The author presented to the readers of cargo mini-mokik Nikolay Krasnov is a great lover and connoisseur motovelotehnika, especially vintage, although similar to modern cars treated with respect — he has not one good vintage motorcycle and when I have time, likes to ride on them.

The author presented to the readers of cargo mini-mokik Nikolay Krasnov is a great lover and connoisseur motovelotehnika, especially vintage, although similar to modern cars treated with respect — he has not one good vintage motorcycle and when I have time, likes to ride on them.

Everything else, Nicholas — skilled hands. A few pre-war motorcycles and motorbikes, he restored virtually from scrap, and now they are on display in the Moscow Museum of crews and cars magazine “auto review” in Kuzminki and thematic exhibitions. Several other similar machines are in the process of recovery or waiting for their turn (completed the missing parts).

When gardening, it took at least some of the cargo vehicle, decided to do it on the basis of available stock of the old, but not yet pulling on the rarity of the mini-mokik RMZ-2.126 the Riga plant.

However, “based on” does not quite fit — he too little left frame, handlebar, front fork, Yes one wheel. Everything else up to the power unit, had to pick up and adapt from other similar equipment or do yourself.

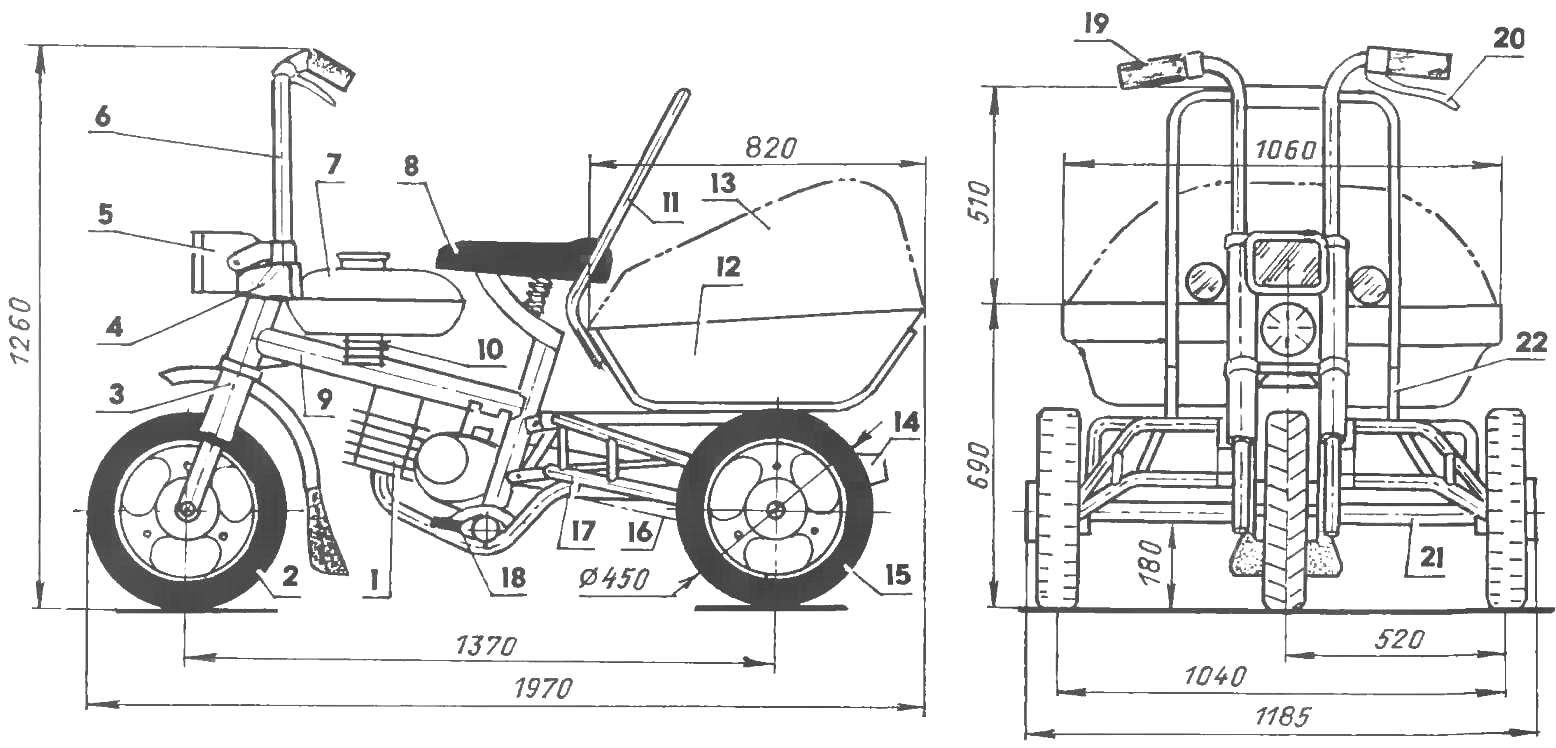

Geometry and layout of cargo mini-mokik:

1 — power unit (moped “Java-210”); 2 — front wheel (from mini-mokik RMZ-2.126); 3 — front fork (from mini-mokik RMZ-2.126); 4 — turning signal (from the mini-mokik RMZ-2.130 “Lux”); 5 — headlight (from mini-mokik RMZ-2.126); 6 — the wheel (from the mini-mokik RMZ-2.1261; 7 — gas tank (from moped RMZ-1.413); 8 — seat (from motorbike RMZ-1.413); 9 — frame (from mini-mokik RMZ-2.126); 10 — e unit (from the moped “Java-210”); 11 — lever of the tilting of the body; 12 — body (from the car, upgraded), 13 — cargo; 14 — silencer (from mini-mokik RMZ-2.134 “Stella”); 15 — rear wheel (from mini-mokik RMZ-2.126, 2); 16 — drive chain (t = 12,7); 17 — subframe body; 18 — brake pedal (from mini-mokik RMZ 2.130) 19 — arm “gas” (from the mini-mokik RMZ-2.126); 20 — brake lever (from mini-mokik RMZ-2.126); 21 — rear axle beam; 22 — the side walls of the body (pipe 20×20, 2 PCs.)

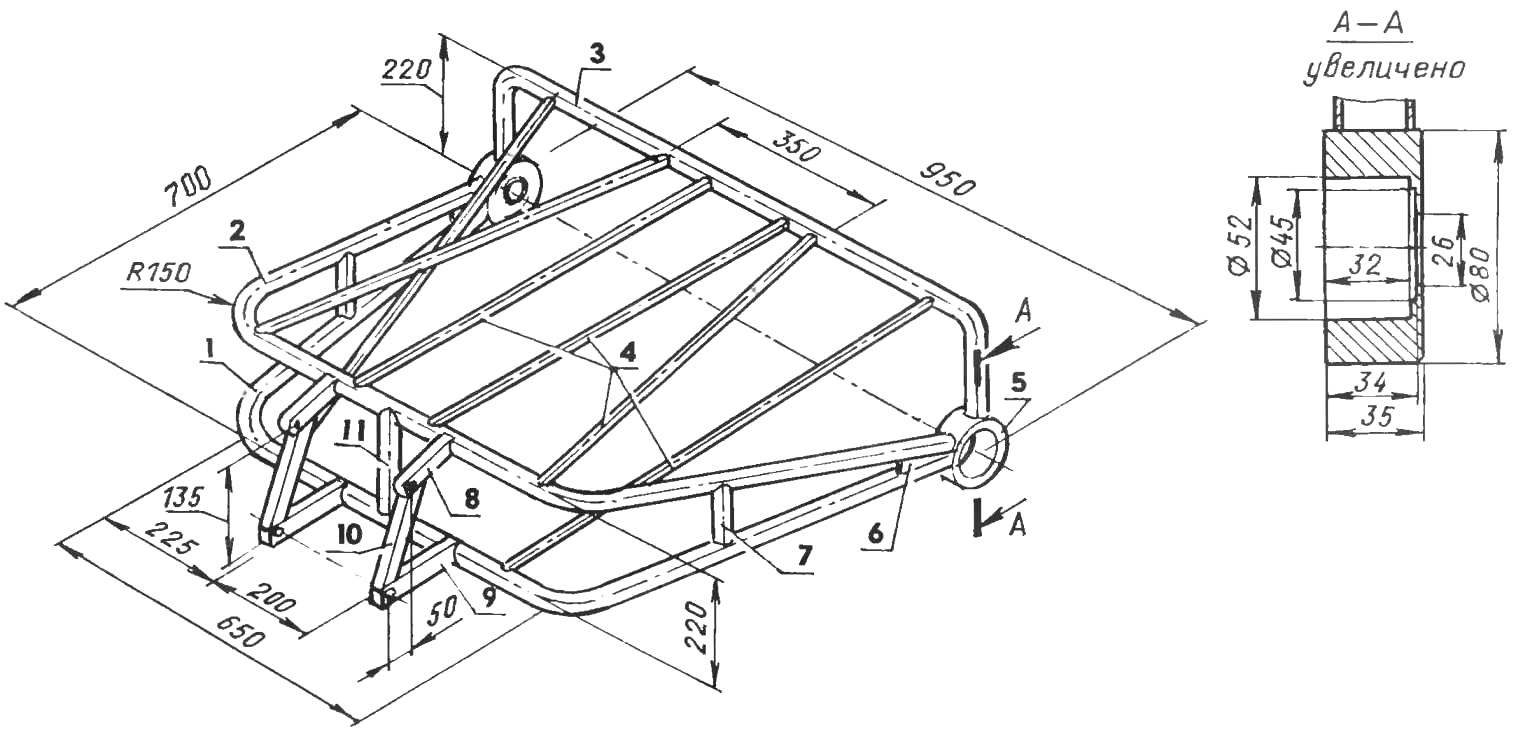

Subframe body (all the cool pipes from the bike):

1 — the bottom arc (Ø25 tube); 2 — upper arc (Ø25 tube); 3 — back arc (Ø25 tube); 4 spacers (tube Ø18, 6 PCs); 5 — the bearing housing (steel 45, range 80, 2); 6 — solitaire (steel sheet s2, 2); 7 — lateral strut (tube Ø25, 2); 8 — upper console (tube 40×25, 2); 9 — lower console (tube 40×25, 2 PCs ); 10 — brace (pipe 40×25, 2); 11 — front (tube Ø25)

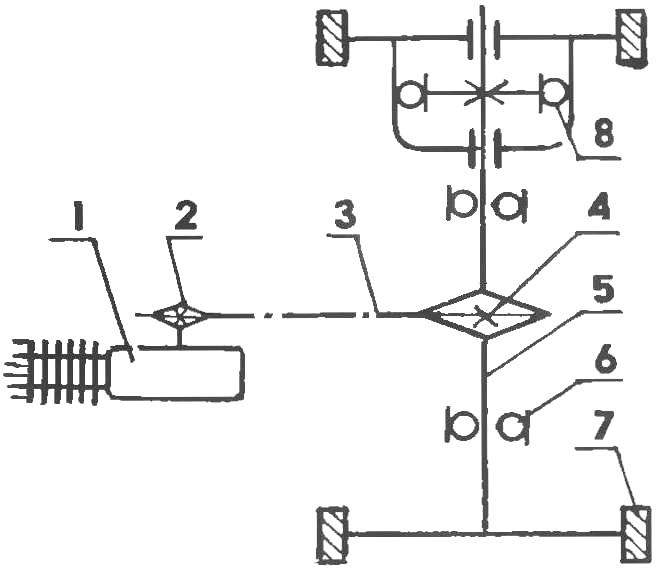

Kinematic scheme of transmission:

1 — power unit; 2 — output shaft sprocket (z=14); 3 — drive chain; a 4 — led (driven) sprocket (z=28); 5 — drive shaft; 6 — the bearing 205 (2-piece ), 7 — drive wheel (2); 8 — roller overrunning clutch (Bendix modified VAZ-2101)

The power unit used from the Czechoslovak (now Slovak) moped “Java-210”. This engine working volume of 49 cm3 and a power of 2.3 horsepower at 5000 revolutions per minute mated to the gearbox, clutch and generator. Clutch mechanism this unit very original and interesting, even by the standards of our time: it has two centrifugal mechanism is controlled by automatic switching two-stage gearbox.

Electrical equipment freight mini-mokiki (and accordingly, the headlight and alarm) is 12 volt Muffler to cylinder engine adapted from the mini-mokik Riga plant RMZ-2.134 “Stella”. By the way, from another machine on the same plant as light moped RMZ-1.413 — used spring loaded seat and fuel tank capacity of 5.5 liters.

Front wheel — standard with a tyre size of 3.00-10″, and two rear — from another of the same mini-mokiki, but with a different, more “all terrain” tread pattern.

Cargo module for the most part improvised, so will tell about it in more detail. Module this part of the machine called that because it is possible to disconnect completely (in Assembly) from the frame, and in its place install the rear fork with the driving wheel, transforming the car again in the usual mini-mokik.

Structurally, the cargo module consists of the rear axle, spatial subframe and the body-hopper.

Rear axle is a hollow shaft made of steel pipes with outer diameter 42 mm Approximately in the middle of it, on the hub of the fixed driven large 28-bevel sprocket chain transmission chain Step -12,7 mm (like a regular road bike). At the end of the shaft is inserted the wheel axles. Hub sprocket attached to the shaft by two pins with M6 bolts inserted through holes drilled simultaneously in it and the shaft. Here I’ll note that the asterisk on both sides covered with duralumin discs, limiters, not allowing the chain to come off the driven sprocket. Such discs (only the relevant dimensions) is equipped and the small 14-bevel sprocket of the output shaft of the power unit. Looking ahead, we say that a special mechanism for chain tension is not done, and her adjustment to produce a small movement of the power unit in the grooves of the mounting bracket, when loosened bolts. When the chain stretches significantly — removed from it one or two locations.

Cargo module (body tilted)

Chain drive rear wheels

The connection joint and the bearing housing of the sub-frame

Rear axle beam (and more precisely axle of the wheels) is mounted in four bearings 80205 installed in two buildings of the subframe, which will be discussed below.

Both rear wheels are leading. Only one (right) is planted directly on the axle shaft and the other through the one-way clutch (modified from Bendix starter VAZ-2101).

Subframe welded cargo module, made mostly of circular thin-walled steel pipes, taken from the old bike. And the pipes didn’t even bend — I used a ready-made radiuses. The whole subframe consists of three arcs, the ends of which converge on the two bearing housings to which they are welded. Between us arcs connected by distance bars, gussets and struts, together with which they form a rigid frame body of the subframe. For connecting the latter to the frame of the mini-mokik to the front parts of the console is welded four arcs of rectangular tube 40×25 with holes at the ends for the mounting studs M10. The rigidity of the coupling of the upper and lower consoles is provided welded to the struts. Body subframe to the frame of the mini-mokik is attached rigidly (as, indeed, regular fork and rear wheel). Depreciation is pneumatic tires rear wheels.

The body is made of hopper cars: it was cut in half lengthwise and in the middle welded insert of sheet steel the same thickness as that of the tank (about 1 mm). The abutting edge and the sheet, and the hopper was bent at 90 degrees downward: after welding, they formed ribs. To him, the sides still welded to the longitudinal elements of the side walls of the square pipe section of 20×20, and to the side members in front — the same crossmember. Thanks to the insert body width was even larger than the length, and the volume was about 0.2 m3 loaded although it is sometimes easy cargo volume and up to 0.8 m3.

The body is attached to the rear arch frame hinge, thanks to the two ladders. Between the arch and ladders with the rubber sleeve — they serve and bearings, and dampers.

Laden body pressed against the subframe under the weight of the cargo, and empty — attract them to each other with a belt.

For ease of unloading (especially bulk materials) to the side members of the body front attached curved lever: the body can simply be tilting, turning mini-mokik in the dumper.

In the original version of “truck” was made without any differential between the rear wheels. But the operation showed that to make turns this little vehicle is no better than and large, do not have this mechanism.

Then from Zhigulevsk starter Bendix made one-way clutch and mounted it in the left wheel: turning is easier, but only in one (left) side. Will have to do the same and right wheel.

Brake cargo mini-mokiki — regular drum, but now with the drive to both rear wheels. Brake control is carried out or the lever mounted on the left handlebar, or pedals with my left foot. To this end, the lever and the pedal are connected by a cable.

Despite its small size and low-power power unit, mini-mokik able to carry in addition to a solid driver and even 80 — 100 kg of cargo at speeds up to 30 km/h. Only fuel consumption in comparison with the passenger variant increases from 2.1 to 2.5 liters per 100 kilometers.

N. RED