The next operation is the machining of holes for bearings. To do this, in the assembled housing on the same lathe is drilled through hole, and then cover rastaquouere seat for the bearing shaft. Further cover is removable, and in the case pritachivajut holes for the bearing and seal. Remains ottercat inner wall of the housing, spaced from the plane of the connector is 43 mm.

To handle the landing collar (Ø 228 mm) will have to carve mandrel — cylinder with external Ø 46 mm.

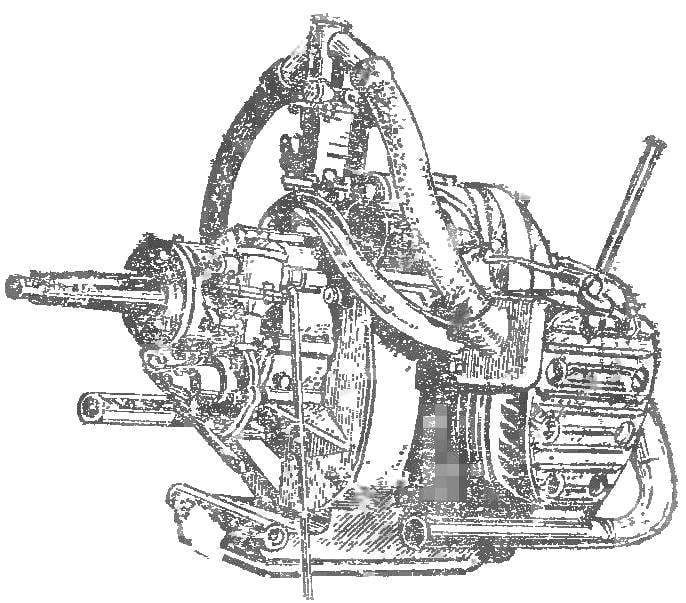

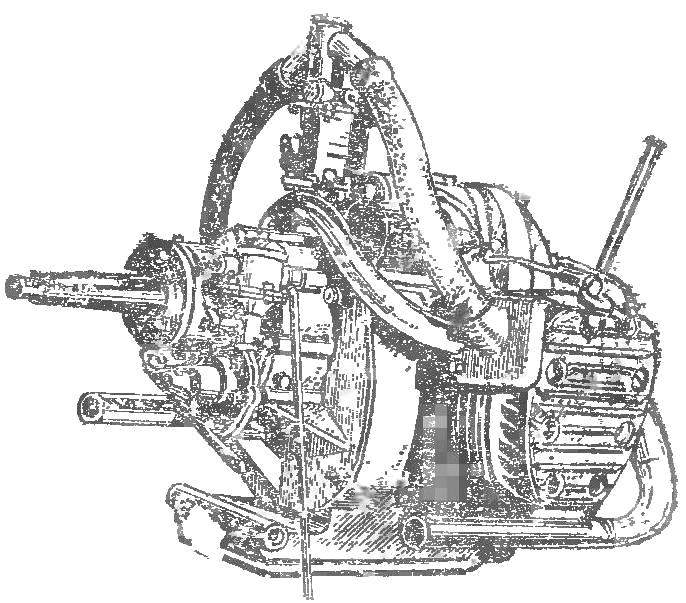

Fig. 2. The layout of the gear:

1 — Carter, 2 — bearing 7305У, 3 — gear, 4 — the bearing 206, 5 — gear cover, 6 — bolt M8 with nut, 7 — spacer, 8 — Cam, 9 — key, 10 — spacer 11—206 bearing, 12 — a cover of the bearing unit, 13 — threaded rod M8 with nut, 14 — oil seal 15 — output shaft of the reducer, 16 — pin M8 mounting fuel pump, 17 — clutch lever, 18 cover, 19 — blank range 20 — bearing 21 — cover of the bearing unit, 22 — stock clutch, 23 — seal, 24, 26, the bearing 303, 25 — gear, 27 — oil seal 28 — drive shaft gear, 29 — Cam, 30 — pusher fuel pump, 31 — M8 stud with nut.

Dolly Carter fixed or rotating bolt is pressed by the tailstock center.

Further processing of the crankcase must be performed in chetyrehochkovym the Chuck of the lathe. Clamping it in detail should be so that the distance between the axis is already split of the hole and the axis of rotation of the cartridge is composed of 74.6 mm (center-to-center distance for the gear set). The sequence of operations in bore holes for bearings and seals is practically the same as that for the secondary shaft.

The manufacturing of other parts and Assembly of the reducer is unlikely to cause particular difficulties.

M. PSAREV

Designers snowmobiles know that linking directly to the crankshaft of the engine and the propeller is unprofitable: too high engine speed do not allow to use aredigital optimally. To reduce the propeller revolutions Amateur designers use chain gear, ploskostopie belts, banded V-belt transmission. You can meet the most reliable and compact single-stage gear reducers. As a rule, however, they are quite complicated. The most simple design managed to develop one of the enthusiastic Amateur “aerosanitary” from the city of Tchaikovsky, Perm region M. Psarev. On the processability of the mechanism at least tells TC that he “produced” a kind of microseries — was repeated at least five times. Today we introduce you to drawings and manufacturing technology of the gear.

Designers snowmobiles know that linking directly to the crankshaft of the engine and the propeller is unprofitable: too high engine speed do not allow to use aredigital optimally. To reduce the propeller revolutions Amateur designers use chain gear, ploskostopie belts, banded V-belt transmission. You can meet the most reliable and compact single-stage gear reducers. As a rule, however, they are quite complicated. The most simple design managed to develop one of the enthusiastic Amateur “aerosanitary” from the city of Tchaikovsky, Perm region M. Psarev. On the processability of the mechanism at least tells TC that he “produced” a kind of microseries — was repeated at least five times. Today we introduce you to drawings and manufacturing technology of the gear.