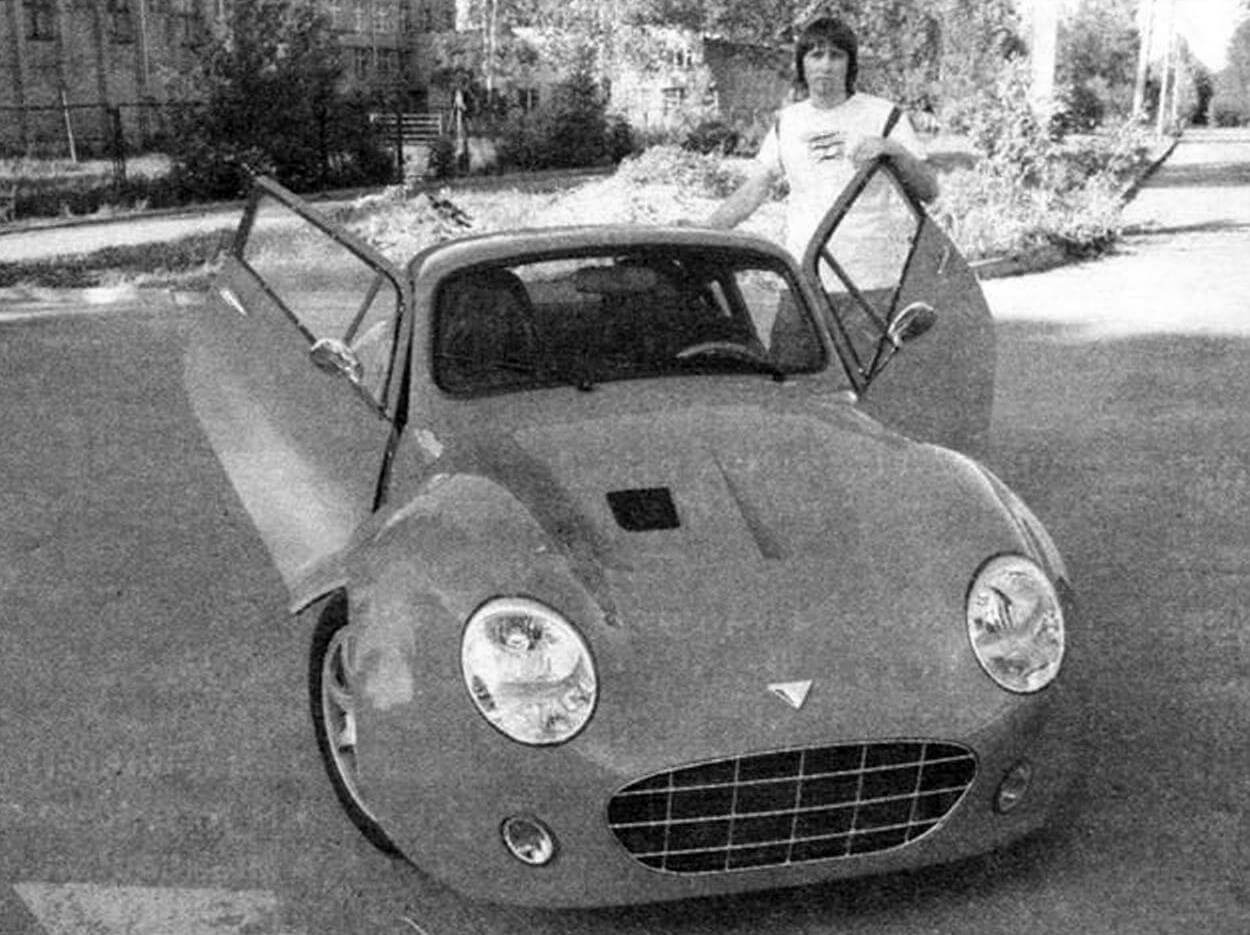

The Pegasus automobile studio, which builds cars of the same name, was founded in Yaroslavl in 2003 by Vadim Shustrov. At that time, he had just graduated from Yaroslavl Polytechnic University. But he had experience of close communication with the guys from the MAMI and NAMI design bureaus. He was inspired to create his own car by Pegaso cars, produced in small series in the 1950s and 1960s in Spain. In addition, Vadim liked English sports cars manufactured using kitcar technology.

Vadim Shustrov conceived the idea of building a light and compact two-seater coupe using components from serial passenger cars. This approach made it possible to make an original car from the most accessible units and components. If necessary, it was possible to change the configuration and use more advanced units and components. The basic donor for the future car was the Oka car.

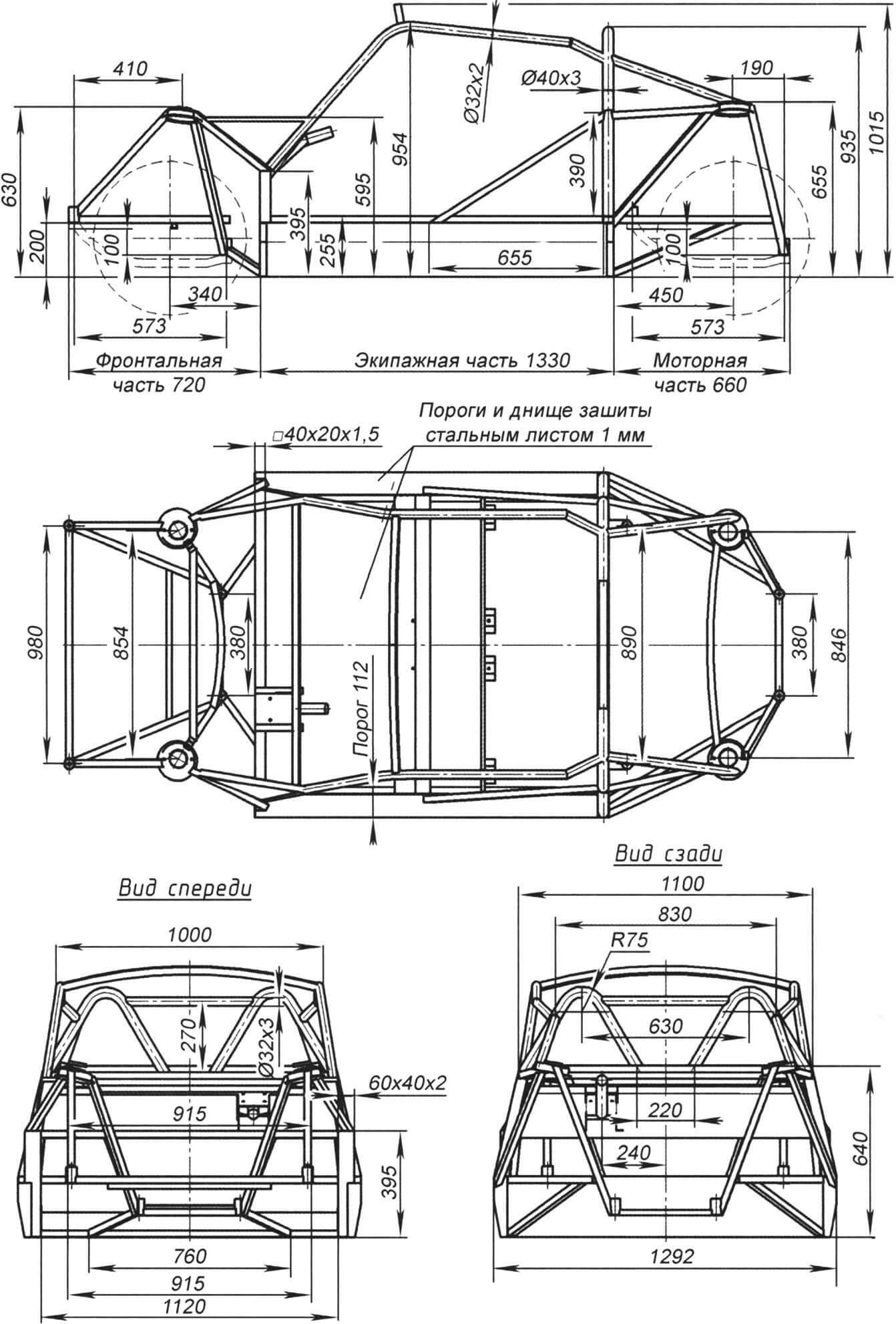

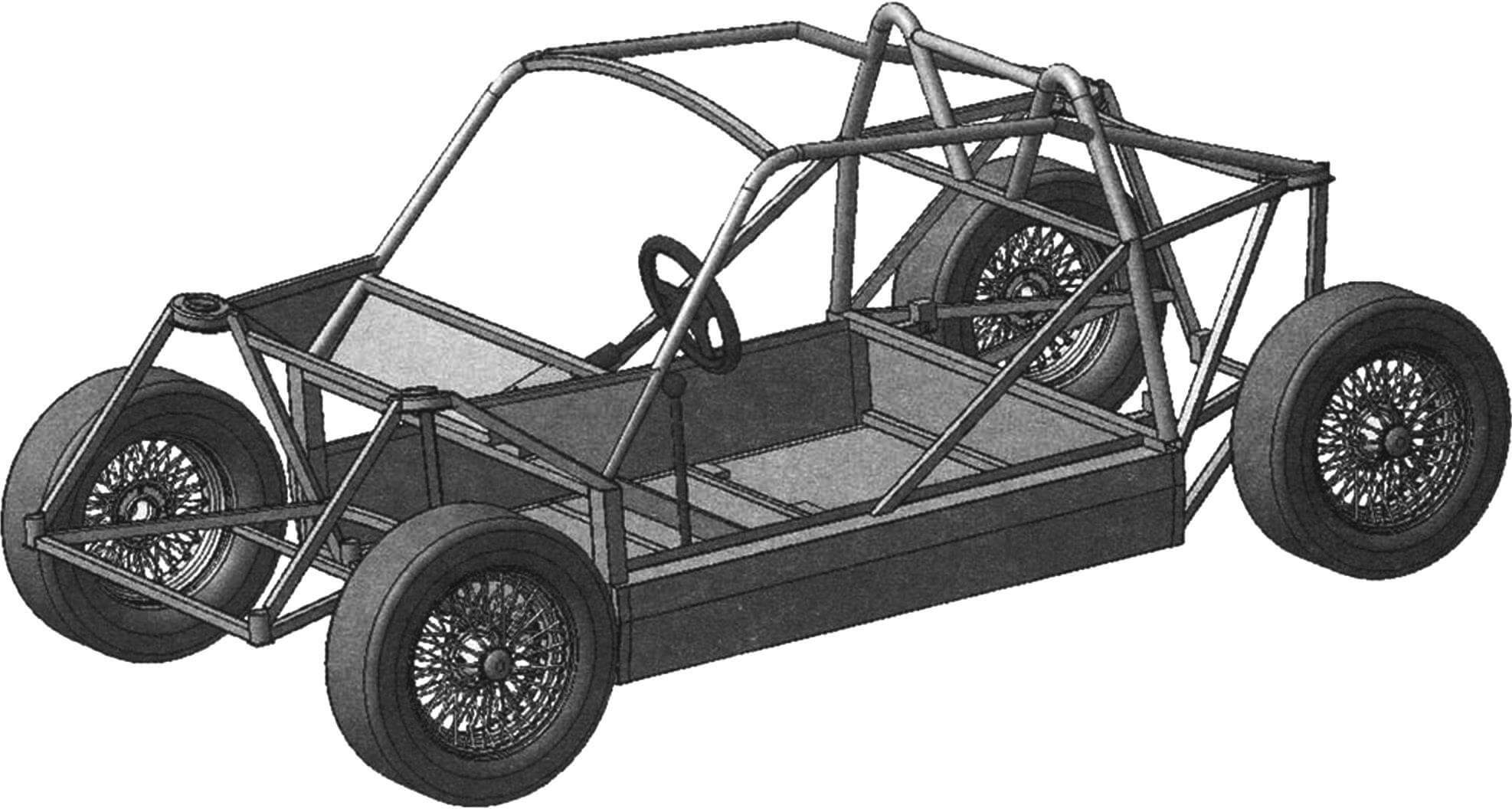

Previously, only a profile sketch of the car was drawn, vaguely reminiscent of the profile of Spanish cars, and a rough model was made from plasticine. An important part of the work was the production of a landing model from wood and metal, which made it possible to determine the dimensions of the frame and the layout of the car as a whole. The landing mock-up below had the shape of a “trough” formed by high sills and the bottom; in the area of the windshield and on top, part of the roof from the “humpbacked” ZAZ-965 was used for mock-up purposes. Seat frames were placed inside, behind which safety arches were formed. By moving the seats, the optimal seating position, position of the steering wheel and pedals were found.

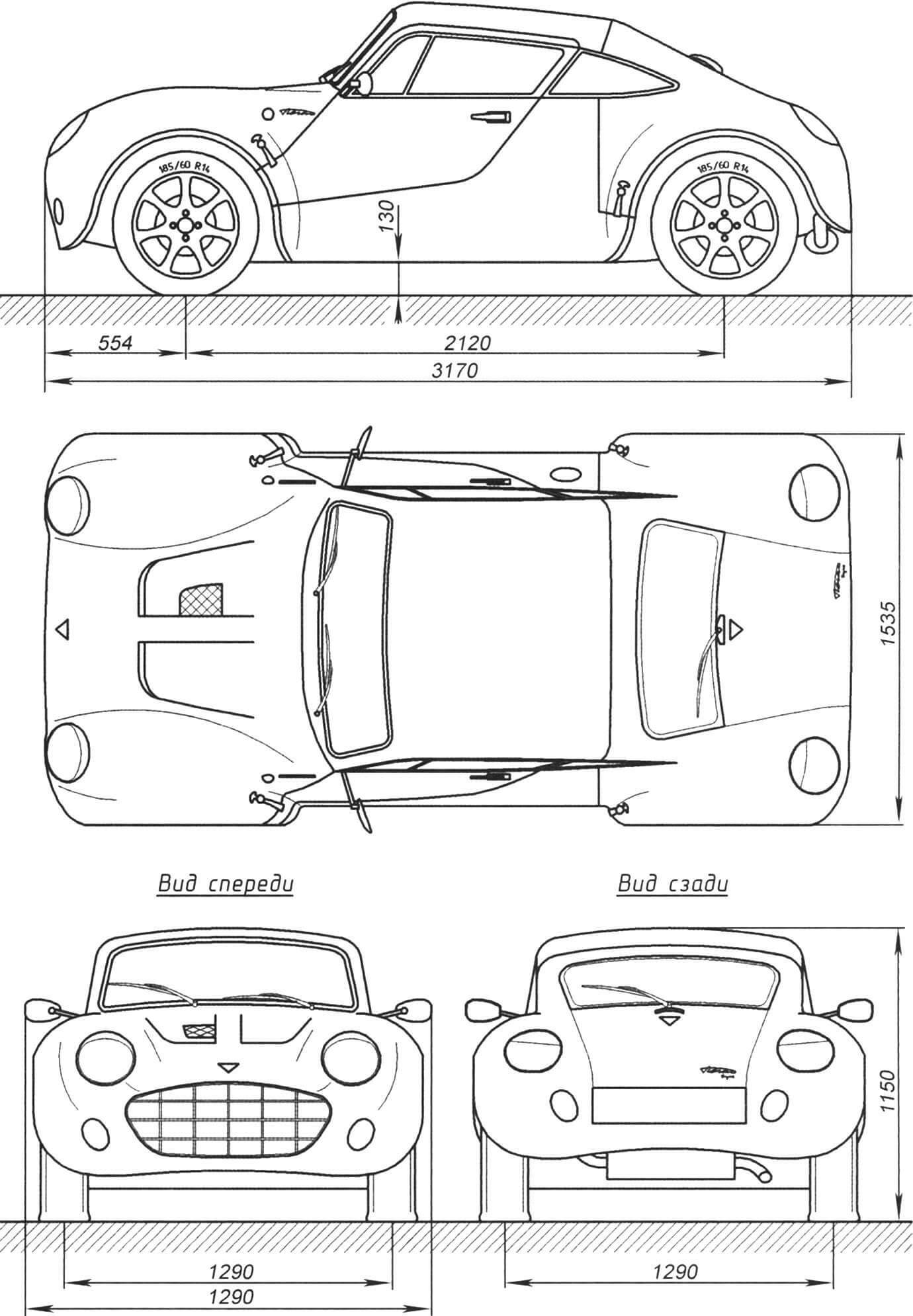

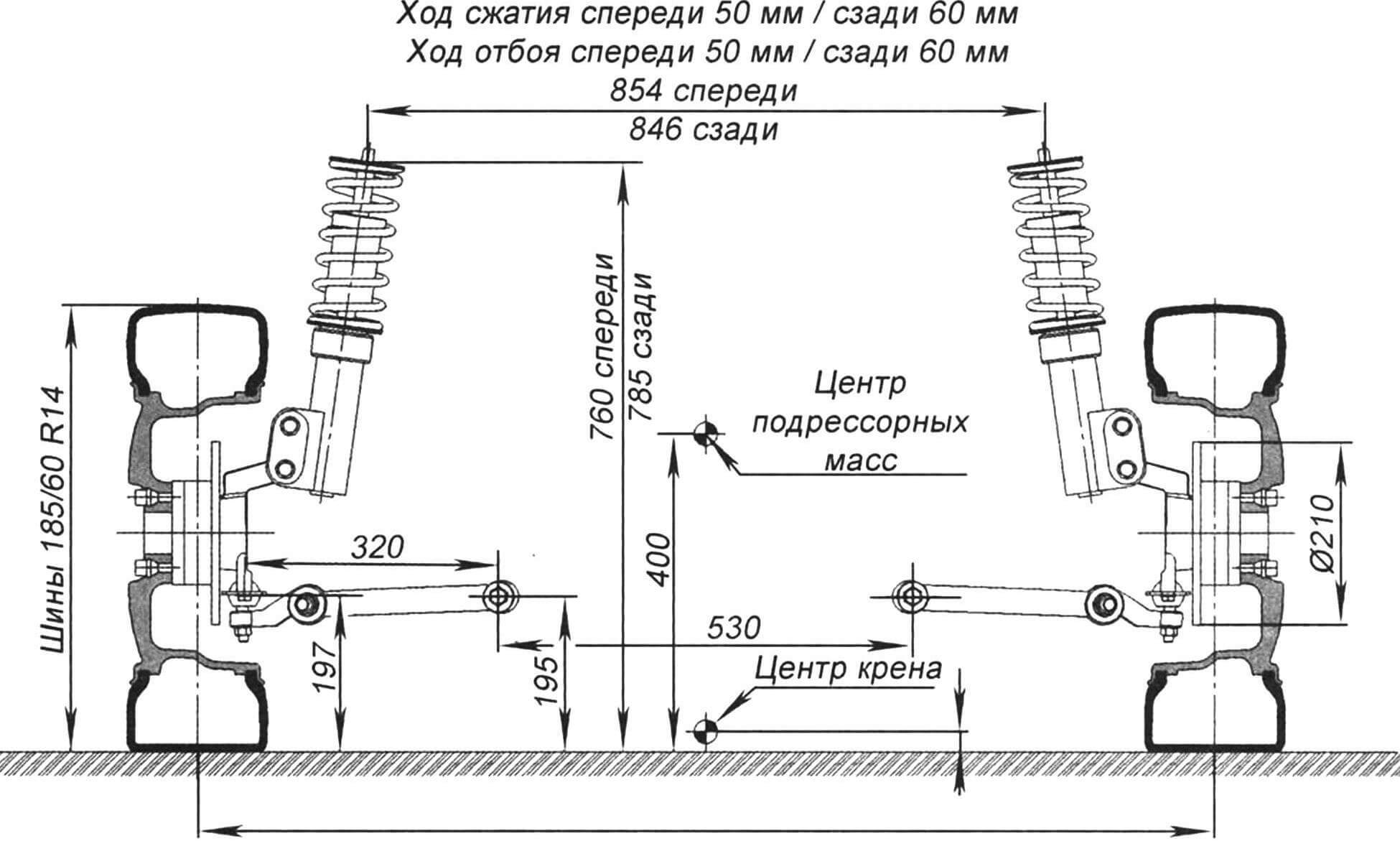

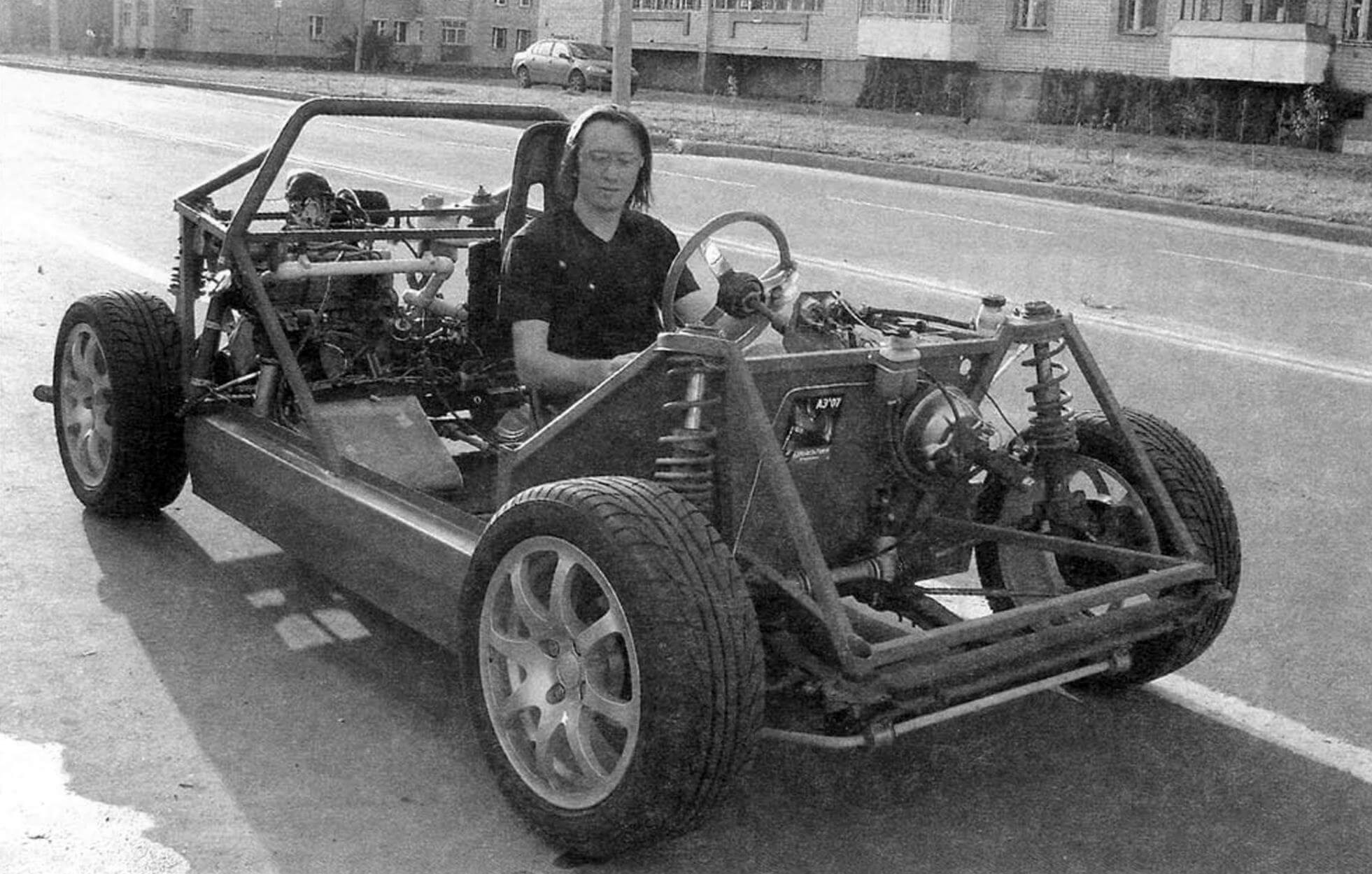

The front and rear suspensions of the car were supposed to be used from the front suspension of the OKA car with some modifications. The landing mock-up had a special subframe with mounting points for the suspension, steering rack and power unit. In addition, the serial “OKA” has a weight distribution in the equipped state that is close to ideal 50/50 along the axes. This moment affected the geometry of its suspension – there are no significant changes in it. Thus, in order to form the chassis of the future car, it was necessary to provide the frame with attachment points for standard subframes and use them as conductors for welding. On the model, using pendants mounted on subframes, the base of the future car was found. The wheel track was widened to 1290 mm compared to 1210 mm for the donor.

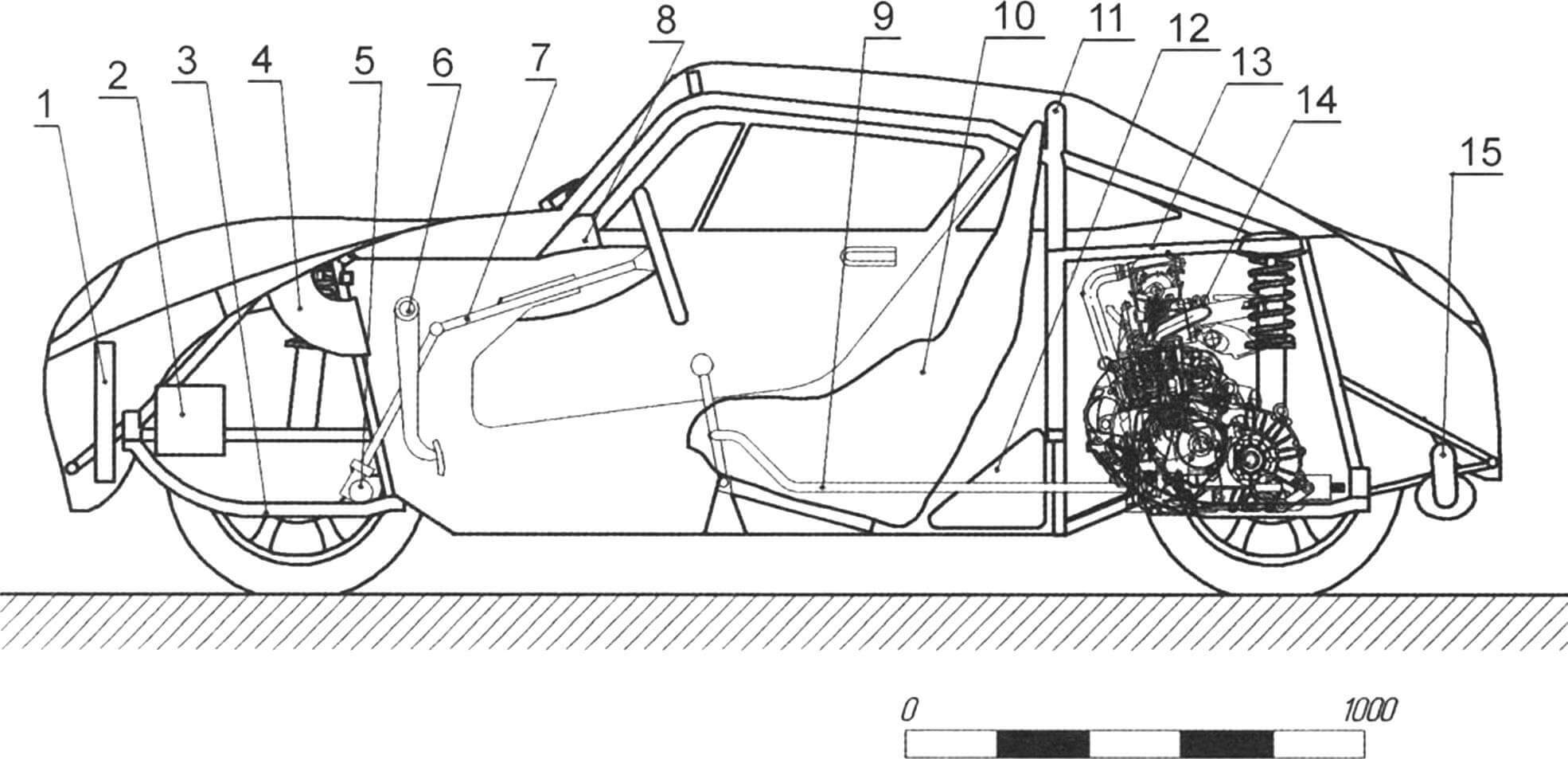

The construction of the landing model was completed with the creation of a frame for the car chassis, consisting of three basic parts: the central part with an integrated safety cage (crew), the front part with a subframe, front suspension and steering, the rear part with a subframe, rear suspension and power unit. The material for the frame was rectangular, square and round pipes of different sizes and a steel sheet 1 mm thick to form high thresholds, the bottom of the car and the fire bulkhead between the engine and the passenger compartment. Frame weight – 90 kg.

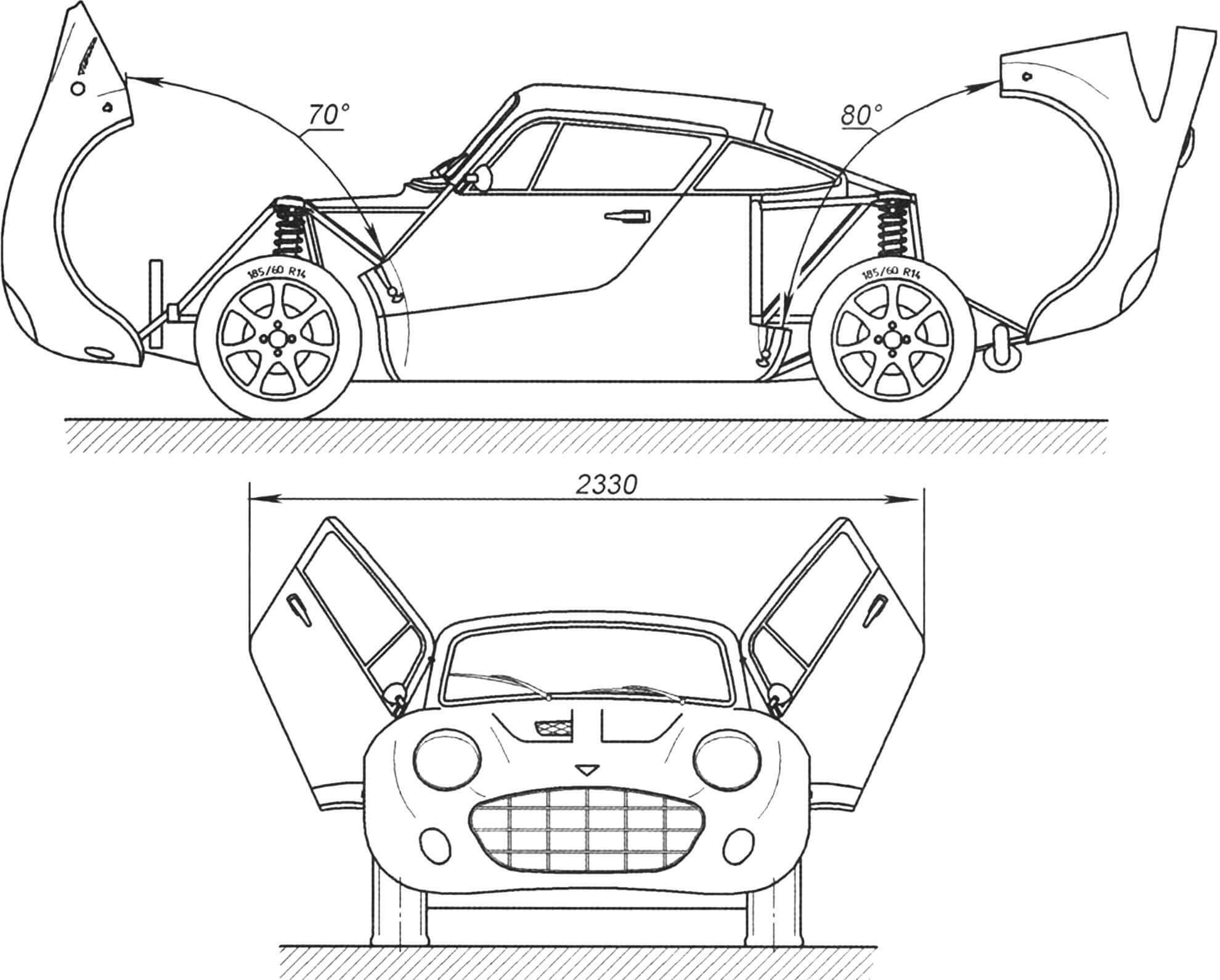

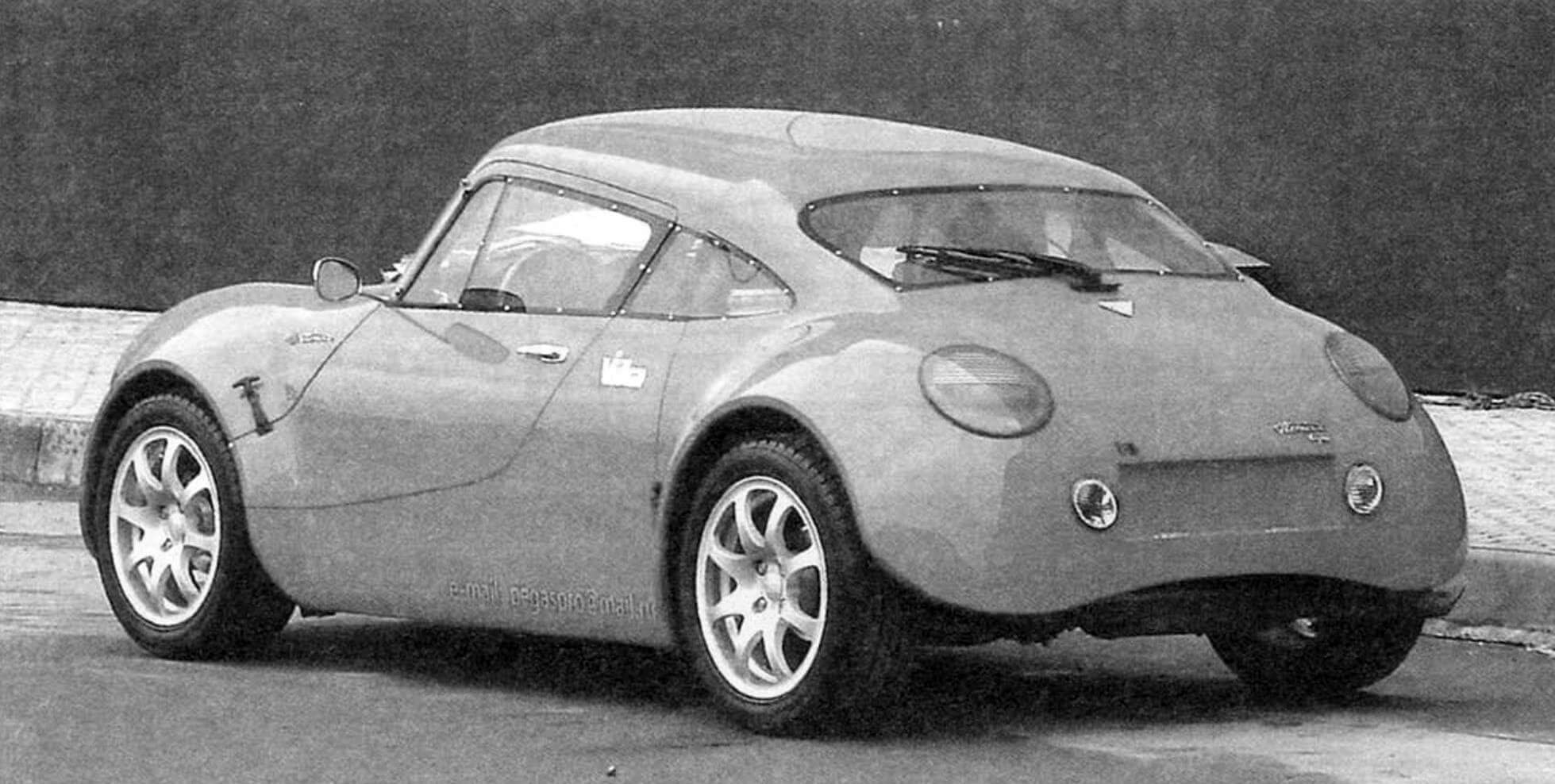

The chassis was pre-assembled on a welded frame and mounted on a sub-model plate, and work began on creating the exterior of the body. In fact, the shape of the roof and windshield, the boundaries of the doorways and the position of the wheels were found; all that remained was to form it all into an aesthetic body. To form the wings, special conical mock-ups were made, secured above the wheels, and the outline of the radiator grille and license plate frame were formed from plywood. The headlights are taken from a Daewoo Matiz car, the rear lights are from a Volkswagen New Beatle. The optics were fixed in place and set the shape of the body surfaces in the corners. Further lines were drawn using plywood templates and sculptural plasticine. Placing the chassis on a sub-model plate made it possible to see the shape of the car, evaluate and adjust it as necessary. These were classic layout works on a 1:1 scale.

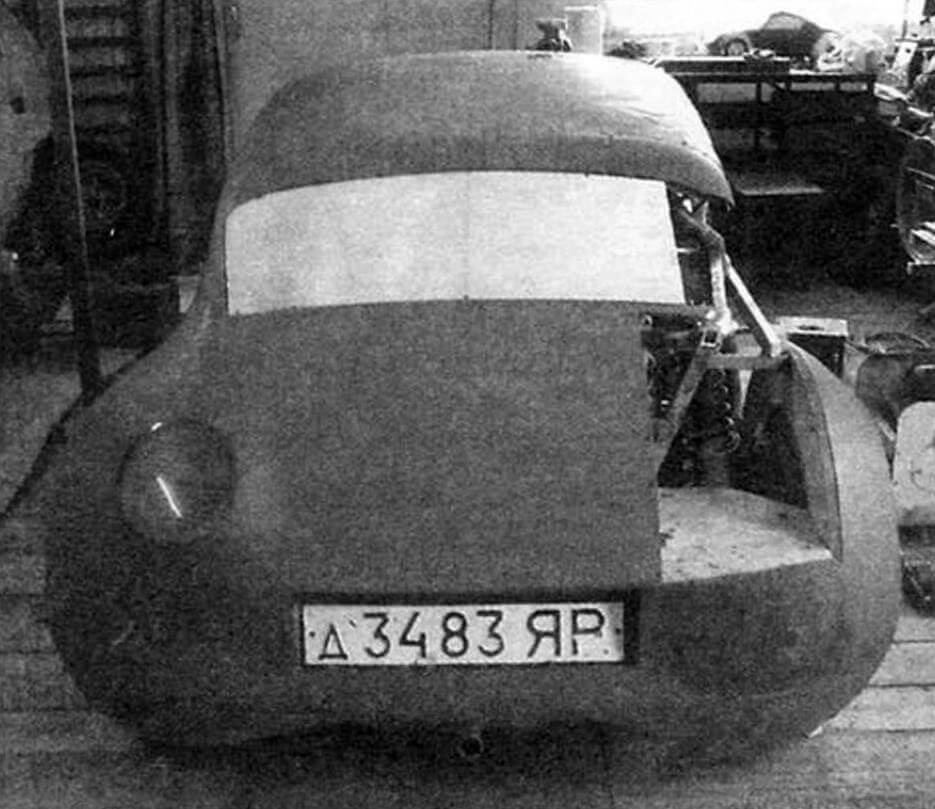

The result of the work on the body was a life-size model of a car made of plasticine, dissected into parts by scratches. Rough matrices were removed from this model, and rough fiberglass parts were glued onto them. After this, all the plasticine was removed from the frame, rough fiberglass parts were installed, interior elements, hinges and locks of the opening panels were modeled. Next, the gaps between the panels were drawn out, the rough parts were covered with primer and putty, then painted. Finishing matrices were removed from the aligned body panels, onto which the finishing body parts were then glued.

The body consists of more than a dozen fixed and folding panels: a hood and trunk lid, a roof, two sidewalls, a pair of doors (glued together in two parts) and several other smaller elements. The thickness of fiberglass panels is 4 mm. The binder was the non-shrinking, fairly fluid, not very toxic epoxy composition “Etal-370”. Massive hinged panels of the hood and trunk lid for greater rigidity have a sandwich structure in places: fiberglass (3 mm) – foam plastic (10 mm) – fiberglass (2 mm). The outer surface of the panels is formed by a layer of polyester gelcoat 0.5 mm thick, then there are two layers of fiberglass with a density of 220 g/ m2 , then three layers of fiberglass mat with a density of 300 g/ m2 . The total weight of the body panels is about 65 kg.

1 – radiator; 2 – battery; 3 — suspension subframe; 4 – stove; 5 — steering rack; 6 — pedal assembly; 7 — articulated steering shaft; 8 — dashboard; 9 — gear lever rod; 10 — sports bucket seats; 11 — integrated safety frame; 12 — fuel tank; 13 — rear shelf; 14 — power unit; 15 — exhaust system

After work on the body was completed, work on the chassis resumed. The basic parts of the suspension from the VAZ-1111 have undergone changes: four studs were used on the wheel hubs instead of three, and to widen the track, 14-inch diameter wheel rims with 20 mm thick spacers were installed. Shock absorber struts and springs from Plaza were installed, originally intended for Oka from the circuit championship among juniors. The compression/rebound travel of the front suspension is 50/50 mm, the compression/rebound travel of the rear suspension is 60/60 mm. The roll centers of the suspensions are close to the road surface, which contributes to minimal yaw on uneven roads. The front suspension uses an anti-roll bar and the longitudinal angle of the shock absorber strut (caster) is increased to 6 degrees (to stabilize the steered wheels). Such suspension settings with minimal travel are only suitable for smooth roads; for roads with large uneven surfaces they are too rigid.

The Oka’s power unit has also undergone changes. The standard engine volume was increased to 850 cm3, a new camshaft and exhaust manifold were used, which increased power from 33 hp. With. up to 48 l. With.

The engine cooling radiator and heater are located in the front of the car. The coolant flows to them through pipes running inside the right threshold of the car. Two interconnected fuel tanks in the form of rounded triangular prisms with a total capacity of 30 liters are welded from aluminum and are located on the floor behind the seats.

A limited slip differential is installed in the gearbox to prevent wheel slipping. A main pair with a gear ratio of 4.54 was also used to compensate for the increased wheel diameter. Gear shifting is carried out by a rod passing under the gearbox.

The braking system is dual-circuit “front-rear”, equipped with a vacuum booster, disc brakes on all wheels and a pressure regulator. The hand brake, like the clutch drive, is hydraulic and acts on the rear wheels.

The steering is adapted from Oka, using a cardan transmission on the steering shaft. The steering wheel is made in a classic style with a steel hub and a wooden rim.

The panel uses sports instruments with white scales from the VAZ-2106. The upper part of the panel with visors is made of fiberglass and covered with black leather, the lower part is covered with varnished wooden trim. The gearshift lever knob is made of wood. The interior is upholstered in black carpet, the sports bucket seats are made of fiberglass in black gelcoat with leather segment inserts. Both seats are equipped with three-point inertial seat belts. Directly above the engine there is a folding shelf made of plywood, which allows access to the engine, and when folded, serves to store light items in the cabin. On the floor in the niches under the seats there are mounts for a first aid kit and a fire extinguisher.

For interior ventilation, there are rotating vents in the door windows; the door windows do not roll down. The door windows themselves and the rear window are made of 3 mm thick polycarbonate, the windshield is made of triplex. The doors open up and forward on gas stops. Landing inside requires special skill, since the opening is still small, but sitting inside is quite comfortable, despite the minimal amount of space. The front and rear hoods are fully tilted to provide access to the vehicle’s components. When closed, in addition to the locks, they are secured at the edges with rubber fasteners. Overall the car is very tightly packed.

The car body is painted bright red with acrylic paint, and another layer of varnish is applied on top. After painting, the body panels are polished, which gives greater depth to the color.

The car’s dynamics, despite the small engine, are befitting of a modern civilian car. The classic rear-wheel drive design, 45/55 weight distribution and sharp steering leave a pleasant driving impression. It responds to the gas pedal with confident acceleration. When braking, the car brakes intensively thanks to disc brakes on all wheels. The force on the brake pedal is easily adjusted using a pneumatic booster.

In straight-line driving on the road, the car behaves stably, thanks to the suspension settings and the significant caster angle of the steering wheels. The wheel suspension with short travel absorbs small bumps and cracks in the road well, but on large bumps it is excessively rigid. When cornering, the car barely rolls, thanks to the low center of mass. When exceeding the speed in a fast turn, the car evenly drifts to the outer trajectory, which corresponds to neutral understeer. It is precisely this behavior of the car that participants in amateur circuit races appreciate.

Overall, we must admit that the Pegasus has the feel of a classic 1960s sports car in both appearance and ride quality. This is also facilitated by retro-styled controls.

The presented car is similar to the classic Porsche 356 Speedster. Today, such cars have become an expensive toy for collectors, fans of classic circuit racing, and just a weekend car.

Basic data of the Pegasus coupe car

Layout diagram of a rear-engine two-door coupe

Vehicle curb weight 500 kg

Gross vehicle weight 640 kg

Weight distribution in % along the axles with two passengers “front/rear” 45/55.

Dimensions:

length 3170 mm

width 1535 mm

height 1150 mm

Engine power 48 hp (35 kW)

Maximum speed 150 km/h

Acceleration time to 100 km/h 12 s

Fuel tank capacity 30 l

A. ZILIN, Yaroslavl