Only two years have passed since that time, as the Federation of auto modeling sport of the USSR adopted a decision on the introduction of a new class of E-2. And this, in General, insignificant for the history of the development of the modeling period, a new class has gained popularity, is not inferior to any other self-similar. What is the secret of success?

Only two years have passed since that time, as the Federation of auto modeling sport of the USSR adopted a decision on the introduction of a new class of E-2. And this, in General, insignificant for the history of the development of the modeling period, a new class has gained popularity, is not inferior to any other self-similar. What is the secret of success?

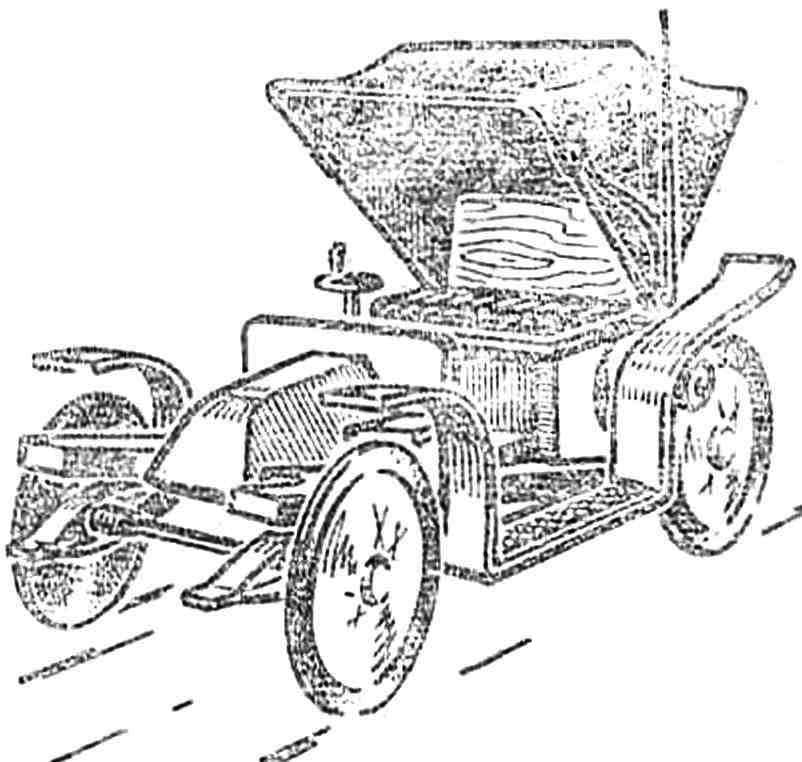

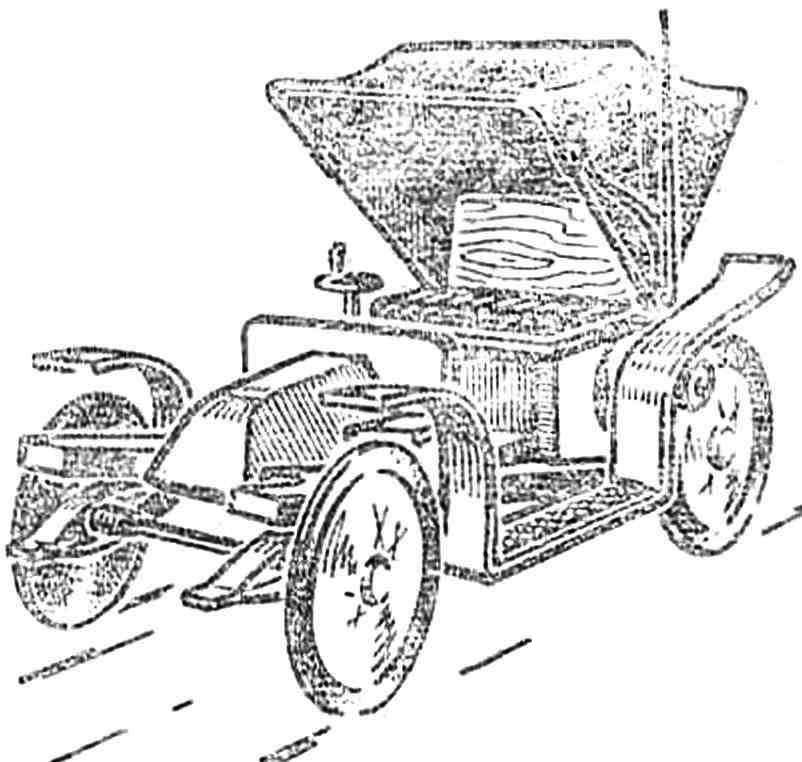

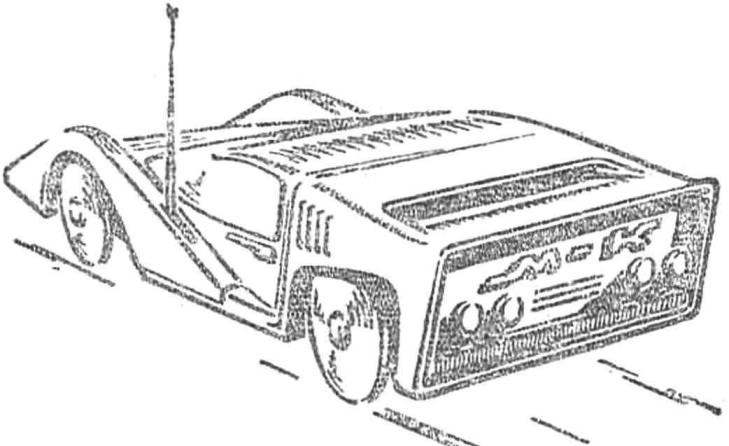

Extensive editorial mail allows you to draw an unequivocal conclusion — the advantage of class E-2 in the ease and availability of manufacturing cord models-polycopy. Simple body structure and chassis, the use of just accelerated motors mass production eliminates the need for semi-professional a fantastically complex and time-consuming work with incredible materials. But without such operations the success of no other self-similar class is simply impossible! Unfortunately, the race for results in the competitions made it so familiar that it seemed, no access to technological processes of manufacture “super”-gears or parts for the “space” of electric motors and internal combustion engines, there is no possibility to produce silver-zinc batteries or secretin for the wheels — nothing to think about the car. Even tracks I think that one of the most important components of victory — proper forcing microelectromotors (which are better than the Japanese!).

It becomes clear why the boys are living away from “self-centers” of the country, had only dreamed about the construction of micromachines any class (except only “hybrids-Vertol”). So it was yesterday. Today, aware of a number of clubs in rural schools, thanks to the introduction of competition rules new classes available (more details about the requirements of the regulations to the design cord powered cars with electric motors and external power supply can be found in the article “In light of new regulations”, “M-K” No. 4, 1984).