Winter fishing is an activity for the most resilient. Try spending a whole day by the ice hole in freezing weather — neither a fur coat, nor a tent, nor a “forty-degree hand warmer” will save you. However, you can indulge in your favorite hobby in comfortable conditions. All you need is a special all-terrain vehicle with low-pressure tires and a closed, heated cabin, designed specifically for your beloved winter fishing.

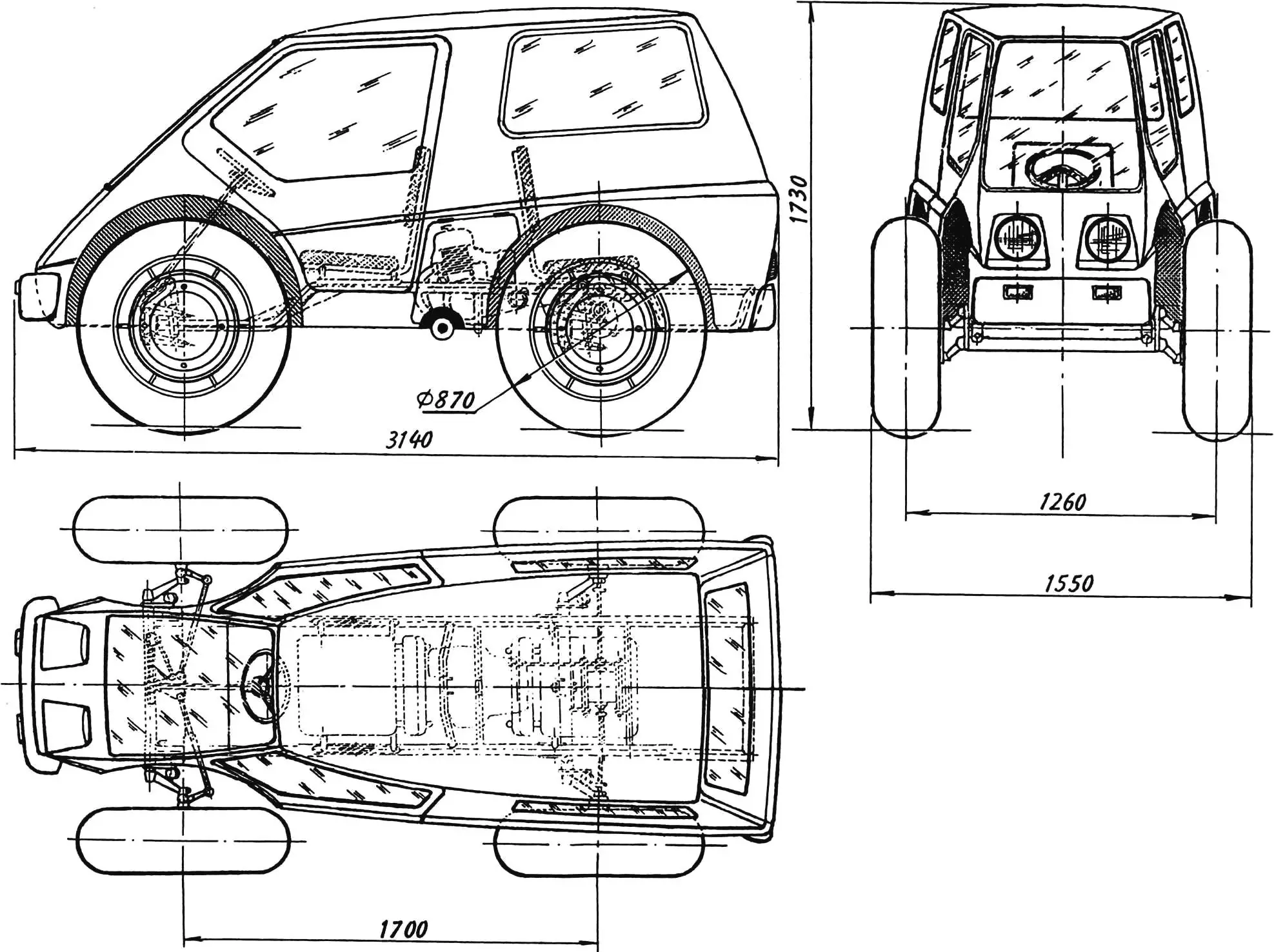

The all-terrain vehicle, named “Comfy,” was developed based on the engine from the TG-200M cargo scooter. Experience shows that this engine is one of the most reliable among domestic two-stroke engines, also equipped with a dynastarter and forced air cooling. The front and rear axles, main drive (reverse gearbox with differential), braking system, and steering were borrowed from the SZD motor tricycle. The transfer of torque from the engine to the wheels is via a bushing-roller chain to the reverse gearbox (main drive from the SZD motor tricycle), and then through shafts with flexible cardan joints from the SZD motor tricycle — to the wheels.

The rear axle of the all-terrain vehicle was designed based on a modified front axle from the SZD motor tricycle — for this purpose, the tubes on the wheel hubs were cut off, and brackets with holes for attachment pins to the axle levers were welded. Additionally, the hydraulic shock absorbers of the rear axle were replaced with motorcycle spring-hydraulic ones, which helped unload the standard torsions and increase the vehicle’s load capacity. The front axle, also borrowed from the SZD motor tricycle, was mounted on the all-terrain frame almost without modifications. The only change was replacing the standard shock absorbers with spring-hydraulic ones.

For “Comfy,” a welded tubular frame was designed, along with a two-seat insulated cabin of mixed construction with a steel tubular frame, internal lining of hardboard, foam filling, and an external shell made of fiberglass and epoxy resin.

The basis of the vehicle frame consists of two side members made of steel tubes 40 mm in diameter with a wall thickness of 3 mm. To mount the front axle, shoes were welded to the front of each side member, while the rear axle is attached to brackets welded to the frame, cut from 3 mm sheet steel. The axles are fixed at the mounting points in exactly the same way as on the SZD motor tricycle — using bolts with nuts and split spring washers.

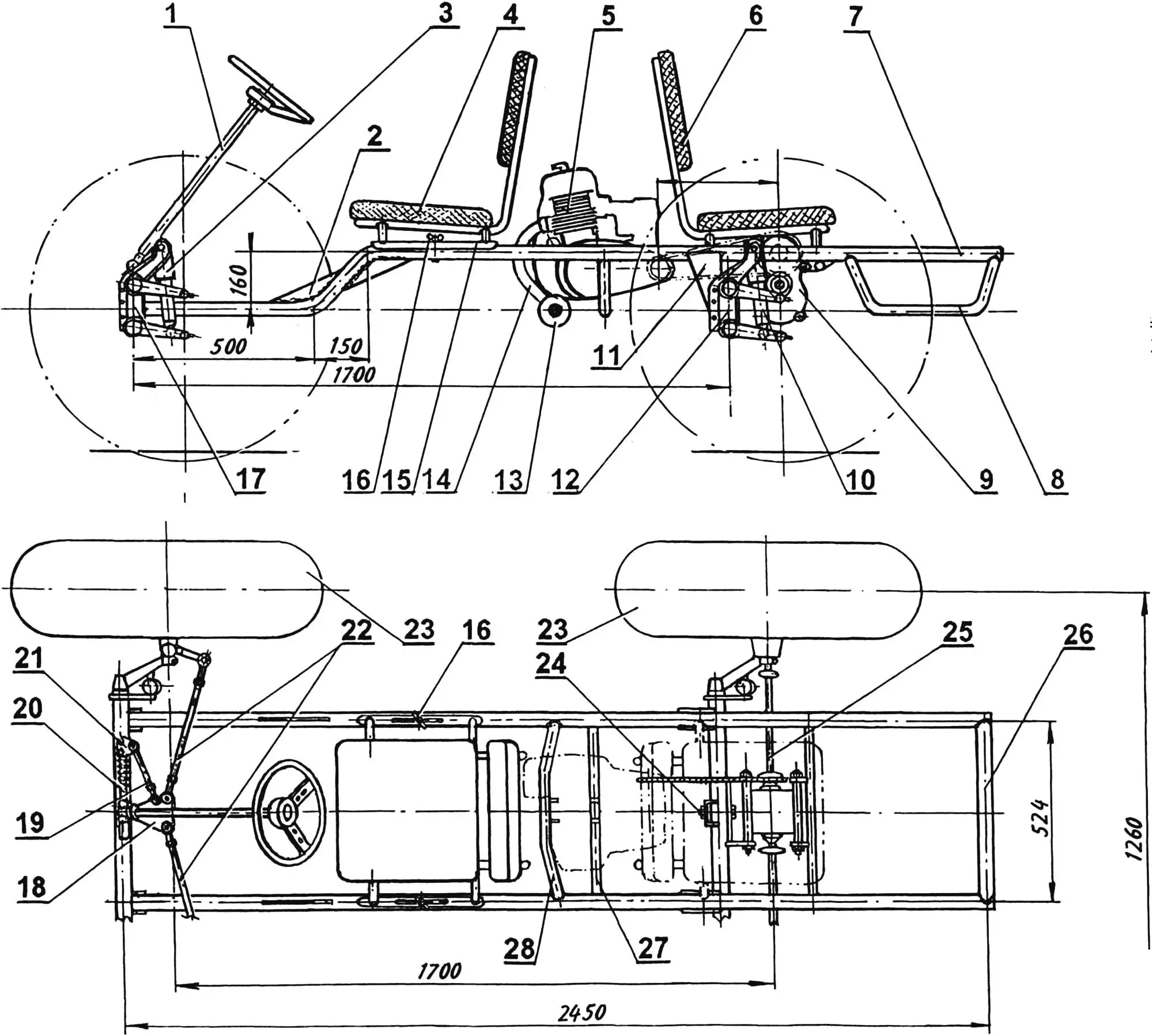

1 — steering column (from SZD motor tricycle); 2 — reinforcing gusset (steel, sheet s3, 4 pcs.); 3,10 — spring-hydraulic shock absorbers (from Voskhod motorcycle); 4 — driver’s seat; 5 — TG-200M engine; 6 — passenger seat; 7 — frame side member (steel, tube 40×3); 8 — additional frame (steel, tube 30×2.5); 9 — main drive (from SZD motor tricycle); 11 — rear axle mounting bracket; 12 — rear axle (modified front axle from SZD motor tricycle); 13 — muffler; 14 — exhaust pipe (from TG-200M engine); 15 — driver’s seat runners; 16 — M10 wing nut for seat attachment; 17 — front axle (from SZD motor tricycle); 18 — pendulum lever of steering; 19 — intermediate steering rod; 20 — steering rack (from SZD motor tricycle); 21 — adapter; 22 — steering rods (from SZD motor tricycle); 23 — pneumatic wheel; 24 — main drive mounting shoe (steel, channel 60x40x3); 25 — shaft with flexible cardan joints (from SZD motor tricycle); 26 — rear cross member (steel, tube 40×3); 27, 28 — cross members for engine mounting (steel, tube 30×2.5)

The frame assembly is carried out on a flat floor or a simple jig made from two three-meter boards 40–50 mm thick and three or four crossbars. After placing the prepared side members on the jig, the future frame must be checked for symmetry, absence of distortions, and conformity to dimensions, after which tubular cross members and body mounting nodes are welded to the side members. The rear cross member is a 40 mm diameter tube. Two 30 mm diameter tubes form the engine mount, and one 30 mm diameter tube supports the main drive (reverse gearbox). As seen in the drawings, the reverse gearbox is mounted vertically, sprocket up, with the reverse lever positioned forward in the driving direction.

The engine is mounted on the frame via lower and front mounting units (forks), providing reliable fixation. To install the engine mounting forks, it is easier to first attach them to the engine, then clamp the engine to the frame with clamps and soft steel or copper wire for precise alignment, and finally tack weld the units. The final welding of the units is done after removing the engine. Similarly, the main drive mounting units are secured to the frame.

The exhaust pipe is from the TG-200M, the muffler is homemade — a hollow cylinder containing tightly rolled fine-mesh steel wire inside.

The steering system is from the SZD motor tricycle, modified for the placement of the steering wheel and column in the middle of the cabin. For this, an adapter was installed on the steering rack, a triangular pendulum lever was fabricated, and a shortened intermediate steering rod was made from the standard steering rod, connecting the rack adapter and pendulum lever.

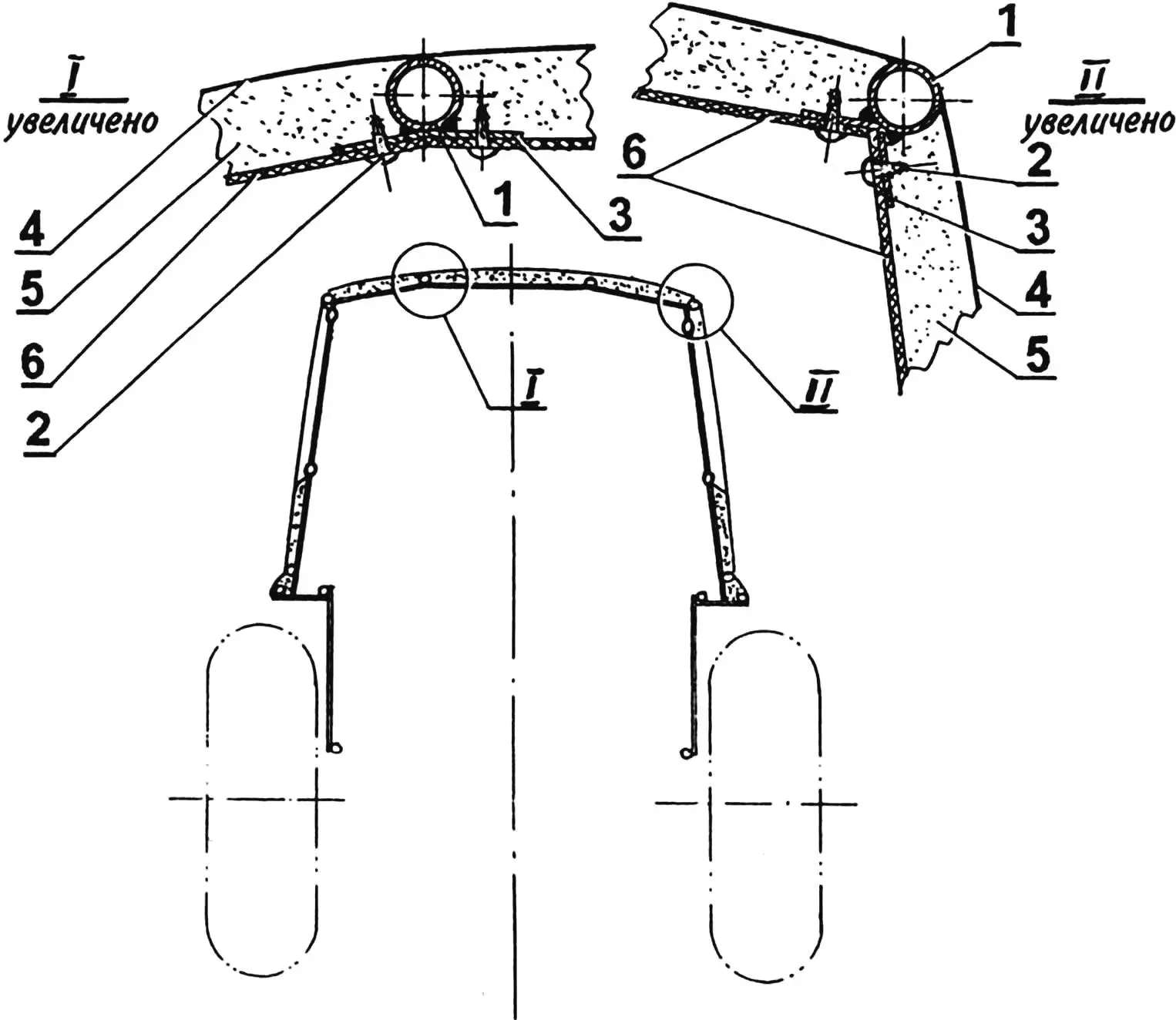

1 — frame (steel, tube 16×2, 18×2); 2 — self-tapping screw; 3 — mounting plate (steel, sheet s1.5); 4 — lining (3 layers of fiberglass and epoxy resin); 5 — filling (construction foam); 6 — inner lining panels (hardboard s4)

The cabin of the all-terrain vehicle is built using a technology described in publications of the journal Modelist-Konstruktor, but the version presented below is simpler and more practical.

The cabin is based on a frame welded from thin-walled steel tubes with diameters of 16 and 18 mm. It is not particularly rigid, and understandably so — its primary function is more for shaping than structural support. On this frame, the windshield and rear side window frames, as well as the door frames, are welded in place. By the way, the all-terrain vehicle has only two doors — a front left door for the driver and a rear end door for the passenger. Ready-made glass for the vehicle was not available, so all windows were cut from plexiglass.

Next, the frame is lined inside with hardboard; the panels cut from this material are attached to the frame tubes with M4 screws. Both doors are also lined with hardboard. Once prepared this way, the frame is covered on the outside with construction foam. The shaping of the cabin and doors is done in one piece. The surfaces are first leveled using a homemade tool consisting of a bow saw, where instead of a toothed blade, a nichrome wire heated by electric current is installed; the heating element is powered through a variable autotransformer (LATР). Then, the foam is shaped with a long, sharply pointed knife and finally sanded using coarse-grain sandpaper glued to strips of plywood.

The prepared cabin surface is then covered with three layers of fiberglass on an epoxy resin binder. After resin polymerization, the shell is sanded, filled with a two-component automotive putty, and painted — first with a primer layer, then two layers of automotive enamel. The interior of the cabin is lined with artificial leather.

The cabin floor is made of 8-mm plywood — panels were twice treated with hot linseed oil and fixed to the frame with screws. The wheel arches are lined with 5-mm plywood, also treated with hot linseed oil.

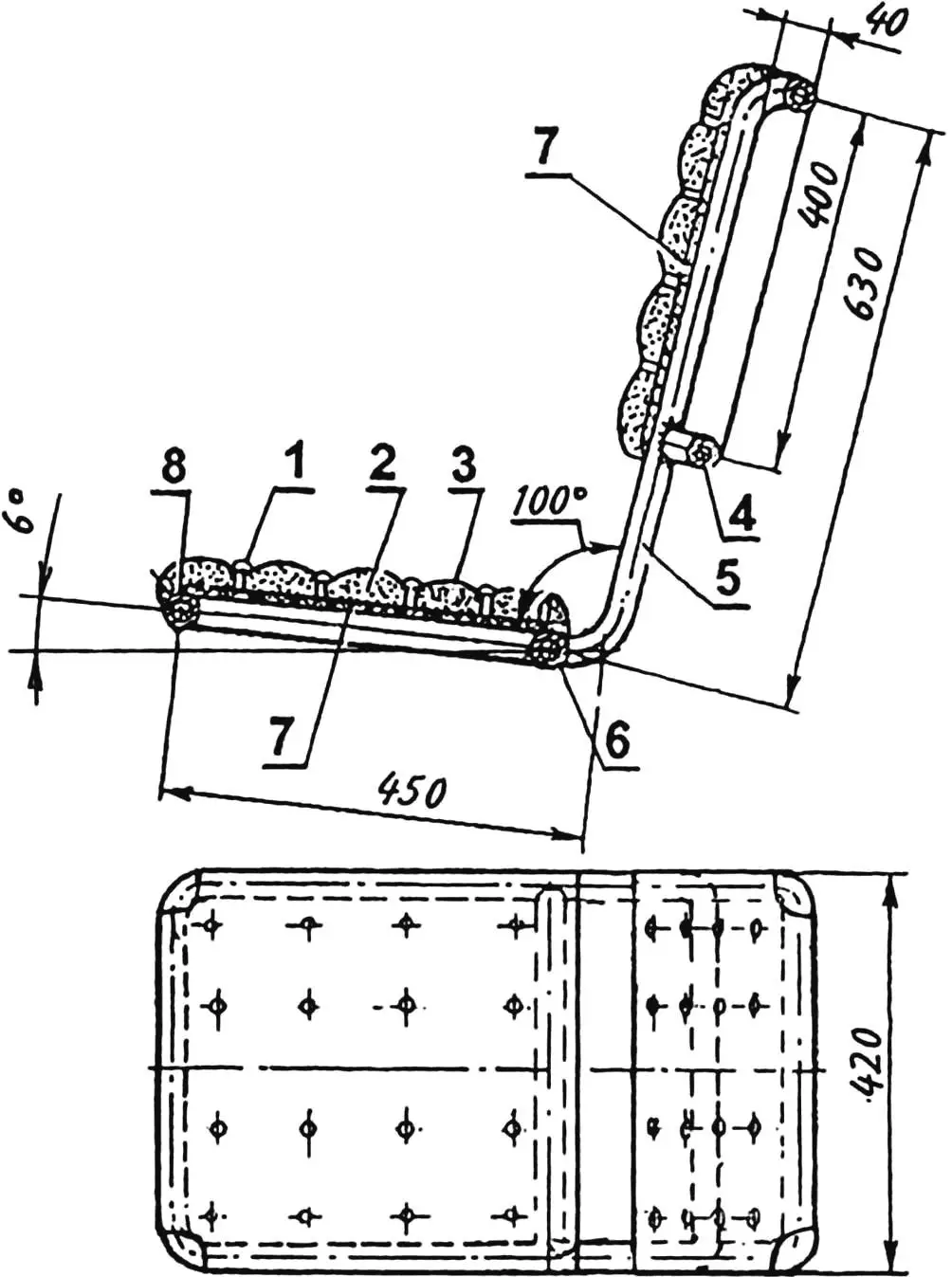

The driver’s and passenger’s seats are homemade. Their frames are welded from steel tubes. Rubber rings cut from a truck inner tube are stretched over the seating and backrest areas. On this elastic base, foam cushions are attached, and then the seats and backrests are upholstered with artificial leather.

The all-terrain vehicle is controlled like a car. The braking system is hydraulic, from the SZD motor tricycle. The throttle and clutch are cable-operated. The pedal assembly, consisting of gas, brake, and clutch pedals, is mounted on hinged units welded to the frame side members. Gear shifting is done via a rigid rod and intermediate lever, with a handle located under the driver’s right hand. On the right side, there is also a handle for engaging the reverse gear.

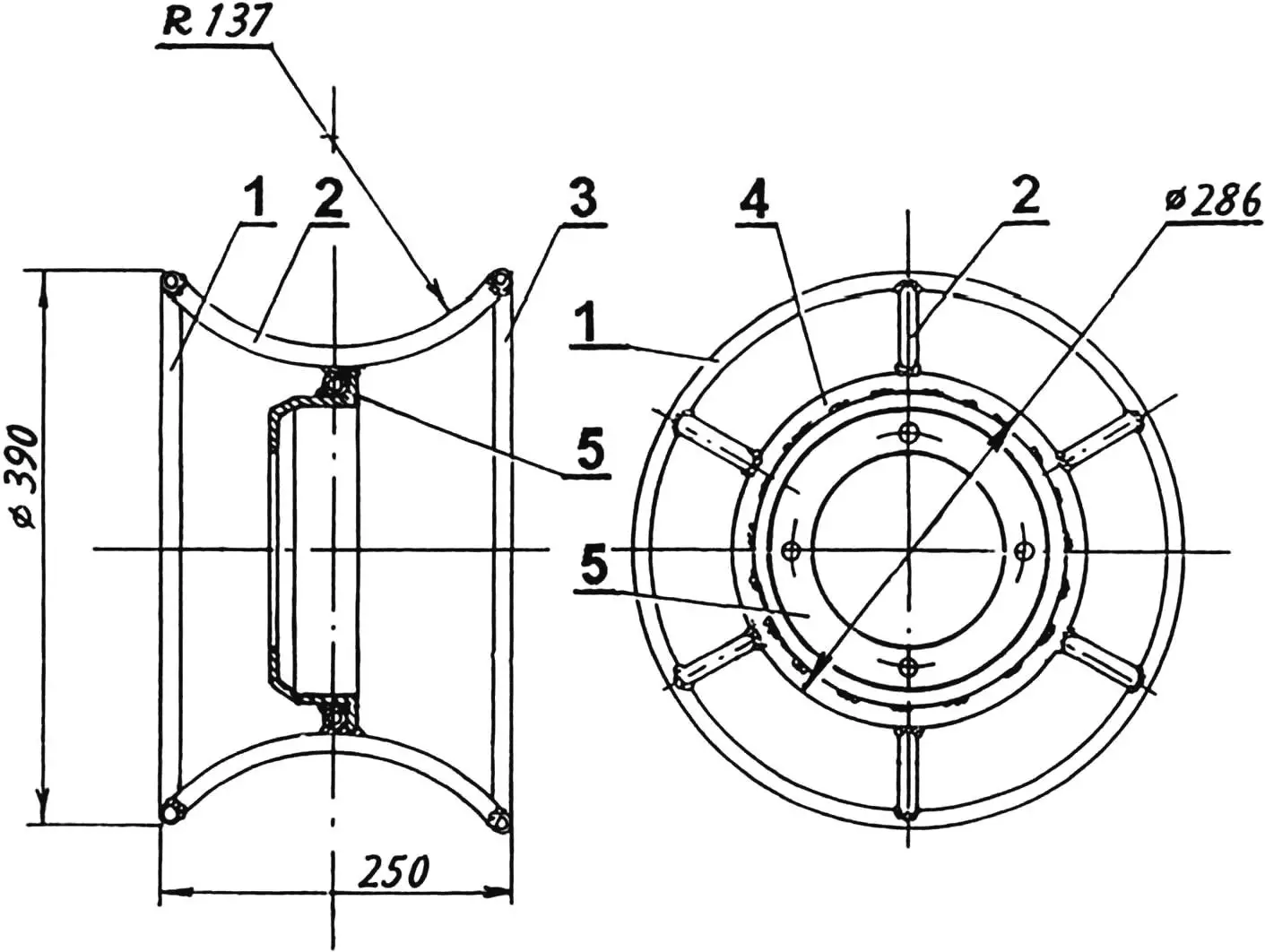

1,3 — outer wheel rims (steel, tube 18×2); 2 — support (steel, tube 18×2); 4 — inner rim (steel, tube 18×2); 5 — wheel disc (from SZD motor tricycle wheel)

The wheels of the pneumatic all-terrain vehicle are lightweight, tubular, and welded. The parts are made from 18×2 mm steel tubes, bent with a tube bender, and assembled by welding. A simple jig was used for assembly: six wooden posts were installed on a particleboard along the planned circumference of the wheel, and the prepared wheel rims were fixed to them. After checking coaxiality and parallelism, crossbars were tack-welded to the rims. The crossbars were finally welded only when the operation did not cause noticeable wheel wobble. Similarly, the inner ring with the welded inner rim of the SZD motor tricycle wheel was installed in two stages.

1 — furniture button; 2 — filling (foam); 3 — upholstery (artificial leather); 4,5,6 — frame (steel, tube 20×2); 7 — elastic seat and backrest base (rubber rings)

In practice, the pneumatic tires hold well on the all-terrain vehicle wheels and provide acceptable traction on any surface — from snow and sand to plowed fields and swamps. In some cases, to improve off-road capability, the pneumatic tire can be laced with nylon rope or synthetic strap webbing. It should be noted that while the pneumatic tires do not turn the vehicle into an amphibious machine capable of crossing water, they do make it virtually unsinkable, which is important for trips on ice.

One more device used exclusively for winter fishing is a hatch with a removable cover in the floor under the rear passenger seat. After drilling a hole in the ice, the all-terrain vehicle is positioned so that the hole is directly under the hatch. In cold or windy weather, a frame with an attached windproof synthetic fabric sleeve is placed over the hatch, effectively placing the ice hole inside the vehicle cabin. With the heater on, it is quite warm and comfortable inside even in severe frost.

I. KHOROSHEV