Winter operation of all-terrain vehicles in the northern regions of our country places a number of specific requirements on it. So, to reduce resistance to movement, the machine must have minimal weight or exert little pressure on the supporting surface and at the same time, to provide the necessary traction, have good adhesion of the mover (in most cases, the tracks) with the snow. And if in industrial transport all-terrain vehicles and special machines for builders, polar explorers, geologists, the choice of design is determined by the requirements of power and load capacity, then when creating lightweight one- or two-seater snowmobiles, the range of engineering and circuit solutions can be much wider.

However, at present, our industry offers only Buran motorized vehicles with tracked propulsion, so many enthusiasts independently develop a wide variety of all-terrain vehicles.

As practice shows, the most popular are machines driven by propeller thrust. What explains this choice? After all, the disadvantages of snowmobiles are known: reduced traction compared to vehicles where engine power is realized through adhesion to the supporting surface; possible difficulties when starting off due to frozen skis; insufficient dynamic characteristics when driving over rough terrain.

But they also have a number of advantages, and they are more significant for do-it-yourselfers. First of all, this is the extreme simplicity of the power plant, frame, chassis, since the propeller is directly or through a gearbox connected to the engine output shaft; lower material consumption, weight and cost and, finally, high reliability, determined mainly by the engine. But the main thing is that the traction force is a function of the power developed by the motor and does not depend on the condition and type of the supporting surface. This allows you to easily convert the snowmobile into an airmobile or airboat.

Ways have also been outlined to overcome the noted shortcomings: the work carried out at the N. I. Kamov Design Bureau made it possible to create a propeller with increased efficiency due to an automatic pitch change device and reduced aerodynamic resistance of metal blades. Reversing the propeller allows for reversing and braking. And in order to prevent the skis from freezing when stopping, the appropriate material for the soles is selected: instead of steel, brass, low-density polyethylene or fluoroplastic-4 are installed. Such a replacement ensures not only free starting, but also improves gliding and increases speed characteristics by 20-25%.

So, the advantages of snowmobiles are significant and significant, and the disadvantages are successfully overcome. Without going into details of a comparative technical analysis of various types of snowmobiles, we can assume that simpler, lighter, more reliable and cheaper snowmobiles will continue to be very popular among snowmobile enthusiasts.

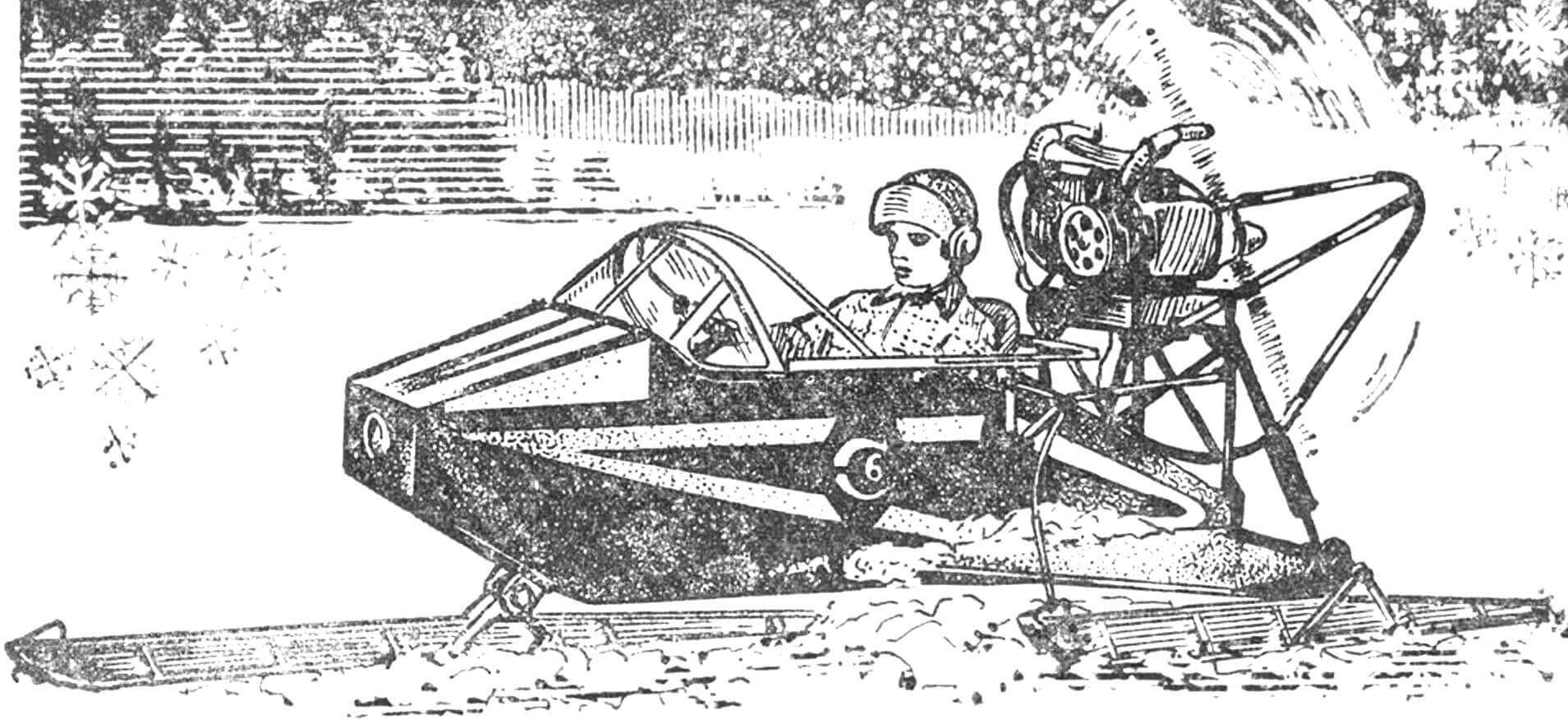

Well, for those who want to build an aero snowmobile on their own, we invite you to familiarize yourself with the sleigh of the Moscow amateur designer I.P. Svetchikov. This is his sixth car. The magazine has already introduced readers to the fourth model – it is remembered for its cockpit equipment with an airplane-type hood (see “M-K” No. 2, 1975).

The latter option is distinguished by its simple and rational design, thorough engineering design of the main components, reliability and ease of use.

I. YUVENALIEV, engineer

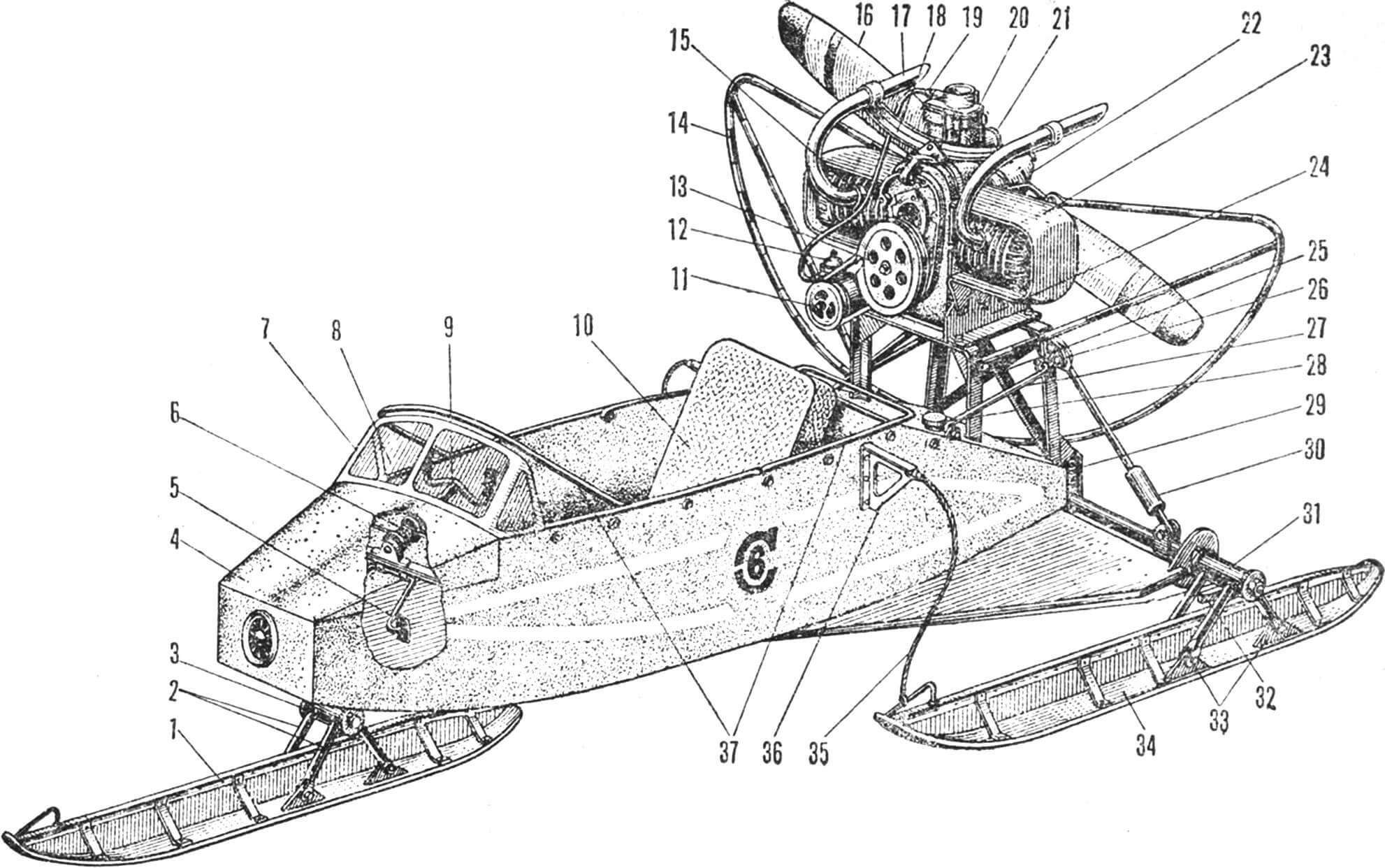

The body of the sled is semi-closed; it is formed by a frame made of aluminum profiles covered with a 0.8 mm thick duralumin sheet. In its rear part, a sub-engine frame is installed – two U-shaped racks made of steel angles 25X25 mm and connected at the top by two longitudinal profiles, between which the engine is mounted. The rigidity necessary for the transmission of traction force is provided by two inclined rods connecting the upper part of the sub-motor frame to the sled body.

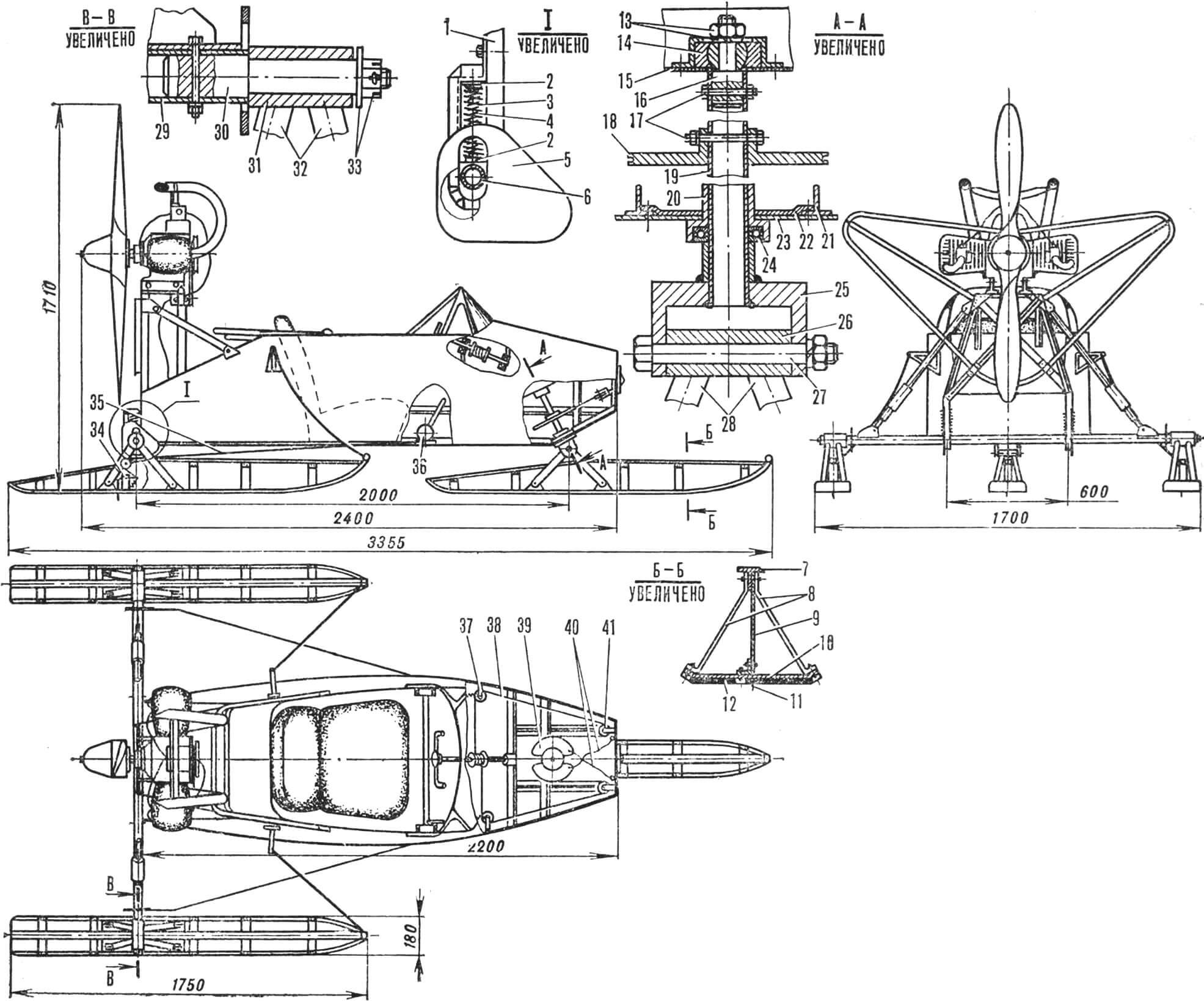

The chassis is made according to a three-ski design: a steerable front one and two rear ones, mounted on a common axis. The latter is placed in vertical guides and supported by two pairs of springs. Two motorcycle shock absorbers help dampen vibrations that occur during movement.

1 — front ski, 2 — ski horns, 3 — steering fork, 4 — housing, 5 — carburetor throttle pedal, 6 — steering column cable drum, 7 — windshield frame, 8 — windshield, 9 — steering wheel , 10 — seat, 11 — fuel pump pulley, 12 — fuel pump, 13 — engine starting pulley, 14 — propeller safety bars, 15 — K-750 engine, 16 — propeller, 17 — exhaust pipe, 18 — exhaust pipe bracket, 19 — fuel hose from the fuel pump, 20 — intermediate fuel tank (float chamber of a car carburetor), 21 — magneto, 22 — propeller fairing, 23 — deflector, 24 — longitudinal profile of the engine frame, 25 — engine frame (angle 25X25 mm), 26 — suspension strut bracket, 27 — inclined rod, 28 — fuel tank neck, 29 — rear ski axle suspension spring, 30 — motorcycle shock absorber, 31 — rear ski hub, 32 — brake mechanism, 33 — ski brackets, 34 — rear ski , 35 — safety cord, 36 — side hull bracket, 37 — folding frames for installing a tarpaulin awning.

All three skis are the same size. They are made from 3 mm thick duralumin sheet and corners. The sole is formed by a sheet of low-density polyethylene 4 mm thick. On the inside of the skis, brackets for fastening hogs are mounted – steel tubes welded to a transverse hub hub, which form a rigid pyramidal “leg” of the ski.

The front ski hub is mounted in the steering shaft fork, and the rear ski hubs are mounted on the rear axle shanks.

To avoid turning over the rear skis when moving over an obstacle, their tips are connected with shock-absorbing cords to the side brackets of the body.

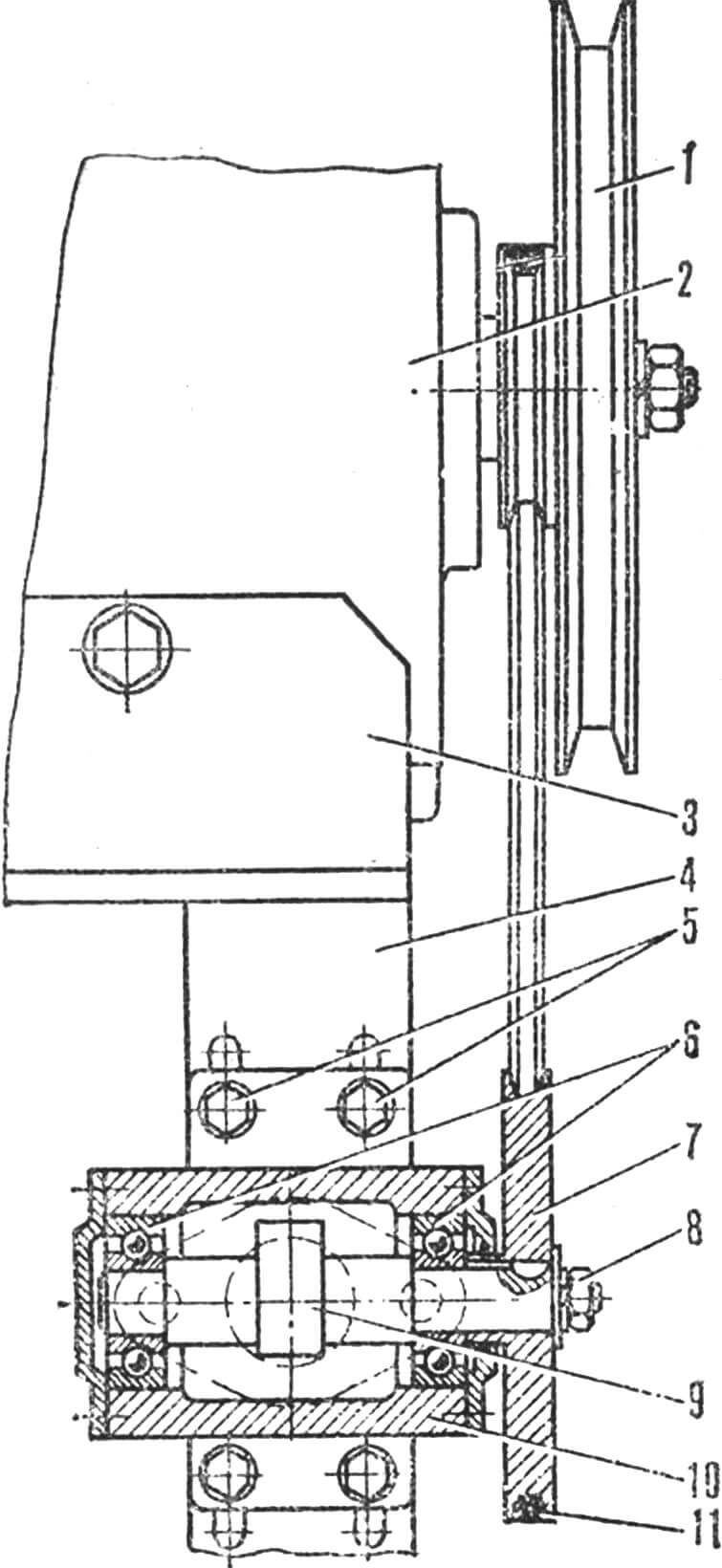

The steering of the snowmobile is formed by two units connected by a cable transmission: a steering column, consisting of a shaft with a steering wheel and a cable drum mounted on it, and a rotary shaft, welded at the bottom into the rotary fork and installed in a bearing unit. At the top, this shaft is equipped with a pulley for connecting control cables. Four intermediate rollers (two of which are spring-loaded for tension) direct the cables from the drum to the rotary shaft pulley: this arrangement allows you to select its optimal tilt, providing a slight roll of the control ski towards the turn, which reduces its lateral slip and improves controllability. In addition, the steering column can be installed in the most convenient position for the driver.

1 — sub-frame stand (angle 25X25 mm), 2 — spring plates, 3 — outer spring (left winding), 4 — inner spring (right winding), 5 — limiter, 6 — axle, 7 — top shelf, T-shaped aluminum profile, 8 – supports, duralumin strips, 9 – rib (duralumin sheet 3 mm thick), 10 – load-bearing surface of the ski (duralumin sheet, thickness 3-4 mm), 11 – undercut (steel strip 0.9 mm thick), 12 — sole (low-density polyethylene, thickness 4 mm), 13 — fastening elements for the rotary shaft, 14 — spherical bearing, 15 — transverse profile of the housing, 16 — shank of the rotary shaft, 17 — M8 bolt, 18 — rotary pulley, 19 — shaft , 20 — thrust bearing housing, 21 — longitudinal profile of the housing, 22 — reinforcing patch, steel sheet 3X300X300 mm, 23 — housing casing, 24 — thrust bearing, 25 — rotary shaft fork, 26 — front ski hog hub, 27 — axle ( M12 bolt with nut), 28 — front ski hogs, 29 — axle, 30 — axle shank, 31 — rear ski hub, 32 — hogs, 33 — hub fixing elements, 34 — brake mechanism, 35 — cable, 36 — brake handle , 37 — tension roller, 38 — steering cable, 39 — rotary pulley, 40 — limit cables, 41 — roller

The snowmobile engine is a two-cylinder, four-stroke, air-cooled K-750 motorcycle. It is reliable, economical and has a power of 27 hp. With. at 4600 rpm, which is quite enough to convey a sleigh weighing 180 kgf to a speed of up to 60 km/h.

To install the engine, remove the gearbox, generator and front crankcase cover. Install deflectors around the cylinders and heads, which ensure their effective cooling and (using the side pipes) blowing warm air over the carburetor. This helps improve fuel evaporation and prevents carburetor freezing when operating in frosty weather.

The fuel system has been slightly modified. Since the tank is located in the lower part of the body, gasoline is supplied from it using a car gasoline pump. But the K-37 motorcycle carburetor is designed to supply fuel by gravity. To prevent forced supply from the pump from causing “overflow” of the float chamber, an intermediate fuel tank is used, installed directly on the engine. For this purpose, the most convenient float chamber from any car carburetor: its valve will maintain the required level, and the fuel will flow by gravity to the working carburetor.

1 – starting pulley, 2 – engine, 3 – engine support, 4 – sub-frame stand, 5 – drive housing fastening elements, 6 – bearings No. 201, 7 – eccentric shaft pulley, 8 – fasteners, 9 – eccentric shaft, 10 — housing, 11 — V-belt.

The fuel pump drive is made in the form of a separate unit installed on the rack of the sub-engine frame. The diaphragm rod interacts with the eccentric of the shaft, rotated in the housing bearings by a V-belt drive from the front crankshaft pulley.

The battery ignition system was replaced with a magneto mounted in place of the removed generator. The rotor drive is gear driven, from the camshaft.

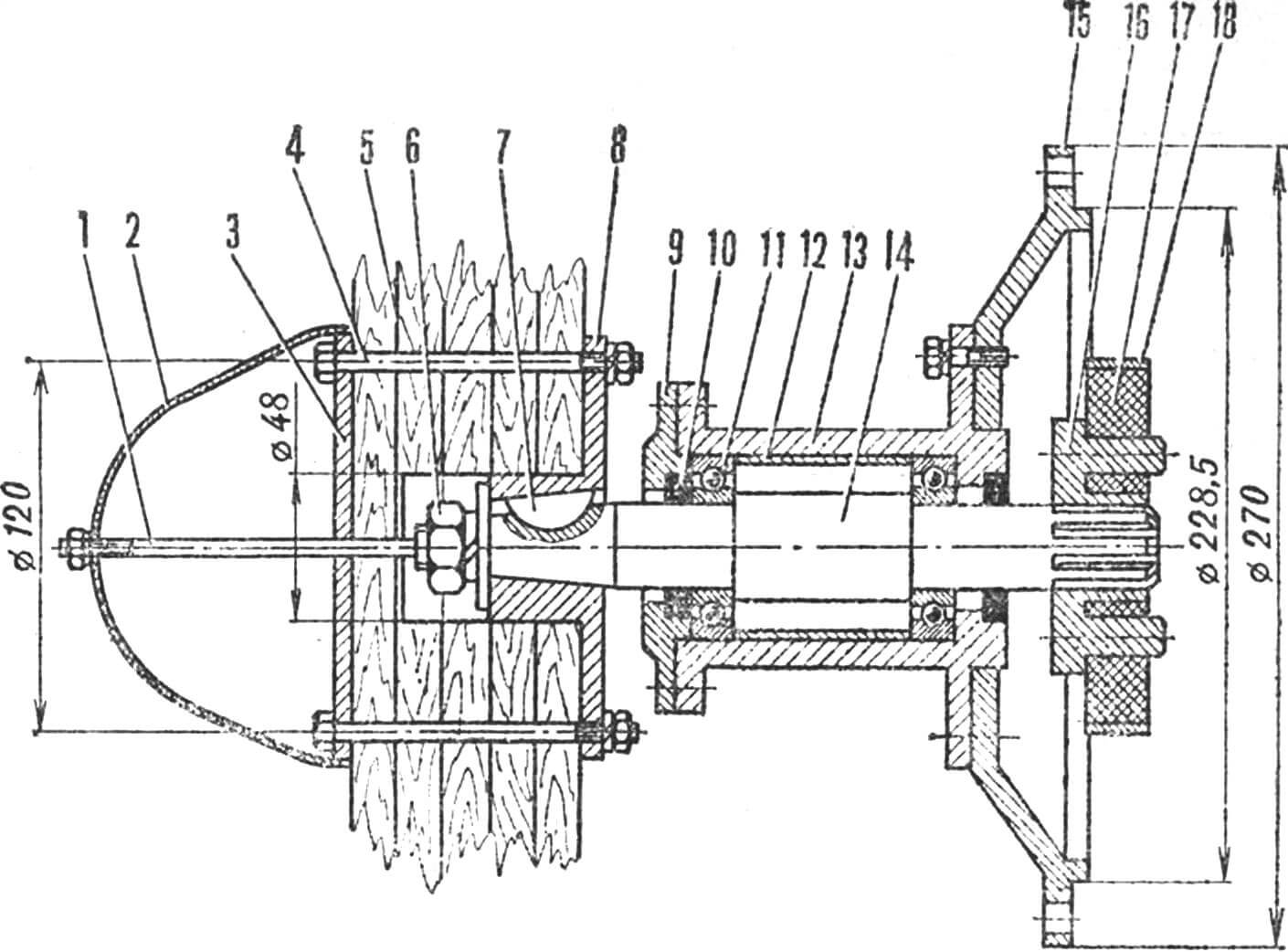

1 — spinner mounting pin, 2 — propeller spinner (fairing), 3 — disk, 4 — propeller mounting bolts, 5 — propeller, 6 — propeller hub nut and washers, 7 — key, 8 — propeller hub, 9 — bearing housing cover, 10 — felt seal, 11 — ball bearing No. 206, 12 — spacer sleeve, 13 — housing, 14 — shaft, 15 — housing adapter flange, 16 — shaft pin coupling, 17 — rubber coupling, 18 – ring.

Since kickstarting the engine is inconvenient, manual starting with a cord is used – as on outboard outboard motors. To do this, a pulley is installed at the front end of the crankshaft, the large groove of which is used for starting, and the small one is used to drive the fuel pump.

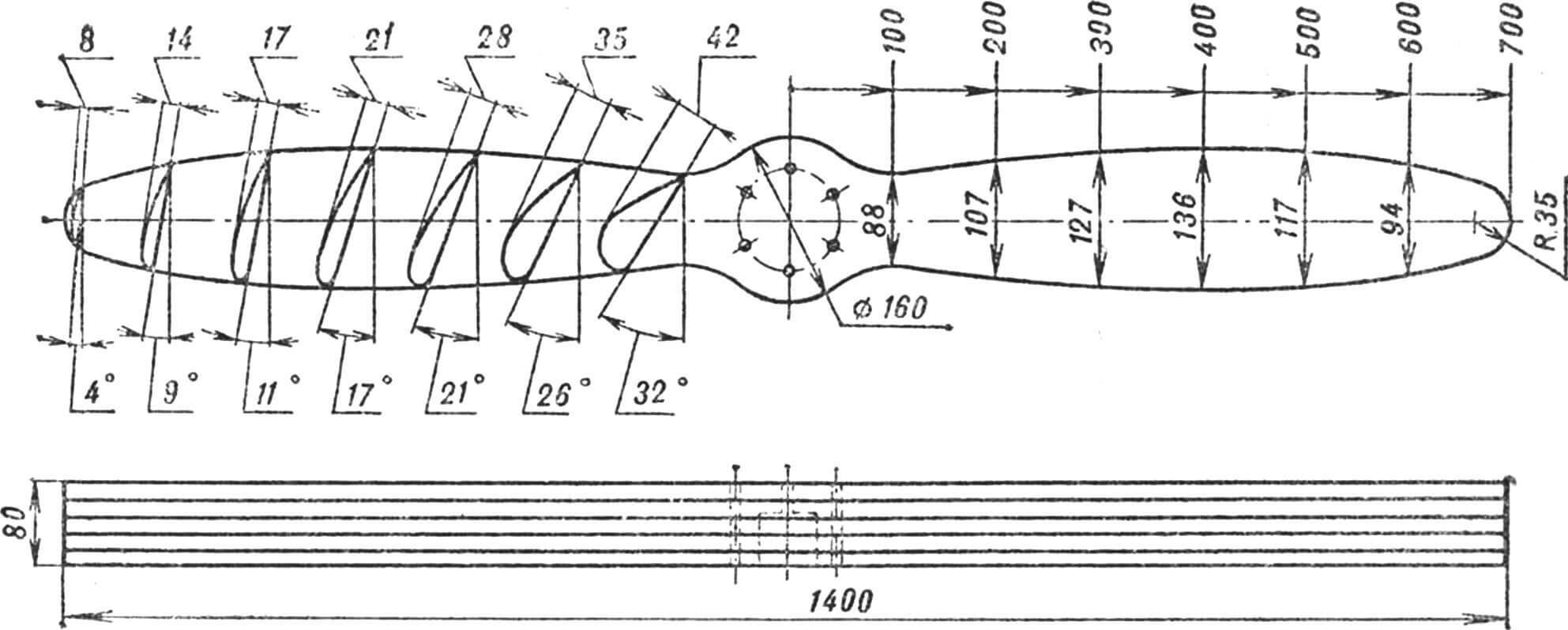

The two-bladed air propeller is glued from pine and spruce bars, and after processing the profiles, it is covered with nylon, painted with enamel and polished. Although the scheme does not provide for speed reduction, it is not advisable to place the propeller on the shank of the engine crankshaft, since the elements of the axial fixation of the crankshaft in the crankcase are not designed for significant axial loads. Therefore, the propeller is mounted through a centering sleeve on a separate shaft installed in the bearing unit. The turned aluminum body of this assembly is mounted directly on the engine crankcase through an adapter flange. Rotation from the engine shaft flywheel to the propeller shaft is transmitted by a finger coupling with an elastic disk surrounded by a steel ring.

The snowmobile’s control is steering, the drive from the gas pedal to the carburetor throttle, as well as from the brake handle to the levers mounted on the rear skis is cable.

A necessary element of snowmobile safety is a tubular propeller guard, which is attached to the sub-engine frame, and from above – directly to the engine. Two struts give the fence additional rigidity.

The driver’s comfort is provided by a windshield, and in inclement weather by a canvas awning stretched over the cabin on two U-shaped frames that fold back.

I. SVETCHIKOV