Such a roof rack will be of interest to car owners who do not have a garage and are forced to leave their steel “horse” outdoors overnight.

Most of them equip their cars with an alarm system. However, it often goes off even from a passing truck or a powerful clap of thunder, disturbing the night’s peace of residents.

Many also install mechanical anti-theft devices on the controls in addition to the alarm system: steering wheel, pedals, etc. But for car thieves, this electronics and mechanics seem to be a small obstacle — thefts are not decreasing.

I designed and built a roof rack for my Moskvich-412, which, in addition to its direct purpose, I also use as an anti-theft (security) device. In the protective position, its grid sides cover the entire glazed surface of the body and prevent unauthorized opening of doors and intruders breaking into the cabin through the windows.

A car with such a “security rack” is not even attempted to be stolen — it creates too much hassle and attracts attention with noise before the thief can get into the car’s cabin.

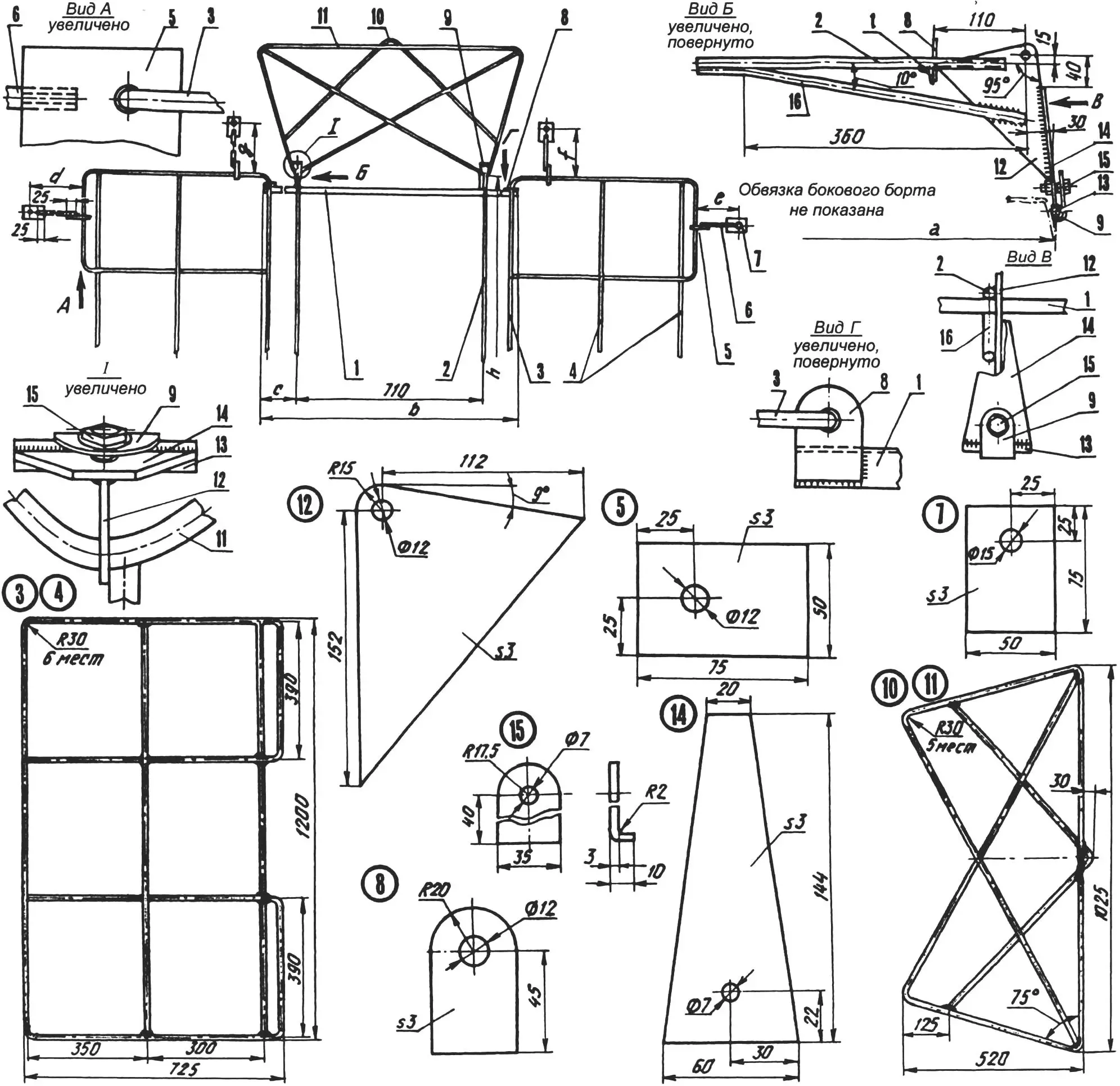

1 — longitudinal beam (steel angle 25×25, L = b, 2 pcs.); 2 — crossbar (L = h, 2 pcs.); 3 — end side frame (L4800, 2 pcs.); 4 — girders (L1180, 4 pcs.); 5 — shackle (8 pcs.); 6 — rod (8 pcs.); 7 — plate (8 pcs.); 8 — eyelet (4 pcs.); 9 — clamp (4 pcs.); 10 — hinged girder (L1200, 2 pcs.); 11 — side frame (L4250, 2 pcs.); 12 — support gusset (4 pcs.); 13 — support sleeper (L60, 4 pcs.); 14 — support post (4 pcs.); 15 — fastening bolt (4 pcs.); 16 — strut (2 pcs.)

If you want to make a similar design and already have a roof rack (factory or homemade), you can use its suitable elements for the new — security — version.

The main (central) part of the rack is a frame consisting of two longitudinal beams (25×25 mm steel angle) and a pair of crossbars. Each crossbar is welded from paired rods (Ø10 mm) arranged in a vertical plane. Such rod is the main material of the entire structure. The ends of the lower rod are slightly bent downward, forming struts that strengthen the crossbar.

To avoid excessive weight, longitudinal decking elements were not installed on the frame: instead, it is formed (as a grid) by foldable sides — two side and two end sections, each also made as a grid structure.

For unification purposes, both side sections are identical, as are the front and rear end sections. The configuration of the side sections is trapezoidal, approximately matching the glazing of the doors of the most common passenger cars, while the front and rear sections are rectangular, according to the dimensions of the windows (the rear one is slightly smaller).

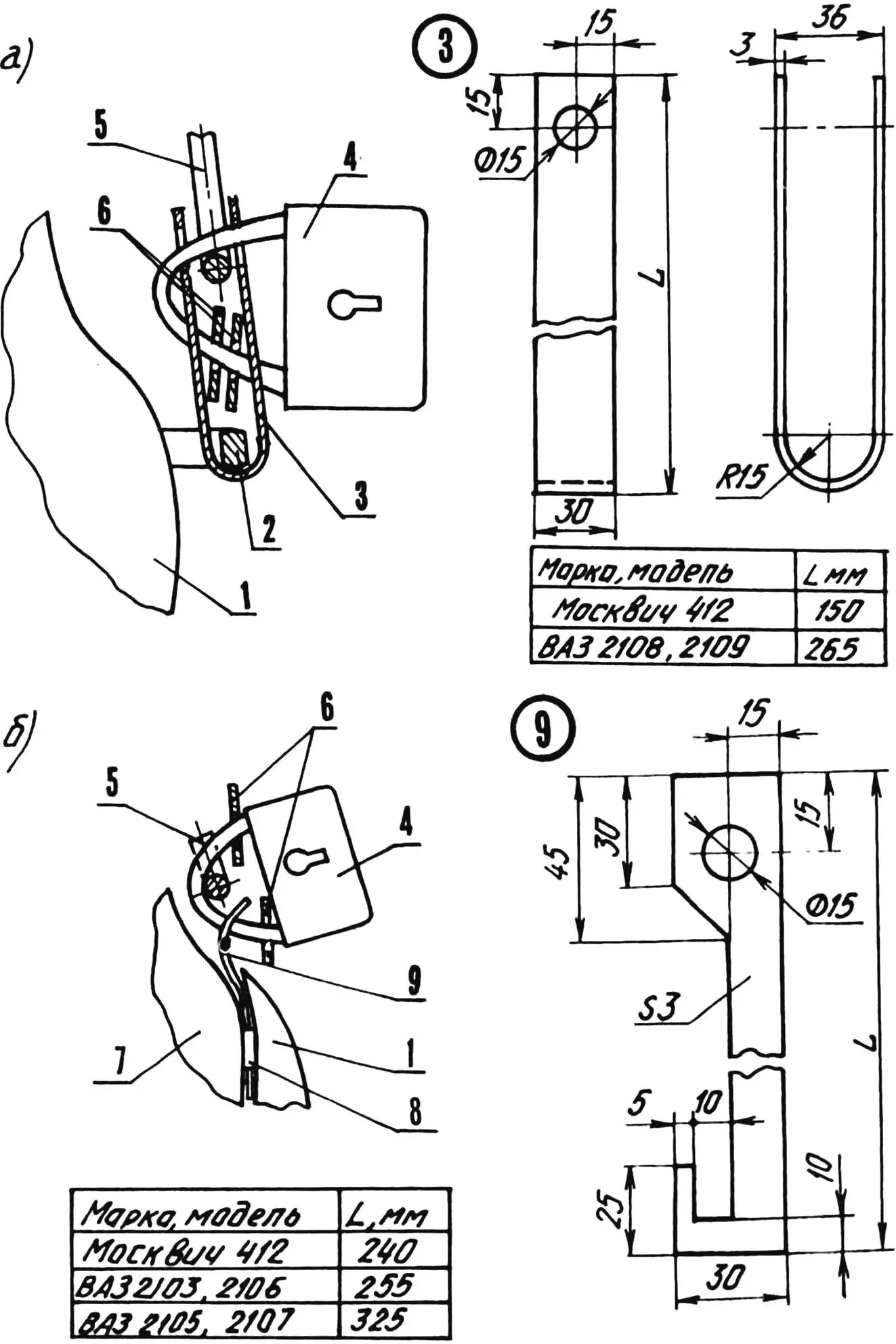

The frame supports (four in total) consist of several small parts: gussets, posts, sleepers welded together, and a fastening device consisting of a clamp and a fastening bolt. This device made the rack removable. The supports are attached to the roof water-drain channels (so the design is suitable only for cars that have such channels).

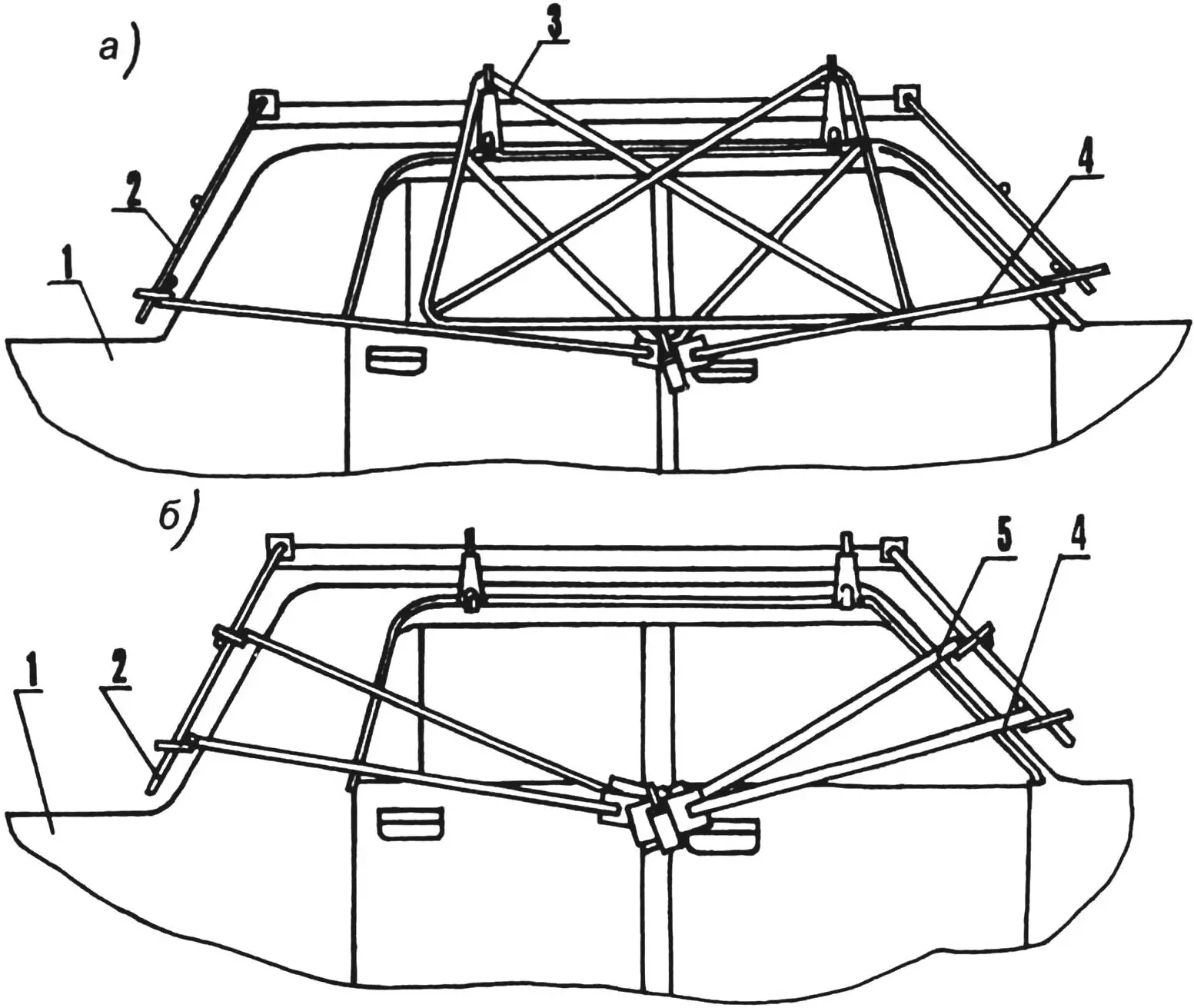

1 — car; 2 — end section; 3 — side section; 4 — main rod; 5 — additional rod

The frame supports (or at least their gussets) must be made before starting the fabrication of the side sections. Then, by bending the frame rod according to the given configuration, the supports are put on it (through holes in the gussets), and after that, the rod ends are welded to the frame. Next, a hinged girder is welded to the sections. After that, the ends of the frame crossbars are first tack-welded to the gussets, and after aligning the elements, welded finally.

The end sections are made in the same way, except that instead of gussets, they have pairs of eyelets and shackles. After welding the sections, the eyelets are welded to the ends of the beams, while the shackles are welded to rods of appropriate length with plates. Plates and shackles are similar parts, differing only in hole diameter: the plate has a larger one. The support elements, plates, and shackles are made of 3 mm steel sheet.

When mounting on the car, the rack with folded grids is installed with its supports on the roof’s drainage channels so that the lock hinges at the bottom of the side grids are positioned near the pillars of four-door cars or above the handles of three-door cars (e.g., VAZ-2108); they are fastened with clamps.

To reduce noise and protect the paint coating of the roof and channels, rubber pads must be placed under the sleepers of the supports, and rubber tube pieces (pre-cut lengthwise) must be put on the grid rods where they touch.

To switch the rack to security mode in four-door cars with recessed handles, you must open the front doors, hook the lugs (bent to fit the pillar shape) onto the top hinges of the rear doors, and close the doors again. Lower the grids onto the windows, pass the shackle of a padlock through the lug hole, the side grid loop, and the rod tips.

1 — door; 2 — handle; 3 — bracket; 4 — lock; 5 — side section hinge; 6 — rod plates; 7 — pillar; 8 — rear door hinge; 9 — lug

For cars with protruding handles, special brackets are used instead of lugs, hooking onto the door handles.

In transport mode, the grid sides are folded onto the frame and secured with two clamps and an M6 bolt. The bracket is the same part as the support clamp. In this position, even long cargo can be transported on the rack. If necessary — for example, to carry bulky (but not heavy) loads in relatively small containers — the grids can be joined with the same brackets in a vertical position, forming sides, and a temporary decking can be arranged on the frame.

| Dimensions (mm) | Moskvich-412 | VAZ-2101 — 2107 | VAZ-2108 — 2109 |

|---|---|---|---|

| a | 1240 | 1270 | 1150 |

| b | 1500 | 1225 | |

| c | 300 | 150 | |

| d | 1055 | 980 | |

| e | 1205 | 1330 | |

| f | 980 | 980 | |

| g | 830 | 730 | |

| h | 1120 | 1150 | 1030 |

A similar security roof rack with adjusted frame and rod sizes can also be made for other cars, both domestic and imported, that have drainage channels. Dimensions for some domestic cars are shown in the table.

To make the construction lighter, instead of side sections, you can install additional rods on both sides of the end sections. In security position, they will diagonally cover the windows of each door.

When driving, the folded security rack provides approximately the same aerodynamic resistance as a regular factory one.

V. TASKAYEV