The article “Acupuncture for metal”, published in the journal “modelist-Konstruktor” No. 2, 1974, provoked numerous responses, not only individual readers, but also many businesses and organizations. Editorial Board, ENEA USSR and VNIIST continue to receive letters and inquiries on the subject.

The article “Acupuncture for metal”, published in the journal “modelist-Konstruktor” No. 2, 1974, provoked numerous responses, not only individual readers, but also many businesses and organizations. Editorial Board, ENEA USSR and VNIIST continue to receive letters and inquiries on the subject.

As shown by post, most issues were of a practical nature and applies to many industries where aglirta as a versatile and high-performance tool can find and has already found application.

We asked the author of the tool is a winner of two gold medals of VDNKH of the USSR, honored inventor of the RSFSR V. S. Salukvadze to answer the most typical questions that numerous letters in order to help their authors and organizations to identify ways of implementing importerade in their production.

“Dear edition!

With great interest I read the article “Acupuncture for metal”, published in the second issue of your magazine in the section “ENEA — school of innovation,” the education I am-nick-technologist, but nothing like I have not had to hear.

Our fishing collective farm “may 9” where I work as a mechanic, recently bought a floating Dong: after each flight the court are cleaned from rust and painted. But what can you do manual scrapers, brushes, and the “hedgehogs”? But this new tool as eglomise is, apparently, a revolution in the fight against corrosion”.

S. ROZHANSKY. The Latvian SSR

“Plant of gas equipment needs a high-performance method of Stripping metal from scale and rust before welding. Would like to apply for this islamizirovannie”.

G. BERAIA, chief engineer

The Sukhumi experimental plant of gas equipment “Innovators of our city showed great interest in the new instrument, eglomise”.

M. GAR, member of the regional Council of VOIR, Kaspiysk

“The Leningrad metro is building a base for a factory repair of electric rolling stock. Until the article was supposed to design a machine for the chemical Stripping of the wheel pairs according to the type of German firms Hegenscheidt.

If eglomise ensure removal of old paint and getting a smooth polished surface to the axis of wheel pairs — there will be no need of creating such a complicated machine.”

A. CHERNOV, head of the engineering Department.

T. KOROTKOVA, senior process engineer

“Islamizirovannie will help to speed up grinding the tram rails: sanding is ineffective, abrasive sticks”.

E. LORENZ, Riga

“The invention described herein may be embedded in our production process during cleaning of steel pipes and steam boilers”.

N. MAKAROV, head of the Montenegrin administration “Energougol”

Donetsk Central design-technological Bureau of the Ministry of local industry of the Ukrainian SSR is a regular subscriber to your magazine and following with interest the novelties that appear on its pages. Of great practical interest have submitted to us an article about igloterapii, as Donetsk TPTB develops technical documentation for construction and reconstruction of enterprises producing consumer goods”.

A. CIRCLES, head TPTB

“Is there the possibility to machine shop to manufacture ignores and what is the technology of its production? Can the journal to publish additional information about this invention?”

V. KANAREYKIN, foreman of the new technology demonstration panevėžys construction trust

HIS “GEOGRAPHY”

Islamizirovannie — new technological process of mechanical cleaning and surface treatment of metals and other materials developed by all-Union scientific research Institute for construction of pipelines (VNIIST). 8 its core, it’s microreserve, which is a special tool — ignorati, made of metal wires or plates and resembling a round brush.

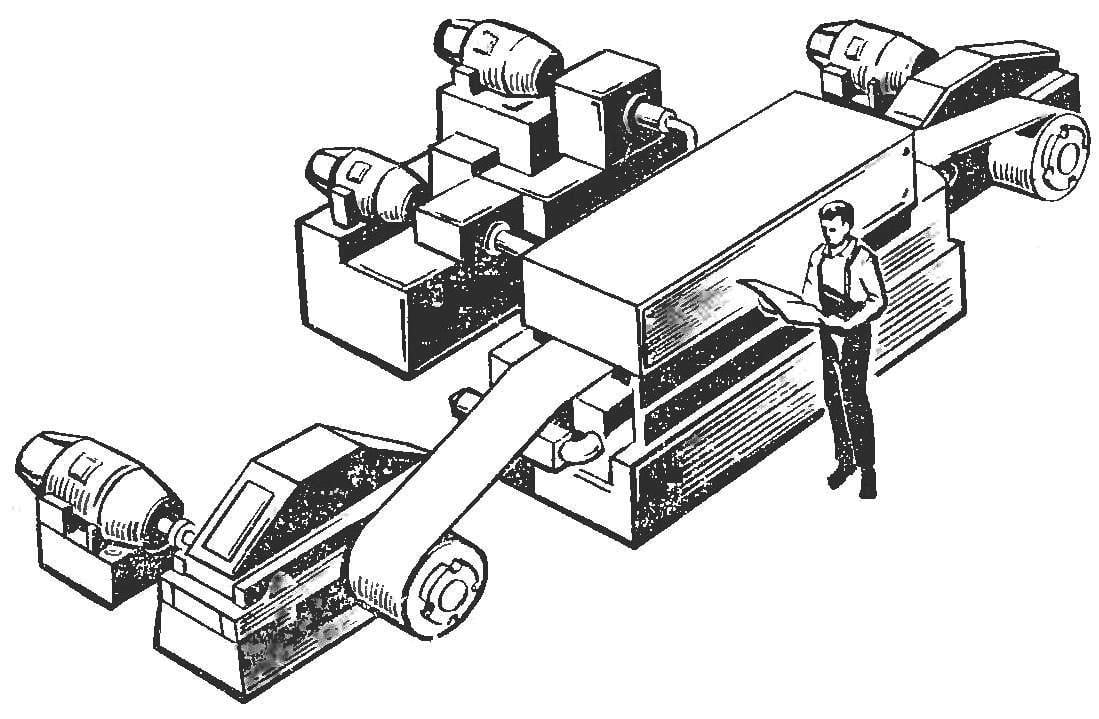

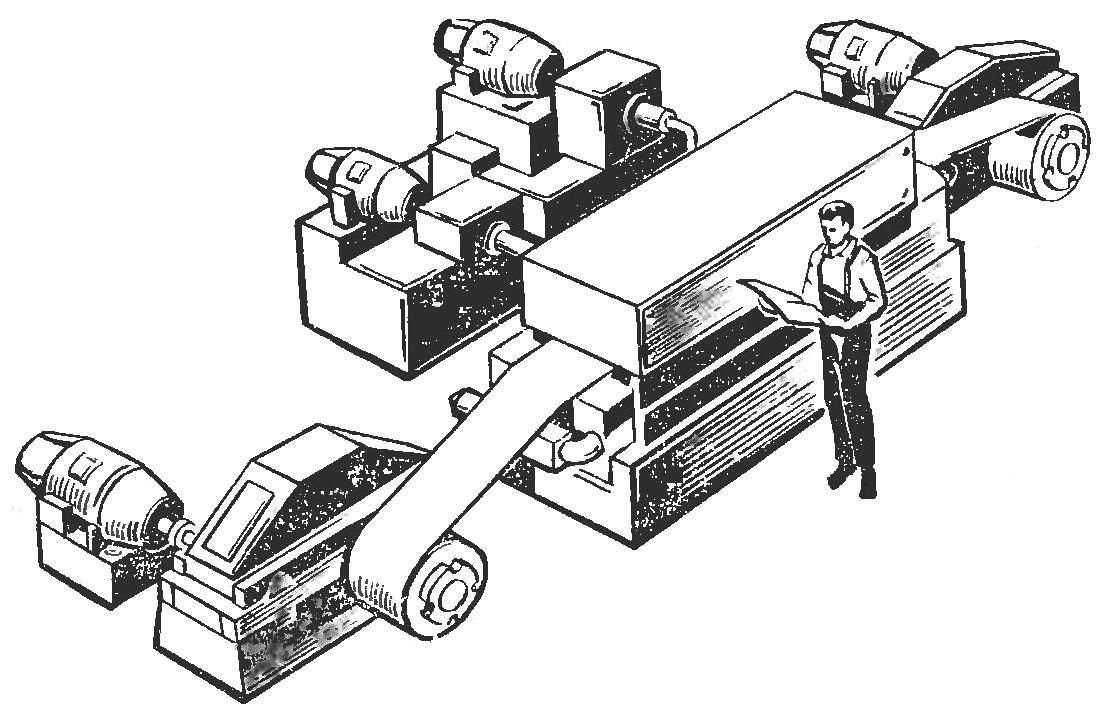

Externally, the new process is similar to the surface treatment of metal abrasive wheels. Here, the tool also needs to rotate, snuggle up to your working surface to a workpiece and to move relatively to this surface (Fig. 1).

Fig. 1. Treatment ipofisari round rental.

However, the modes importerade very different from the modes of operation of the abrasive tool. For example, the speed of rotation ignores 5-10 times smaller, and the contact force to the cutting, respectively, more than during abrasive processing of metal. Therefore, to use this process, it is necessary to create specialized equipment.

Standard metal-cutting equipment for epiretinal processing without alteration can only be used horizontal milling machines. Therefore, islamizirovannie is useful for bulk operations and only where it is possible to realize the mechanical clamping and movement of the tool relative to the work surface.

As a hand-held mechanized tool ignorez is not useful and can be recommended only for those cases when other treatments are not applicable. Currently, however, tested new types of ignorez that will help solve this issue.

Islamizirovannie can handle almost all kinds of materials, including carbon and alloy steels, cast iron, nonferrous metals, wood, plastic, rubber, even paper. Interesting that ignorez indifferent, in what state are metals — hot or cold. Moreover, it is possible to obtain a predetermined surface roughness, from 1-th to 8-th class of purity according to the State standard of the USSR 2789-59.

This feature of the process allows to use it for cleaning products and materials prior to application of various anti-corrosion and decorative coatings, including metallization and the cladding, as well as in the preparation of surfaces for the manufacture of bimetals. In addition, the opportunity to obtain a predetermined roughness, which is held lubrication is of great importance in the drawing.

As experience has shown, islamizirovannie can “cvetlit” hire, to remove surface products and materials rust, scale, penetration, rabito, cut obesplozhennym or defective metal layer and casting crust with the items, choose the local defects, as well as to cut the weld reinforcement, burrs, burrs.

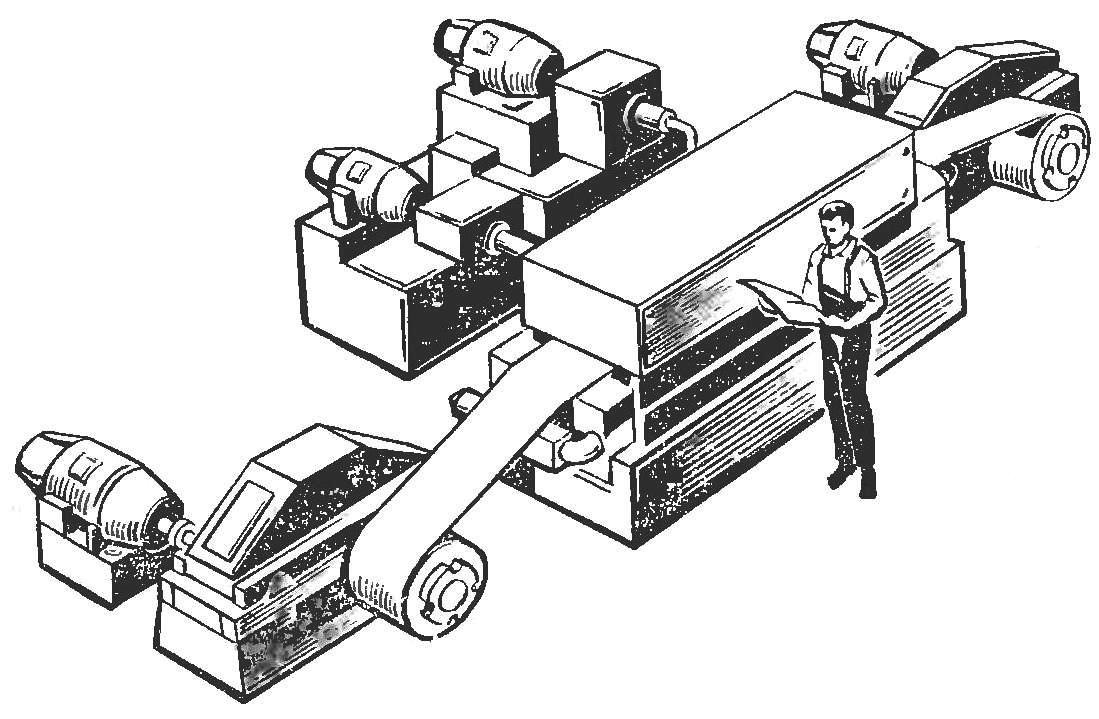

Figure 2 shows a diagram igaratinga unit for surface treatment of rolled materials (tapes, strips), or sheet metal. The strip is pulled through this device, and eglomise rotates and cleans the surface of the metal with one or both sides.

Fig. 2. Epiretinal Assembly for Stripping the metal strips.

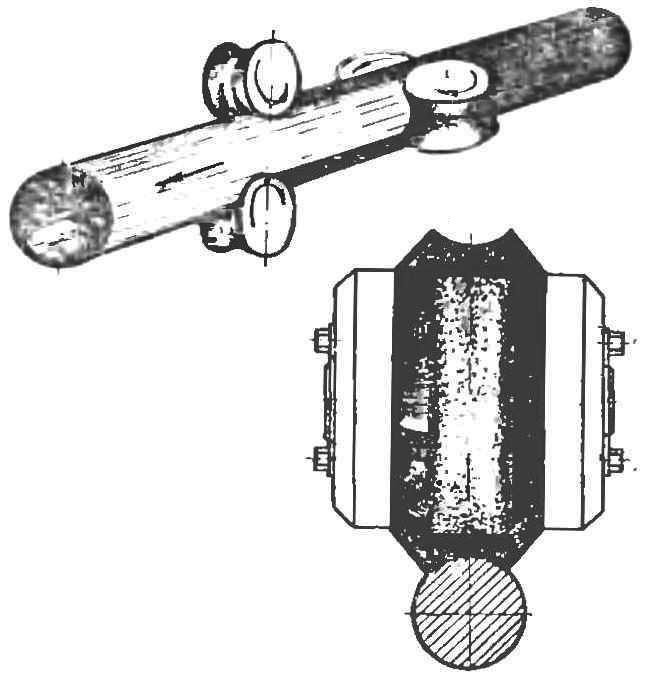

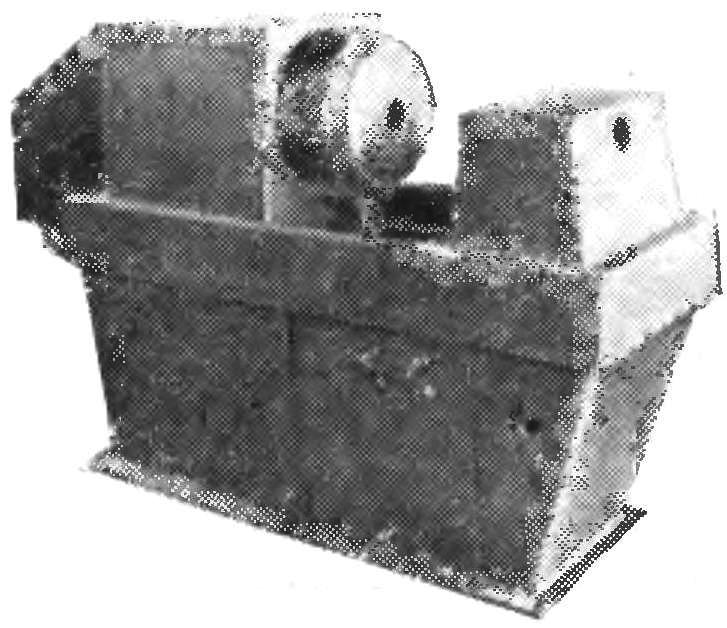

Fig. 3. Machine importerade rod.

During the cleaning of metal of rectangular cross section of the cutter can be positioned on all four sides. Machines for processing rod shaped material (Fig. 3) can have different schemes: when the rod moves along its axis, and the planetary ignorez revolve around him and its axis; when ignorez rotates around its axis, and the rod rotates and moves along them, and so on.

Operating experience hloretilnykh units showed that this process successfully replaces abrasive, blast cleaning and chemical etching of the metal, allows to increase productivity, to mechanize time-consuming and unhealthy process of Stripping the metallurgical, machine-building factories and in construction.

FEATURES IMPORTERADE

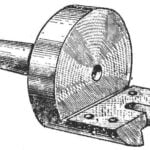

It is now developed about 20 types of igloves. Design and characteristics of them, depending on the destination, are very diverse. Typically, the tool has a cylindrical or conical shape, and part of it is the outer surface.

One of the main features of this tool is exceptional durability and samasamajist. In a production environment properly selected and precisely calculated ignorez work almost 2000 hours.

The geometric dimensions, configuration, design and features of this tool are estimated values. They depend on the type of workpiece and material characteristics, required performance and design of the unit, so ignorez are selected and computed depending on the particular task.

Instruments that do not meet these requirements or incorrectly selected or do not work, or fail 10-20 times faster than well-chosen.

The diameters used in practice ignores range from 25 mm to 600 mm Width of the working surface is practically unlimited, so the treatment of strips, tapes and sheet metal is advantageously carried out directly on the entire width on all sides.

Production technology of some structures ignores is such that their working surfaces can be given various shapes. This gives you the opportunity to handle such a tool some profiles with complex cross-section.

Manufacturer ignores not difficult and is mastered to workers of average skill within 5-10 days. Their production will need a simple fixture and standard equipment. However, each eglomise must be specially designed.

Epiretinal process deprived of most of the drawbacks of the known methods of Stripping materials — blast, chemical, abrasive: they have high cost of the process, they pollute the environment, almost preclude the use of a cut (in the process of cleaning) of the surface layer of metals, resulting in metals lost up to 2% of the weight of trimmed product.

When epiretinal cleaning no matter the state of processed surface contamination, the presence of grease, moisture, ice. Cut with surface oxide or shavings of metal is not sprayed, so there is no need of powerful ventilation devices.

This technology does not require and flow of water: even in the case of liquid cooling or getrootnode chip uses closed-loop recycling system. New tool under certain conditions, may operate without cooling.

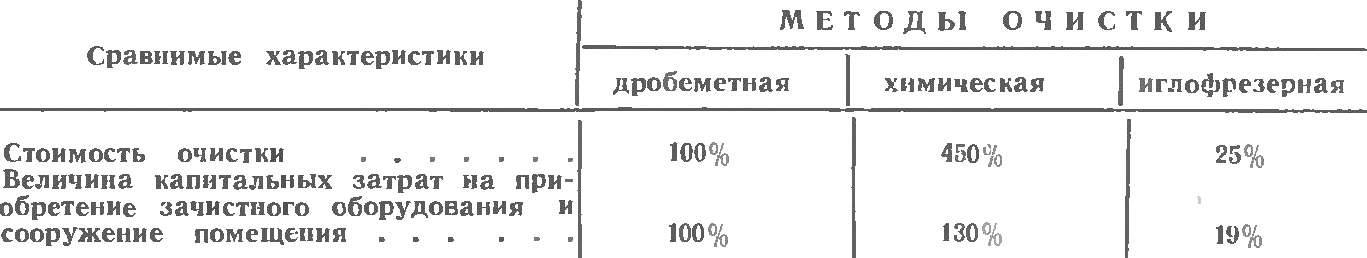

On the economic efficiency of importerade can be judged on the following below table.

THE WAY OF IMPLEMENTATION

Experience shows that in the absence of a reference technology importerade designing any equipment for this process is advantageously carried out under a leading scientific direction of the VNIIST, the developer and leading organization ignorethem.

This Institute on contractual terms develops and coordinates with the concerned organization and technological design assignment igaratinga machine or unit. This job includes concept design of the machine or unit, as well as the technical parameters considered in this (cutting speed, feed, clamping force applied, the required power and torque).

The Institute is developing a design tool in relation to the given conditions; produces working drawings, determines the manufacturing technology specific ignores and, if necessary, teach the customer’s personnel or provides Assembly starter kit ignores.

For the development of technological tasks, the customer shall identify the specific objects on which the appropriate implementation of importerade as well as the order and terms of their design. Their design organizations need to be developed and confirmed by the VNIIST technological requirements on ipofisario units. This should include the following basic data: type of products to be treated; the material from which it is produced, and as we clean the surface (curvature, presence of burrs, etc.); the purpose of cleaning (descaling, preparation for painting) and the thickness of the shear layer; the possibility of liquid cooling and flushing chips; requirements to the machine or to the surface.

Anyone who plans to implement epiretinal processing of materials, consider the following. The main criteria that determine the applicability of the new method are the mass and, if possible, uniformity of operations, and the presence of mechanical compression and movement of the tool relative to the workpiece, as for manual operation model ignorez not adapted.

Power igaratinga unit is determined by the amount of metal that must be cut eglomise per unit of time. Therefore, with increasing chip thickness and productivity growth unit to grow its capacity and dimensions. Full in the development of technological requirements for epiretinal unit these elements must be determined with care and not be excessive.

Comparison chart of treatment PROCESSES of metals IN the performance of the GRINDING UNITS 100 m2/h

Ignorez average characteristics per one centimeter of width of the working surface of the tool can cut about 60 grams of metal per minute, spending of 0.6—1.0 kWh of energy for every kilogram of cut metal. The rate of Stripping of strips with thickness up to 0.5 mm can reach 15-20 m/min, and at a thickness of about 2 — mm to 5— 10 m/min. Speed of processing round bars and tubes of 30 mm diameter will be equal to 10-15 m/min; the time of Stripping larger diameter is determined by calculation.

When Stripping roll materials up to 3 mm individual surface irregularities not exceeding 3 mm, for the cleaning process does not significantly affect and can be ignored. However, when Stripping the sheet metal with the same errors it is advisable to use the correct devices or special circuitry igaratinga unit.

Ipofisario machines to clean small parts is very compact, constructively simple and cheap. For small batch production it is possible to create either a series of inexpensive specialized machine tools or universal, allowing its transformation into different types of products.

V. SALUKVADZE