The second necessary condition was the making of independent-wheel long-travel soft suspension — only such could provide high-speed movement over rough terrain. But more on that later.

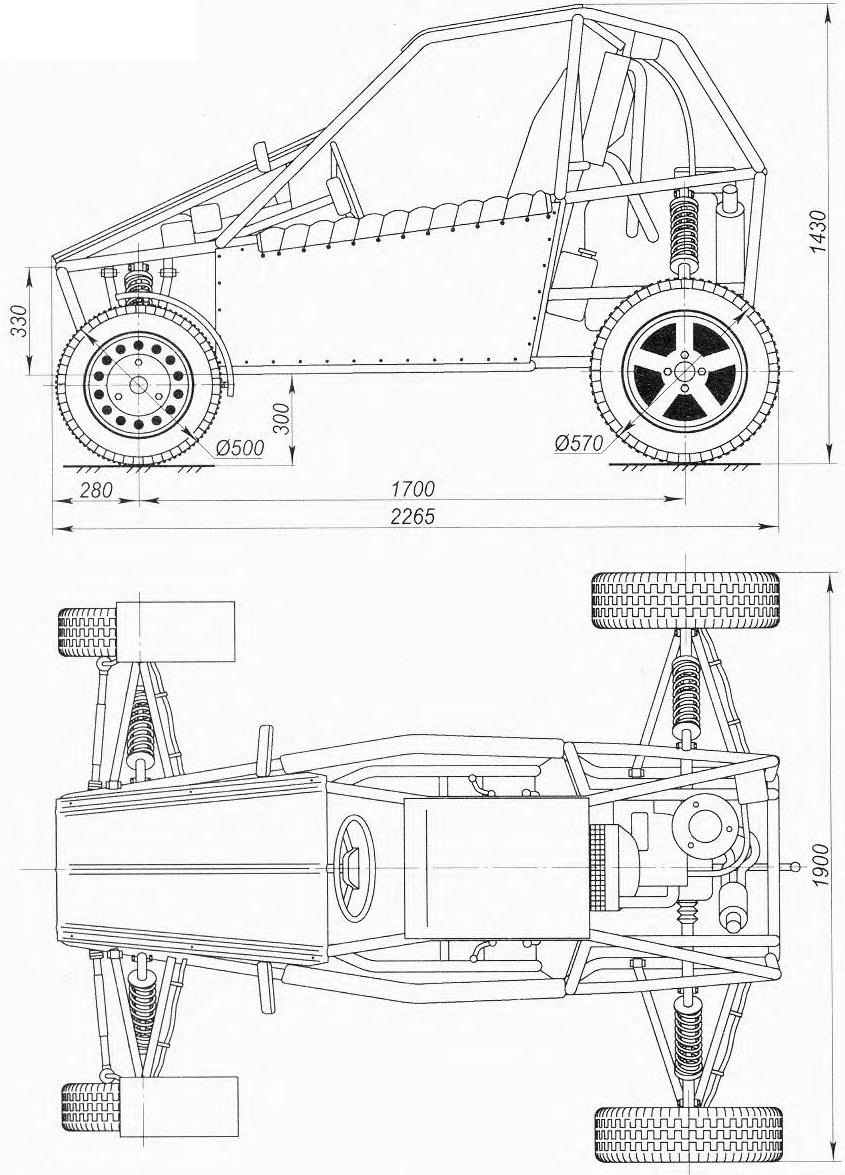

The car type is “buggy”.

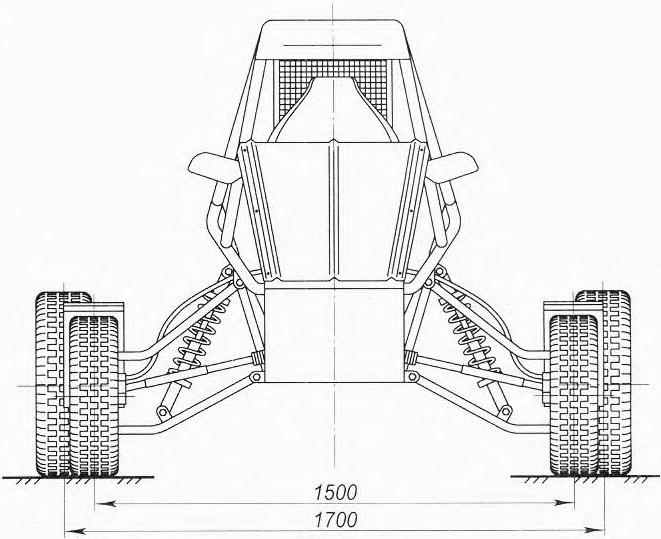

The machine — welded space frame-a frame that includes force elements and the mounting and safety elements. Logic told me that the roll over bar should be located along the frame — after all, if suddenly the car will turn over, then it by inertia will continue moving forward and then cross the arc, not being reinforced struts, must it be “goes.”

Cooked frame using an old but quite efficient welding machine 380 volt.

Frame (all parts except specifically stated, is made of steel tube Ø30×2,7):

1 —rails (2 PCs.);

2 — side arc;

3 — short crossbars (2);

4 — the portal steering rack;

5 — bent struts (2 PCs.);

6 — long crossbars (2);

7 — arc seatpost (tube Ø22, 2 PCs.);

8 — struts (2 PCs.);

9 — roll over bar (2 PCs.);

10 — b-pillar (2 PCs.);

11 — arcs backup security (2 PCs.);

12 — back arc;

13 — bent stringers support the top rear arms (2 PCs.);

14 — rear rack (2 PCs.);

15 — the drag hook;

16 — mounting bracket of the radiator (pipe Ø22);

17 — spacer arcs of safety (2 PCs.)

Because of the limited funds allocated for the implementation of the project from the family budget, the frame was welded from ordinary water pipes with a diameter of 34 mm and a wall thickness of about 3 mm. Bends were done on the bending: radius — cold and small — with local heating with a blowtorch.

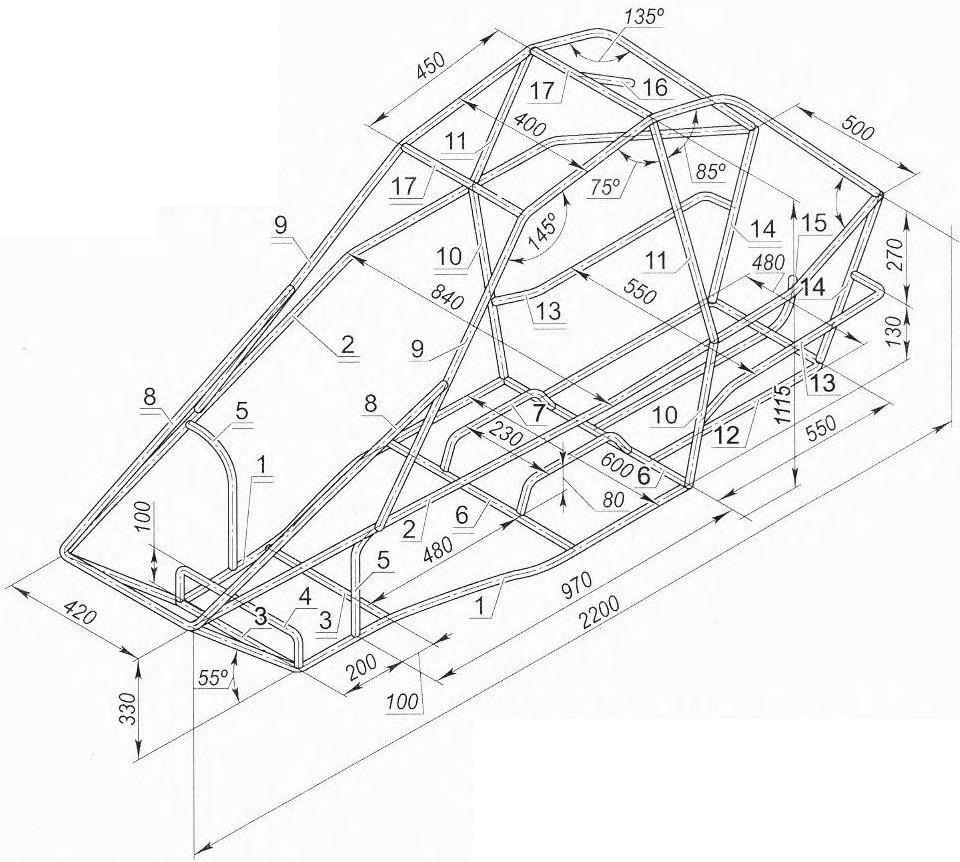

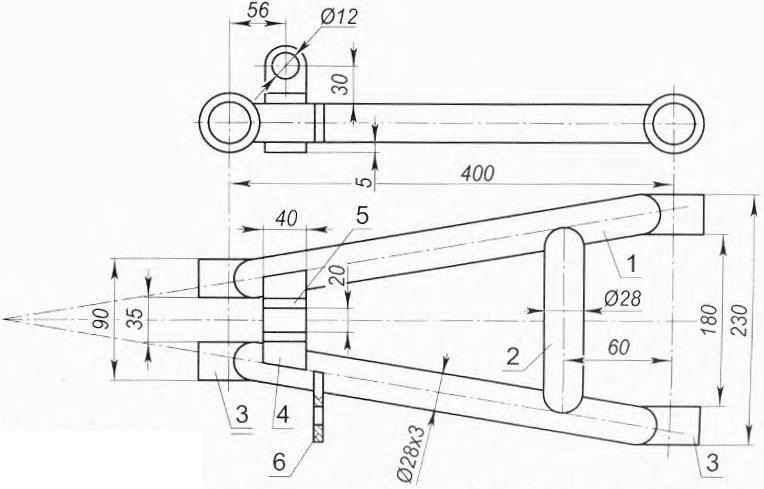

Upper front control arm:

1 — beam (pipe Ø28×3, 2);

2 — strut (tube 28×3);

3 — Bush silent block (from the car “Oka”, 2 sh.);

4 end plate (steel sheet s5);

5 — tip the ball (from the car “Oka”);

6 — eyelet brake hose (steel sheet s5, 2 PCs.).

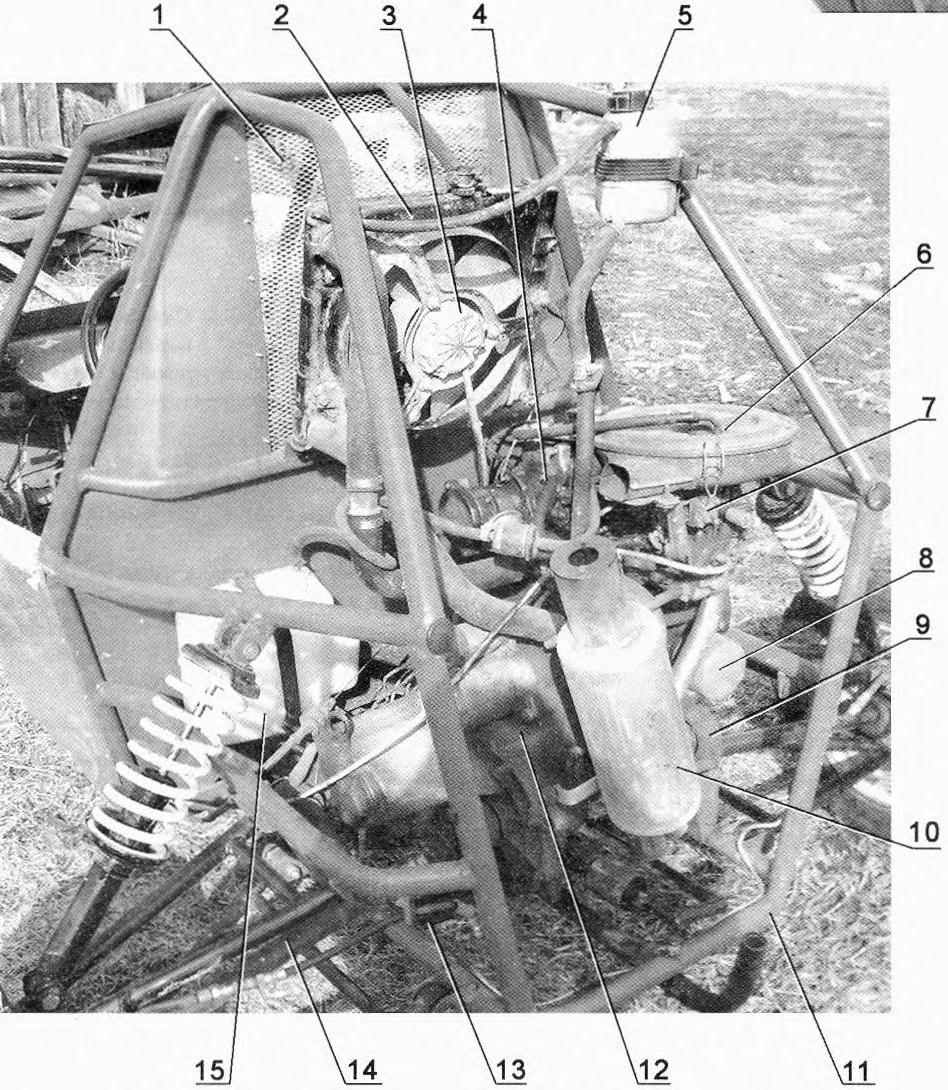

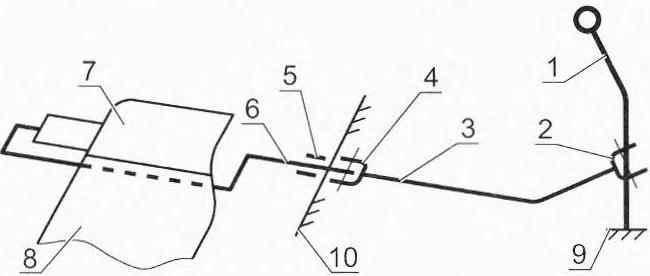

The engine capacity of 749 cm3 and 33 HP from the used car “Oka” VAZ-1113 together with the standard gearbox, clutch, transmission. Since the power unit with the gearbox moved back (and as you know, on the base car he is standing in front of), had to redo the shift linkage. But the task was not so difficult. Was a bit unsightly and with more weight, but fast and simple to manufacture. The stock gearbox docked homemade curved rod-“poker” and missed it from below between the engine and transmission forward. And then — regular wings (only unfolded backwards) and a gear shift grip, as it should be to the right of the driver’s seat. Switching circuit speeds remain standard.

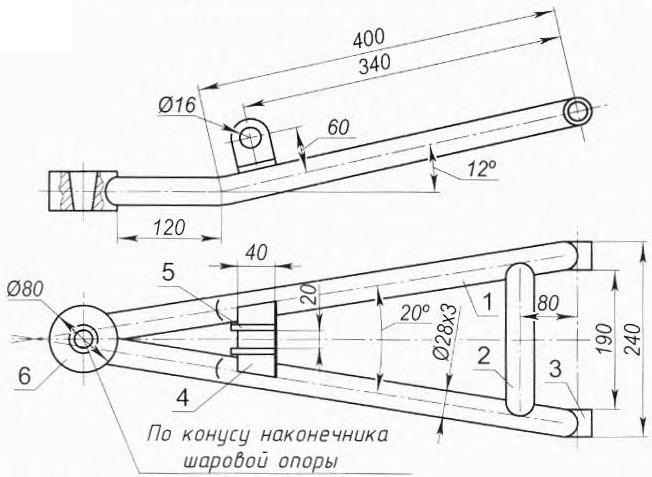

Rear upper control arm:

1 — beam (pipe 28×3, 2);

2 — strut (tube 28×3);

3 — sleeve of silent blocks (from the car “Lada”, 4 PCs.);

4 — platform (sheet s5);

5 — lug (steel sheet s5,2 PCs.);

6—eyelet brake hose (steel sheet s5).

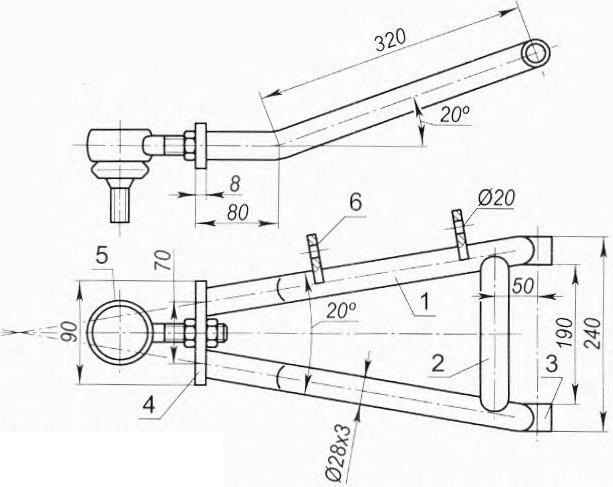

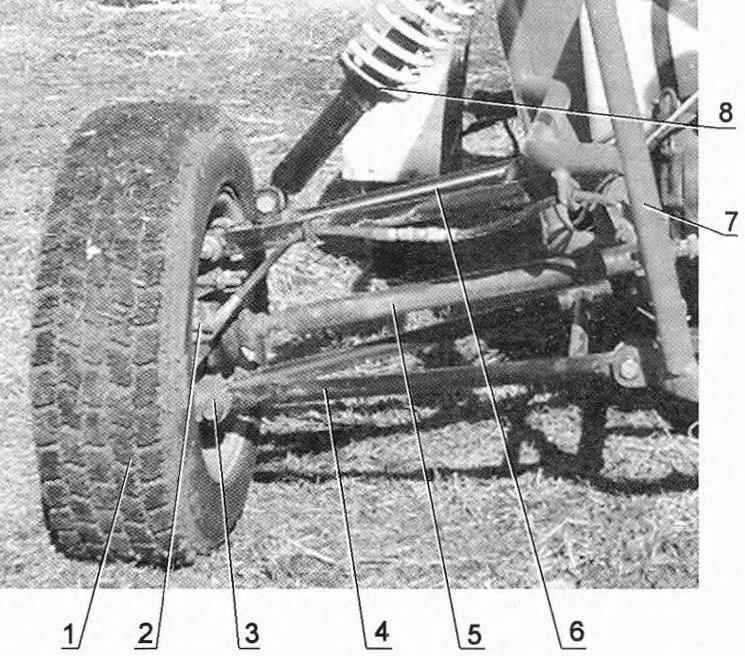

Each wheel suspension is double wishbone. The a-arm is of circular tubes 28×3 mm. On the frame levers are suspended in the eye via silent blocks on the VAZ-2101. Eyes ordered the Miller and welded them to the frame in place during the mounting of the suspension arms. The rear arms are straight, and the front curved.

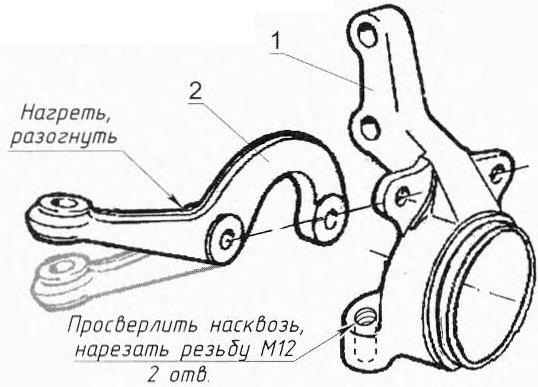

Front (steering) knuckles — from “Oka”, modified by dohry-chinoy suspension. The front wheels are adjustable in camber and toe-in. Steering rack “okovsky”, is located in the front axles of the front wheels and rotated 180 degrees. Steering levers, unlike placing them on the base car, is also rotated forward, and besides, more and straightened in the heated state. All this was done to compact to establish all the mechanisms and management nodes, decreasing the size and accordingly the weight of the machine, which in turn affects the improvement of the dynamics.

Lower front control arm:

1 — beam (pipe Ø28×3, 2);

2 — strut (tube 28×3);

3 — Bush silent block (from the car “Oka”, 2);

4 — platform (sheet s5);

5 — eyelet of the shock absorber (steel sheet s5, 3).

6 — the mounting bracket arm to the knuckle (steel, circle 80, s30).

The bottom of the machine of galvanized steel sheet with a thickness of 1.2 mm. It is welded to the frame rails and the front sloping racks, moving here in the fairing. The sides, front hood and roof are made of sheet (thickness 1.2 mm) aluminum. These sheets are attached to parts of the frame-frame by self-tapping screws through pre-drilled holes (slightly smaller diameter).

The attenuators are combined in one unit with the springs on the principle of motorcycle. Themselves dampers and springs — from “Oka” and “Lada”.

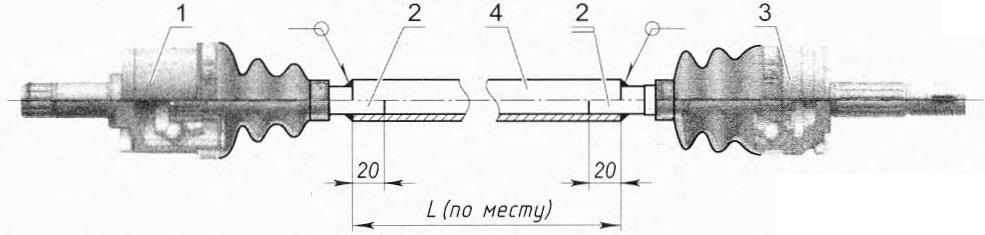

Because the track of the buggy much more than the standard car, drive shafts (half shafts) are elongated. To do this, they approximately in the middle of the cut, and these ends are inserted in a thick-walled pipe with the same inner diameter as the outer from the axle shaft. After checking the alignment of parts welded together. Back fist — front, too, from the “Okie” and also under modified double-wishbone suspension. They are not turning, — that they hold the bolts connecting these blocks with the top levers. At the bottom instead of ball bearings bolted polaki with welded bushings for silent blocks. Through them, the fists are attached to the lower suspension arms.

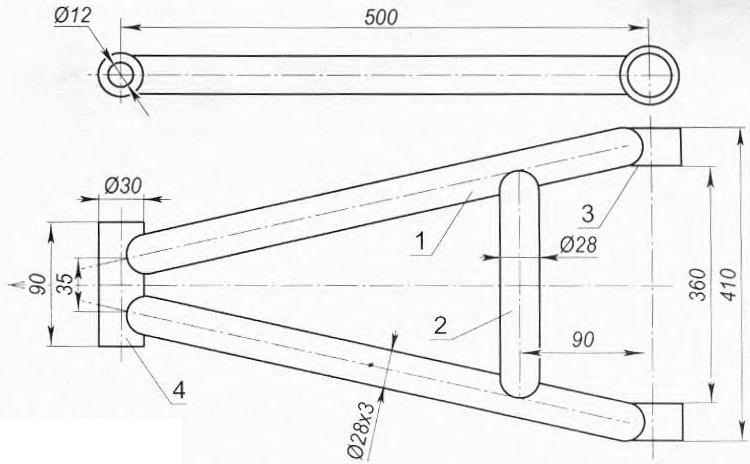

Rear lower control arm:

1 —beam (pipe 28×3, 2);

2 — strut (tube 28×3);

3 — Bush silent block (from the car “Lada”);

4 — Bush (round 30).

The radiator cooling fluid, again for reasons of rationality and layout for better cooling, up. The air it enters through the grille in the partition wall behind the driver between the cab and engine compartment.

![The suspension of the front steering wheel]()

The suspension of the front steering wheel:

1 — mud flap (duralumin, sheet s2);

2 — front mud flap (steel, circle 10);

3 — wheel (from the car “Oka”);

4 — knuckle (from the car “Oka”, modified);

5 — caliper (from the car “Oka”);

6 — steering knuckle(from the car “Oka”);

7 — lower suspension arm;

8 — absorber ( VAZ-2108);

9 — tie rod (from the car “Oka”, extended);

10 — upper arm;

11 — Rama.

The seat is made from sheet metal with a thickness of 1 mm, and then laminated foam and covered with leatherette (in the same way finished and armrests). Though it is not adjustable, but it turned out comfortable, anatomical. To the left of the seat is the lever gear shift and ignition.

Because the cabin is quite wide, the left of the seat mounted battery. Here were placed and the fuel tank, but later I moved it over the partition into the engine compartment that does not interfere with boarding facilities.

Suspension rear drive wheel:

1 — wheel (of a car “Zhiguli);

2 — brake caliper (front of the car “Oka”);

3 — the fist (from the car “Oka”);

4 — the bottom lever;

5 — drive shaft with constant velocity Joint (from the car “Oka”, extended);

6 — upper arm;

7 — frame;

8 — shock absorber (from the car “Oka”).

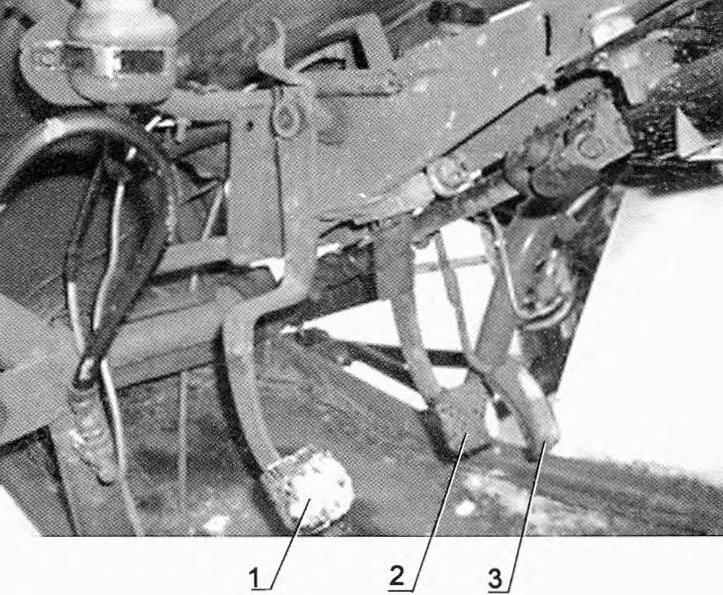

The controls (pedals, steering wheel, etc.) taken from “Oka”. The pedals are a little shortened and split among themselves. The first revision is marginally increased force applied to them, but the second has increased the convenience and speed of reaction, as the foot never falls on two pedals at once as the base car. Brakes all four wheels — disc (“Oki”), with hydraulic drive, but without a vacuum booster. Experience has shown that on a light machine it is possible to do without it.

Lengthening the drive shaft (axles):

1 — the internal hinge of equal angular speeds (shrus CAT);

2 — drive shaft-driveshaft (cut);

3 — outer CV joint (wheel joint);

4 — lengthening the pipe.

Throttle control of the carburettor and the clutch cable runs through in budenovskoy braid. The wheels are intentionally made different (the front is smaller diameter than the rear), to underline the rapid sport style machine, which, as it tapers in the front. This had the rear wheel hubs and brake discs drilled new holes for the four studs for a “Zhiguli” of the wheels.

Revision knuckle and the steering knuckle:

1 —fist;

2 — pivot arm.

Homemade silencer welded. There are rear view mirrors. Since the machine was supposed to use for daytime “rides”, the lights are not yet mounted, facilitating, and most importantly — simplifying construction. But mud flaps on the front wheels put still had, although at first did not plan to.

The layout of the engine compartment:

1 — mesh partition;

2 — radiator;

3 — the fan;

4 engine;

5 — expansion tank coolant;

6 — air filter;

7 — carb;

8 — the oil filter;

9 — support the engine mounts to the rams (4 PCs.);

10 — silencer (homemade);

11 — frame;

12 — transmission units (clutch basket, transmission, main gear);

13 — under engine cross member;

14 — driveshaft (modified);

15 — fuel tank V=10 l (nylon canister).

Dimensional data machine following. Dimensions (length x width x height) —2265x1900x1430 mm. wheel Track: front — 1500mm, rear — 1700 mm. Base 1700 mm ground clearance — 300 mm Weight — 350 kg.

On the car ride on the weekends with the whole family, the so-called rough terrain. Especially loves to ride on her daughter. And friends with the “cool” jeeps, too, often asking for a ride.

Pedal control:

1 — clutch;

2 — brakes;

3 — “gas”.

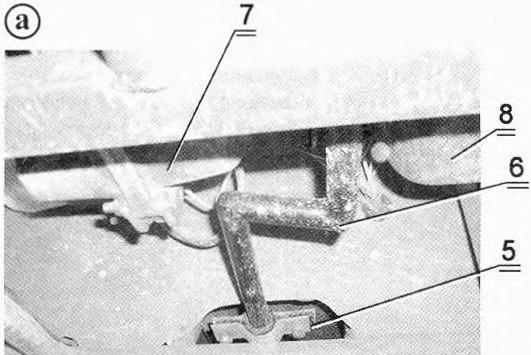

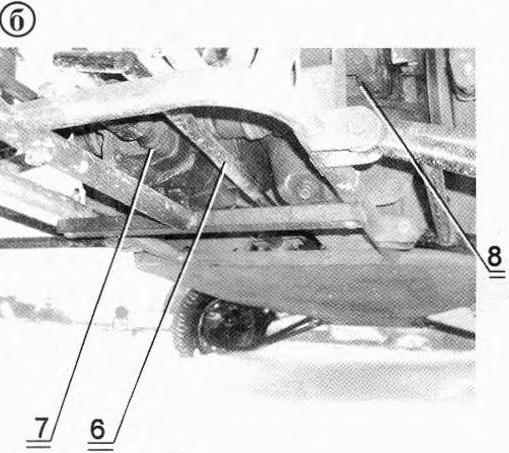

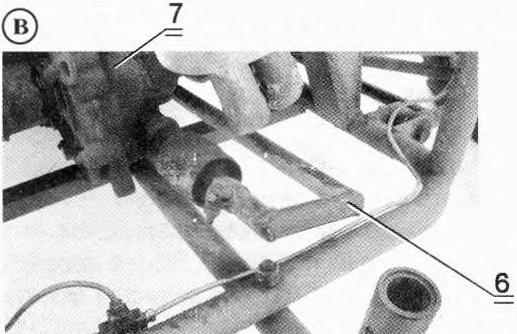

Diagram of the shift linkage and figure thrust (position in the figure in the photo is the same):

1 — arm (from the car “Oka”);

2 — yoke; 3 —the slider (tube Ø16);

4 — universal joint;

5 — guide sleeve-clamp;

6 — figure thrust (photo: a — front section, bottom view; b — rear part bottom view; b — rear part, top view);

7 — gear shift;

8 engine;

9 — Poliana;

10 — the partition between the passenger compartment and engine compartment.

Hand controls car:

1 — the wheel (from the car “Oka”);

2 — arm gear shift (from the car “Oka”);

3 — the slider (steel, circle 10) with the yoke drive gear;

4 — switch off the battery ground;

5 — the ignition switch;

6 — universal joint.

The car is stable thanks to the wide track, runs comfortably on high speed turns and bumps due to the soft and long-travel suspension. At this ratio of mass and power of the machine is quite dynamic. Is enough to receive the portion of adrenaline.

Recommend to read

Center indicator

Center indicator

My fifth-grade grandson recently came to me with a request: he needed to come up with a project for 3D printing, the kids from the internet would download toy soldiers, but he wanted to... Winter steed

Winter steed

Old people humorously recall fun rides down snowy slopes on primitive sleds — bowl-shaped rounds made from frozen wet hay in old sieves. Or noisy descents "in a small heap" on ordinary...

Dream-the idea of making a car, even simple, like buggy, appeared in his teenage years, when machines were in short supply. But for many UNDERSTANDABLE reasons (had neither the experience nor the tool nor the means) she could not at that time be done — and ended only with drawings on paper. Over the years the opportunity came to build, and the boyish idea has revived in my mind. On the profile of their work by this time, I’m already quite versed in the device of conventional cars, which helped me during the implementation of the project.

Dream-the idea of making a car, even simple, like buggy, appeared in his teenage years, when machines were in short supply. But for many UNDERSTANDABLE reasons (had neither the experience nor the tool nor the means) she could not at that time be done — and ended only with drawings on paper. Over the years the opportunity came to build, and the boyish idea has revived in my mind. On the profile of their work by this time, I’m already quite versed in the device of conventional cars, which helped me during the implementation of the project. The car, which will be discussed, is the second built by me. At first I gained experience, took my lumps. The same wanted to make a more graceful, easy, a pleasure, but also with “easy drayverskoy manners.”

The car, which will be discussed, is the second built by me. At first I gained experience, took my lumps. The same wanted to make a more graceful, easy, a pleasure, but also with “easy drayverskoy manners.”