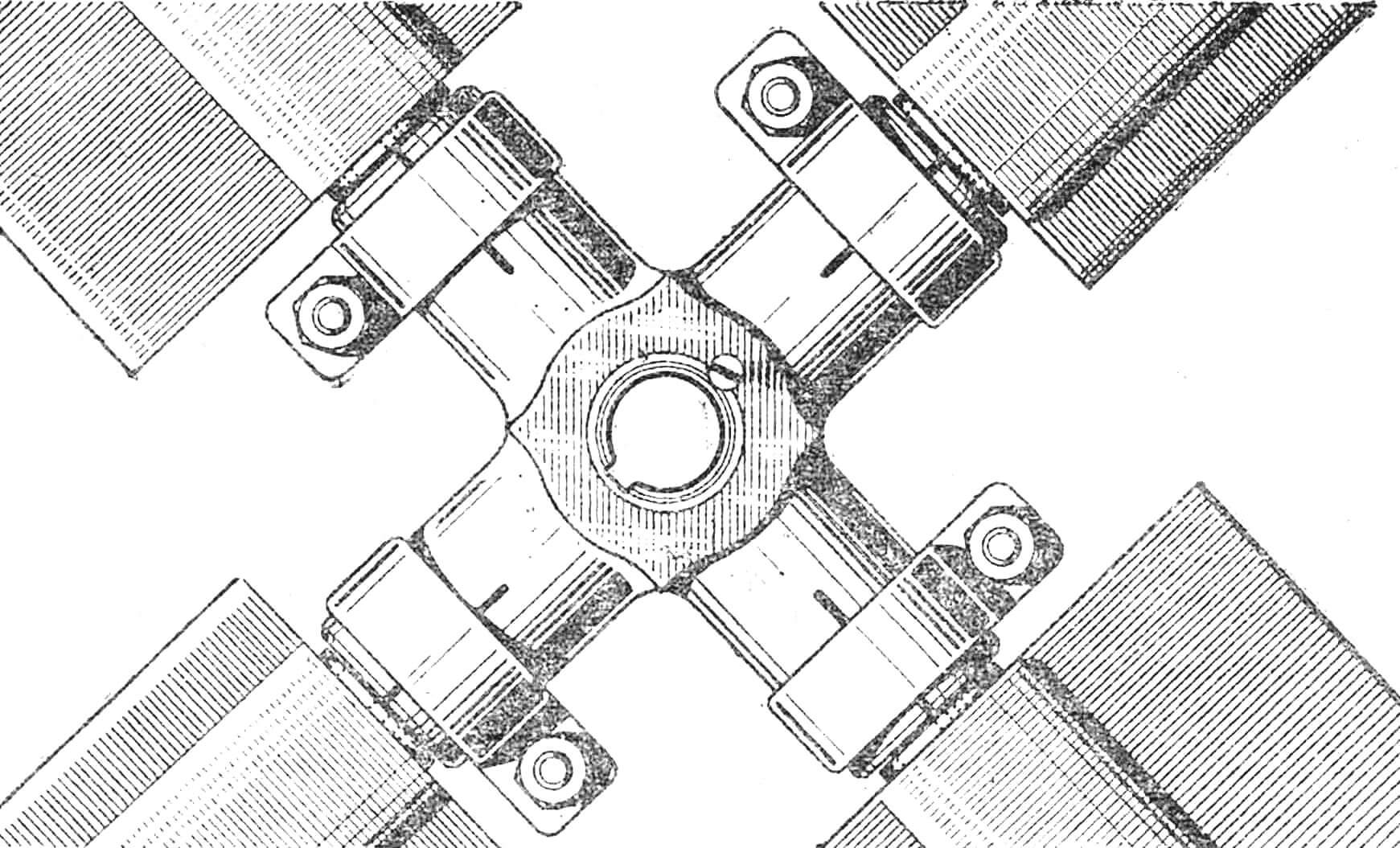

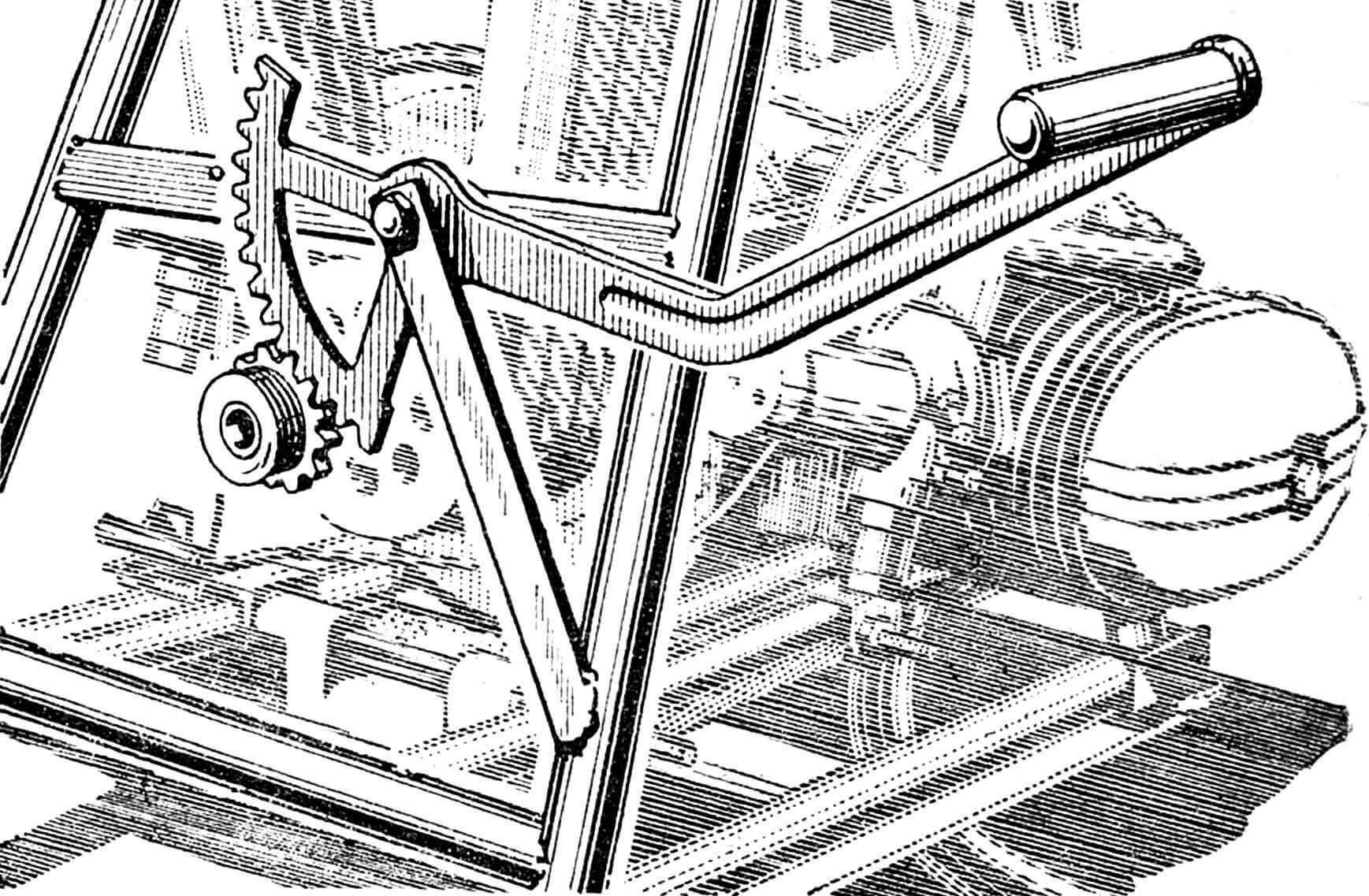

The propeller installation is assembled on an engine from motorcycles M-72, M-62, K-750. The propeller is four-blade, 2000-2500 rpm, mounted on a tubular frame. The transmission of force from the engine to the propeller can be carried out in the following ways: a chain reducer (Fig. 2), a gear reducer with a chain to the propeller (Fig. 3), a bevel gear reducer with transmission rollers (Fig. 4), V-belts. The simplest chain transmission; The only difficulty is to select a chain that matches the given load and engine speed. We recommend double-row drive bushing chain 2 PV-9, 525 GOST 10947-64. The number of teeth is selected based on 4000 rpm on the motor shaft. The drive sprocket is attached to the flywheel. With a gear reducer, you can use a double chain from an IZH-56 motorcycle. A gearbox with bevel gears is the most reliable, but more complex; it can only be made in a factory. Textrop transmission is relatively bulky; it uses five series B belts with a length of 1600-1800 mm. In all cases, the chain and gears should be lubricated, for which a breather tube can be connected to the chain. The propeller shaft hub is made for bearings No. 206 and angular contact roller bearings 7506.

1 — seal, felt; 2 — ring NK35. steel 65G; 3 — bolt M6x20, steel 35; 4 — adjusting gasket, steel 10; 5 — glass, steel 45; 6 — intermediate ring, steel 45; 7 — radial bearing No. 207; 8 — gear shaft, steel 40ХН; 9 — body, silumin AL-2; 10 — needle bearing No. 4024826; 11 — key 10x8x25 mm, steel 45; 12 — gear wheel, teeth — 73, steel 40Х; 13 — bolt M8x16, steel 35; 14 — gasket Ø 210 mm; 15 — housing cover, silumin AL-2; 16 — bearing cover, steel 35; 17 — bolt М6×16, steel 35; 18 – asterisk. steel 45; 19 — key; 20 — bolt M5x8; 21 — washer 5; 22 — clip; 23 — M4x8 bolt; 24 — washer 4; 25 — seal Ø 10/5×1; 26 — bolt M5X12; 27 — gasket: 28 — key 5x5x14; 29 — M3X6 screw; 30 – round nut; 31 – seal; 32 — key 6x6x20; 33 — coupling 1-50×20 MNZ-61; 34 – shaft; 35 — casing; 36 — gasket Ø 90Х70Х1; 37 — clip cover; 38 — M4x8 screw; 39 – round nut; 40 — gasket Ø 170X120x1; 41 – bolt M10X175.

The most painstaking, responsible and time-consuming part of the work is the creation of a propeller, especially the processing and polishing of the blades. We offer a four-bladed metal propeller consisting of individual blades, which allows you to change its pitch during adjustment and operation (Fig. 5). When using engines of lower power, the propeller can be selected from two or three blades.

It is very tempting to use a reversible propeller, especially for braking. For additional cooling, a fan impeller with blades beveled to the right is installed on the flywheel. If possible, magneto ignition should be installed (Fig. 6). It is necessary to achieve a pulling force from the propeller of the order of 4 kg per 1 liter. With. engine power. For the M-72, you can get thrust “in place” of up to 85-90 kg. With the “quality” of the snowmobile, that is, the ratio of the traction force “in place” to the total weight, equal to 0.2, we get a total weight of about 400-450 kg.

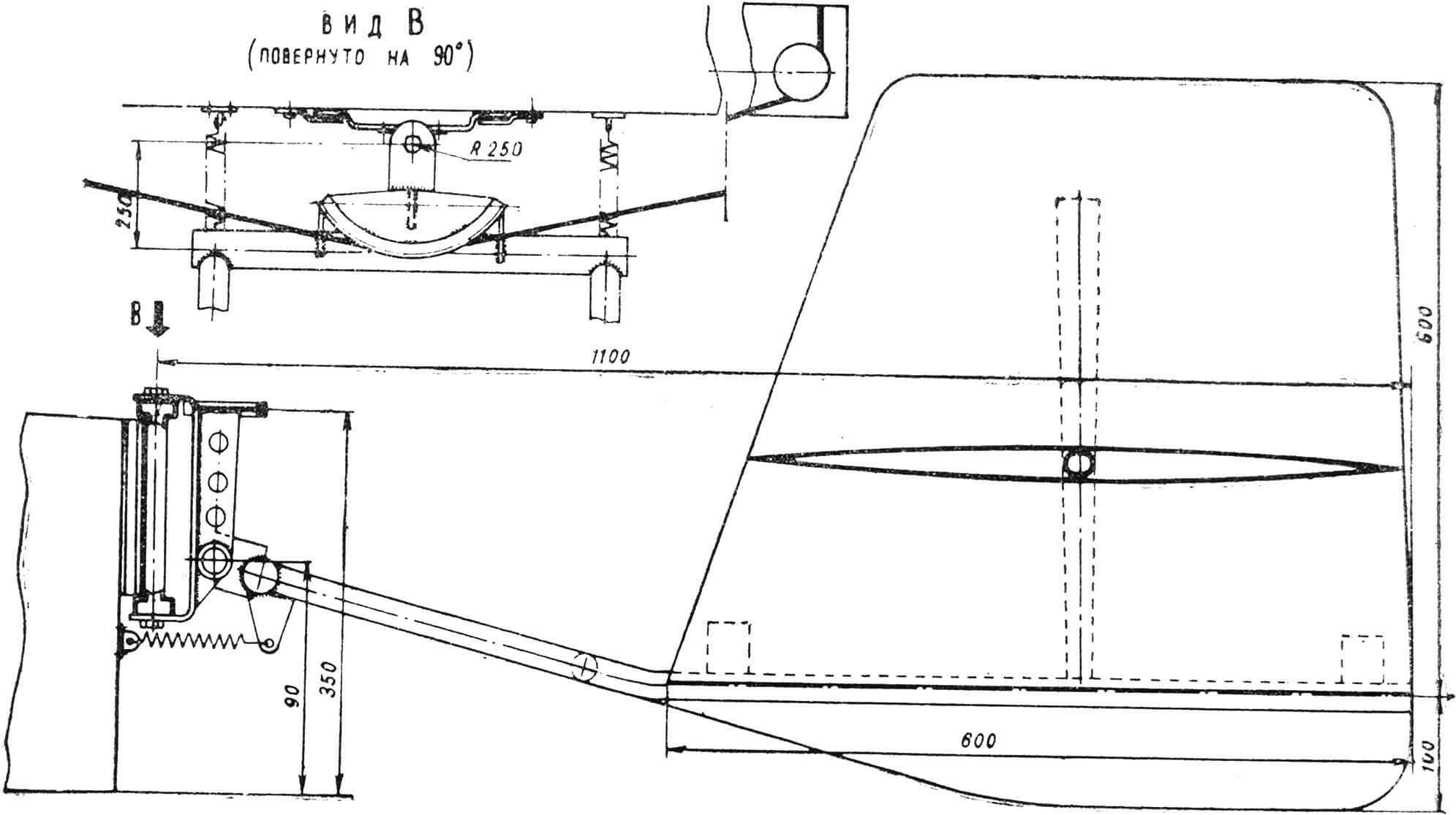

To control the NETI amphibian, combined spring-loaded rudders are used (Fig. 7), interacting with snow and air flow. The movement of the rudders in the vertical plane should be somewhat limited. Steering wheel play is extremely dangerous. You can attach both pin and scraper brakes to the transom, which will ensure good braking of the amphibian. On water there is no need for a brake. The amphibian is suitable for use all year round: in winter on snow and water, in summer on water, reeds and partly on small bushes and grass.

Materials required for making the case

Bottom: sheet duralumin D16AT 1.5-2 mm thick; sheathing – polyethylene sheet 3 mm thick. You can use nylon, vinylprose, fluoroplastic and stainless steel (however, the latter will freeze to the snow when the amphibian leaves the water in severe frost).

Side sheathing: D16AT duralumin, 1.2-1.5 mm thick; deck covering: 3 mm plywood or AMO duralumin—1 mm; frames: 2 mm duralumin; chine and sides; corner D16AT size 30X30 mm.

Keel: channel D16AT size 60X60X3 mm; stringers – channel D16AT size 30X25X2 mm.

For runners and undercuts, you can use stainless steel strip measuring 40X5 mm. (In the area of the center of gravity, an undercut edge 100 mm long and 10-12 mm high is welded perpendicular to the strip to prevent skidding when driving on a hard, well-worn road. Duralumin D16AT is very hard, but when heated to 500° it becomes soft for 2-3 days and is easy to handle.) The center of gravity is at a distance of 1/3 of the total length from the norm. The frame can also be made from wooden slats, which will greatly simplify all the work, but the strength will decrease.

Three thousand letters to designers, a thousand to the editors of our magazine – this is the reader’s response to the little information published in No. 9 of 1968. It told about the work of the student design bureau “Amphibian”, headed by graduate student V. Sboev, at the Novosibirsk Electrotechnical Institute, and about light amphibious snowmobiles created by young technology enthusiasts.

And here are the drawings of the NETI-3 snowmobile in front of you. As always, we tried to give them as completely as possible, and make the text explaining them extremely concise, because the language of technology is drawing.

Table of plasma ordinates

| Height (mm) | Half width (mm) | ||||||

| Keel | Cheekbone | Board | Deck | Keel | Cheekbone | Board | |

| 433 | — | 433 | 433 | 202 | — | 202 | 0 |

| 138 | 138 | 450 | 477 | 202 | 202 | 483 | 1 |

| 51 | 117 | 451 | 492 | 202 | 354 | 627 | 2 |

| 20 | 97 | 441 | 477 | 202 | 477 | 675 | 3 |

| 5 | 77 | 418 | 446 | 202 | 553 | 684 | 4 |

| 0 | 58 | 390 | 405 | 202 | 577 | 684 | 5 |

| 0 | 37 | 350 | 354 | 202 | 571 | 674 | 6 |

| 0 | 19 | 302 | 302 | 202 | 550 | 657 | 7 |

Just one small piece of advice for those who are going to build snowmobiles like the ones in Novosibirsk – the activists of SKB Amphibia asked to pass it on to the readers: work in a team, because, despite its apparent simplicity, an amphibious snowmobile will require both technical savvy and calculations from you, and “speculation” of a number of components, based on the availability of parts and equipment. So, “NETI-3”…

TECHNICAL DATA

The engine is from an M-62 motorcycle with a power of 28 hp. With.

Total weight – 400 kg.

Own weight – 150 – 160 kg.

The weight of fuel and tools is 50 kg.

Payload – 200 ng.

Body length – 4 m.

Width – 1.6 m.

Height with screw – 1.8 m.

Recommended speed: on snow – 50 km/h, on water – 35 km/h.

V. SBOEV, head of SKB Amphibia, Novosibirsk